uniform wave artifact on all prints

-

@jay_s_uk

if i read my settings correctly i think extruder is PWM and heatbed is bid bang?here are settings

; Heaters M140 H-1 ; disable heated bed (overrides default heater mapping) - enabled Alexus 12.8.23 M308 S0 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e0temp M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0 M307 H0 R8.944 K0.806:0.000 D1.44 E1.35 S1.00 B0 V24.2 M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H0 S300 ; set temperature limit for heater 0 to 280C ;add heatbed sensor and heaters M308 S1 P"bedtemp" Y"thermistor" T11000 B4138 ; configure sensor 1 as for heatbed M950 H1 C"bedheat" T1 ; create bed heater output on bedheat and map it to sensor 1 M307 H1 R0.072 K0.332:0.000 D33.57 E1.35 S1.00 B0 ; auto tune settings M140 H1 ; map heated bed to heater 1 M143 H1 S120 ; set temperature limit for heater 1 to 120Cthough not sure how it related to heat bed? as all part top to bottom has same artifact even when far away form bed

-

@alexus

This might sound weird, but loosen all the bolts that hold the z lead screws onto the bed.

Make it so you can manually wiggle the threaded nuts and then try printing again. Obviously you dont want to print like this in the future, but doing a test print like this is a really good test to check if the issue is firmware or if its hardware. -

@Notepad said in uniform wave artifact on all prints:

doing a test print like this is a really good test to check if the issue is firmware or if its hardware.

Just curious: what hardware issue exactly can you determine (or exclude) by this?

-

@infiniteloop

There are really 2 possible reasons for it.- The z nuts are mounted slightly off axis, causing the z motion to be non linear. the spacing of the "wave artifact" looks consistent. If you measure peak to peak, I would be interested to see what the distance is, it may be 4mm spacings which would line up with the thread pitch of a T4 or T8 threaded rod.

- The Threaded Z rod could be imparting force against the bed or frame causing either to flex slightly

There are a couple sub reasons, but most of it is a faint hunch from past experience ive had.

If it does fix the issue, I'm happy to send you some info about how to design around it / eliminate the issue with some hardware tweaks.Sneaky edit: for future posting, i would recommend converting your .heic files which iphone uses as default to something else. Windows11 PCs now need users to pay to view them, so some newer users might not be able to open them

-

@Notepad

HEIVEC - yea iphone makes things hardermy rods are 1605 fairly large and heavy byt yes interestingly enough distance form same repeate line is exactly 5mm (manual not scientific measurement though i can grab microscope ) so is full spin on 1605 gives us 5mm we can relate to that but i dont see how especially that there 3Z bolts and tables sits on ball baring pillows ... well unless its uneven pressure some how

i will try to loosen both belts that drive rods and loosen pillows and print cube wase or something (unfortunately im out of grey material that was showing artifact very well)

-

Can you share a photo of your Z axis arrangement?

If you turn off the bed heater, do you get the same pattern? Just to rule out the bed heater. -

@Phaedrux

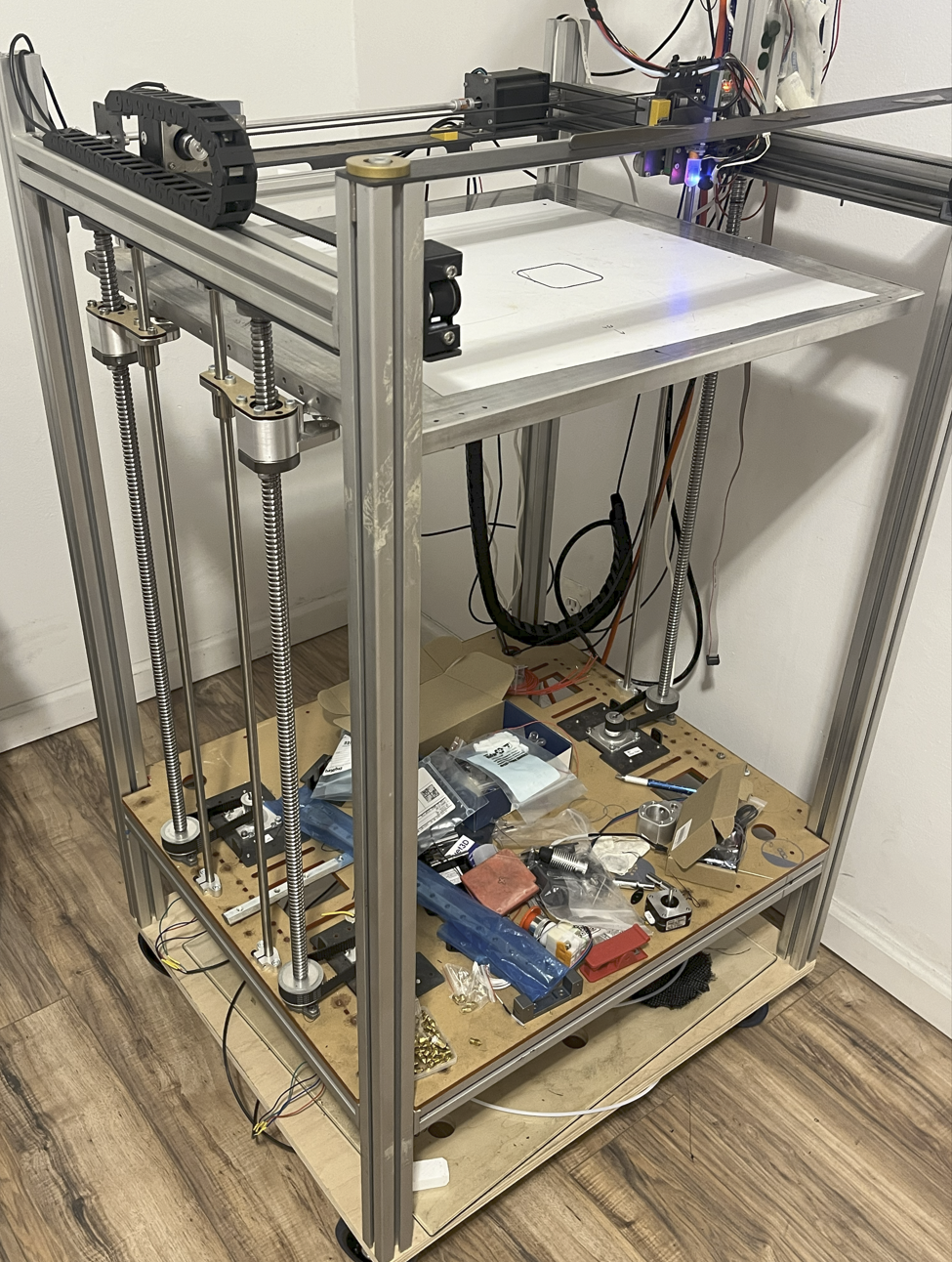

here is build pix

i will try to turn off heater... shodl i fully turn it off in confog file... or just deactivating in GUI can be ok for test?also i troed to loosen pillows and belts on Z and i dont think it made difference,,, i also increased print speed

-

@alexus said in uniform wave artifact on all prints:

r just deactivating in GUI can be ok for test?

Just turn it off after the first couple layers

-

@Phaedrux

i turned heated in GUI for full build and waves still there -

That leaves your Z axis mechanism. Maybe a ball screw is bent or binding.

Can you post your full config.g?

-

@Phaedrux

will load file tomorrow, alredy left officebent scew kinda unlikely, 16mm diameter not that easy to bend, also if one is bent it needs to drug 2 others which is harder, and finally if its bent in certain section should artifact change over part height? caz lines stay uniform top to bottom

im thinking to disable mesh compensation and see what happens

-

OH THESE ARE BALL SCREWS.

I am now 100% certain that the issue is with the alignment of the ball screws. The main issue with ball screws is that they are so well manufactured, the steel used is also exceedingly hard meaning any deviation in the alignment of the rods will cause the frame and bed of the printer to warp ever so slightly.

I have made about a dozen machines using various ball screws including ones integrated directly into the motor (as i though the issue of non concentric pulleys might have been the cause of issues exactly like yours) to no avail.Thankfully there is a perfect product for you that is relatively inexpensive that should remove any XY impact caused by the z-motion system

https://www.aliexpress.com/item/1005004227149356.html - the YouTuber who designed these only made a deal with mellow, so i suggest getting them from there in the size "WS16"Any other oldham coupling should also work, but I have had the best experience from the wobbleX's

-

@Notepad

u have some part coming form china now will add it to order and see what happens... i guess i can also make loose ball screw on top that would allow it to be more flexible -

@Notepad said in uniform wave artifact on all prints:

WS16

ok so i loosened lead screws and waves got even woth so i think i need to work in makeing sure build plate is stable...

before is did 3Z itwas perrry well i guess let me play with mechanincs and try that adapter too

before is did 3Z itwas perrry well i guess let me play with mechanincs and try that adapter tootnx for leading me to right direction