tuning LW-PLA

-

@o_lampe not a stupid question at all!

The grub screw felt tight as I couldnt rotate the heat block at all. But I stripped and reassembled anyway..Voilà, the same part as above (the white bits are just refections)

I'll continue with @sebkritikel's pressure advance tuning next.

-

@nick9one1 said in tuning LW-PLA:

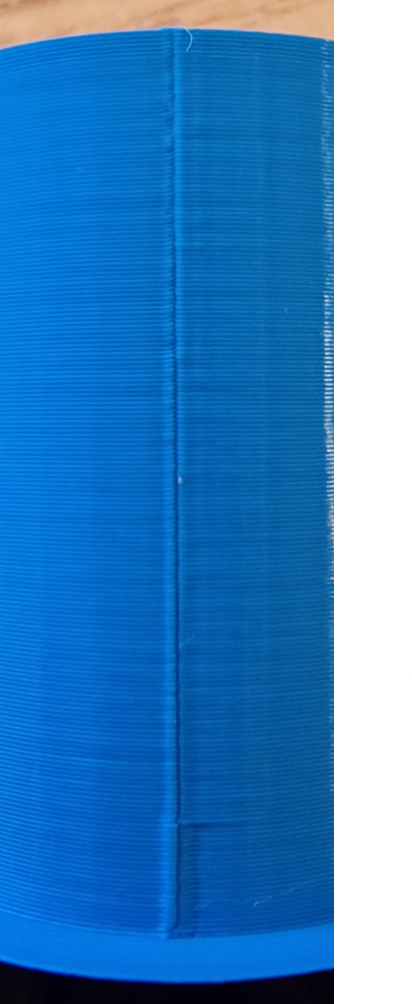

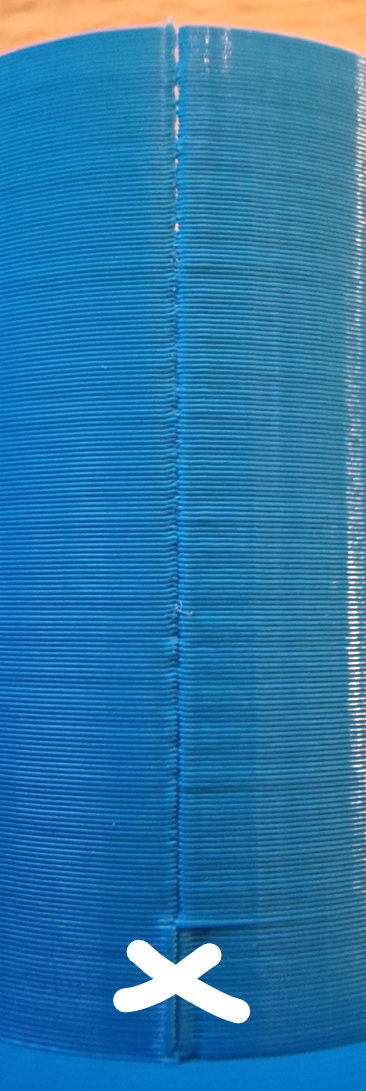

I did a test here; the top trint is with your latest suggestions. And the the descond print has 0.5mm extra length on deretraction. That's quite a lot, but visually I can barely tell any difference.

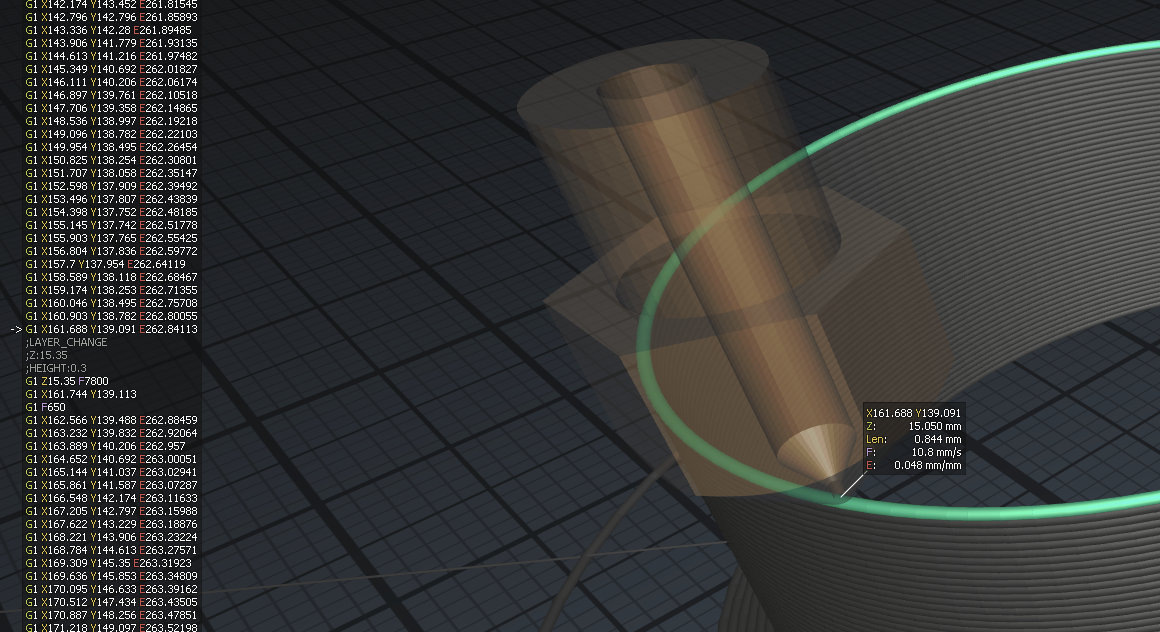

other image even closer, seems to show the layer change looking ok. The gaps happen after the de-retraction and when it starts to print the new layer?Important to note!!! Your cylinder print does not have any retractions or de-retractions! I would not add a slicer-generated extra length move at this time (or at all honestly. wait until PA and stuff is 100% tuned).

Notice there are not any retract moves in the image and gcode snipped above. -

Can you make a video of it in action?

-

thanks @sebkritikel I hadn't considered there was no retraction on layer change. It makes sense now that I can't see any difference with the +0.5 after retract.

@Phaedrux

I think the main issue is resolved now. It was some sort of mechanical issue that has disappeared after I stripped and rebuilt the hot end. I no longer get the gaps at the start of a new layer.@sebkritikel thank you for providing the PA cylinder test. I've since re-tuned the flow, temp and retraction so used some after layer change code in prusaslicer,

; 0.2mm layer, 8 bands 5mm each, total height 40mm {if layer_num== 1}M572 D0 S0.4 {elsif layer_num== 25}M572 D0 S0.05 {elsif layer_num== 50}M572 D0 S0.06 {elsif layer_num== 75}M572 D0 S0.07 {elsif layer_num== 100}M572 D0 S0.08 {elsif layer_num== 125}M572 D0 S0.09 {elsif layer_num== 150}M572 D0 S0.10 {elsif layer_num== 175}M572 D0 S0.11 {endif}

towards the top looks best, so I then printed another 0.12 - 0.18 (ignore the bottom band I mistakenly left it at 0.4)

-

@nick9one1 said in tuning LW-PLA:

The grub screw felt tight as I couldnt rotate the heat block at all

I meant the screw that tightens the filament roller to the gear-shaft. Any loose fit there would add bulge and gap at a layer seam.

But as was mentioned, you're printing in vase mode.

//edit OK, it's single wall, but no vase mode, so my above tip is still valid. -

Are you going to print airplane wings with this LW PLA? If yes, even and stable extrusion factor is important, I.e. you should look into vase mode. Recent Prusa Slicer has updated their vase mode to match the spiralize outer contour algorithm of Cura which should help with keeping extrusion more equal... and as always, printing slower will also help.