Tool fan not working after upgrade firmware

-

Hi,

I've recently upgraded the firmware on my duet2 wifi to latest (3.4.4).

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.4 (2022-10-20)

Duet WiFi Server Version: 1.27In the same step, I've also updated the configuration file. It took me a while to get all the configurations correct, but I'm almost there.

The only thing at the moment that doesn't seem to be working is the tool fan (controlled by the slider).

The other fans (thermal controlled) work without issue.

The UI indicates the tool fan is spinning at 100%, but there's no movement.The old configuration:

G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 3 Pro" ; set printer name ;M665 R105.6 L215 B85 H250 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P4 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E4 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E99.00 ; set steps per mm M566 X600.00 Y600.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z600.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z120.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E900 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 E0 S1 ; set minimum Z M208 X235 Y235 Z260 S0 ; Endstops ;M574 X1 Y1 Z1 S1 ; set active high endstops M574 X1 Y1 S1 ; set active high endstops M574 Z1 S2 ; define Z to use prove. home to min M591 D0 P1 C3 S1 ; Z-Probe M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch M558 P5 H5 F500 T6000 X0 Y0 Z1 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X-46 Y-13 Z1 ; set Z probe trigger value, offset and trigger height M557 X10:180 Y10:225 S20 ; define mesh grid ; Heaters M305 P0 T98801 B4185 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 150C M305 P1 T98801 B4185 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S275 ; set temperature limit for heater 1 to 275CThe new configuration:

M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 3 Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P4 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E4 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation ;M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm M92 X80.00 Y80.00 Z400.00 E99.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z120.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y235 Z260 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-46 Y-13 Z0.95 ; set Z probe trigger value, offset and trigger height M557 X20:180 Y20:225 S50 ; define mesh grid ; Fillament run-out sensor M591 D0 P1 C"e0stop" S1 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 ;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M307 H0 R0.345 K0.290:0.000 D3.90 E1.35 S1.00 B0 M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H1 R2.674 K0.607:0.000 D6.00 E1.35 S1.00 B0 V24.2 M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossI did a print before the upgrade, in which the tool fan worked without complaining. This leads me to believe the issue is probably something in the config.

Suggestions/ideas are welcome.

Hopefully usefull information from the M122 command:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.4 (2022-10-20 16:17:41) running on Duet WiFi 1.02 or later Board ID: /// Used output buffers: 1 of 26 (24 max) === RTOS === Static ram: 23860 Dynamic ram: 79332 of which 0 recycled Never used RAM 5720, free system stack 92 words Tasks: NETWORK(notifyWait,102.7%,215) HEAT(notifyWait,1.5%,308) Move(notifyWait,72.2%,292) MAIN(running,119.8%,421) IDLE(ready,2.7%,30), total 298.8% Owned mutexes: === Platform === Last reset 23:32:47 ago, cause: power up Last software reset at 2022-11-28 09:33, reason: User, GCodes spinning, available RAM 8960, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 19.1, current 30.2, max 30.8 Supply voltage: min 23.8, current 24.4, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/12/0, gc cycles 0 Events: 2 queued, 2 completed Driver 0: ok, SG min 0 Driver 1: ok, SG min 0 Driver 2: standstill, SG min 0 Driver 3: standstill, SG min n/a Driver 4: standstill, SG min n/a Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: Date/time: 2022-11-29 11:33:59 Cache data hit count 4294967295 Slowest loop: 59.77ms; fastest: 0.12ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 9 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 9.4ms, write time 8.5ms, max retries 0 === Move === DMs created 83, segments created 13, maxWait 4403528ms, bed compensation in use: mesh, comp offset 0.017 === MainDDARing === Scheduled moves 532123, completed 532093, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 16], CDDA state 3 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 1 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 F3000 X165.319 Y102.787 E0.03006" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0 sensor: ok -

@fraksken your config for the fan looks fine to me. You've got M950 and M106 correct and you've mapped the correct fan to the tool.

Does using the slider not work at all?

Can you test the fan on one of the always on ports to check it? -

@jay_s_uk Thank you so much for your fast response.

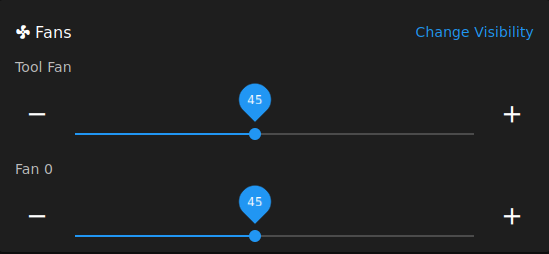

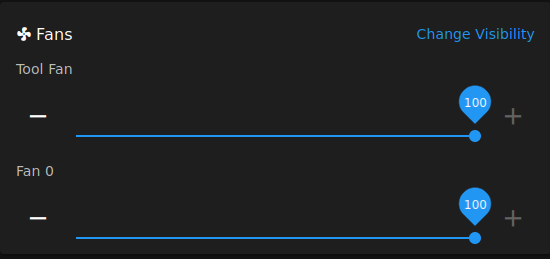

Using the slider has no effect. What I find a bit confusing is I have 2 sliders: One for "Tool Fan" and one for "Fan 0".

Sliding either fan (they are both on 100% right now) makes no change in the fan speed, but the second slider also moves to the same position as to what I put the first slider.

Screenshots for illustration

I'm currently printing, but it should finish in about 10 hours. I'll test the fan on one of the always on ports when the print is finished.

-

@fraksken the Tool Fan is the part cooling fan of the currently active tool. In your setup fan 0 and tool fan are the same thing.

Looking forward to seeing how you get on -

@fraksken As @jay_s_uk has said, your configuration looks fine. Also, your screen shots show that fan 0 is the part cooling fan and that the web control is setting the fan speed. Have you set the fan jumper to the correct voltage for the fan? If so then it has to be a wiring issue (the fan is physically connected to a different output, or there is a bad connection) or the fan itself is faulty.

-

Thanks for your advice.

I've connected the fan to the always-on connector. The fan did not start after turning on the printer.I'll double check some wiring again, but it looks like I'll be in the market for some new fans.

Thanks!

-

@fraksken I suggest you check the crimp connection between the fan wires and the connector, in case the problem is a bad crimp or a broken wire.