Duet2 WiFi generating polygons instead of circles

-

@flopes please can you clarify what are your actual X and Y steps/mm, before you do the x10 or x100 conversion?

BTW the reason for the late response is that this thread was marked as "solved" so I was ignoring it. Posting to a thread marked as solved is not a good idea . You should either marked the thread as "unsolved" again (which you can do if you are the thread author) or start a new thread.

-

undefined dc42 has marked this topic as unsolved

undefined dc42 has marked this topic as unsolved

-

undefined flopes marked this topic as a regular topic

undefined flopes marked this topic as a regular topic

-

@dc42 Done. Any tips on where I should start?

-

@flopes said in Duet2 WiFi generating polygons instead of circles:

@dc42 Done. Any tips on where I should start?

Not sure what you mean. @dc42 asked you to clarify what are your actual X and Y steps/mm, before you do the x10 or x100 conversion. Maybe post your current config.g and firmware version. As far as I'm aware there has been no change in the arc segmentation resolution in the latest firmware versions.

Ian

-

@flopes I've reduced the minimum arc segment length from 0.1 to 0.02mm in 3.5.0-beta.4. Perhaps that will go some way to resolving this for you? I'm still waiting to know what steps/mm you are using.

-

@droftarts Thank you very much for your reply.

I am using today (with my 30x version, meaning to cut 1mm, I send a 30mm long cut command)

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Wed Jun 14 2023 09:27:16 GMT-0700 (Pacific Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Laser Cutter" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X8 Y8 Z8 E8 I0 ; configure microstepping without interpolation

M92 X53.33 Y53.33 Z53.33 E1.00 ; set steps per mm

M566 X660.00 Y660.00 Z660.00 E6.00 ; set maximum instantaneous speed changes (mm/min)

M203 X19800.00 Y19800.00 Z19800.00 E6.00 ; set maximum speeds (mm/min)

M201 X300.00 Y300.00 Z300.00 E1.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E300 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S1 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z-600 S1 ; set axis minima

M208 X3300 Y3300 Z2265.6 S0 ; set axis maxima; Endstops

M574 X2 S1 P"!^xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin !^xstop

M574 Y1 S1 P"!^ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin !^ystop

M574 Z2 S1 P"!^zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin !^zstop; Z-Probe

M558 P0 H0 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X5:100 Y5:100 S5 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 S"Z Pogo" D0 H1 F0 ; define tool 0

G10 P0 X5 Y5 Z5 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Laser" F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings

;(30x); Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@droftarts Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.4 (2022-10-20)

Duet WiFi Server Version: 1.27 -

@flopes

short answer = 1600steps/mm -

@dc42 Thank you. I will give that a try. that is 5x improvement.

-

@flopes I hope it helps. I had to guess what resolution to use because when we had to freeze the beta 4 code, I did not know what steps/mm you were using and hence what resolution would be appropriate.

In the future we may adjust the resolution according to the configured steps/mm for the axes concerned.

-

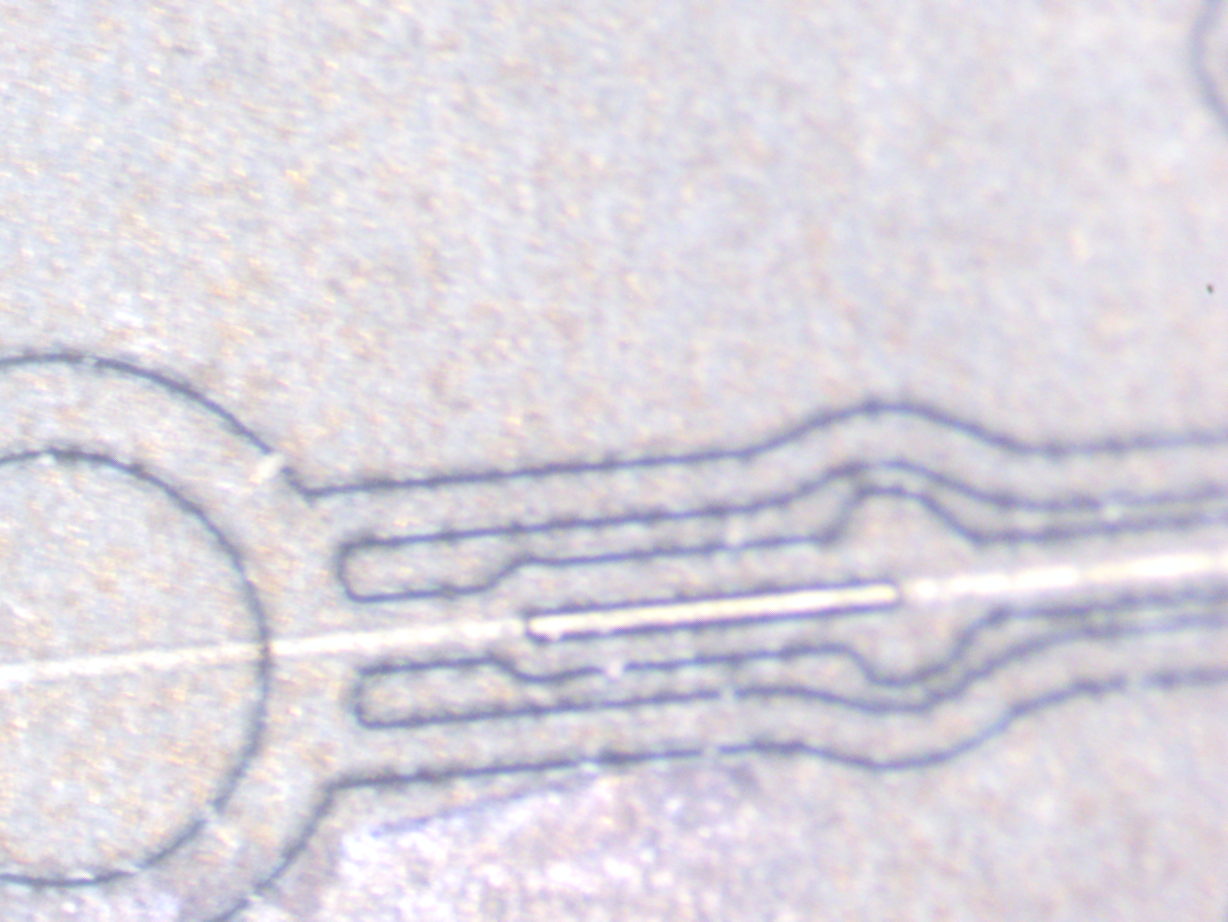

@dc42 Hello. The Beta 3.5.0 with segments of 0.02 is sufficient for my aplication at the moment.

We build this custom laser printer cut brain implants and the programs are quite long - 10's of thousands arcs connected together. Usually takes 3 days to cut one batch. During these last 6 motnhs we come up with a series of methods to minimize the offset in position from the first features cut to the last ones. We figured out there is no more mechanical possibilities for this offset to be happening. We even added temperature control on the whole printer.I believe there may be some rounding going on in the system. We also notice this offset is larger on y axis.

Do you believe we could benefit from adding encoders to the Nema17 stepper motors?

by the way we use 1600steps/mm

Thanks -

undefined droftarts referenced this topic

undefined droftarts referenced this topic