z offsets for different tools

-

@MIke-1 you're setting a negative z offset but you can only go as low as Z0.

Best update your M208M208 X-35:328.5 Y-49:245 Z0:300 C-45:360 -

Unfortunately that did not help

M208 X-35:328.5 Y-49:245 Z-20:300 C-45:360

But it think it goes into the wrong direction because the nozzle is lower than the switch probe. Probing can only work without a tool.

-

@MIke-1 whats in your homez?

-

@jay_s_uk

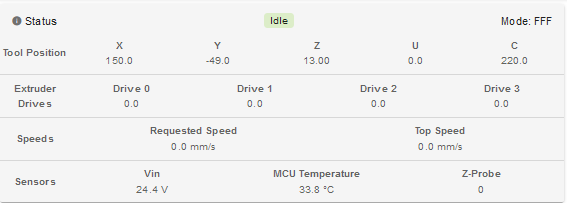

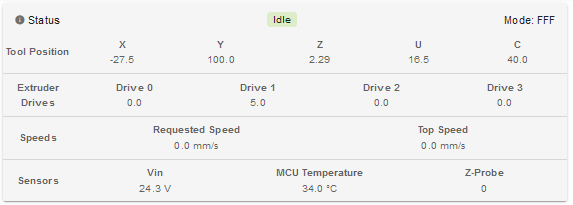

This here after probing:

Tool T1

Tool T2

With

; G10 OFFSETS

G10 P0 X20.803 Y43.444 Z-5.07 ; Set tool 0 axis offsets

G10 P1 X-7.861 Y38.650 Z-5.71 ; Set tool 1 axis offsets

G10 P2 X20.615 Y43.681 Z-16.41 ; G10 P2 X20.615 Y43.681 Z-6.06 mehr Abstand z.b. von -1 nach -2 (Offset wird kleiner) ; Set tool 2 axis offsets

G10 P3 X-7.717 Y38.818 Z-5.61 ; Set tool 3 axis offsetsBut I dont see this effect on the nozzle

-

@MIke-1 ok, whats in you tpre2.g and tpost2.g?

-

-

@MIke-1 you aren't restoring the X/Y/Z position in tpost. see here https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x#:~:text=After changing tool,or similar commands.

-

-

@MIke-1 yea

-

It is not working. The first layer with the first extruder is fine. After the extruder change the layer is more or less on the same level, as they are on a similar hight. The second layer has a big offset to the first one with the second extruder because the offset in the config is unrelistic to high to check the functionality.

A Z move is needed in the gcode to get on the right level...; tpost2.g

; called after tool 2 has been selected;heatup

M116 P2

M116 H0 S5;prime nozzle

;M98 P"prime.g"M98 P"brush_right"

M106 R1 ; restore print cooling fan speed

;M593 F42.2 ; cancel ringing at 42.2Hz (https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/)

G60 S0

G1 R0 X0 Y0 Z-5;G91

;G1 Z-5 F1000

;G90 -

undefined Phaedrux moved this topic from Firmware installation

undefined Phaedrux moved this topic from Firmware installation

-

@MIke-1

This here at the very end fixted the issue!G1 R2 Z2 F2000

G1 R2 Z0 F2000Thanks to the Duet Team!

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved