Ringing is only present while printing slow.

-

I have noticed a strange behavior while printing a model. When the prinspeed is slow (~30-100mm/s) I have very prominent ringing on corners. With print speeds from roughly 100-300mm/s I have almost no ringing issues.

First, I thought my jerk values were off. So I printed the Test below with input shaping and Pressure advance disabled.

The test alternates between a print speeds of 60 and 300mm/s every 5mm. Every 10mm of print height the jerk for X and Y is increased by 200 starting at a jerk value of 600. My goal was to find jerk values that would always produce clean circles/arcs without introducing too much ringing at sharp corners.

But what I also found was, that at low print speeds the test showed substantial ringing even at low jerk values, whereas high print speeds produced almost no ringing. Furthermore the ringing at 60mm/s does not really get much worse when the jerk value is increased. What also baffles me is the fact that X and Y show the exact same ringing pattern, although the Y has far more moving mass than X.

I am on RRF 3.4.3, running in closed loop with 1HCL-Boards on X and Y.

My congi.g;/// Drives /// M569 P0 S0 V0 ; Drive 0.0/Z1 motor (rear left) M569 P1 S1 V0 ; Drive 0.1/Z2 motor (rear right) M569 P2 S1 V0 ; Drive 0.2/Z3 motor (front right) M569 P3 S0 V0 ; Drive 0.3/Z4 motor (front left) M569 P4 S0 V0 ; Drive 0.4/E1 motor M569 P5 S0 V0 ; Drive 0.5/E2 motor M569 P1.0 S1 V0 ; Drive 2.1/A M569 P1.1 S1 V0 ; Drive 2.2/B ;Closed loop drives M569 P123.0 S1 V0 ; X-Motor M569 P124.0 S1 V0 ; U-Motor M569 P125.0 S1 V0 ; Y1-Motor M569 P126.0 S0 V0 ; Y2-Motor M569.1 P123.0 T2 C20 H25 R150 I3000 D0.20 ; Configure the 1HCL board at CAN address 123 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569.1 P124.0 T2 C20 H25 R150 I3000 D0.20 ; Configure the 1HCL board at CAN address 124 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569.1 P125.0 T2 C20 H25 R150 I3000 D0.20 ; Configure the 1HCL board at CAN address 125 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569.1 P126.0 T2 C20 H25 R150 I3000 D0.20 ; Configure the 1HCL board at CAN address 126 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. ;/// Motion System /// M584 X123.0 Y125.0:126.0 Z0:1:2:3 U124.0 E4:5 A1.0 B1.1 ; set 4 Z drivers and add one U driver -> Must come earlier than M350,M906,M92, M201, M203, M208, M350, M566, M574, M667 and M669 M350 X32 Y32 Z32 U32 A4 B4 I1 ; Configure microstepping with interpolation M350 E16:16 I0 M92 X160 Y160 Z1280 U160 E400:400 A11 B11 ; Set steps per mm M201 X10000 Y10000 Z500 U10000 E10000:10000 A6000 B6000 ; Set maximum accelerations (mm/s^2) M203 X42000 Y42000 U42000 Z2100 E6000:6000 A200000 B200000 ; Set maximum speeds (mm/min) M566 X1200 Y1200 Z300 U1200 E5000:5000 A500 B500 P1 ; set maximum instantaneous speed changes (mm/min) M579 Z1.001335113484646 ; scaling of Z-Axis M906 X1200 U1200 Y2400 Z1800 E900:900 A300 B300 I25 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M917 X25 Y25 Z50 U50 ; Set holding current in percent -

@MaxGyver the ringing might be caused by the PID values for the 1HCLs being to aggressive. What does the step response in the closed loop tuning plugin look like?

-

@dc42 the ringing is also present when printing in open loop mode. I have a dual motor Y-gantry with 1HCL boards. So since dual axis closed loop tuning is not available. I had to kind of guess the correct values. I retuned my Motors on X and U which are shorter versions of the motors I have in Y. Since the same settings I have for X and Y cause some noise in Y I bumped up the P-Value from R=75 to R=125 and lowered D from D=0,2 to D=0,1.

But after lots of testing, I think there are two distinct issues at play. I found that the Y-Axis has some serious resonance caused by the motors. In open loop, the Y-motors cause a lot of noise and vibration, especially when thy Y-axis is moving slow. This explains the ripples that can be seen at the top of each half circle -> the resonance is most notable if the Y-Axis is accelerating from standstill or decelerating to a standstill. This resonance is most prominent while the axis is moving at roughly 40-100mm/s. I tried different belt tensions and even dampened the belts to ensure that the issue is not some resonance in the motion system. I read somewhere that altering the blanking time can alter the or even lower the motors resonance frequency?

The lower part was printed at 80mm/s the top at 30mm/s.

EDIT: while moving in circles both X and Y axis are quite noisy at low speeds and cause lots of vibrations. It is just much more obvious on Y-While printing. (the clicking/rustle is from the Bowden tubes)

-

@MaxGyver perhaps you are experiencing mid-band resonance?

You could try collecting data during a small part of the print using the

input shapingclosed loop plugin with the custom GCode option. -

@dc42 said in Ringing is only present while printing slow.:

@MaxGyver perhaps you are experiencing mid-band resonance?

You could try collecting data during a small part of the print using the input shaping plugin with the custom GCode option.

From what I have gathered, so far, most probably yes. Changing the motors on Y did bring a slight improvement as well as setting the holding current in closed loop mode to 100%.

I have the 3.4.1-b1 plugin installed, but other than the "custom" input shaper tab I did not find anywhere to put custom Gcode. I would like to run ad G2 circle and record the vibration at different speeds.

Cheers Max

-

@MaxGyver I'm sorry, I meant the closed loop plugin, not the input shaping plugin.

-

@dc42

Any news here?

I have the same problem with a my Y-Axis. It has also 2 motors. -

I downgraded to RRF stable branch and upgraded again to unstable, after downgrading did not resolve my problem. I swapped the Y motors to cheap ones I got from omc-stepperonline. It fixed the vibration issue, but unfortunately, I don't know whether It was the Firmware upgrade or switching of motors.

I will investigate this issue further as soon as I have a little more time.

-Max

-

@MaxGyver

thanks

I use also the stepper of stepper-online.

Can you tell me your timing and your motors or the PID tuning of the y axis motor?

Tuning is sadly still not available for double y-axis.

Richard -

@IndeX4D said in Ringing is only present while printing slow.:

Tuning is sadly still not available for double y-axis.

The tuning move only moves the motor by a little over 4 full steps. Is that too much skew for your Y axis to handle? Alternatively, can you set the second motor to zero current while you tune the first one?

-

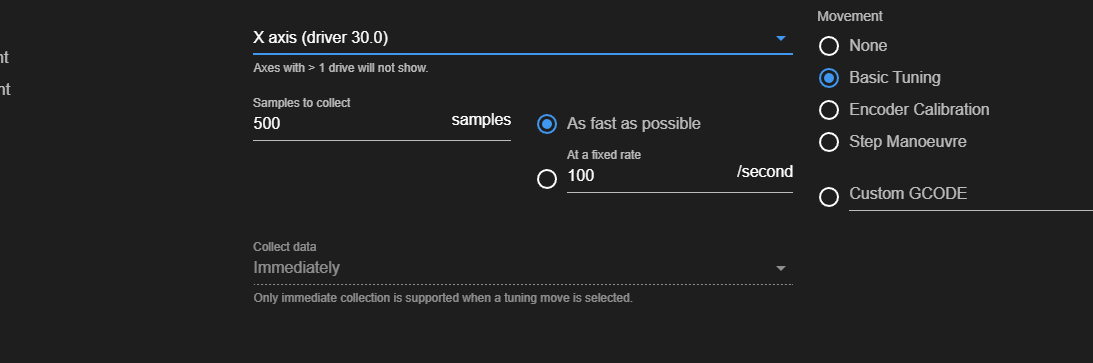

@dc42

I think we got a little missunderstanding. I should describe it better....´´Axis with > 1 drive will not show´´ so I can´t do a basic tuning in the plug-in.

-

@IndeX4D thanks for the clarification. If we enable axes having more than one motor in the closed loop plugin, and give you the ability to select which motor to tune, would that be of any use to you?

-

@dc42

yes, that would be great.After a few tests, it seemed to be better when Using different R I D parameters, so I´m positive that a good tuning solve this problem.

Other options may? - wrong Timing? What would you suggest?Thanks Richard

-

@IndeX4D tuning one driver of a multi-driver axis is supported in the 3.5beta1 version of the plugin. We hope to release RRF 3.5beta1 later today or tomorrow.

-

This post is deleted! -

@dc42

Very nice. thanks

Please tell us when it's uploaded. I'm waiting for it since the very first hour of the 1hcl

-

This post is deleted! -

undefined MaxGyver referenced this topic

undefined MaxGyver referenced this topic