Reboots/resets randomly - RRF 3.5.0-b4

-

@Exerqtor thanks, I've been running your configuration for nearly 3 hours now - hasn't reset yet.

I included a PanelDue in the setup because I saw that you had the line to enable it in config.g .

I also saw that you have enabled FTP. The comment says it is for remote backups. Do you have anything running on your PC that makes FTP requests when the printer is idle?

-

@dc42

I haven't had any resets myself today either so I have no clue whats going on. And I have NOT changed anything just to be clear

Yeah I have a 5" PD v3 connected.

I only use ftp manually with WinSCP for the times I need to extract something, it's not automated process for backups anywhere

EDIT:

Still no more resets as of 6:40 in the morning of June 8th on my end

🤷♂️ -

@dc42

And there it happened again, a new reset. This time it was in the home stretch of a 6h46min print

I have since last time moved over to 3.5b4 on everything, so i'm changing the post title to reflect on that (with a note in the first post).

2023-06-10 15:02:08 [warn] Started printing file 0:/gcodes/job_file_0.16mm_ABS_0.4n_6h46m.gcode 2023-06-10 15:02:08 [debug] File 0:/gcodes/job_file_0.16mm_ABS_0.4n_6h46m.gcode selected for printing 2023-06-10 15:02:11 [info] M291: - [no title] - Print started, preheating. 2023-06-10 15:02:12 [info] G10 P0 S150 R150 2023-06-10 15:02:52 [info] G10 P0 S150.0 2023-06-10 15:02:53 [info] G10 P0 S150.0 2023-06-10 15:02:53 [info] M291: - [no title] - Pre-print mesh probing enabled, probing new bed mesh! 2023-06-10 15:02:53 [debug] Default grid: X10.0:340.0, Y10.0:340.0, Number of points: X12 Y12, 144 points 2023-06-10 15:02:53 [debug] Adaptive grid: X78.9777:271.022, Y108.141:158.156, Number of points: X7 Y3, 21 points 2023-06-10 15:02:58 [info] G10 P0 S150.0 2023-06-10 15:02:58 [debug] Z probe trigger height set to -1.434 mm 2023-06-10 15:02:58 [info] M291: - Mesh Probing - Probing now! Please wait... 2023-06-10 15:03:29 [info] G10 P0 S150.0 2023-06-10 15:03:29 [warn] 21 points probed, min error -0.041, max error 0.010, mean -0.012, deviation 0.013 Height map saved to file 0:/sys/heightmap.csv 2023-06-10 15:03:29 [debug] 21 points probed, min error -0.041, max error 0.010, mean -0.012, deviation 0.013 Height map saved to file 0:/sys/heightmap.csv 2023-06-10 15:03:29 [debug] Height map saved to file 0:/sys/adaptive_heightmap.csv 2023-06-10 15:03:35 [info] M291: - Mesh Probing - Done 2023-06-10 15:03:35 [info] G10 P0 S150.0 2023-06-10 15:03:36 [info] G10 P{global.initial_extruder} R{global.hotend_temp} S{global.hotend_temp} 2023-06-10 15:04:01 [info] M291: - [no title] - Purge location, X min: 53.9777; Y min: 98.141; Purge move speed: 4.802495; Prepurge speed: 4.158004 2023-06-10 15:04:12 [debug] ABS filament loaded & config applied 2023-06-10 15:04:12 [debug] ABS filament loaded & config applied 2023-06-10 18:28:09 [warn] HTTP client 192.168.10.226 login succeeded (session key 0) power up + 00:00:03 [info] Event logging started at level debug power up + 00:00:03 [info] Running: Duet 3 Mini5plus WiFi: 3.5.0-beta.4 (2023-06-08 23:40:14) power up + 00:00:03 [debug] Done! power up + 00:00:03 [debug] RepRapFirmware for Duet 3 Mini 5+ is up and running. power up + 00:00:04 [warn] WiFi module started power up + 00:00:07 [warn] WiFi module is connected to access point RV32-IOT2G, IP address 192.168.10.50 power up + 00:00:08 [warn] HTTP client 192.168.10.100 login succeeded (session key 767325465) 2023-06-10 19:08:45 [warn] Date and time set at power up + 00:00:08 2023-06-10 19:08:45 [warn] HTTP client 192.168.10.226 login succeeded (session key 0)M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.0-beta.4 (2023-06-08 23:40:14) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: FAP55-Q967A-G65J0-401GL-0S02Z-RF9TL Used output buffers: 4 of 40 (40 max) === RTOS === Static ram: 102996 Dynamic ram: 125612 of which 12 recycled Never used RAM 10580, free system stack 182 words Tasks: NETWORK(1,ready,17.9%,215) HEAT(3,nWait,0.0%,352) Move(4,nWait,0.0%,358) CanReceiv(6,nWait,0.0%,672) CanSender(5,nWait,0.0%,337) CanClock(7,delaying,0.0%,351) TMC(4,nWait,1.2%,108) MAIN(1,running,79.6%,704) IDLE(0,ready,0.4%,29) AIN(4,delaying,0.8%,266), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:59:15 ago, cause: software Last software reset at 2023-06-10 19:08, reason: HardFault bfarValid precise, Gcodes spinning, available RAM 2588, slot 2 Software reset code 0x4063 HFSR 0x40000000 CFSR 0x00008200 ICSR 0x00000803 BFAR 0x00000004 SP 0x20011fa8 Task NETW Freestk 482 ok Stack: 0000019e 00000002 200014ec 0000019d 2003337a 0009d43d 0002fcde 810f0000 0002fcd5 00000000 00000000 00000000 200321ac 00000800 20035ea0 2002c558 20018670 2002c3f5 20018670 2001e920 0002fe6f 00000000 00000000 00000000 20012058 00000014 b5dd9f97 Error status: 0x04 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 3556399, completed 3556399, timed out 0, errs 0 MCU temperature: min 38.5, current 39.2, max 48.2 Supply voltage: min 23.5, current 23.8, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/32, heap memory allocated/used/recyclable 2048/1244/820, gc cycles 138 Events: 0 queued, 0 completed Driver 0: standstill, SG min 4, read errors 0, write errors 1, ifcnt 78, reads 61095, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 1, ifcnt 78, reads 61095, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 2, read errors 0, write errors 1, ifcnt 45, reads 61095, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 45, reads 61095, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 45, reads 61096, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 5: standstill, SG min 0, read errors 0, write errors 1, ifcnt 21, reads 61098, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 1, ifcnt 21, reads 61098, writes 10, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2023-06-10 20:07:52 Cache data hit count 4294967295 Slowest loop: 38.41ms; fastest: 0.14ms === Storage === Free file entries: 18 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 4.3ms, write time 3.9ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is doing "G4 S1 " in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000803 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 32011, received 71157, lost 0, boc 0 Longest wait 3ms for reply type 6023, peak Tx sync delay 271, free buffers 18 (min 17), ts 17780/17779/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 22.10ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Interface state: active Module is connected to access point Failed messages: pending 0, notready 0, noresp 0 Firmware version 2.1beta4 MAC address bc:ff:4d:e6:b1:62 Module reset reason: Power up, Vcc 3.38, flash size 2097152, free heap 42980 WiFi IP address 192.168.10.50 Signal strength -55dBm, channel 1, mode 802.11n, reconnections 0 Clock register 00002001 Socket states: 0 0 0 0 0 0 0 0M122 B121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-beta.4 (2023-06-08 16:22:30) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 708, free system stack 88 words Tasks: Move(3,nWait,28.2%,111) HEAT(2,nWait,25.8%,57) CanAsync(5,nWait,0.0%,53) CanRecv(3,nWait,5.0%,75) CanClock(5,nWait,0.9%,66) ACCEL(3,nWait,0.0%,53) TMC(2,nWait,153.0%,57) MAIN(1,running,443.9%,336) IDLE(0,ready,0.0%,27) AIN(2,delaying,249.5%,142), total 906.2% Last reset 09:44:30 ago, cause: power up Last software reset data not available Driver 0: pos 0, 568.8 steps/mm, standstill, SG min 0, read errors 6, write errors 0, ifcnt 19, reads 6302, writes 19, timeouts 28, DMA errors 0, CC errors 0, failedOp 0x6a, steps req 0 done 40949660 Moves scheduled 513631, completed 513631, in progress 0, hiccups 9486, step errors 0, maxPrep 1375, maxOverdue 28990, maxInc 7907, mcErrs 0, gcmErrs 0, ebfmin -1.00, ebfmax 1.00 Peak sync jitter -5/11, peak Rx sync delay 345, resyncs 0/1, no timer interrupt scheduled VIN voltage: min 23.4, current 24.3, max 24.6 MCU temperature: min 51.1C, current 55.1C, max 83.3C Last sensors broadcast 0x00000012 found 2 40 ticks ago, 0 ordering errs, loop time 1 CAN messages queued 703196, send timeouts 0, received 834690, lost 0, free buffers 18, min 17, error reg 110000 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 533, adv 35645/74663 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0 -

i'm getting nearly continuous reboots with the new Beta 4. the fans, pumps etc spin up upon each reset as an actual reboot.

-

@RogerPodacter From your other post https://forum.duet3d.com/topic/32674/rrf-3-5-0-beta-4-broken-kinematics it looks like you were able to run some commands etc. after a reboot. What has changed since then, this might provide an indication as to what is causing the problem. If possible grabbing the output from M122 might also help. You could also try replacing your config.g file with a minimal version, that might allow you to boot the board and grab the m122 output.

-

@RogerPodacter

Yeah it's a full out reboot here to, the first time it happened i thought i had left something up against the main power switch of the printer that momenteraly switched it off and on again

-

@RogerPodacter as @gloomyandy says, please get a M122 report if you can. If you can't, then please revert to whichever firmware version you used before and then run M122.

@Exerqtor thanks for the new M122 report. It is resetting at the same point that it did under beta3. I haven't managed to pin down the problem yet, and I ran your configuration for a whole day without it resetting. Please try disabling FTP protocol to see if that makes a difference.

-

@dc42 said in Reboots/resets randomly - RRF 3.5.0-beta4:

@Exerqtor thanks for the new M122 report. It is resetting at the same point that it did under beta3. I haven't managed to pin down the problem yet, and I ran your configuration for a whole day without it resetting. Please try disabling FTP protocol to see if that makes a difference.

Ok, FTP is disabled as of now. Let's see if that makes any difference

It ran without any resets almost 3 days before it shat the bed last time, so it's for sure intermittent.

Oh i just came to remember, have you included the extra checks you added in the last beta3 binaries you gave me on the "over the shelf" beta4? If their still of any value i mean.

-

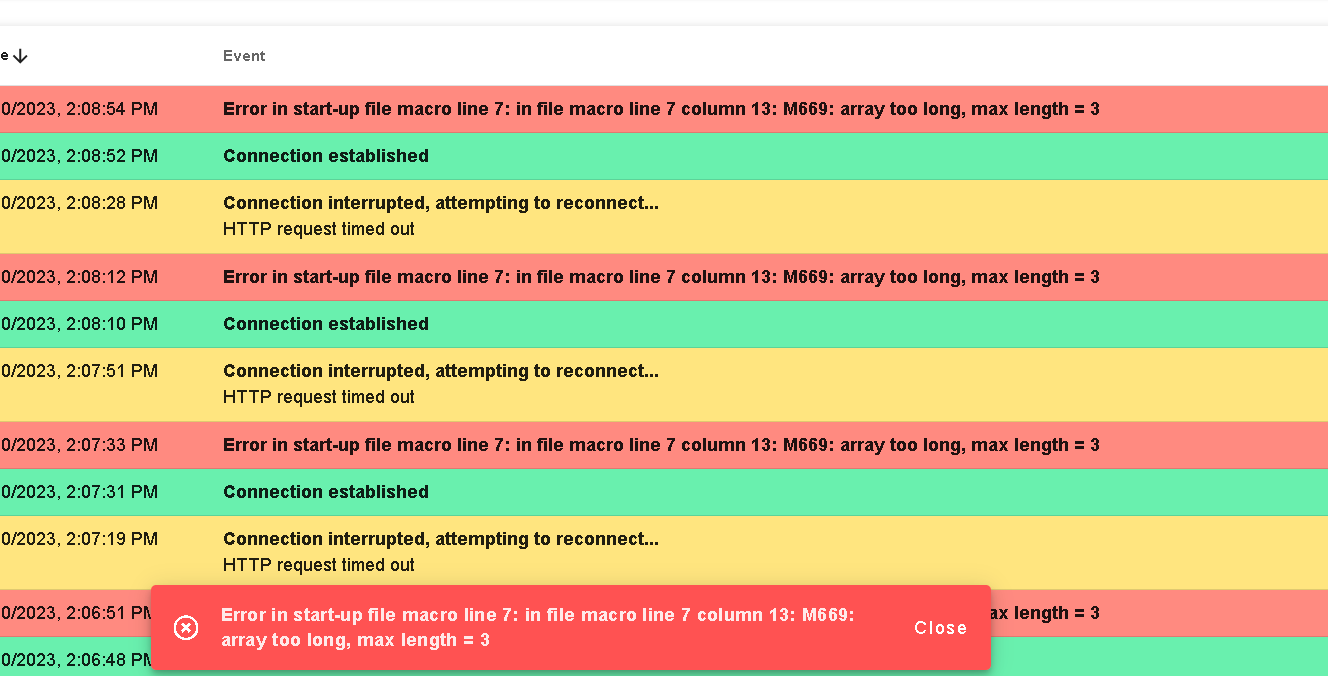

@dc42 here is my M122 immediately after a reboot.

/11/2023, 8:13:23 AM M122 B0 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.0-beta.4 (2023-06-08 23:40:14) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: J6RFD-NR6KL-K65J0-409NN-LK02Z-7M5YU Used output buffers: 1 of 40 (40 max) Error in macro line 7 while starting up: in file macro line 7 column 13: M669: array too long, max length = 3 === RTOS === Static ram: 102996 Dynamic ram: 125476 of which 104 recycled Never used RAM 10624, free system stack 188 words Tasks: NETWORK(2,ready,47.7%,173) HEAT(3,nWait,0.1%,333) Move(4,nWait,0.0%,358) CanReceiv(6,nWait,0.1%,658) CanSender(5,nWait,0.0%,337) CanClock(7,delaying,0.0%,351) TMC(4,delaying,1.1%,108) MAIN(2,running,38.0%,672) IDLE(0,ready,12.2%,29) AIN(4,delaying,0.8%,266), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:05:35 ago, cause: software Last software reset at 2023-06-11 08:07, reason: HardFault imprec, Gcodes spinning, available RAM 10624, slot 2 Software reset code 0x4063 HFSR 0x40000000 CFSR 0x00000400 ICSR 0x00000803 BFAR 0xe000ed38 SP 0x200120a0 Task NETW Freestk 544 ok Stack: 00000000 000af3d0 200014ec 2000dfe0 ffffffff 0009ded7 000120fe 210f0000 00012121 2000dfe0 00000000 000af350 00000083 e000e000 2001e920 a5a5a5a5 00012195 20036408 00000000 016c82f6 00031b41 00000000 2001a590 00000001 20036408 00000000 00033dc7 Error status: 0x04 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 335765, completed 335765, timed out 0, errs 0 MCU temperature: min 36.2, current 37.1, max 37.1 Supply voltage: min 23.9, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/4, heap memory allocated/used/recyclable 2048/484/368, gc cycles 426 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 5: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 0, ifcnt 41, reads 5479, writes 0, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2023-06-11 08:13:22 Cache data hit count 553598465 Slowest loop: 407.58ms; fastest: 0.19ms === Storage === Free file entries: 19 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 6.3ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: mesh, height map offset 0.000, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters 2 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is ready with "M122 B0" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 543, received 3374, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 6, free buffers 18 (min 18), ts 302/302/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 217.65ms; fastest: 0.06ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Interface state: active Module is providing access point Failed messages: pending 0, notready 0, noresp 0 Firmware version 2.1beta3 MAC address ea:68:e7:e5:63:f4 Module reset reason: Power up, Vcc 3.39, flash size 2097152, free heap 39484 WiFi IP address 192.168.1.10 Connected clients 1 Clock register 00002001 Socket states: 0 0 0 0 0 0 0 0 6/11/2023, 8:13:13 AM Error in start-up file macro line 7: in file macro line 7 column 13: M669: array too long, max length = 3 6/11/2023, 8:13:11 AM Connection established 6/11/2023, 8:13:05 AM Connection interrupted, attempting to reconnect... HTTP request timed out 6/11/2023, 8:12:23 AM M122 B0 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.0-beta.4 (2023-06-08 23:40:14) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: J6RFD-NR6KL-K65J0-409NN-LK02Z-7M5YU Used output buffers: 24 of 40 (36 max) Error in macro line 7 while starting up: in file macro line 7 column 13: M669: array too long, max length = 3 === RTOS === Static ram: 102996 Dynamic ram: 125476 of which 104 recycled Never used RAM 10624, free system stack 188 words Tasks: NETWORK(2,nWait,16.7%,181) HEAT(3,nWait,0.1%,333) Move(4,nWait,0.0%,358) CanReceiv(6,nWait,0.1%,658) CanSender(5,nWait,0.0%,337) CanClock(7,delaying,0.0%,351) TMC(4,delaying,1.2%,108) MAIN(1,running,78.1%,704) IDLE(0,ready,3.0%,29) AIN(4,delaying,0.8%,266), total 100.0% Owned mutexes: WiFi(NETWORK) HTTP(MAIN) === Platform === Last reset 00:04:35 ago, cause: software Last software reset at 2023-06-11 08:07, reason: HardFault imprec, Gcodes spinning, available RAM 10624, slot 2 Software reset code 0x4063 HFSR 0x40000000 CFSR 0x00000400 ICSR 0x00000803 BFAR 0xe000ed38 SP 0x200120a0 Task NETW Freestk 544 ok Stack: 00000000 000af3d0 200014ec 2000dfe0 ffffffff 0009ded7 000120fe 210f0000 00012121 2000dfe0 00000000 000af350 00000083 e000e000 2001e920 a5a5a5a5 00012195 20036408 00000000 016c82f6 00031b41 00000000 2001a590 00000001 20036408 00000000 00033dc7 Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 275495, completed 275495, timed out 0, errs 0 MCU temperature: min 29.4, current 36.2, max 36.4 Supply voltage: min 23.9, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/4, heap memory allocated/used/recyclable 2048/1492/1376, gc cycles 384 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24999, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24998, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24998, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24998, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24998, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 5: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24998, writes 13, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 1, ifcnt 41, reads 24998, writes 13, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2023-06-11 08:12:22 Cache data hit count 471457659 Slowest loop: 304.77ms; fastest: 0.16ms === Storage === Free file entries: 19 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 6.3ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: mesh, height map offset 0.000, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters 2 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is ready with "M122 B0" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 2525, received 15490, lost 0, boc 0 Longest wait 3ms for reply type 6053, peak Tx sync delay 7, free buffers 18 (min 17), ts 1377/1376/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 207.85ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(2) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Interface state: active Module is providing access point Failed messages: pending 0, notready 0, noresp 0 Firmware version 2.1beta3 MAC address ea:68:e7:e5:63:f4 Module reset reason: Power up, Vcc 3.39, flash size 2097152, free heap 36540 WiFi IP address 192.168.1.10 Connected clients 1 Clock register 00002001 Socket states: 0 0 0 0 0 0 0 0 6/11/2023, 8:12:14 AM Error in start-up file macro line 7: in file macro line 7 column 13: M669: array too long, max length = 3 6/11/2023, 8:12:13 AM Connection established 6/11/2023, 8:07:54 AM Connection interrupted, attempting to reconnect... HTTP request timed out 6/11/2023, 8:07:41 AM Error in start-up file macro line 7: in file macro line 7 column 13: M669: array too long, max length = 3 6/11/2023, 8:07:39 AM Connection established 6/11/2023, 8:07:21 AM Connection interrupted, attempting to reconnect... HTTP request timed out 6/11/2023, 8:06:48 AM Error in start-up file macro line 7: in file macro line 7 column 13: M669: array too long, max length = 3 6/11/2023, 8:06:46 AM Connection established 6/10/2023, 2:15:03 PM Connection interrupted, attempting to reconnect... HTTP request timed out6/11/2023, 8:14:24 AM M122 B1 Diagnostics for board 1: Duet EXP3HC rev 1.02 or later firmware version 3.5.0-beta.4 (2023-06-08 16:24:05) Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 156280, free system stack 202 words Tasks: Move(3,nWait,0.0%,182) HEAT(2,nWait,0.0%,90) CanAsync(5,nWait,0.0%,67) CanRecv(3,nWait,0.0%,79) CanClock(5,nWait,0.0%,70) TMC(2,nWait,5.9%,103) MAIN(1,running,92.7%,405) IDLE(0,ready,0.0%,40) AIN(2,delaying,1.3%,265), total 100.0% Last reset 00:08:02 ago, cause: power up Last software reset data not available Driver 0: pos 0, 690.0 steps/mm, standstill, SG min 0, mspos 8, reads 44125, writes 32 timeouts 0, steps req 0 done 0 Driver 1: pos 0, 690.0 steps/mm, standstill, SG min 0, mspos 8, reads 44126, writes 32 timeouts 0, steps req 0 done 0 Driver 2: pos 0, 80.0 steps/mm, standstill, SG min 0, mspos 8, reads 44141, writes 17 timeouts 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00, ebfmax 0.00 Peak sync jitter -8/9, peak Rx sync delay 182, resyncs 0/2, no timer interrupt scheduled VIN voltage: min 21.0, current 24.2, max 28.6 V12 voltage: min 12.3, current 12.3, max 12.3 MCU temperature: min 22.2C, current 29.9C, max 29.9C Last sensors broadcast 0x00003000 found 2 33 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 7784, send timeouts 0, received 8203, lost 0, free buffers 38, min 38, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 06/11/2023, 8:15:26 AM M122 B20 Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.5.0-beta.4 (2023-06-08 16:22:30) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 1504, free system stack 142 words Tasks: Move(3,nWait,0.0%,175) HEAT(2,nWait,0.3%,100) CanAsync(5,nWait,0.0%,54) CanRecv(3,nWait,0.0%,77) CanClock(5,nWait,0.0%,66) ACCEL(3,nWait,0.0%,53) TMC(2,delaying,3.0%,57) MAIN(1,running,91.7%,336) IDLE(0,ready,0.0%,27) AIN(2,delaying,4.9%,142), total 100.0% Last reset 00:09:04 ago, cause: VDD brownout Last software reset data not available Driver 0: pos 0, 690.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 21, reads 10157, writes 21, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00, ebfmax 0.00 Peak sync jitter -3/8, peak Rx sync delay 215, resyncs 0/2, no timer interrupt scheduled VIN voltage: min 20.8, current 24.1, max 27.7 MCU temperature: min 21.1C, current 27.6C, max 27.7C Last sensors broadcast 0x00000312 found 4 190 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 10952, send timeouts 0, received 9271, lost 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0 -

@RogerPodacter please can you add the following command to config.g and reboot:

M122 P500 S0

That will provide more data in the M122 report after the next uncommanded reset.

Also please upgrade to wifi firmware 2.1beta4 which is now the version in the RRF 3.5.0-beta.4 github release.

Please post your config.g file, daemon.g (if you have one), config-override.g (if you have one), and any other macro files that those call.

When this problem next occurs, please post a new M122 report.

-

@Exerqtor in reply to your question in the firmware announcement thread, you are already running wifi firmware 2.1beta4 according to your M122 reports - but please check that you haven't inadvertently downgraded to 2.1beta3.

-

@dc42

From the last M122 i posted exactly that seems to be the case, that i downgraded to 2.1b3

-

@Exerqtor I will run my test setup with your config and RRF3.5.0-beta.4 and wifi server 2.1beta4 to see if the problem occurs; but if @RogerPodacter responds with his configuration then I will switch to that, as it seems that the issue occurs much more frequently on his machine.

-

@dc42 here is my config.g. my reboots happened right after boot up but in certain homed states. it was combinations of homing individual axis vs a homeall which would crash and not complete successfully. and i was experimenting with adding K11 and removing K11 vs K1 from my M669. i dont recall which i was using at the time. they all rebooted, but some worse than others in terms of repeating over and over.

M669 K11 X1:0:0:0 Y1:-1:0:-1 Z0:0:1:0 U0:0:0:1; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core3" ; set printer name ;M669 K11 Y1:-1:0:-1 ; Dual Markforged Kinematics https://forum.duet3d.com/topic/7796/haq-xy/125 https://forum.duet3d.com/topic/21021/dual-markforged-kinematics?_=1672244913067 ;M669 K1 X1:0:0:0 Y1:-1:0:-1 Z0:0:1:0 U0:0:0:1 ; Matrix mapping for Axis - X:Y:Z:U M669 X1:0:0:0 Y1:-1:0:-1 Z0:0:1:0 U0:0:0:1 ; Matrix mapping for Axis - X:Y:Z:U G21 ; Set Units to Millimeters ; Network M552 S2 ; enable network, note P0.0.0.0 sets auto DHCP M553 P255.255.255.0 ; set subnet mask M554 P192.168.1.20 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet G4 S2 ; wait for expansion boards to start ; Drives M569 P0.0 S0 D2 ; Left Z physical drive 0.0 goes forwards M569 P0.1 S0 D2 ; Rear Z physical drive 0.1 goes forwards M569 P0.2 S0 D2 ; Right Z physical drive 0.2 goes forwards M569 P0.3 S1 D2 ; Right U toolhead drive 0.3 goes forwards M569 P0.4 S1 D2 ; Left X toolhead drive 0.4 goes forwards M569 P0.5 S0 D2 ; Left Y drive 0.5 goes forwards M569 P0.6 S1 D2 ; Right Y drive 0.6 goes reverse M569 P20.0 S1 D2 ; Extruder physical drive 20.0 goes forwards Toolboard 1LC M569 P21.0 S1 D2 ; Extruder physical drive 21.0 goes forwards Toolboard 1LC M569 P1.0 S0 D2 ; Extruder physical drive 1.0 goes forwards Expansion 3HC M569 P1.1 S0 D2 ; Extruder physical drive 1.1 goes forwards Expansion 3HC M569 P1.2 S1 D2 ; Extruder physical drive 1.2 goes forwards Expansion 3HC M584 Z0.0:0.1:0.2 Y0.5:0.6 X0.4 U0.3 E20.0:21.0:1.0:1.1 ; set drive mapping M350 U16 X16 Y16 Z16 E16:16:16:16 I1 ; configure microstepping with interpolation M92 U80.0 X80.00 Y80.00 Z800.00 E690:690:690:690 ; set steps per mm M906 U2000 X2000 Y2000 Z1800 E1000:1000:1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent -- safe for Duet 3 mini 5+ M84 S30 ; Set idle timeout ;M98 P"0:/sys/setspeeds.g" ; Set speed and acceleration M566 U500.00 X500.00 Y500.00 Z60.00 E300:300:300:300 P1 ;E300:300 P1 ;X1500.00 Y1500.00 Z6.00 E300 P1 ;E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 U30000.00 X30000.00 Y30000.00 Z1000.00 E7200:7200:7200:7200 ;E7200:3600 ;E3600.00 ; set maximum speeds (mm/min) M201 U10000.00 X10000.00 Y10000.00 Z100.00 E10000:10000:10000:10000 ;E10000:3600 ;E3600.00 ; set accelerations (mm/s^2) M207 S0.6 F7200 Z0.2 ; firmware retraction orbiter 2.0 ; Axis Limits M208 X-70 U0 Y0 Z0 S1 ; set axis minima M208 X300 U380 Y306 Z300 S0 ; X310 ; set axis maxima ;M208 X-70:310 Y0:308 U0:308 Z0:300 ; Endstops M574 X1 S1 P"20.io2.in" ; configure active high endstops Toolhead 1 X low end M574 U2 S1 P"21.io2.in" ; configure active high endstops Toolhead 2 U high end M574 Y2 S1 P"io2.in" ; configure active high endstops Y. IO0 and IO1 also are UART, so do not put endstops on them, use them elsewhere to free up UART. M574 Z1 S2 M671 X-71:155:381 Y-1.5:305:-1.5 S5 ; NEW WIDEBOI WITH EXTRUSION SUPPORT LEADSCREW POSITIONS define positions of Z leadscrews or bed levelling screws ;M671 X-4.5:155:304.5 Y-4.5:305:-4.5 S5 ; OLD NON-WIDEBOI EXTRUION SUPPORT LEADSCREW POSITIONS define positions of Z leadscrews or bed levelling screws ;M557 X30:280 Y20:300 P5 ; define 5x5 mesh grid M557 X30:270 Y20:270 P5 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Keenevo 600W Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 Q10 ; Define Heater0 as the heated bed, bind to Sensor0 M140 H0 P0 ; Define Heated Bed M307 H0 R0.602 K0.401:0.000 D2.44 E1.35 S1.00 B0 ; PID Tuning for Heater0, Heated Bed (100C) M143 H0 S140 T0 A0 ; Set temperature limit for Heater0 to 120C M308 S1 P"20.temp0" Y"thermistor" T100000 B4725 C7.060000e-8 A"Slice Hotend 0" ;Slice Engineering 300C thermistor, settings are online M950 H1 C"20.out0" T1 Q100 ; Define Heater1 as Extruder0 heater, bind to Sensor1 M307 H1 R2.808 K0.368:0.000 D4.56 E1.35 S1.00 B0 V23.8 ; PID Tuning for Heater1, Extruder0 (240C) M143 H1 S325 T1 A0 ; Set temperature limit for heater 1 to 285C M308 S2 P"temp1" Y"thermistor" T100000 B3950 C7.060000e-8 A"Chamber" ; configure sensor 2 as thermistor on pin temp1 M950 H2 C"out1" T2 ;Q10 ; create chamber heater output on out1 and map it to sensor 2 M307 H2 R0.01 K0.200:0.000 D60 E1.35 S1.00 B1 ; enable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S120 T2 A0 ; set temperature limit for heater 2 to 60C M308 S3 P"21.temp0" Y"pt1000" A"Slice Hotend 1" ;Slice Engineering RTD PT1000 450C, settings are online M950 H3 C"21.out0" T3 Q100 ; Define Heater1 as Extruder0 heater, bind to Sensor1 M307 H3 R2.808 K0.368:0.000 D4.56 E1.35 S1.00 B0 V23.8 ; PID Tuning for Heater1, Extruder0 (240C) M143 H3 S425 T3 A0 ; S325 ; Set temperature limit for heater 1 to 285C M308 S4 P"20.temp1" Y"thermistor" A"Cooling Block" T100000 B3950 C7.060000e-8 ; Define Sensor as Chamber temperature M308 S5 Y"drivers" A"4028 Power" ; 4028 power using spare heater M308 S6 Y"mcu-temp" A"Mini 5+ MCU" ; Define Sensor3 as the integrated MCU temperature sensor M308 S7 Y"drivers" A"Mini 5+ TMC Drivers" ; Define Sensor4 as the TMC overheat sensor M308 S8 Y"mcu-temp" P"20.dummy" A"Toolboard0 MCU" M308 S9 Y"drivers" P"20.dummy" A"1LC0 Stepper" M308 S10 Y"mcu-temp" P"21.dummy" A"Toolboard1 MCU" M308 S11 Y"drivers" P"21.dummy" A"1LC1 Stepper" M308 S12 Y"mcu-temp" P"1.dummy" A"3HC MCU" M308 S13 Y"drivers" P"1.dummy" A"3HC TMC Drivers" M308 S14 P"temp2" Y"thermistor" T100000 B3950 C7.060000e-8 A"Orbiter Motor" ; configure sensor 9 as thermistor on pin temp2 M308 S15 P"spi.cs1" Y"thermocouple-max31856" K"K" A"TC0 Chamber Heater"; define temperature sensor number 10 as a K Type thermocouple on the first port of a temperature daughter board plugged into the expansion board with CAN bus address 3. M308 S16 P"spi.cs2" Y"thermocouple-max31856" K"K" A"TC1 Chamber Fins"; define temperature sensor number11 as a T Type thermocouple on the first port of a temperature daughter board plugged into the expansion board with CAN bus address 3. ;M308 S17 P"21.temp1" Y"thermistor" T4500000 B5315 C3.219245e-9 A"BLUE MELLOW" ; blue Mellow high temp thermistor (toolboard)https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors#Section_RepRapFirmware_3_x ;M308 S17 P"21.temp1" Y"pt1000" T500000 B4666 C1.117125e-7 A"WHITE MELLOW" ; white Mellow high temp pt1000 (toolboard)https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors#Section_RepRapFirmware_3_x ; Fans M950 H4 C"!out2" T2 Q10 ;H2 ; Define Heater2 as the 4028 fan power, bind to Sensor3 M143 H4 P2 S200 A0 ; Needed M143 to set max temp so the graph scaled correctly M950 F0 C"!20.out1+out1.tach" Q25000 ;Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"T0 Layer Fan" L0.0 X1.0 S0 H-1 B0.1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"20.out2+out2.tach" Q500 ; Fan 1 uses out3, and using out3.tach as a tacho input M106 P1 C"T0 Hotend Fan" S0 H1 T45 ; For M106 the H is sensor # and NOT heater #. set fan 1 name and value. Thermostatic control turned on for Hotend M950 F2 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P2 C"Mini 5+ Board Fan" S0 H5:6:7 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F3 C"!out3+out3.tach" Q25000 ; Q500 ; Chamber Heater Fan Noctua NF-F12 Industrial M106 P3 C"Chamber Heater Fan" H15 T30 ; H15 S0.3 L0.3 X0.6 B0.1 T30:40 ; set fan 1 name and value. Thermostatic control turned on for Hotend. M950 F4 C"1.out3" Q500 ; ; out6 on old mini 5+ ; create fan 4 for Water Cooling 12V Fan 4 on pin out4 and set its frequency M106 P4 C"Radiator Cooling Fan" S0 H4 T35 ; set fan 1 name and value. Thermostatic control turned on for liquid cooling hotend M950 F5 C"!out4+out4.tach" Q25000 ;Q500 ; create fan 4 for Water Cooling 12V Fan 4 on pin out4 and set its frequency M106 P5 C"Liquid Cooling Pump" L0.0 X1.0 S0.5 H4 ;S0.0 T20 ; set fan 4 name and value. Thermostatic control turned on for liquid cooling hotend M950 F6 C"!21.out1+out1.tach" Q25000 ;Q500 ; create fan 6 on pin out4 and set its frequency M106 P6 C"T1 Layer Fan" L0.0 X1.0 S0 H-1 B0.1 ; set fan 6 name and value. Thermostatic control is turned off M950 F7 C"21.out2+out2.tach" Q500 ; Fan 7 uses out3, and using out3.tach as a tacho input M106 P7 C"T1 Hotend Fan" S0 H3 T45 ; set fan 7 name and value. Thermostatic control turned on for Hotend M950 F8 C"1.out6" Q500 ; create fan 1 on pin out5 and set its frequency M106 P8 C"3HC Board Fan" S0 H12:13 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend M950 F9 C"!1.out4+out4.tach" Q25000 ;Q500 4028 filter fan ; create fan 0 on pin out4 and set its frequency M106 P9 C"Testing Chamber Fan" H-1 T30 ; Tool 0 X Axis M563 P0 D0 H1 X0 F0 S"Mosquito Mag Liquid" ; define tool 0 G10 P0 X0 Y0 Z-0.54 ; Z-0.54 S210 R175 ; set tool 0 axis offsets, set initial tool 0 active 60C and standby temperatures to 0C M568 P0 S210 R175 ; Tool 1 U Axis M563 P1 D1 H3 X3 F6 S"Mosquito Mag Air" ; define tool 0 G10 P1 U0 X0 Y0 Z0 ; S210 R175 ; L1 ; set tool 1 axis offsets, set initial tool 1 active 60C and standby temperatures to 0C M568 P1 S210 R175 ; Tool 2-- Toolhead 2 with ROME 1 M563 P2 D1:2 H3 X3 F6 S"ROME 1" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P2 U-2.31 X0 Y0.24 Z0.00 ; Z0.04 S210 R175 ; L1 ; set tool 0 axis offsets, set initial tool 0 active 60C and standby temperatures to 0C M567 P2 E1:1 ; set mix ratio 100% on both extruders for copy mode M568 P2 S210 R175 ; Tool 3-- Toolhead 2 with ROME 2 M563 P3 D1:3 H3 X3 F6 S"ROME 2" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P3 U-2.31 X0 Y0.24 Z0.00 ; Z0.04 S210 R175 ; L1 ; set tool 0 axis offsets, set initial tool 0 active 60C and standby temperatures to 0C M567 P3 E1:1 ; set mix ratio 100% on both extruders for copy mode M568 P3 S210 R175 ; Tool 4-- copy mode ;M563 P4 D0:1 H1:3 X0:3 F0:6 S"copy mode" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans ;G10 P4 U-77.5 X77.5 Y0 S210 R175 ; set tool offsets and temperatures for tool 2 ;M567 P4 E1:1 ; set mix ratio 100% on both extruders for copy mode ; Tool 5-- mirror mode ;M563 P5 D0:1 H1:3 X0:3 F0:6 S"mirror mode" ; tool for mirror mode ;G10 P5 U-77.5 X77.5 Y0 S210 R175 ; tool offset for mirror mode (flipped X offset) ;M567 P5 E1:1 ; set mix ratio 100% on both extruders for mirror mode ; Z-Probe Euclid Probe ;M558 P5 C"20.io0.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds M558 P8 C"^20.io0.in" H8 F400 T9000 A1 ; S0.01 ; set Z probe type to unmodulated and the dive height + speeds G31 P1000 X-28 Y-20 Z9.71 ; Z9.21 ; K0 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch ; M950 S0 C"io7.out" ; Create a servo pin on io7 ; M558 P9 C"io7.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P25 X-28.00 Y-13.00 Z0.78 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;Accelerometer M955 P20.0 I14 ;Input Shaper M593 P"zvdd" F31 ; for 10k acceleration ;M593 P"mzv" F42.5 ; for 15k acceleration ;Filament Sensor0 ;M591 D0 P3 C"20.io1.in" S1 ;M591 D0 L27 R10:190 ;ROME Filament Sensor0 ;M591 D2 P1 C"21.io0.in" S1 ;M591 D2 L27 R10:190 ;M574 U2 S1 P"21.io0.in" ; configure active high endstops Toolhead 2 ROME toolhead filament sensor ;M577 wait until endstop is triggered. Does equivalent exist for a general IO sensor? M950 J0 C"^!21.io0.in" ;PanelDue 5i M575 P1 S1 B57600 ;NeoPixels x3 M150 X3 Q4000000 ;R128 U128 B128 P128 S2 F0 M150 X3 R255 U255 B255 W255 P255 S2 F0 ; display led ; Custom settings G29 S1 M572 D0:1:2:3 S0.045 ; set Pressure Advance K-factor M501 M376 H3 ;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss global daemonLoop = true ; init filament sensor error global variables if !exists(global.filamentTimestamp) global filamentCounter = 0 global filamentTimestamp = state.Uptime ; init print time logging if !exists(global.runtime) M98 P"runtime.g" ; init LED variables if !exists(global.warmUp) global warmUp = false ; Select default tool M404 N1.75 ; Define filament diameter for print monitor T0 -

@RogerPodacter thanks. Can you confirm that you have no daemon.g file in /sys on the SD card?

-

@dc42 said in Reboots/resets randomly - RRF 3.5.0-beta4:

@Exerqtor in reply to your question in the firmware announcement thread, you are already running wifi firmware 2.1beta4 according to your M122 reports - but please check that you haven't inadvertently downgraded to 2.1beta3.

Yup, no problem I know intermittent issues can suck to track down

-

@dc42 ah yes, here is my daemon.g.

daemon.g

while global.daemonLoop ;----------------------------------------------------------------------------- ;Heater Checks and Safety ;----------------------------------------------------------------------------- ;check if Chamber heater fans are running ; if fans[3].rpm < 100 ; M141 H2 S-273.1 ; disable chamber heater ;----------------------------------------------------------------------------- ;Keeps a lifetime running print time variable for the printer ;----------------------------------------------------------------------------- ;if global.warmUp = true ; echo "setLEDbyTemp = true" ; M98 P"0:/macros/set_LED_while_heating.gcode" if state.status == "processing" if exists(global.runtime) set global.runtime = {global.runtime + 10} echo >"runtime.g" "global runtime = " ^ {global.runtime} ^ " ; seconds AUTO GENERATED by daemon.g" ;echo >"runtime.g" "minutes = "^{global.runtime}/60 ;echo >"runtime.g" "hours = "^{global.runtime}/60/60 ;echo >"runtime.g" "days = "^{global.runtime}/60/60/24 ;----------------------------------------------------------------------------- ;LED Controls ;----------------------------------------------------------------------------- if {state.status} == "paused" M150 R255 B255 P255 S2 ; purple M300 S4000 P50 G4 P300 M300 S4000 P50 ; double beep elif {state.status} == "processing" || {state.status} == "busy" M150 R255 U255 B255 W255 P255 S2 ; white elif {heat.heaters[0].current} > 50 || {heat.heaters[1].current} > 70 M150 R255 U0 B0 W0 P255 S2 ; red elif {state.status} == "idle" M150 R0 U255 B0 W0 P255 S2 ; green else M150 R150 U0 B150 W0 P255 S2 ; purple G4 S10 ;there is a delay of 10 seconds between consecutive executions of daemon.g. This is to avoid SD ; card access contention between daemon.g and a file being printed. If you need a smaller delay, put ; all that code inside a while-loop, and include a shorter delay (e.g. G4 S1) at the end of the loop. ;ADD SOMETHING LIKE THIS FOR HEATER SAFETY. USE REALLY USEFUL EXAMPLE GCODE DAEMON.G FILES. ;if fans[1].rpm < 100 && heat[1].heaters > 50 ; abort "No fan motion detected, stopping all macros, jobs, and disabling heaters" ; M140 P-273.1 ; disable bed heater ; M568 P0 A0; set tool 0 to off ;############ from dc42 ;while true ;while iterations<10 ; ; while iterations < #sensors.analog ; var red = sensors.analog[iterations].lastReading ; var green = 255 - var.red ; var blue = var.green ; M150 R{var.red} U{var.green} B{var.blue} S2 F{min(#sensors.analog-iterations-1,1)} ; ; G4 S3 ; ;############# ; ; daemeon.g ; ; Adafruit #1426 8 led neopixel ; ; M150 X1 ; ; if heat.heaters[1].current > 50 ; temp ; M150 R0 U255 B0 P255 S2 F1 ;M150 R{var.redValue} U{var.greenValue} B{var.blueValue} P{var.setBrightness} S{var.pixelsPerTool} F{var.F} ; ; elif heat.heaters[1].current <= 50 ; M150 R0 U0 B255 P255 S2 F1 -

@RogerPodacter thanks.

- Please also provide your homing files, since you said the machine resets during homing.

- Although this doesn't explain the reset, I can see a problem in your config.g file. Your M669 command to set the kinematics at line 7 refers to the U axis, however the U axis doesn't exist until it is created in the M584 command at line 35. You should move the M669 command to be after the M584 command.

-

This post is deleted! -

@dc42

Just as a little update, i have as of today not had any more resets. I'm trying to turn out some small parts, just to see if anything can trigger a reset, but so far no luck =/