Is there a need to upgrade my stepper drivers?

-

@izeman Unless you plan to figure a way to cool them you won't be running them at the full rated amps. I bought 5 of those and run the A and B at 85% of rated power and they run very warm. Just below 100C.. So just below the plastic stage of the ASA used to make the parts.Never have missed a step so I am debating lowering the power a little at a time and see how it responds. I also used 3 of them for the Z drive. Those are at 55% power and work perfectly. They stay cooler.

Edit, remember they are sitting on a plastic part to no heat is being removed. I stuck radiators to the top which helped some. Lowering the current should help, they can run warm but I am not thrilled with them being almost hot enough to deform the towers. Its cool here now, summer might be enough to cause problems.

-

@KenW Thanks for your reply. Not sure I understand you correctly: You recommend actively cooling the stepper drivers, but don't do yourself - just run them at 85% rated current.

Or are you talking about the motors?

The z-axis shouldn't be an issue, as this remains unchanged. The motors never ever got above room temperature anyway. So I guess they are save, as well as the stepper drivers. Sames goes for the extruder.

You say "the are sitting on plastic" - I assume you're referring to the MOTORS? The motor mounts will be printed in ASA. They should take quite some heat before deformation, but at some point they will deform.

-

@izeman I am talking about the stepper motors. I am using a Duet 3 mini 5+. I do have a fan cooling the stepper drivers but have never noticed the board having issues with heat.. The A and B ( what you are calling X and Y ) are running very warm. When I measured one time it read 97,something C so was warm. That is below the deformation point but it is cooler now. In the summer when the shop is around over 90 degrees F the 30 or so degrees warmer might be enough to cause floppy towers.

-

@izeman Are you planning on doing the hydra mod too? Is yours a 5 plus and are you planning on a cast bed too? If so you might want to upgrade the Z steppers. I had 42-34 steppers and found they needed a bit more current to run without skipping. So I noticed they too were running warmer. That was my first change. When I was ready to do the upper I bought 5 stepper motors when they were on sale one day for $39.95 and changed the Z's to 42-48's . A bit over kill, 42-40's would have been fine there, If you do that you will need to do at least the feet for the enclosure to gain the depth needed.

Edit by warm they under 80c. Figured in the summer they would be hotter so decided to change. Then when the stepperonline motors appeared on the Black Friday sale could not resist.

-

I'm not concerned about the stepper MOTORS, I'm concerned about the stepper DRIVERS. Using TMC2130 right now, and no active cooling.

That works fine, as the stepper motors the Ender5 comes with only take 0.4A. And the Ender5 is NOT enclosed. I'm concerned that enclosing the printer and running motors that go up to 2A will make the stepper drivers overheat.

That's what I was asking. If the motors themselves go above 90°C you are facing troubles as well, as that's the temperature the motor mounts will start deforming.

So my questions remains: Is there a reason to upgrade my stepper drivers to something more capable, or is this not needed at all?!

-

I am using a different board. The Extruder is on a RRF-36 toolboard so is separate. There is a fan to blow across the board which is mounted in the lower electronics enclosure. There is plenty of room inside you are using it. Mine is fully enclosed that is why I am experiencing heat issues. If it was open would probably be fine. But it is motor heat, the board is fine. Even with the door open the rear where the stepper motors are is hot. In a way that is what I get for designing my own enclosure I guess. I need to redo it and have doors or louvers on the sides to adjust heat. Did not realize my bed would be so effective as an enclosure heater.

I also did not realize TMC2130's were more prone to overheating than the TMC2209s. 85% is probably way more than is needed. I just lowered it to 83% and will go down 2% at a time until it starts to act up. But no print is scheduled so will be awhile before I can tell how that works out.

For now, Z current is set to 55% or 1100, X and Y are set to 83% or 1660. Do not use the calculator on the Mercury one site. Klipper uses RMS values. but minus the ,707 they set to 80% so 1.6 to start. Can yours handle 1600ma of current?

Again that might be more than is needed but I plan to drop slowly and see if print issues pop up. Still tuning, I am increasing speed too and that can affect how much current is needed. But at the moment the orbitor extruder is taking all my attention. Getting problems with it stopping extruding.

-

@KenW I see. Good to know that the board is fine.

I don't know if the TMC2130 are more prone to overheating than any others. Hence my question. If there are some that can handle more amps at lower heat than they may be a better choice. But we'll see how they perform.TBH the enclosure may only be installed every now and then. There is no need for it when printing PLA. But I want to be able to print ABS/ASA/PC. And if I print those I may print at reduced speed. That should bring heat down as well?

-

@izeman I enclosed the printer in coroplast twinwall. If you have the tent type enclosure it is larger so you will not get as hot inside. But will also be heating the electronics since the whole inside is warm. On mine the electronics bay is underneath and separate from the heated area. The heating plate on yours is on top so it should not heat the electronics to high if you zip the flap closed.

I started on mine because my heating plate was basically a potato chip. Decided I also wanted faster heating and while looking found the zerog hydra mod. So mod one was done and now I have a thick cast aluminum bed with a line powered heater and 3 point leveling.

Probably did not really need mod two but what the heck why not. So the Mercury one.1 conversion was also installed. And after it was done it became obvious it would be easy to enclose so mod three.

In other words, warning, you are about to redo your whole printer. It can't be helped, it just happens.

Resistance is futile.

-

@izeman Also, is yours the plus or Ender 5? If it is the plus I printed all the ASA and ABS parts without an enclosure.Printed in a area with no air current and over 75 degrees F and used the draft shield option in Cura . Kept the print area 2 inches inside the bed all the way around and printed ASA at 255c with the bed set to 110c. Worked fine , no lifting, all parts were strong. So did not even need the giant plastic bag trick some use.

Might be partially due to the goop used to adhere parts to the bed. It is 5 grams of VP/VA copolymer mixed into 1 pint of 50% rubbing alcohol. Sprayed 3 coats on the PEI bed and they stuck so well I had to use the freezer trick to release them.

-

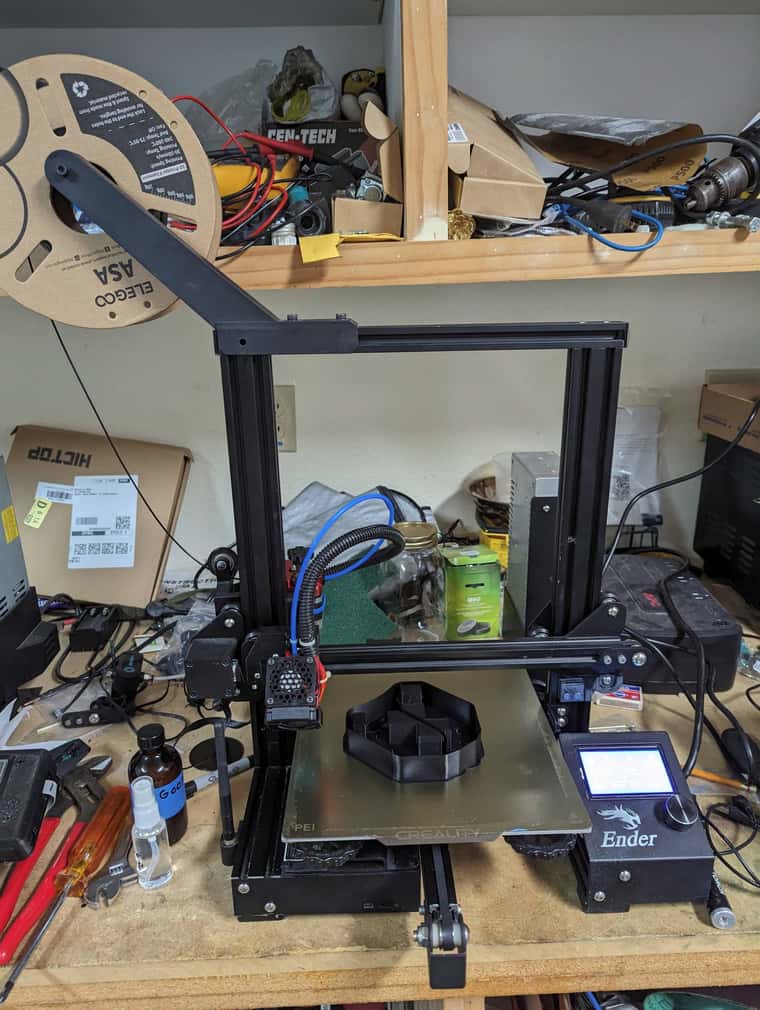

@izeman For example, here are two ASA prints done on an unenclosed Ender 3 It does have a PEI bed and the hotend has a titanium heatbreak so it can reach higher temperatures.

The part is to solve a problem with the Mercury one printer. I had to remove the parts used to lower the front bar on it to install the 2 front Z assemblies. As a result I can't easily watch the hotend anymore.

So these are combination bar lowerer/belt tensioners so I can lower the font bar again. Could not print them on the larger enclosed printer due to the extruder problem.

Do I get an award for the messiest workshop?

-

@KenW said in Is there a need to upgrade my stepper drivers?:

Do I get an award for the messiest workshop?

Yes, yes you do!

Ian -

@droftarts you haven't seen mine yet

-

@dc42 said in Is there a need to upgrade my stepper drivers?:

@droftarts you haven't seen mine yet

@dc42 @KenW You all got NO idea. Mine EASILY tops your's !! But I'm to frightened to post a picture of it

@KenW This is an Ender5 non plus. I heard of printing with draft shield. I may try that. And I also have used ABS slurry before. Sticks like hell, especially when using raft, but gives a bad surface quality. When I printed PC this sticked sooo good that when the piece was contracting the magnetic bed lifted !! (but the piece was still attached).

EDIT: Diving a little more into this juice/glue/slurry stuff it seems I made some slurry, but should have used juice instead. It was just too thick - but sticked well

-

@izeman I tried using the ABS juice but it tends to leave a messy finish to the print surface. Plus you have to match colors. The super hairspray goop does not do either of those but is a bit harder to apply as it wants to bead up if you are not careful when applying it. I have two version, the one normally used is the VA/VP copolymer mix. I also use another that cannot be used on glass beds as it will pull chunks out of them. It does work well on PEI so I use it for large ASA prints.

-

@KenW exactly what I experienced. It leaved a bad surface. But maybe be juice was a bit too thick and it was applied unevenly. I will try to make some new one and apply with a pump spray bottle. We'll see how this goes. This together with a new roll of ASA and an enclosure should hopefully give the results I need.

And btw: THIS is the bench of HORROR:

-

@izeman said in Is there a need to upgrade my stepper drivers?:

THIS is the bench of HORROR

Nah, I can still see bench space!

Ian