Very slight systematic waves every about 2mm on the prints

-

@droftarts

I thank you for the very detailed answer that took up a lot of your time for me.Let's go step by step:

Cases like this, unfortunately, are dealt with by the exclusion technique. That is, you have to check the many possible causes in a way that excludes them one by one and then examine another possible cause.The mechanical part is the first to be checked, and from the checks done on the pulleys (4 of 8 were fitted new even though they were perfect for me) it did not produce any changes on the prints. The other four that were not replaced before were disassembled and tested by fixing them to a vise and putting them in tension with a belt and they kept swearing smooth so I think the pulleys are all ok.

The belt was replaced. Upon disassembly the old one was not in good mechanical condition even though they looked ok to the eye. The old ones were hard to the touch, almost wooden, and if they hung down they did not stay taut but tended to curve in places.

The new one, identical in make and model to the old one seems a bit too rubbery to me and I am waiting to receive new Gates brand 9 mm belts.So, I would like to try Gates belts before venturing into the driver talk, which I study in the meantime.

In the meantime of all this, I also tried using Orca Slicer instead of Prusa Slicer and found no difference.

Instead, I found a VFA test inside Orca Slicer setting it with speeds from 40 to 200 mm/sec and got a print where the difference of the vertical lines, even at 200mm/sec was still visible though slightly less. I mean that in the face of a very large difference in speed the lines varied very little but they were present so now I have a doubt if indeed the driver speech is the cause. That said, considering that the common and unvaried part are the non-Gates belts (even if replaced) perhaps I'd better try these before thinking about anything else.

FYI:

My M569 P0.0 response:

M569 P0.0

Drive 0 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x101b4, toff 4, tblank 2, hstart/hend/hdec 3/3/0, pos 0Between yours and mine I notice the difference mode stealthChop / mode spreadCycle

-

@luc worn, stretched belts could cause the VFA. I think it’s worth holding off doing anything more until you fit those.

Between yours and mine I notice the difference mode stealthChop / mode spreadCycle

The TMC2660 drivers on the Duet 2 only support spreadcycle, no stealthChop.

Ian

-

@droftarts said in Very slight systematic waves every about 2mm on the prints:

@luc worn, stretched belts could cause the VFA. I think it’s worth holding off doing anything more until you fit those.

IanYes I know, but in fact that is why I replaced them. Replaced them, however, with new ones that were identical in make and model to the ones that had aged.

I expected some difference in the prints but instead between the old worn and hard belt and the new one I didn't notice any difference. Incredible but so it was.

I will try the Gates as soon as they arrive.In the meantime I saw Duet 3 6HC and saw that I could use my 6 motors without expansion board (3xZ - 2 x XY + 1 Extruder) but I also noticed the price.

-

@luc said in Very slight systematic waves every about 2mm on the prints:

I will try the Gates as soon as they arrive.

Ah, right, I didn't see the part where you said you had already changed the belts once. See if the Gates belts help.

In the meantime I saw Duet 3 6HC and saw that I could use my 6 motors without expansion board (3xZ - 2 x XY + 1 Extruder) but I also noticed the price.

Unfortunately, that's the cost of UK manufacture, full-compliance testing, board testing post-manufacture, hardware and firmware research and development, sales and marketing, support and documentation. Our competitors don't incur these costs, and largely rely on the community and open source competitors (like Duet3D) to provide R&D, firmware, and support.

Also, changing the controller board is unlikely to help with the VFAs if they are mechanical or electrical in nature.

Ian

-

@luc Just to confirm this is definitely VFAs in the XY system, not the extruder, please watch these two videos, particularly the second one:

https://www.youtube.com/watch?v=dL6u0UwPJOQ

https://www.youtube.com/watch?v=32dTLRNIYmwPrint this object with your normal settings and see if you get the 'woodgrain' effect: https://mihaidesigns.com/inconsistent-extrusion/

If you get the woodgrain effect, then you'll know if the issue is the extruder. If the lines line up, it's something in your X and Y movement.

Ian

-

@droftarts said in Very slight systematic waves every about 2mm on the prints:

@luc Just to confirm this is definitely VFAs in the XY system, not the extruder, please watch these two videos, particularly the second one:

https://www.youtube.com/watch?v=dL6u0UwPJOQ

https://www.youtube.com/watch?v=32dTLRNIYmwPrint this object with your normal settings and see if you get the 'woodgrain' effect: https://mihaidesigns.com/inconsistent-extrusion/

If you get the woodgrain effect, then you'll know if the issue is the extruder. If the lines line up, it's something in your X and Y movement.

Ian

Thanks for the information but I had already seen those videos and had filed down the teeth of a gear and made a printout without noticing any difference.

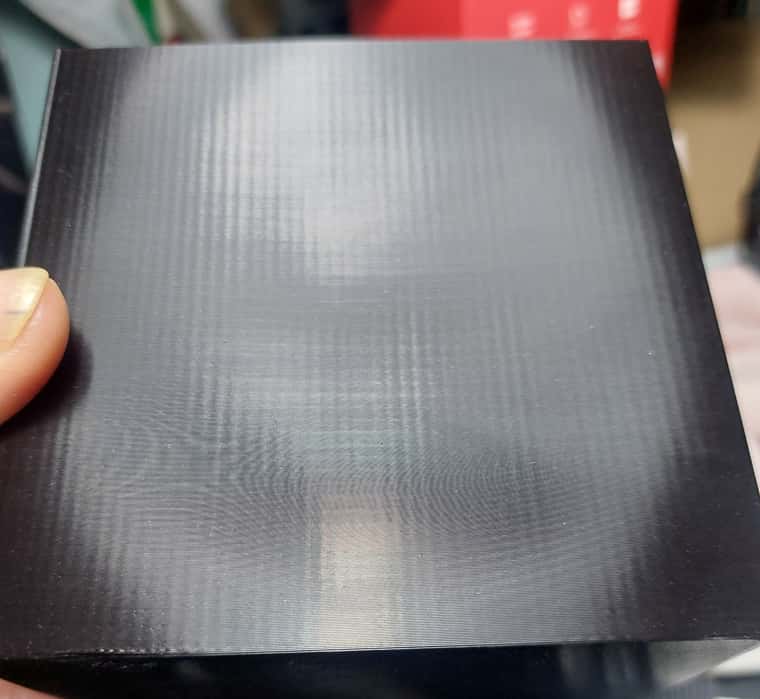

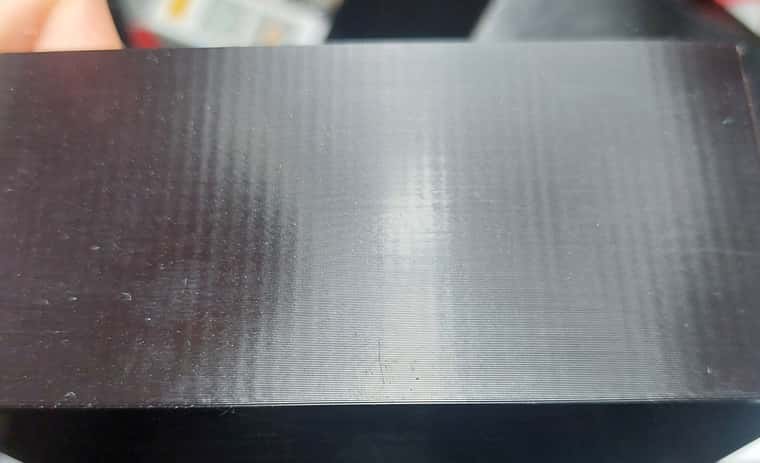

Mine is not wood grain effect.....it's really straight vertical lines...it looks just like VFA.

Consider that in the photo it looks like there are more stripes because of light reflections, but I assure you that the stripes are only vertical.

-

Are you using Gates pulleys as well? It is very important to have pulleys where the hole is perfectly centered and the perfect diameter. The teeth must be an exact match to the belt tooth pattern as well.

When you place the pulley on the motor driveshaft there should be no play. That way when you tighten the set screws they will not be able to force the pulley off-center.

Best of luck,

Tony.

-

@luc Before going through all of that, did you print a tapered object? Because the objects shown are straight. Another test; do the vertical lines always appear in exactly the same position? If you move the object over 1mm, do the lines move, or do they stay in the same place?

Ian

-

@droftarts said in Very slight systematic waves every about 2mm on the prints:

@luc Before going through all of that, did you print a tapered object? Because the objects shown are straight. Another test; do the vertical lines always appear in exactly the same position? If you move the object over 1mm, do the lines move, or do they stay in the same place?

Ian

Here I am, sorry but I was at work.

Printed tapered object? What object could I print? Consider that I notice that effect only on flat surfaces. If I print a cylinder, the result is perfect.Also consider that if you run your fingers over it, the surface is smooth. Those waves can only be seen against the light.

If you move the object over 1 mm, do the lines move or do they stay in the same place? I'll have to try. If I can tomorrow or as soon as I can.

-

@luc said in Very slight systematic waves every about 2mm on the prints:

What object could I print?

A pyramid/cone.