Best way to wire Can Bus on large printer ?

-

Just wondering what is the most reliable way to wire a Duet Can Bus System?

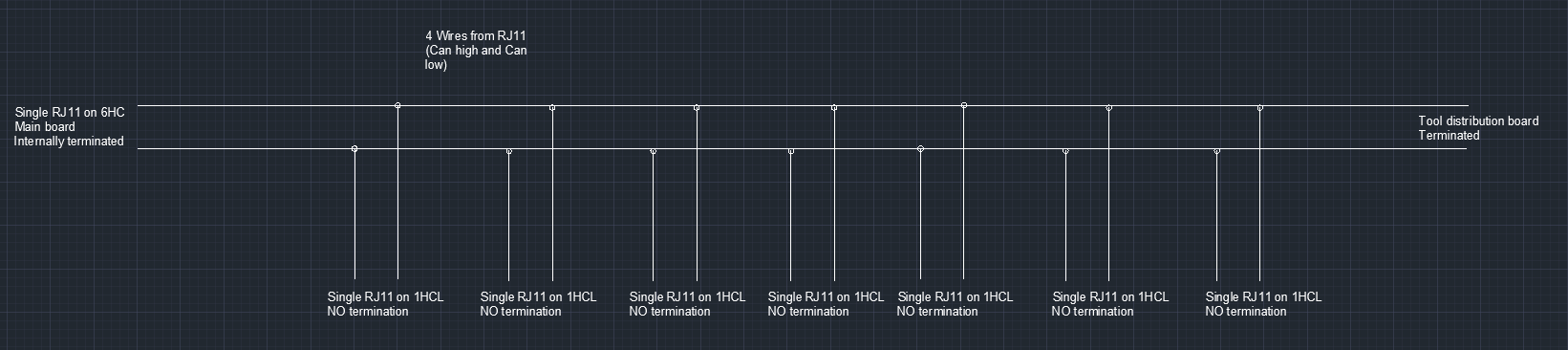

(A) Do I follow typical automotive can bus systems and have a central back rail which is terminated at both end, using a single RJ11 cable from the central backbone. as below:

Maximum unterminated node length 1m

(B) Do I daisy chain to each individual board using the in and out connectors on each board (which will almost double up the can bus cabling)?

-

@kj3d you can do it either way, provided that any stubs you use are short enough. The subs should preferably use ferrite beads to suppress ringing.

The CAN bus on Duet 3 boards normally runs at 1Mbit/sec. We don't currently use bit rate switching, but we will provide the option to do so if it is needed on large systems. If bit rate switching it enabled then it will most likely use 4Mbits/sec for the data phase. At this speed, reflections caused by stubs would be more significant, making it more important to keep stubs short and/or use ferrite beads.

-

@dc42 - Thanks for your reply. I will let you know how I get on. For the majority of the harness am using Chainflex Bus cable CFbus.PVC with at each node point a Gravitec RJ11 connector - The bus cable loops through the Gravitech connector. The cable to the RJ11 on the 1HCL is some simple flat 4 core (Unscreened) approx 150mm long with a ferrite core near the Chainflex bus cable.

I will let you know how it works out.

Thanks again