Possible corrupt sd card, G29 Network Error

-

No, Only Raspberry Pi's.

-

I still have the original sd card shipped with the 6hc. I've not touched that.

I'll give that a try.

-

@Dizzwold ok, format the SD card using the sd card formatter https://www.sdcard.org/downloads/formatter/sd-memory-card-formatter-for-mac-download/

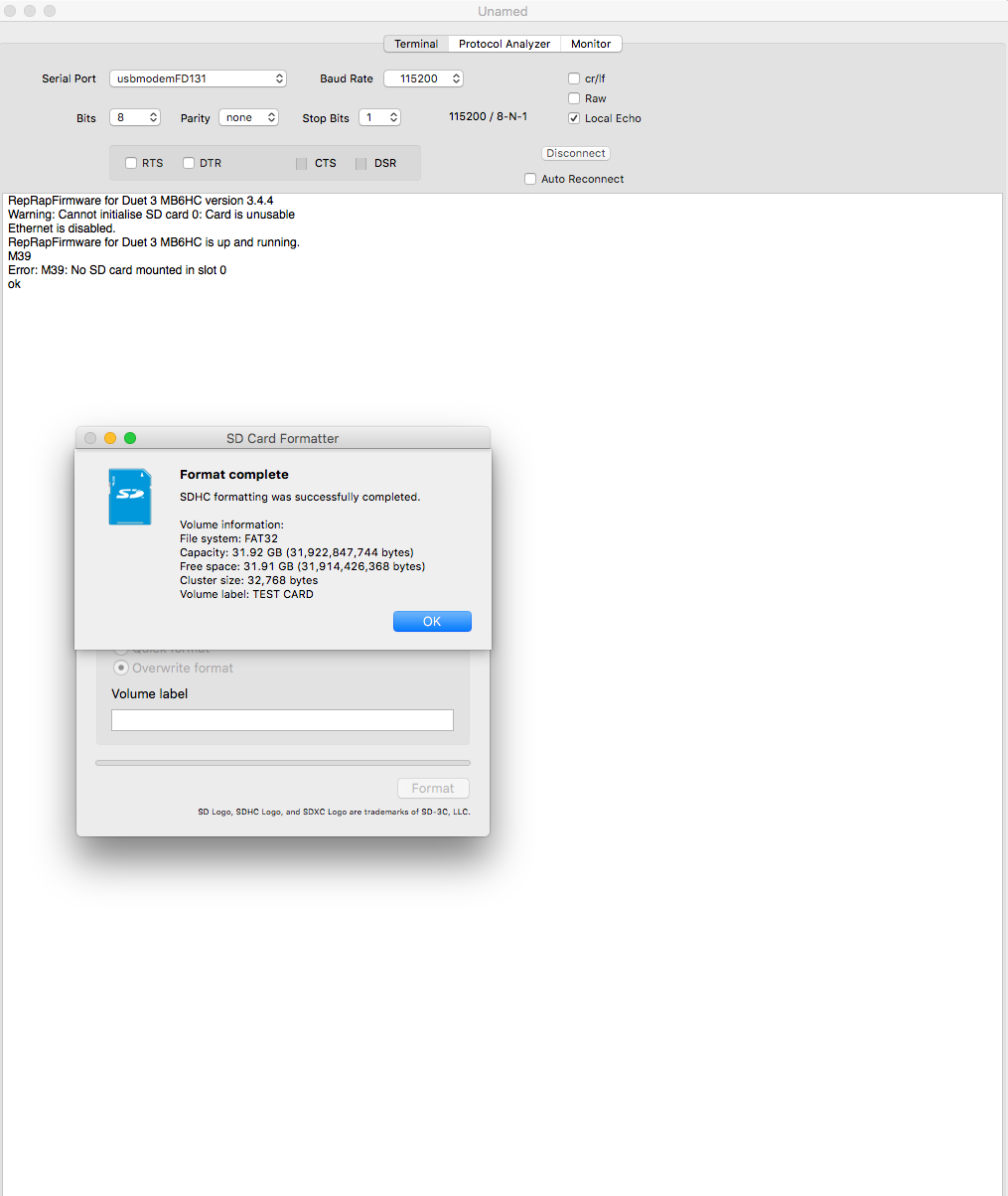

don't bother loading any files to it. just pop it in the duet and then run M39 again -

The sd card that came with the 6HC does exactly the same. I've not touched this card until ow, so that should be Fat 32???

Original sd card;RepRapFirmware for Duet 3 MB6HC version 3.4.4 Warning: Cannot initialise SD card 0: Card is unusable Ethernet is disabled. RepRapFirmware for Duet 3 MB6HC is up and running. M552 Ethernet is disabled, configured IP address: 0.0.0.0, actual IP address: 0.0.0.0 ok M552 S1 P192.168.1.70 ok MEthernet running, IP address = 192.168.1.70 552 Ethernet is enabled, configured IP address: 192.168.1.70, actual IP address: 192.168.1.70 ok M552 Ethernet is enabled, configured IP address: 192.168.1.70, actual IP address: 192.168.1.70 ok M39 Error: M39: No SD card mounted in slot 0 ok -

@Dizzwold in which case looks like a warranty might in order

when and where did you purchase the duet?

hopefully @Phaedrux or maybe @droftarts will authorise -

Originally purchased 29/1/21

Replaced 11/2/21 as the original had a broken connector retainer.I was going to install the board then, but then I had to move house, so nothing has been done until September, except for opening and checking to makes sure there were no broken connectors etc.

Just waiting for the new sd card to be formatted with the link you sent, doing an overwrite....

-

@Dizzwold see what the duet guys say then. in the mean time can you take a high res picture of the sd card socket and the pins that are soldered to the board?

-

-

@Dizzwold nothing more i can do now. There's obviously an issue with the SD card slot

will leave it to the duet guys -

-

Sorry to see you're still having some issues with that board. The SD slot appears to have failed. Perhaps a marginal solder joint. As you were using the SBC before, you wouldn't have noticed.

Please send an email to warranty@duet3d.com and CC your reseller. Include a link to this forum thread and the details of your original purchase. You'll receive a reply with a form to fill out.

I don't think this is related to your other issues when using the SBC, as the SD card slot on the duet is obviously unused in that setup, but perhaps there is something else weird going on with it. Regardless, this would give you a fresh start.

-

Hi Guys,

Well a new 6HC arrived yesterday.

Got things started today "getting connected" etc. This time, I'm not going to bother with a RPi.

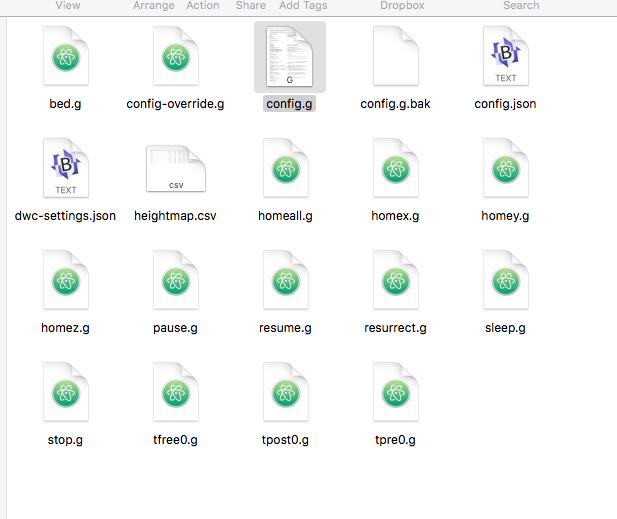

Now with a blank file system and updated firmware, can I just upload my original files from the DWC Upload System Files, should I upload all of these?

-

@Dizzwold I wouldn't bother with the config.json and the dwc-settings.json.

The rest you should be fine with -

Thank you.

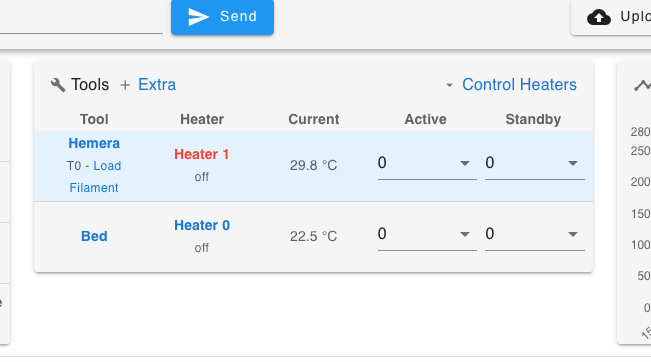

I've also just noticed something in my config.g that I thick, with looking in the dictionary ,is causing conflict. In M950 shouldn't my bed heater be H0 (H zero), rather than T0 (T zero), and my nozzle be T0 (T zero) instead of T1?

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 P ; Bed Leadscrew Positions M671 X5:278 Y146:146 P2.0 ; middle left, middle right G4 S1 ;wait for expansion boards to start ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 M569 P121.0 S0 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2:0.3 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E333.40 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X900 Y900 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-2 Y-8 Z0 S1 ; set axis minima M208 X330 Y330 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!121.io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin !io1.in M574 Y1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin !io2.in ; Z-Probe M574 Z1 Z1 S2 ; set endstops controlled be probe M558 P8 C"^!121.io0.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X-46 Y-19 Z2.45 ; set Z probe trigger value, offset and trigger height M557 X19:244 Y-2:304 P9 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.187 K0.192:0.000 D1.89 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"121.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.498 K0.275:0.349 D6.79 E1.35 S1.00 B0 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"121.out1" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"Print Cooler" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 C"Extruder Cooling" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Emergency Stop M950 J1 C"io4.in" M851 P1 T0 S0 R0 ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 M501

So far so good with using the ethernet, and without fully commissioning I ran a G32 once with no problems, no running a second scan for unknown reasons and no network error.

Without further testing I can't say if this was linked to the previous board, found to have an sd card issue or not.Sorry "I thick" , * I think.

-

@Dizzwold said in Possible corrupt sd card, G29 Network Error:

In M950 shouldn't my bed heater be H0 (H zero), rather than T0 (T zero), and my nozzle be T0 (T zero) instead of T1?

No.

T When creating a heater: temperature sensor number, required (see M308). When creating a LED strip: LED type (optional): 0 = DotStar, 1 = RGB Neopixel (default), 2 = RGBW Neopixel. DotStar LEDs can normally be assigned only to an output intended for them.