RepRapFirmware 3.6.0-alpha.4+3 available for testing

-

@edsped I haven't decided yet. We'd need to either disable IS throughout tool change files, or implicitly wait for motion to stop between certain pairs of moves - but what pairs, exactly? I'm not sure that either of those would be appropriate in all circumstances. We could add a means of specifying that a certain axis is used as a tool locking mechanism, but would that be any better than advising users where to use M400?

-

If people don't want to sprinkle M400s, they could also disable and re enable IS at the beginning and end of the macros.

-

@oliof yes. I am considering extending M593 to allow IS to be turned off and then turned on again without needing to specify the parameters.

-

Okay, I'm back with a problem report with my delta. I noticed during extrusion "blob" testing tonight that it was making a light clunking noise during each blob extrude. At first I assumed it was the extruder, but it was happening on all the blobs, and doing it the most on the lowest cubic (slowest) ones. To judge from finger-on-arms, it may only be the Z axis (AWD, so this is two steppers). IS on/off does not affect it. It is reproducible without extrusion, too, using a very slow move with Z component like G1 X3 Y1 Z20.5 F16.84 starting from X0 Y0 Z1. There is no discernible interval to the clunking; it sounds random, and it happened at least once on most of the blobs, which were done across the bulk of the bed area. M122 shows nothing amiss to my eyes. I can confirm that this wasn't happening with nigh-identical GCode in 3.5.1. I think I've seen this or something similar reported already, but I thought that was connected somehow to IS, and this doesn't seem to be.

-

@Kiolia Hi, thanks for your report. I think this may be related to this issue: https://github.com/Duet3D/RepRapFirmware/issues/1015. I don't think this has been fixed in 3.6.0 yet, so one for @dc42.

Ian

-

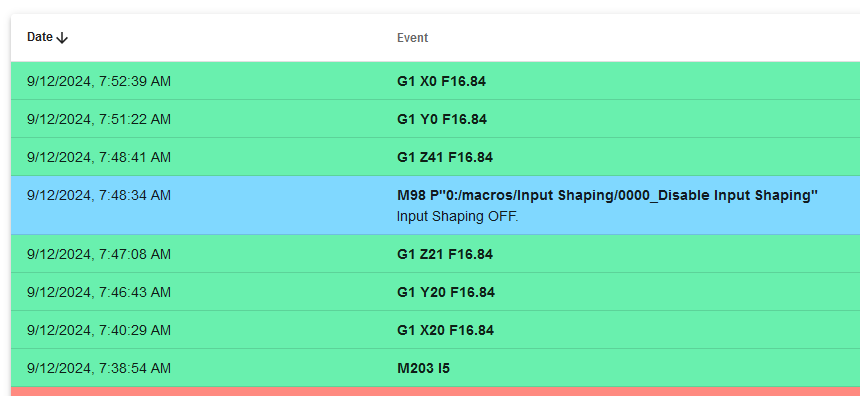

@droftarts Some additional test results. At least for me, it is new for 3.6.0 and specific to very slow moves, not IS or bed location-related. I executed the following sequence of moves this morning, starting from X0 Y0 Z1, and heard the noise (which sounds like a light motor skip) multiple times on all 6. With the exception of move number 4, which had many skip/clunk noises throughout, the starts of the moves did NOT make noises at first -- I would estimate at least the first 10-15 seconds of the other 5 were all noise-free.

-

@Kiolia thanks, I'll test this on my own delta next week. @droftarts can you test this too?

-

@dc42 If it's needed for repro, I'm running x32 on 0.9s / 16Ts for 400 steps / mm and set segmentation to 400/sec 0.2mm min length. (if you need the rest of my config let me know.) I haven't tested to see if there's a specific speed threshold for the behavior, but the way that the noises often don't start for some seconds makes me wonder if the duration of the move is a factor, rather than just the speed.

-

I just started a long print (6+ hours) and approximately 2.5 hours into the print, the job failed with the "Error: Movement halted because a step timing error occurred (code 3). Please reset the controller." error. This is with the 3.6.0-alpha.5+1 firmware.

Here is the output of M112 right after the error:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-alpha.5+1 (2024-08-31 17:50:58) running on Duet WiFi 1.0 or 1.01 Board ID: 08DAM-999TL-MQ4SD-6JTDL-3SS6N-968BX Used output buffers: 13 of 26 (21 max) === RTOS === Static ram: 23360 Dynamic ram: 67504 of which 12 recycled Never used RAM 11864, free system stack 102 words Tasks: NETWORK(2,nWait 6,15.3%,195) HEAT(3,nWait 5,0.1%,309) Move(4,invalid,5.2%,266) MAIN(1,running,79.4%,752) IDLE(0,ready,0.0%,29), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 02:31:01 ago, cause: software Last software reset at 2024-09-16 11:25, reason: User, Gcodes spinning, available RAM 28192, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU temperature: min 27.7, current 48.5, max 49.4 Supply voltage: min 23.5, current 24.2, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/1132/1072, gc cycles 1 Events: 0 queued, 0 completed Date/time: 2024-09-16 13:56:21 Slowest loop: 218.04ms; fastest: 0.13ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 8 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 9.4ms, write time 3.1ms, max retries 0 === Move === Segments created 639, maxWait 442509ms, bed comp in use: none, height map offset 0.000, hiccups added 5 (0.15ms), max steps late 1, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 68366.00/68371/-0.79 66822.00/66848/-0.92 76754.00/76740/0.84 no step interrupt scheduled Driver 0: standstill, SG min 0 Driver 1: standstill, SG min 0 Driver 2: standstill, SG min 0 Driver 3: standstill, SG min 0 Driver 4: standstill, SG min n/a Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: === DDARing 0 === Scheduled moves 912010, completed 912008, LaErrors 0, Underruns [17, 0, 0] === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.1 Heater 1 is on, I-accum = 0.2 === GCodes === Movement locks held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 X-6.539 Y47.848" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Q0 segments left 1 Code queue 0 is empty === Network === Slowest loop: 195.01ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(4) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.1.0 MAC address 5c:cf:7f:2c:25:00 Module reset reason: Turned on by main processor, Vcc 3.40, flash size 4194304, free heap 40984 WiFi IP address 192.168.1.61 Signal strength -28dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0Here is config.g:

; Setup some global variables global power_fail_retract = 2 ; Retract 2mm when power fails ; Communication and general M550 P"BigDelta" ; Machine name and Netbios name (can be anything you like) M551 Preprap ; Machine password (used for FTP) M552 S1 ; Enable WiFi. Disabled for setup and testing. Enable once set up on your network. ; Enable telnet M586 S1 P2 ; Debugging M111 S0 ; Debug off M929 P"eventlog.txt" S1 ; Start logging to file eventlog.txt M555 P2 ; Set output to look like Marlin G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Axis and motor configuration M569 P0 S0 ; Drive 0 goes backwards M569 P1 S0 ; Drive 1 goes backwards M569 P2 S0 ; Drive 2 goes backwards M569 P3 S0 ; Drive 3 goes backwards ; Assign extruder drive M584 E3 ; Set homing switch config M574 X2 S1 P"!xstop" ; Set homing switch configuration on S1 = high-end, active-low M574 Y2 S1 P"!ystop" ; Set homing switch configuration on S1 = high-end, active-low M574 Z2 S1 P"!zstop" ; Set homing switch configuration on S1 = high-end, active-low ; Set it as a linear delta M669 K3 ; Setup paneldue 5i M575 P1 S1 B57600 M665 R215.062 L395.317:395.475:395.433 B160 H374.050 ; set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M350 X16 Y16 Z16 E16 I1 ; Set 16x microstepping with interpolation M92 X200 Y200 Z200 ; Set axis steps/mm M906 X1400 Y1400 Z1400 E1400 I60 ; Set motor currents (mA) and increase idle current to 60% M84 S60 ; Set idle timeout M201 X12000 Y12000 Z2000 E10000 ; Accelerations (mm/s^2) M203 X30000 Y30000 Z5000 E3600 ; Maximum speeds (mm/min) ;M566 X900 Y900 Z300 E1200 P1 ; Maximum instant speed changes mm/minute ;M566 X300 Y300 Z300 E450 P1 ; Maximum instant speed changes mm/minute M566 X600 Y600 Z300 E900 P1 ; Maximum instant speed changes mm/minute M204 P9000 T9000 ; Set acceleration for print and travel moves ; Configure Input shaping M593 P"zvdd" F45 ; Thermistors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 R4700 H30 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction M308 S1 P"e0_temp" Y"thermistor" T100000 B3950 R4700 H30 L0 ; 100K NTC ;M308 S1 P"e0_temp" Y"thermistor" T100000 B4658 C6.5338987554e-08 ; 104-NT Aliexpress thermistor M950 H0 C"bed_heat" T0 ; Set up H0 as the bed heater using T0 as the sensor M950 H1 C"e0_heat" T1 ; Set up H1 as the extruder heater using T1 as the sensor M140 H0 ; Map H0 as the bed heater ; Set temperature excursion warnings M570 H0 P20 M570 H1 P20 M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper M308 S4 Y"drivers" A"Drivers" ; configure sensor 4 as temperature warning and overheat flags on the TMC2660 on Duet M912 P0 S-3.5 ; Calibrate MCU temp ; Fan definitions M950 F0 C"fan0" M950 F1 C"fan1" M950 F2 C"fan2" ; Thermostatic fan on 1 for cooling the hotend M106 P1 T50 H1 ; Thermostatic fan on 2 for cooling the board M106 P2 H3:4 L.3 X1 B0.3 T35:70 ; set fan 2 value ; Tool definitions M563 P0 D0 H1 ; Define tool 0 G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E1392 ; Based on https://www.thingiverse.com/thing:1359717; 2023/01/06 M92 E1077.1646 ; This is the new value for the hobb-goblin extruder. 03/07/2023 ;M92 E319.2005 ; Set extruder steps per mm. This is for the MK8 gear ; Z probe and compensation definition M558 P8 C"^!zprobe.in" R0.4 H4 F1200 T6000 A5 S0.01 ; Z probe is a piezo sensor G31 X0 Y0 Z-0.08 P100 ; Set the zprobe height and threshold M557 R150 S20 ; Probe within a radius of 150mm and mesh spacing of 20 M376 H5 ; Taper off bed compensation after 5mm ; Configure power failure and resume M911 S21.0 R23.0 P"G91 M83 G1 Z3 E{-global.power_fail_retract} F1000" ; Relative movement and extrusion. Move head up and retract 2mm filament. M208 S1 Z-0.5 ; set minimum Z T0 ; select first hot end M501 ; Load any config overrides -

@dc42 I just had the same error as reported by @balajiramani . In my case, the error occurred during the first layer of a print job.

=== Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.6.0-alpha.5+1 (2024-08-31 17:51:17) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 0JD2M-999AL-D25S4-7J1D2-3SJ6K-T51V3 Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 135136 Dynamic ram: 96472 of which 0 recycled Never used RAM 68768, free system stack 198 words Tasks: SBC(2,ready,0.8%,796) HEAT(3,nWait 6,0.0%,369) Move(4,nWait 6,0.0%,333) TMC(4,nWait 6,2.8%,353) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,353) MAIN(2,running,93.9%,440) IDLE(0,ready,2.4%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:00:37 ago, cause: software Last software reset at 2024-09-18 18:45, reason: User, Expansion spinning, available RAM 65064, slot 0 Software reset code 0x6012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 MCU temperature: min 33.9, current 34.3, max 34.5 Supply voltage: min 22.7, current 23.5, max 23.6, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.1, under voltage events: 0 Heap OK, handles allocated/used 99/4, heap memory allocated/used/recyclable 2048/88/40, gc cycles 0 Events: 0 queued, 0 completed Date/time: 2024-09-18 18:46:21 Slowest loop: 25.07ms; fastest: 0.07ms === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 next step interrupt due in 297 ticks, disabled Driver 0: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 1: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 2: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 3: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 4: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Driver 5: standstill, SG min n/a, mspos 8, reads 8720, writes 11 timeouts 0 Phase step loop runtime (us): min=0, max=2, frequency (Hz): min=1913, max=2089 === DDARing 0 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] === Heat === Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x80000003 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 0 Extruder 0 sensor: no filament === CAN === Messages queued 252, received 2403, lost 0, ignored 0, errs 315, boc 0 Longest wait 55ms for reply type 6041, peak Tx sync delay 50472, free buffers 50 (min 49), ts 187/186/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 1854/1854 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x2858c Buffer RX/TX: 0/0-0, open files: 0 === Duet Control Server === Duet Control Server version 3.5.2 (2024-06-12 07:09:26, 32-bit) HTTP+Executed: > Executing M122 Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 60.06, max time between full transfers: 125.2ms, max pin wait times: 33.5ms/14.1ms Codes per second: 2.94 Maximum length of RX/TX data transfers: 4476/1040 -

@MaxGyver is it repeatable? If so then please post your config.g file and the GCode file.

-

@dc42 I was wondering when we might a fix for this issue? I really like the quality of the prints with 3.6 and hence don't want to downgrade, but can't start a long print because of the step timing error.

-

@balajiramani I'll need to either find a reproducible test case, or add some debug to get more information when this fault occurs.

-

@dc42 Understand. Let me know if I can help in any way.

-

I have just had the same error about 3 hours into a 5 hour print.

22/09/2024, 1:55:16 pm Error: Movement halted because a step timing error occurred (code 3). Please reset the controller.Duet 2 WiFi 3.6.0-alpha.5+1

M122 after error

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.6.0-alpha.5+1 (2024-08-31 17:50:58) running on Duet WiFi 1.02 or later Board ID: 08DGM-917NK-F2MS4-7J1DA-3S86T-TZTWD Used output buffers: 7 of 26 (24 max) === RTOS === Static ram: 23360 Dynamic ram: 72224 of which 12 recycled Never used RAM 8368, free system stack 106 words Tasks: NETWORK(2,nWait 6,16.3%,202) ACCEL(6,nWait 5,0.0%,345) HEAT(3,nWait 5,0.1%,315) Move(4,invalid,3.3%,266) MAIN(1,running,79.8%,672) IDLE(0,ready,0.5%,29), total 100.0% Owned mutexes: === Platform === Last reset 05:49:08 ago, cause: software Last software reset time unknown, reason: User, Gcodes spinning, available RAM 19896, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x08 Aux0 errors 0,2,0 MCU temperature: min 23.6, current 31.4, max 31.9 Supply voltage: min 1.1, current 24.3, max 24.6, under voltage events: 1, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/22, heap memory allocated/used/recyclable 2048/1704/1320, gc cycles 572 Events: 0 queued, 0 completed Date/time: 2024-09-22 14:34:22 Slowest loop: 451.79ms; fastest: 0.13ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 8 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 10.1ms, write time 97.4ms, max retries 0 === Move === Segments created 588, maxWait 153529ms, bed comp in use: mesh, height map offset 0.000, hiccups added 276 (8.29ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 6390.00/6368/0.76 14761.00/14757/0.70 40648.00/40648/0.00 no step interrupt scheduled Driver 0: standstill, SG min n/a Driver 1: standstill, SG min 241 Driver 2: standstill, SG min 0 Driver 3: standstill, SG min 0 Driver 4: standstill, SG min 228 Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: === DDARing 0 === Scheduled moves 1473967, completed 1473965, LaErrors 0, Underruns [9, 0, 0] === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.3 Heater 1 is on, I-accum = 0.3 === GCodes === Movement locks held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 X80.404 Y147.896 E.00085" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is doing "G4 S2" in state(s) 0 0, running macro Autopause is idle in state(s) 0 Q0 segments left 1 Code queue 0 is empty === Filament sensors === check 79464683 clear 1287376 Extruder 0 sensor: ok === Network === Slowest loop: 117.01ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.1.0 MAC address bc:dd:c2:89:a0:bb Module reset reason: Power up, Vcc 3.38, flash size 4194304, free heap 38948 WiFi IP address 192.168.1.163 Signal strength -52dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 4 5 0 0 0 0 0 0EDIT:

Of interest to anyone testing , I think I've saved the print by turning off the power and recovering from power failure. -

I don't have a way to reproduce yet, but I'm seeing intermittent issues that may be related to machine uptime and/or changes to stepper current settings via M906. Several times now, I have seen a problem where a new print underextrudes severely after 1) running a print to completion and then 2) changing at least one stepper current with M906. There's no sound of step loss or evidence of grinding. As before, this is a 6HC with E on a 3HC as a mixing extruder with 2 steppers at ratios 100% each. I'm running a 0.5 CHT nozzle, but cold pulls after these incidents reveal no debris, and each time I've cold-pulled and restarted the machine, all was fine.

I wouldn't be reporting this yet, except that today, after the issue repeated, I discovered that I was able to easily hand-feed filament through the extruder while it was tensioned, which is normally only possible on startup before the extruder has been moved -- yet this was shortly after commanding retraction moves to unload the filament and trim the end, so the E steppers must have been at least engaged at idle (set to 25%). M122, M122 B1, and checking the current settings revealed nothing obvious, but the extruder acted like its steppers were unpowered or at least significantly under-currented. I'm pushing my machine hard right now, so it's always possible something else is going on, but I wanted to document this in case it's a thing with the alpha. Also worth noting that I had never clogged this hot end/nozzle before switching to the alpha.

EDIT: I had not yet switched off the machine, but after reloading the filament and just letting everything sit while I wrote this report, I tried hand-feeding the filament again and it is significantly harder -- more what I'd expect from the idle state.

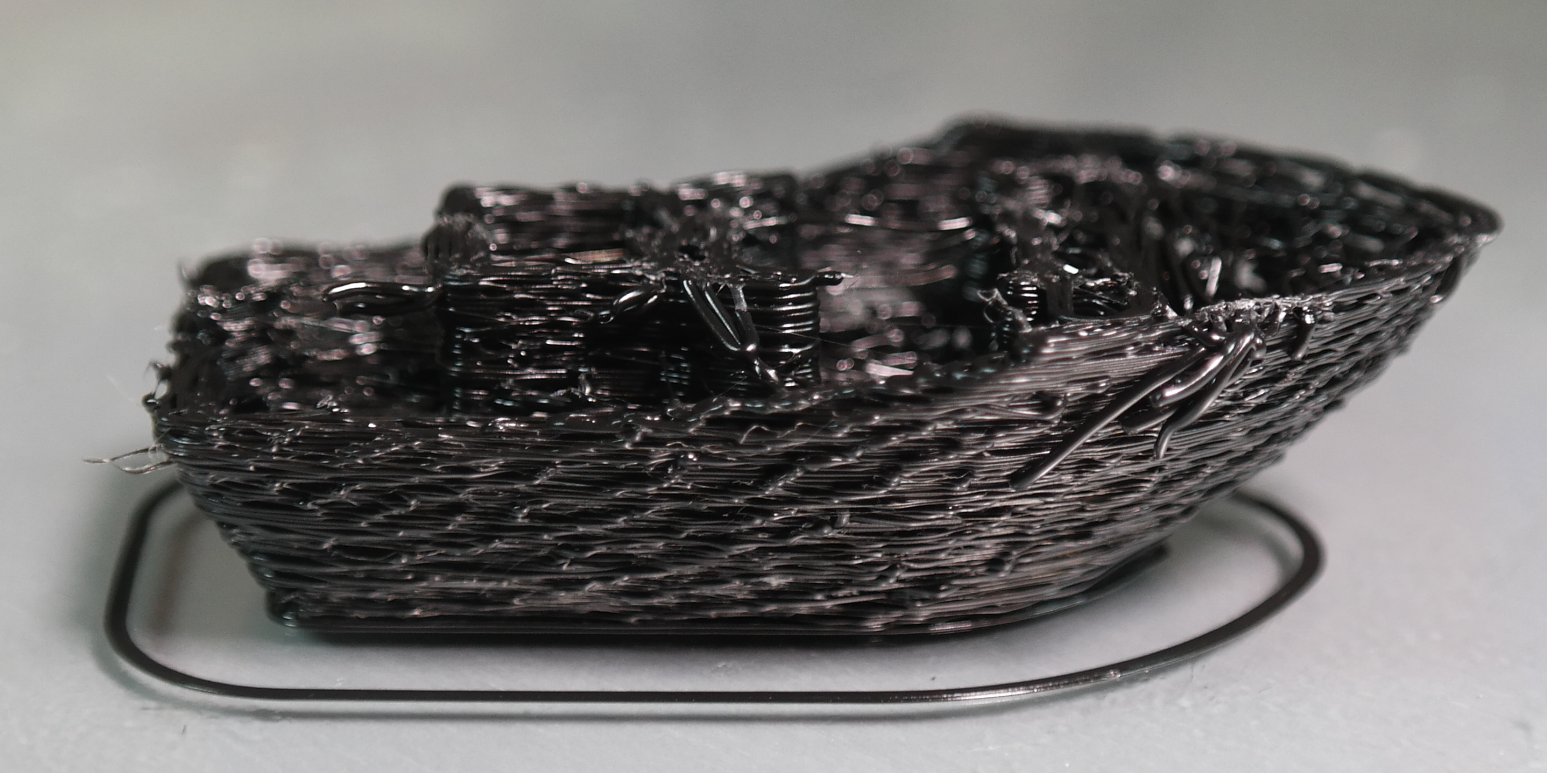

Some specifics for the prints I ran this afternoon: I ran a speedbenchy print that finished in 3:36 with no extrusion issues, allowed about 10 minutes for board and stepper temps to steadystate, re-sliced with a change only to accels (100->120k), used M906 to change E current from 1800 to 2000 (a value I've run many times -- I was testing lower current), then ran the new gcode and got the result shown. To my eye this does not look like a clog -- it's too consistent.

-

@Kiolia What version of RRF are you using?

-

@gloomyandy 3.6.0 5+1.

-

To follow up on the strange extrusion event, I re-ran the same print with the same config settings as before today, and extrusion appeared normal again -- so it wasn't the gcode's fault. Both prints layer shifted and were cancelled at about the same point, so out of curiosity I weighed them. The first one with the extrusion issue weighed 58% of the second one. I wondered if it would be a nice round number like half, but I guess not.

-

All, please upgrade to 3.6.0-beta.1. If you reported any issues with 3.6.0 alpha releases, test whether they are still present in 3.6.0-beta.1; and if so start a new thread about your issue, including [3.6.0-beta.1] in the topic title.

-

undefined dc42 locked this topic

undefined dc42 locked this topic