Trouble with M201 and M566 settings

-

@Jered said in Trouble with M201 and M566 settings:

If I make these same changes on my cnc machine, the difference is VERY noticable. But not here.

That's likely because your CNC machine does not have an extruder. Therefore it's only X and Y moves that need to be synchronised. Whereas your printer needs to have extruder moves start and end in sync with the X and Y axes moves. Because you have capped the speed of the extruder by having very low accelerations and instantaneous speeds, then the X and Y axes will be slowed to keep in sync with the (slow) extruder. So you can change X and Y as much as you like but unless you also raise the thresholds for "E", then in order to maintain synchronisation, the X and Y acceleration and jerk will be capped by the low extruder settings.

I explained all this to you in my earlier post.

-

@Jered

I already wrote to you in another thread that you should set the jerk values for Z and all extruders to 1200mm/min.

Because 6mm/min for Z and 120mm/min each for the extruder is too slow.Please post...

-

Your current config.g

-

A GCode of a printed part.

-

A screenshot of your printer settings in your slicer

This might help to solve your problem faster.

Google Translate

-- Original Text --Ich hatte Dir in einem anderen Thread auch schon geschrieben dass Du die Jerk Werte für Z und alle Extruder auf 1200mm/min stellen solltest.

Denn 6mm/min für Z und je 120mm/min für die Extruder ist zu langsam.Bitte poste...

-

Deine aktuelle config.g

-

Ein GCode eines Druckteil.

-

Ein Screenshot Deiner Drucker Einstellungen in Deinem Slicer

Dieses könnte helfen Dein Problem schneller zu lösen.

-

-

I wonder if there is a problem with the M201 setting using the 1XD boards. I am using these boards for x y and z.

-

@Jered how are actually testing? With a Gcode file? Try testing manually. Set M201 for X and Y axis. Send a long G1 move, just in X and/or Y. Change M201 and repeat. This should show the effect of changing acceleration.

As others have already said, if you have mesh levelling or run the extruder at the same time, motor settings for them may affect the acceleration and speed of the X and Y axes, so test without these.

If you are sending a Gcode file to test, send M201 on its own to show current setting before it starts, and during, then you will know if the Gcode file is overriding the values you set.

Ian

-

@droftarts

I will check this. It will take me a while as a print is currently running. -

You can send M201 by itself at any time and it will report the current values.

-

I have been testing this with the latest version of Super Slicer (SS) as it allows more control over accel throughout the print than Simplify (which has none), and the results are, it is working. However, I am not sure why the machine is operating out of the config limits with Simplify.

In SS the accel is controlled per feature, and is changing all the time, which is nice.

However, it is weird that the Ender and the Vcore perform completely different with the same settings.

Ender accel is set at 500 mm/m and jerk is set to 10 mm/s. I change these to match in the Duet config, and it doesn't seem to matter about the accel, the jerk setting does seem to do something.

So having SS adjust the settings where I want them works, but the limiting factors in the config, for accel, do not seem to matter.

So I am guessing that changing them while a print is running would also work. But if I rely on the config alone, then my print suffers.

It still bothers me that I have to go through the extra leg work of using a different slicer to get the Duet to work, but with Enders cheap board, it does what I want without dictating everything the machine is doing through the slicer.

Any thoughts?

What slicer does Duet recommend? -

@Jered said in Trouble with M201 and M566 settings:

Any thoughts?

@Phaedrux said in Trouble with M201 and M566 settings:

How are you sending the command?

Does your sliced gcode file include M201 commands from the slicer?

If you send M201 by itself, what does it report the current values as? -

@Jered said in Trouble with M201 and M566 settings:

but the limiting factors in the config, for accel, do not seem to matter.

I would guess that somewhere along the line the value is getting changed from what you have in your config.g to whatever value is in the sliced gcode file. y previous post has questions that would help determine if that's the case.

Do you also happen to have an M204 command that sets print move and travel acceleration? M201 is the upper limit, but M204 can set it lower. Send M204 by itself in the console and see what it reports.

And if you're still running with low jerk values on Z and E, it could be the limiting factor.

-

@Jered said in Trouble with M201 and M566 settings:

Any thoughts?

My only thoughts have to do with horses, water, and drinking.

-

Super Slicer adds an M204 500 command towards the beginning of the print. Simplify does not.

But I did find only 1 instant of this command throughout the Super Slicer version of gcode.

I will add that command into an existing Simplify gcode to see if it now behaves the same on the Vcore.

-

So I added that command at the beginning (M204 500) of my Simplify gcode and the Vcore is now behaving like the Ender.

Not sure why the gcode would need this added to it when it is in the config. Maybe it is because I am using 1XD boards for my axis and somehow it is not being reported to those boards through the config.

I guess this is also a non-issues as long as I know how to get around it. I will add this code to my gcode from now on.

Just thought I would include my config:

-

What does M201 and M204 report on a fresh reboot?

What do they report when running a simplify3d gcode file that doesn't have the added M204?

-

@Jered said in Trouble with M201 and M566 settings:

Just thought I would include my config:

config (1).gM566 X300.0 Y300.0 Z6.00 E120Your jerk values are still incredibly low. 6mm/min is 0.1mm per sec.

120mm/min isn't much faster at 2mm per sec.

Those will be a major limiting factor on the XY speeds, especially if you use mesh compensation that requires moving the Z axis in relation to XY position.

I suggest you change Z jerk to at least 60, and E jerk to 3000

-

@Phaedrux

M201 reports 3000 for x and y

M204 reports 500 for x and YI am printing currently with the Simplify gcode that I added the M204 500 command. I will have to try again without it and set the accel from 3000 to 500 and see what happens.

The jerk value for Z I got from the Vcore firmware setup for Duet. Maybe they meant 60. I will change it.

-

Before I run this next test, you can see from the info above and my attached config, there is a discrepancy. Why?

M201 reports 3000 when you can see in the config that it is set to 500.

-

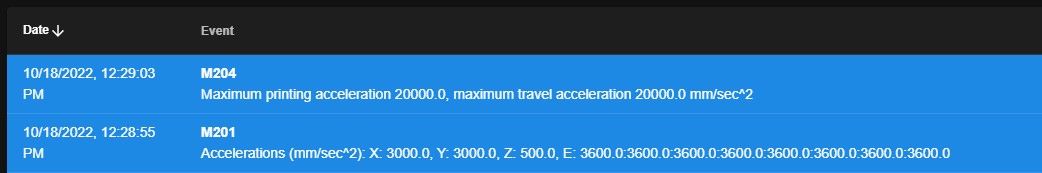

Ok, the second test is done. Which was to remove the M204 500 command. Below are the results.

I don't understand what is going on. The Z and E have the correct accel. What happened to the x and y? Also, what is this max accel doing at 20,000! Do I need to add this to my config?

I have also attached my config so you don't have to search for it.

-

The command was M204 P500 Just to be clear. I left the "P" out of the reply from above.

-

@Jered

I find the config.g OK now, couldn't find any errors there.

Except...

I would change the following command line, meaning...

M557 X15:450 Y15:450 S50 ; define mesh gridAn area of 435mm x 435mm is to be scanned there (450mm - 15mm = 435mm)

On this 435mm there should be a measuring point every 50mm (S50), which means... 435 : 50 = 8.7

However, 8.7 measuring points cannot be used because this always has to be a whole number, so a slightly wider edge is not used on the right and upper side of the print bed.Therefore you should change the command line as follows...

M557 X15:450 Y15:450 P9 ; define mesh gridThe parameter P9 allocates this 435mm exactly 9 measuring points and calculates the distance automatically.

The complete area of 435mm x 435mm is scanned by the probe.If you always enter an odd number here, the center of the print bed will also be probed automatically.

So P5, P7, P9...Google Translate

-- Original Text --Ich finde die config.g jetzt OK, konnte da keine Fehler entdecken.

Außer...

Folgende Befehlszeile würde ich ändern, gemeint ist...

M557 X15:450 Y15:450 S50 ; define mesh gridDort soll ein Bereich von 435mm x 435mm abgetastet werden (450mm - 15mm = 435mm)

Auf diesen 435mm sollen alle 50mm ein Messpunkt sein, was bedeutet... 435 : 50 = 8,7

Es können aber keine 8,7 Messpunkte da dieses immer eine ganze Zahl sein muss, daher wird an der rechten und oberen Seite des Druckbettes ein etwas breiterer Rand nicht genutzt.Daher solltest Du die Befehlszeile wie folgt ändern...

M557 X15:450 Y15:450 P9 ; define mesh gridDer Parameter P9 teilt diese 435mm genau 9 Messpunkte zu und berechnet den Abstand automatisch.

So wird der komplette Bereich von 435mm x 435mm von der Sonde abgetastet.Wenn Du hier immer eine ungerade Zahl eingibst, wird automatisch die Mitte des Druckbettes mit sondiert.

Also P5, P7, P9... -

@Norder

Thanks, I will make that change.