Ihsv42

-

@4eIIIuP You may want to tag @mrehorstdmd in your question, as he was the user who was using these servos. Also, you will get more response if you post in English, or at least provide a translation. Are you using Duet/RepRapFirmware? If not, then it's unlikely we can help.

Ian

-

@droftarts Thank you for the advice and for the user tag of such servos, I will try to stick to it. I'm currently using mks skipr, but I'm considering duet controller as an upgrade. But if it is necessary. At the moment, I have found few forums where there is any mention of these servos at all, and therefore I wanted to ask a question here. I still don't know how to set up the servos correctly in order to remove the ripples on the model.

-

@4eIIIuP It is difficult to say what the problem might be. The thread you linked in your first post talks about similar banding problems, and some 'auto tune' moves, which is often the case with drives with encoders. Unfortunately I have no experience with this drive. @mrehorstdmd would be the best person to advise you.

Ian

-

@droftarts Thank you for responding. I can't say that it's urgent, but maybe someone will respond and help. And so yes, I tried automatic adjustment, set the stiffness, changed the parameters (P01-03, P01-04), tried to manually adjust, but so far only ripples on the walls come out, which I really don't like.

-

@4eIIIuP maybe post a picture? Also, are you sure it’s the XY motion, not extrusion? See my post here for some videos and test prints that can help isolate what is causing these issues: https://forum.duet3d.com/post/321097

Ian

-

@droftarts

Unfortunately, I don't communicate much on forums and I don't know what is better to show so as not to overload the message. They send photos, I will definitely watch your videos, in my case it is exactly the X and Y axes and the ripples are on them, since vertical stripes are observed.

Unfortunately, I don't know if there is a note or something like that, so that the image is under it and does not take up much space.

-

@4eIIIuP In my tests I didn't see problems with straight sides, but did see a lot of "salmon skin" in curved surfaces which I ultimately attributed to poor resolution of the servo motors. I was not able to find much useful info on tuning the motors. I made one more test in which I used a 3:1 belt drive reducer to improve the resolution, but still could not get it to deliver the same print quality as my 400 step/rev steppers, and ultimately gave up on the servos.

One nice thing about the servo motors- they were super quiet. The only sound from the printer was the sliding of the corexy mechanism and the hot-end fan.

The IHSV servos work great in my sand table where the resolution isn't really important, but speed and noise are.

-

@mrehorstdmd It's a pity that we couldn't win. Most likely you are right and these servomotors do not have enough resolution, which is confirmed by the frequency of ripples. I've been messing with them for more than 3 weeks, but I've never found a way to beat this other than changing the kinematics or adding a gearbox. By the way, have you measured the frequency of the ripples increased by 3 times and decreased in amplitude?

-

@4eIIIuP Here are some of my test prints. I don't recall all the settings used, but my blind tuning of the motors didn't improve anything. You probably know more about tuning servos than I do...

Test print made with 400 step/rev steppers at 160 steps/mm:

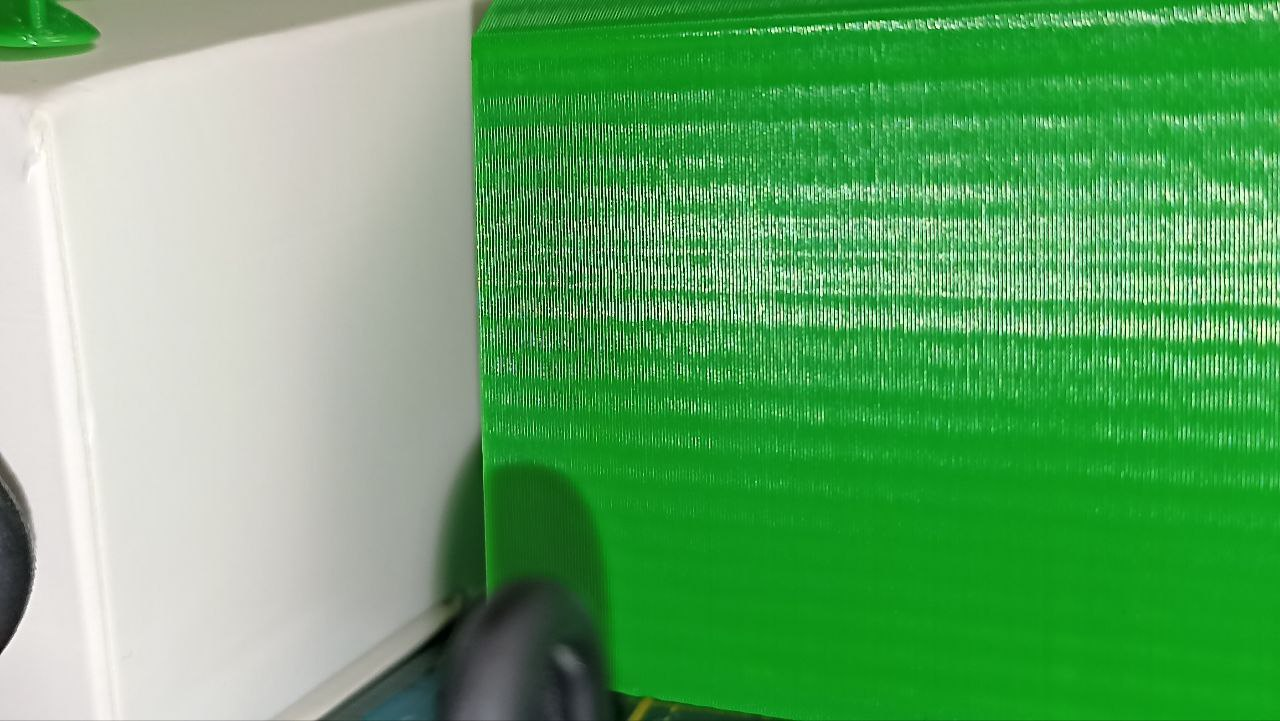

Test print made with IHSV-42 servomotors at 500 steps/mm:

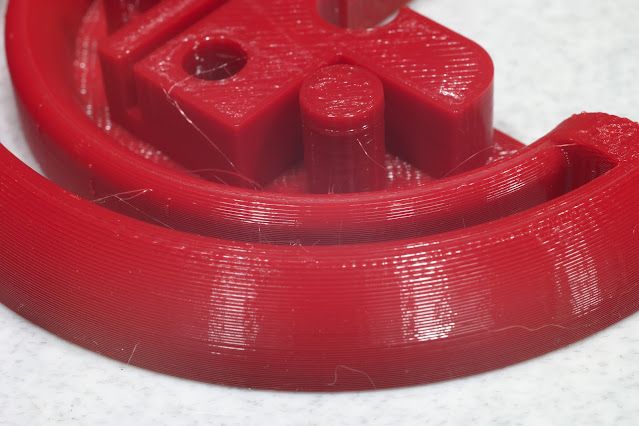

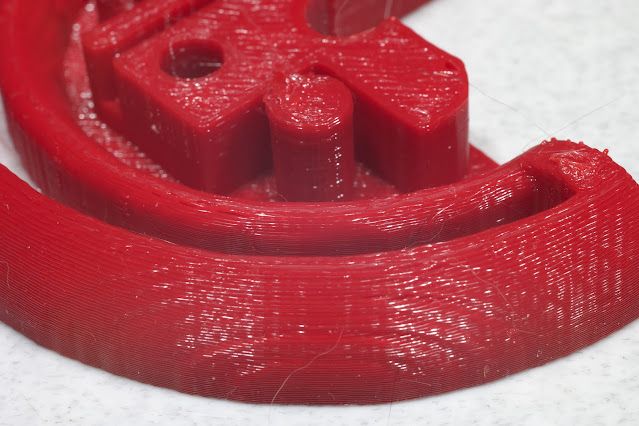

Test print made with IHSV servomotors and 3:1 reduction. This print was made at 4000 steps/rev, 3:1 drive reduction, 300 steps/mm, 50 mm/sec, with accel 5000 mm/sec^2, 0.2 mm layers, 1mm line widths:

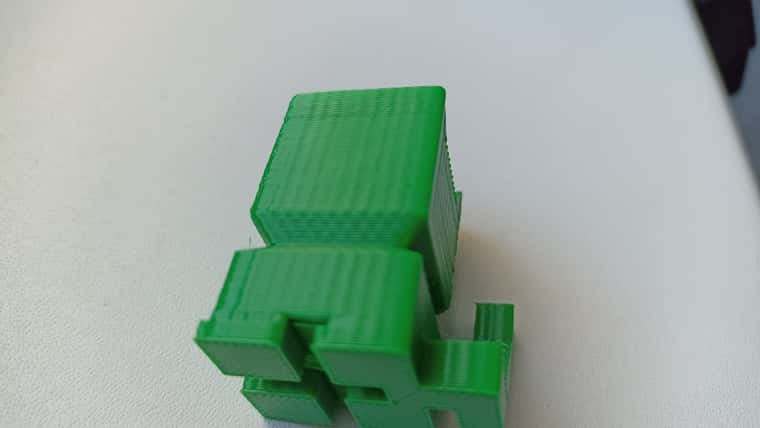

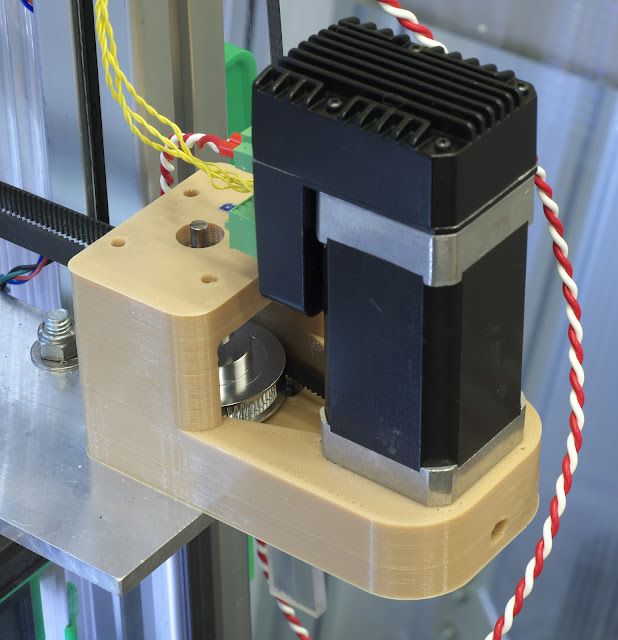

Motor mount with 3:1 belt reduction:

I believe I've seen other photos of prints made using these motors in this forum and they looked great, but I've never seen the details of the mechanical setups or the motor parameter settings, either dip switches or firmware.

In the flat areas of the prints I didn't see the same artifacts you're getting- those might be caused by a dual drive extruder or by using too small pulleys in the XY mechanism. I use F608 skate bearings for pulleys and don't have that problem, but the dual drive extruder causes a wood-grain appearance in prints:

-

@mrehorstdmd Thank you for the detailed answer, I have seen these photos. Well, then I'll try, try, but honestly I'm already giving up a little... I get either a noisy printer or low rigidity, but all options are combined by ripples.