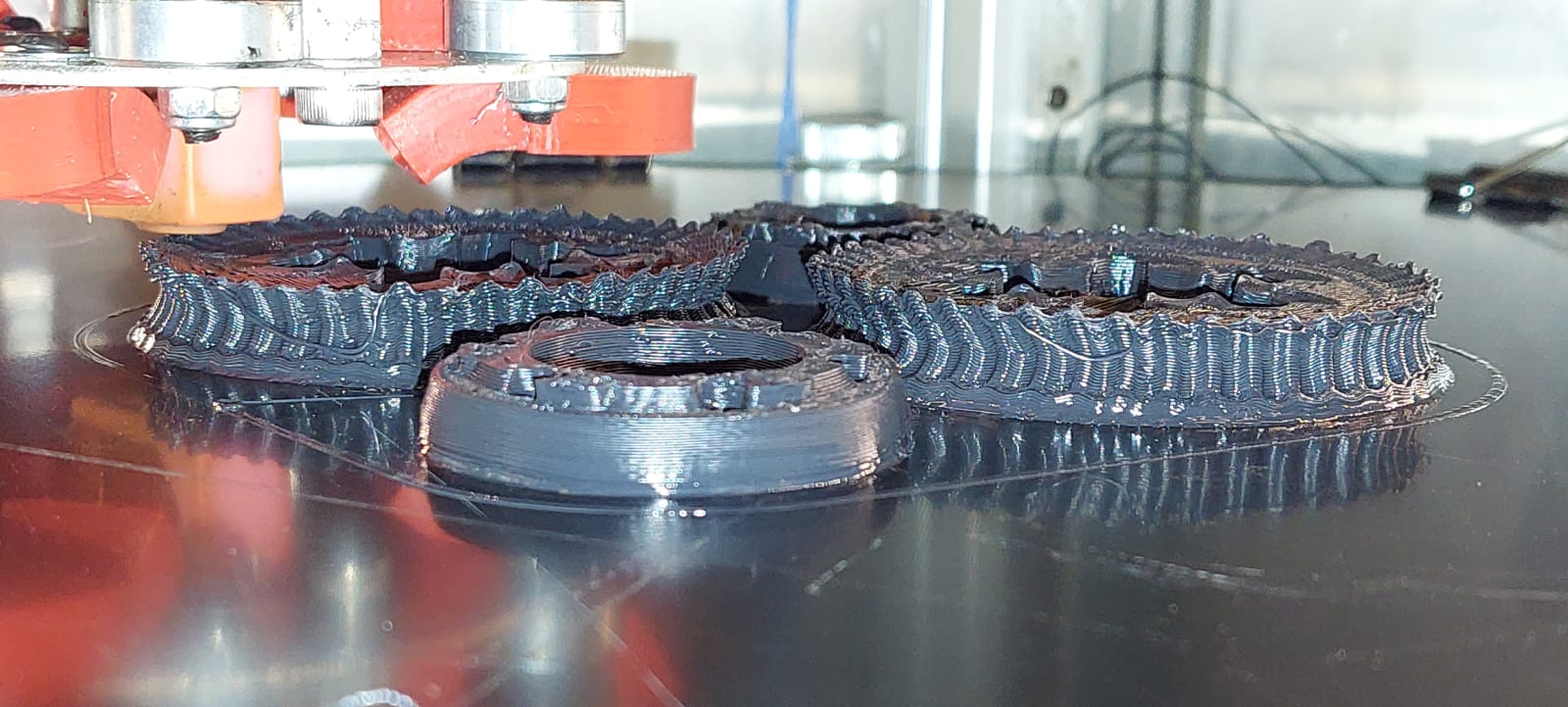

Mushrooming print - What could cause this?

-

@leav could it simply be shrinkage/warping?

It looks like the faster layers without solid infil (I.e. the ones that are laid down faster) are just contracting, but the slower layers are maintaining size better.

I'd try a different reel/brand of filament, or a different material

-

@leav

At first glance it looks like over-extrusion or wrong Z-axis stepps.

The retract doesn't seem to be there either, if you look at the blobs on the skirt and where you move from the skirt to the first layer of the component, the filament runs through without interruption.

But this taper in the middle of the gears is very strange and can actually only be explained by a hardware problem.I would first measure all parts and make sure that all components and screws etc. are tight.

Then measure the axes (travel / stepps) precisely and also measure the extruder stepps again to see whether 100mm is really being conveyed there if this was set in the DWC.Then I would check the bed level sensor to see if it is delivering accurate readings.

I can not imagine that the glass bed is so crooked.

You should also do a PID tuning of the hotend and the print bed.Once that is done, the flow must be determined and set correctly in the slicer.

Do it meticulously, i.e. measure the filament diameter etc.Do some test prints to find out the best temperature for your filament.

At least that's how I would do it in your case.

Google Translate

----- Original Text -----Auf den ersten Blick sieht es nach Überextrusion oder falschen Stepps der Z-Achse aus.

Auch der Retract scheint gar nicht vorhanden zu sein, wenn man sich die Kleckse beim Skirt so ansieht und wo vom Skirt zum ersten Layer des Bauteils gefahren wird, da läuft das Filament durch ohne Unterbrechung.

Aber diese Verjüngung in der Mitte der Zahnräder ist schon sehr merkwürdig und eigentlich nur durch ein Hardware-Problem zu erklären.Ich würde erst einmal alle Teile vermessen und auf den festen Sitz aller Bauteile und Schrauben etc. achten.

Dann die Achsen (Verfahrwege / Stepps) genauestens vermessen und auch die Extruder Stepps nochmals vermessen ob dort wirklich 100mm gefördert wird wenn dieses im DWC eingestellt wurde.Dann würde ich den Bed-Level-Sensor überprüfen ob er genaue Werte liefert.

Ich kann mir nicht vorstellen dass das Glasbett so schief und krumm ist.

Auch ein PID-Tuning vom Hotend und vom Druckbett solltest Du machen.Ist das erledigt, dann muss der Fluss ermittelt werden und im Slicer richtig eingestellt werden.

Mache es ganz penibel, also mit messen des Filament Durchmessers etc.Mache einige Testdrucke um die beste Temperatur für Dein Filament heraus zu finden.

So zumindest würde ich in Deinem Fall vorgehen.

-

How about the rod-distance? The effector looks like the magnets are arranged in a regular pattern (more or less)

It seems easy to match the wrong pair of magnets, which would lead to non-parallel rods. -

@leav said in Mushrooming print - What could cause this?:

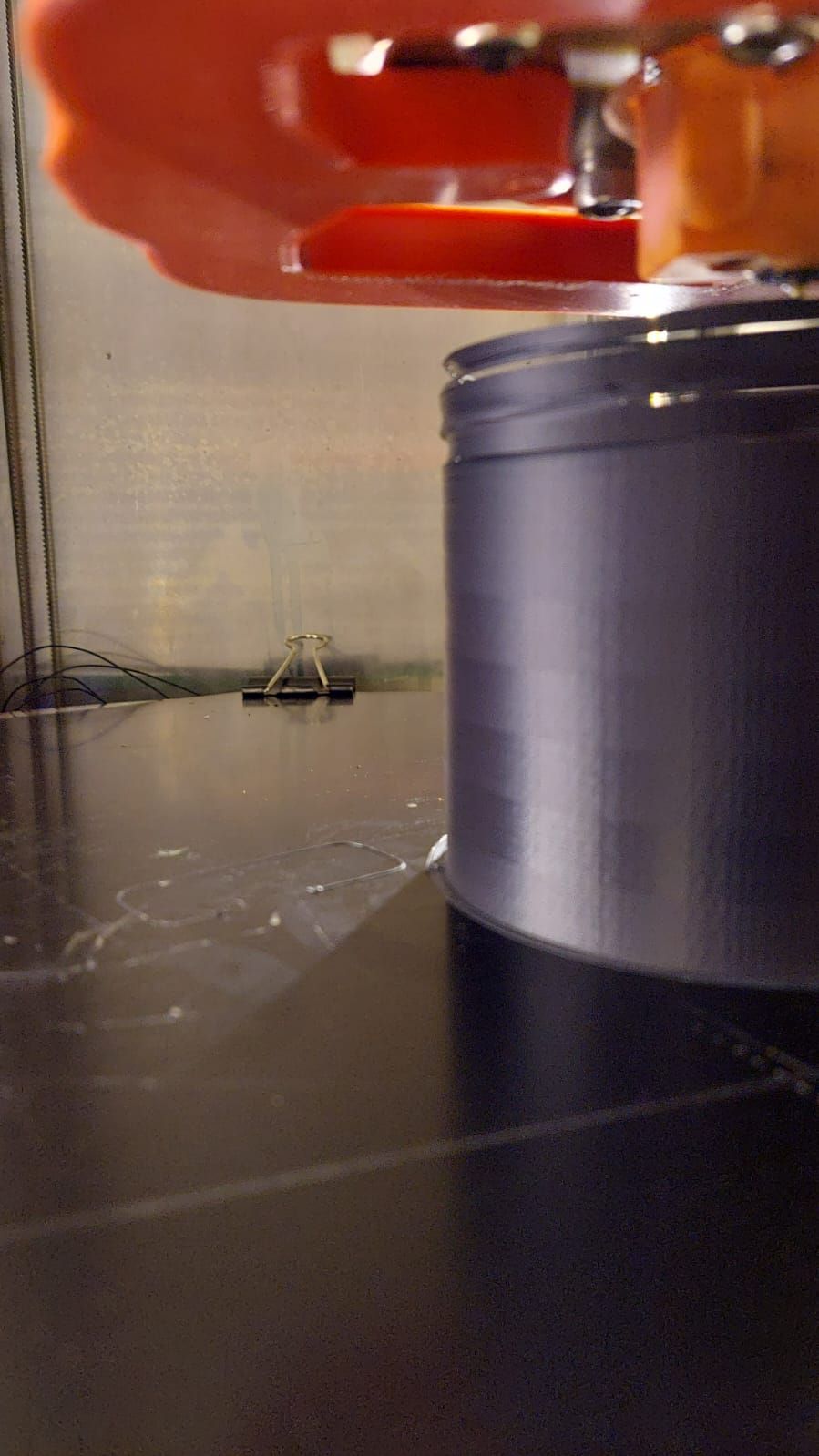

Did you use the printer to print the red fan-duct that you can see in the photo here ?

This effect can also be seen there, that the outer wall collapses inwards.

But it seems to be worse on the left side than on the right !?Print a 100mm high cylinder (or even higher) in vase mode and show us the result.

It is best to do this in different places on the print bed one after the other.

For example, as close as possible to each of the three Z-axes and once in the middle.Just to make it clear where this effect occurs.

Google Translate

----- Original Text -----Hast Du den roten Fan-Duct der hier auf dem Foto zu sehen ist, auch mit dem Drucker gedruckt ?

Dort ist dieser Effekt auch zu sehen, das die Außenwand nach innen einfällt.

Bei der linken Seite scheint es aber schlimmer zu sein als rechts !?Drucke doch mal einen etwa 100mm hohen Zylinder (oder auch gerne höher) im Vasenmodus und zeig uns das Ergebnis.

Am besten nacheinander an verschiedenen Stellen auf dem Druckbett.

Zum Beispiel so nah wie möglich an jedem der drei Z-Achsen und einmal in der Mitte.Nur um es einem bildlich klar zu machen wo überall dieser Effekt auftritt.

-

@alankilian said in Mushrooming print - What could cause this?:

Is there any way you could post your STL files (And GCODE for comparison?)

I'd love to try printing this on my Delta to see if there's anything in the model or sliced code that's causing this.

Shoot, I meant to do this with the previous post.

Here is a link to a zip with the two STL files and the SuperSlicer 3mf project (not sure if it's compatible with prusa slicer or other versions). Please let me know what you find.@engikeneer said in Mushrooming print - What could cause this?:

@leav could it simply be shrinkage/warping?

It looks like the faster layers without solid infil (I.e. the ones that are laid down faster) are just contracting, but the slower layers are maintaining size better.

I'd try a different reel/brand of filament, or a different material

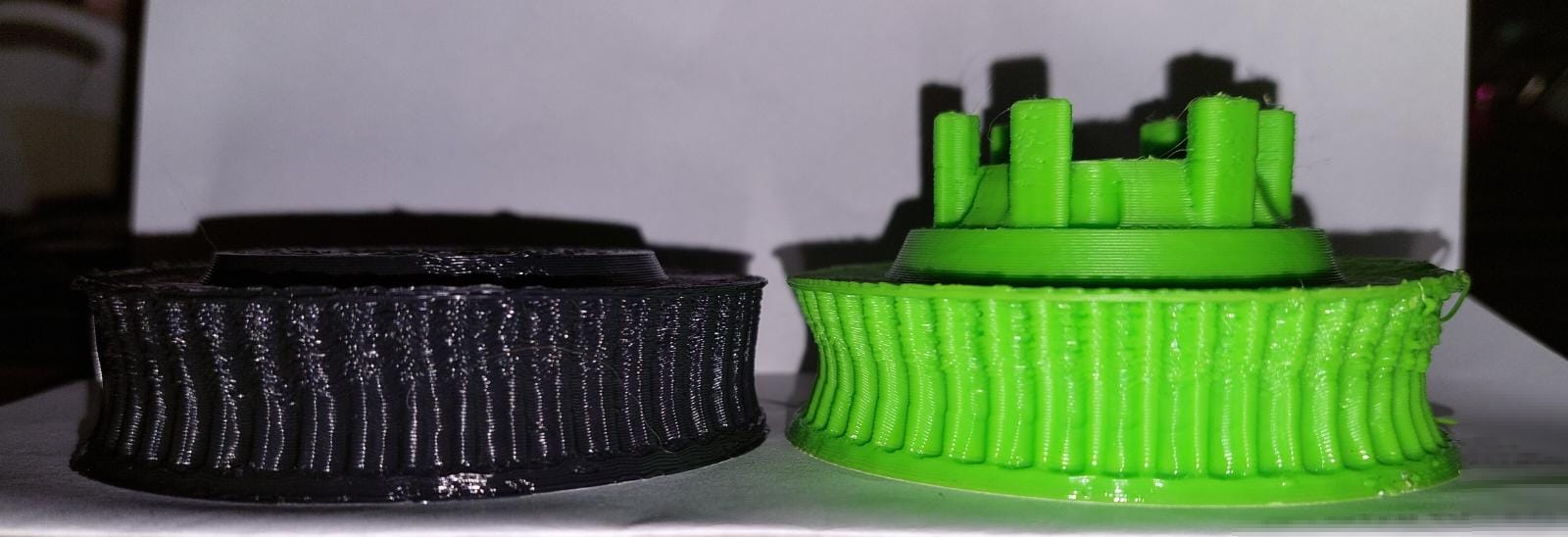

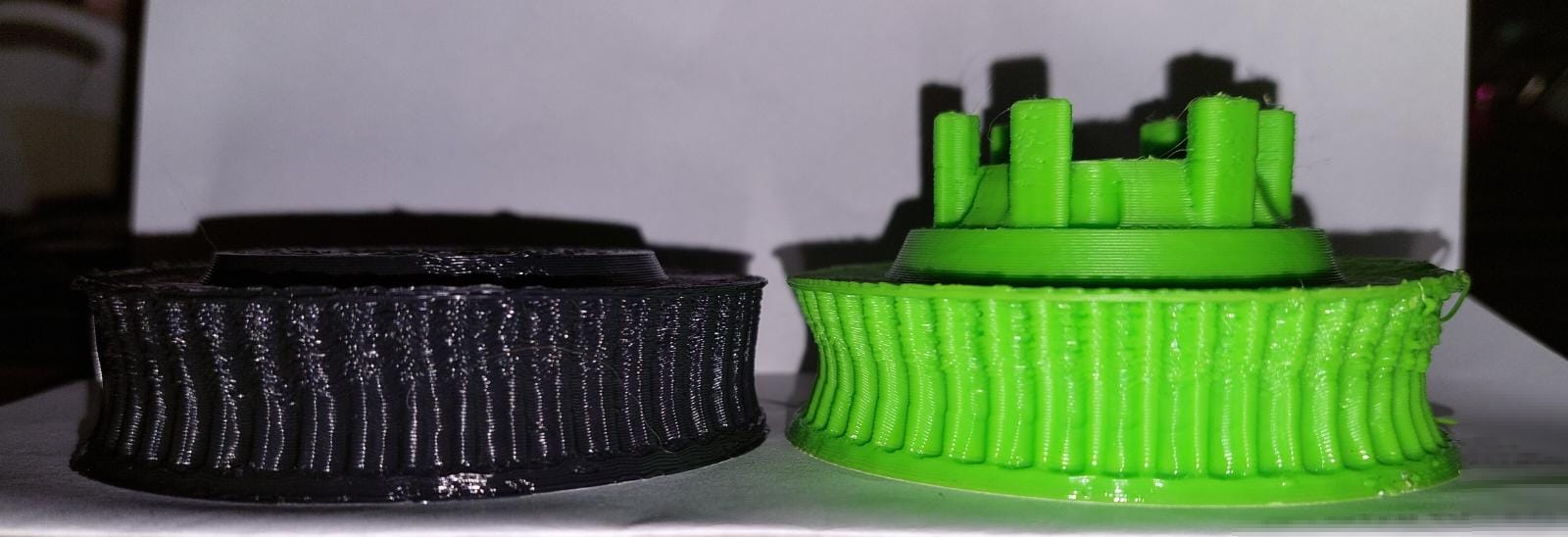

Could very well be. The green material was eSun ABS+, and I printed these black items with Polymaker ASA (same exact gcode).

The deformation is noticeably smaller, leading me to believe plastic shrinkage may be the main mechanism here.

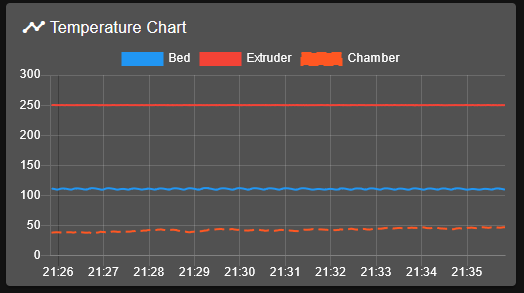

My printing temps:- Extruder 250°c

- Bed 110°c

- Chamber (passively heated by 2000w bed heater) ~40-50°c (rises during the print)

@norder said in Mushrooming print - What could cause this?:

At first glance it looks like over-extrusion or wrong Z-axis stepps.

The retract doesn't seem to be there either, if you look at the blobs on the skirt and where you move from the skirt to the first layer of the component, the filament runs through without interruption.Thanks for calling attention to that. I have a super long bowden tube (>1000mm), and retraction is currently set to only 8mm. I think it's very likely it needs to be much larger to account for the extra length of the filament snaking around in the capricorn tube.

Regarding your calibration suggestions, I am jotting down a list here:

- Check drive item tightness (including pulley set screws in all 4 steppers)

- measure axis travel (all 4 steppers)

- Bed level sensor repeatability test

- Check flatness of travel to bed after mesh probing using an indicator that clips on the effector

- Calibrate flow from scratch (filament diameter + flow calibration print)

- Optimal printing temperature test (temperature tower?)

Will report back the results

@o_lampe said in Mushrooming print - What could cause this?:

How about the rod-distance? The effector looks like the magnets are arranged in a regular pattern (more or less)

It seems easy to match the wrong pair of magnets, which would lead to non-parallel rods.You are correct that it is easy to get a mismatch pair, but in this case it is correct - Thanks!

@norder said in Mushrooming print - What could cause this?:

Did you use the printer to print the red fan-duct that you can see in the photo here ?

Yes

@norder said in Mushrooming print - What could cause this?:

This effect can also be seen there, that the outer wall collapses inwards.

But it seems to be worse on the left side than on the right !?Good eye, I didn't catch that!

@norder said in Mushrooming print - What could cause this?:

Print a 100mm high cylinder (or even higher) in vase mode and show us the result.

It is best to do this in different places on the print bed one after the other.

For example, as close as possible to each of the three Z-axes and once in the middle.

Just to make it clear where this effect occurs.In progress now, will update soon, including results of the above tests.

I would like to say thanks to everyone pitching in to try and figure it out, much appreciated!

-

@leav said in Mushrooming print - What could cause this?:

Could very well be. The green material was eSun ABS+, and I printed these black items with Polymaker ASA (same exact gcode).

The deformation is noticeably smaller, leading me to believe plastic shrinkage may be the main mechanism here.

I can't imagine with the best will in the world that it's due to the shrinkage factor of the filament, sorry.

I printed a shrinkage test for each filament I use (large cross, 150mm x 150mm with a height of about 5mm, since my calliper can only measure up to 156mm) and after cooling down I measured the length of the cross and calculated the shrinkage factor.

You can then enter this value in the slicer and the component will then be printed enlarged by this factor.

But this value is not so high for all filaments that collapsed walls could arise as with your printouts.All axes of my printer were also measured with calipers.

I attach the caliper to the linear rails with a strong magnet and let the print head or print bed move very slowly against the caliper until it moves a few mm, then set the caliper to zero and then let it move 100mm very slowly.Therefore, the calculated shrinkage values are very accurate and agree with the later measurements.

No matter which filament I print... if the stl says one side is 27mm long, then the printout is also 27mm (+- 0.1mm).

The +-0.1mm is then due to the flow, which I find difficult to set exactly.

If the measured wall thickness is correct for calculating the flow, then you may not like the stability of the component and you are happy to add a little more.

What's the point of a beautiful component if the stability suffers as a result.

You have to die a death here!?

Therefore, I would want to rule out such extreme shrinkage in your prints.

My guesses...

The unattractive / unclean print image is due to incorrect values for the flow, retract and possibly also incorrect printing temperatures, with the temperature playing a smaller role here.

The stepps could also not be set exactly, so the Z10 entered in the DWC, measured maybe 9mm.For me, the tapering of the sides is more of a mechanical problem like rods of different lengths or a frame that is not at an exact angle or a loose component or something like that.

And this inaccuracy in the construction makes the already poor print image even worse.As I said... a guess on my part.

I am very excited to see the photos.

P.S.:

Is it s.Wide Angle or are the two gears wedge-shaped?

The black gear has the left side higher than the right and the green gear is the other way around.Google Translate

--- Original Text ---Ich kann mir beim besten Willen nicht vorstellen das es am Schrumpffaktor des Filaments liegt, Sorry.

Ich habe für jedes Filament welches ich benutze einen Schrumpftest gedruckt (großes Kreuz, 150mm x 150mm mit einer Höhe von etwa 5mm, da meine Schieblehre nur bis 156mm messen kann) und habe nach dem abkühlen die Längen des Kreuzes genauestens vermessen und den Schrumpffaktor berechnet.

Diesen Wert kann man dann im Slicer angeben und das Bauteil wird dann um diesen Faktor vergrößert gedruckt.

Aber dieser Wert ist bei allen Filamenten nicht so hoch das so eingefallene Wände entstehen könnten wie bei Deinen Ausdrucken.Alle Achsen meines Druckers wurden auch mit der Schieblehre vermessen.

Ich hafte die Schieblehre mit einem starken Magneten auf die Linearschienen und lasse den Druckkopf oder das Druckbett sehr langsam an die Schieblehre fahren bis sie wenige mm bewegt wird, stelle dann die Schieblehre auf Null und lasse sie dann sehr langsam, sich 100mm bewegen.Daher sind auch die errechneten Schrumpfwerte sehr genau und stimmen mit den späteren Messungen überein.

Egal welches Filament ich drucke... sagt die stl eine Seite ist 27mm lang, dann ist der Ausdruck auch 27mm (+- 0,1mm).

Die +-0,1mm liegen dann am Fluss, den ich schwierig finde exakt einzustellen.

Stimmt die gemessene Wandstärke um den Fluss zu berechnen, dann gefällt einem vielleicht die Stabilität des Bauteils nicht und man gibt dann gerne mal ein wenig mehr dazu.

Was bringt mir ein schönes Bauteil wenn die Stabilität darunter leidet.

Einen Tod muss man hier wohl sterben !?

Daher würde ich ein so extremes schrumpfen bei Deinen Drucken ausschließen wollen.

Meine Vermutungen...

Das unschöne / unsaubere Druckbild ist auf falsche Werte für den Fluss, Retrakt und eventuell auch falsche Drucktemperaturen hinzuführen, wobei die Temperatur hier eine kleinere Rolle spielen.

Die Stepps könnten auch nicht exakt eingestellt sein, so das Z10 im DWC eingegeben, gemessen vielleicht 9mm ergibt.Das sich verjüngen der Seiten ist für mich eher ein mechanisches Problem wie unterschiedlich lange Rods oder ein Rahmen der nicht exakt im Winkel steht oder ein lockeres Bauteil oder so etwas in der Richtung.

Und diese Ungenauigkeit der Konstruktion verschlimmert dazu noch das eh schon schlechte Druckbild.Wie gesagt... eine Vermutung von mir.

Ich bin gespannt auf die Fotos.

P.S.:

Liegt es am Weitwinkel oder sind die beiden Zahnräder Keilförmig ?

Bei dem schwarzen ist die linke Seite höher als die Rechte und bei dem grünen Zahnrad ist es anders herum. -

Thanks for the STL files.

I saw that you are using all perimeter features for your infill, so I sliced using Simplify3D and set perimeters to 30.

I also printed "outside-in".

And...........

I got a strangely distorted print!!!

It's not the same as yours, mine looks fine vertically and does not have the shrinkage your does, but mine leans to the left quite a bit.

This is VERY strange as my printer has produces nice (not perfect, but darn-nice) prints for years.

I suppose this could a layer-shift, but since a Delta printer doesn't have layer-aligned axis it's kind of hard to tell. The thickness of the pulley varies from 18.3mm to 18.6mm but that's only 1 layer, so I'm not sure.

I resliced with three perimeters and I'm printing now, so I'll post results in a few hours.

This looks like some kind of print shrinkage due to nonuniform cooling to me. There might be a breeze in my room due to a window being open on one side of the room and a door on another side.

I'll post results later today.

-

OK, so the one I printed using 3 perimeters printed perfectly.

The pulley height is 0.75 inches as I expect you intended it to be.

My conclusion is that when you slice with the interior being "All perimeters" rather than infill that differential cooling causes massive distortions.

Can you try reslicing with three perimeters and something like 42% (more or less

) infill and see what you get?

) infill and see what you get?

-

If it helps, this is the recommended setting for Voron parts, some are structural and some are for the look.

- ABS

- Nozzle: 0.4mm

- Layer height: 0.2mm.

- Extrusion width: 0.4mm, forced.

- Infill percentage: 40%

- Infill type: grid, gyroid, honeycomb, triangle, or cubic.

- Wall count: 4.

- Solid top/bottom layers: 5.

- Supports: NONE.

Not mentioned but I also run the material cooling fan low.

-

in my humble opinion, this is a combination of issues, like others said.. temps seem too hot, over extrusion maybe..

BUT none of that explains the absolutely incredible geometrical deviation from your design. This is not shrinkage lol, not in this way, not in such amounts. And then it switches to reverse-shrinkage? heh...

If it was bowden related, you would expect similar defects within each layer, not a continuous geometry change over many layers.

I have a sneaking suspicion, that something is screwed up with the geometry settings of your delta. Arm length in the FW perhaps wrong.. anything related to M666 and M665

Do you have a log of what you did to the machine? Was it working well before your changes? -

- 3 drive motors tested and all good

- 3 axis travel tested, all good

- Z probe repeatability: 0.065mm and 0.061mm (two different tests, 10 probes each in center)

- Flatness of travel after mesh - to be tested

- Calibrate flow from scratch - to be done

- Temp calibration TBD

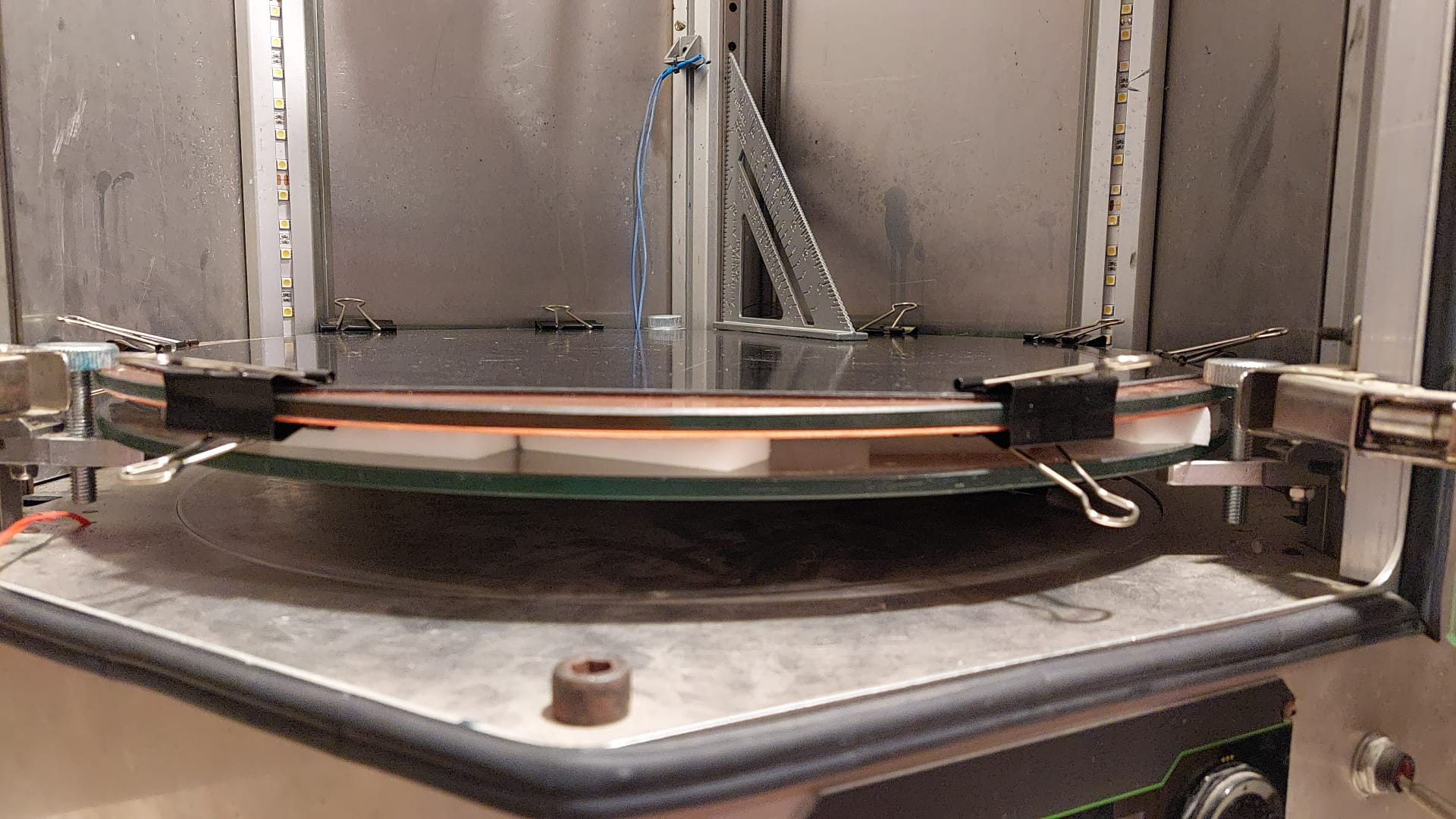

I had the same train of thought as @pjl , and found this sentence in the guides:

Bed should be at right angles to the towers in both X and Y directions

Actually, this isn't essential, because RepRapFirmware can compensate for bed tilt. Unfortunately, auto calibration can't easily distinguish between bed tilt and differences in tower separation. One approach to getting the bed level is to mount it on 3 equal-length spacers attached to the lower horizontal frame. If you are using metal corners, the horizontal frame should be at right angles to the towers. If you do need to make any adjustment, you can stack washers or shims on top of one or two of the spacers.

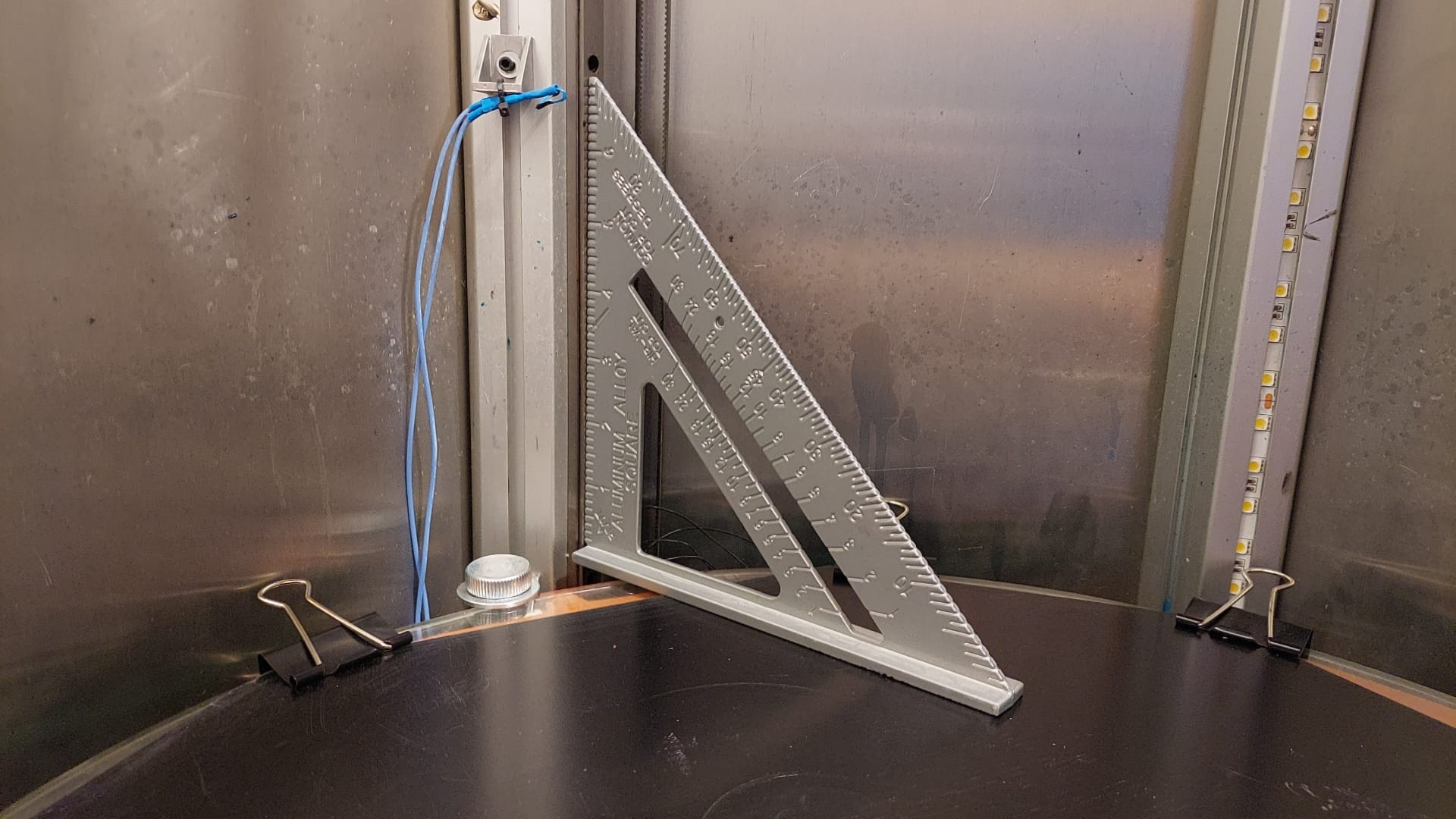

This is actually NOT the case in my printer: the bed flatness must be calibrated by hand every time you need to access the electronics (see pic1 below) and I always just assumed the mesh probing will take care of it.

Running M665 I get:

M665 Diagonals 511.070:511.070:511.070, delta radius 172.890, homed height 341.889, bed radius 160.0, X 0.399°, Y 1.141°, Z 0.000°An angle deviation of 1.141° means a position deviation of ~5mm, which is just not possible in my printer (the tower tops and bottoms are held in place by two laser cut sheets).

This confirmed my suspicion that I was wielding the G30 command without understanding its power and limitations.

Steps taken now:

- Bed perpendicular-ed to towers with a carpenter's square (see below, it's what I had...)

- bed.g changed to 4 factor calibration (was 6 factor)

Printing test file now, will update!

-

Happy to report that:

- Changing to 3-parameter calibration removed almost all of the waviness

- Reducing extrusion temp from 250°c to 230°c eliminated the warping near the edge in test parts

- I did indeed find that the socket was coming loose at the edge of the print area as @o_lampe suspected (though I estimate that it was not an issue in the original pulley parts. [Video 1] and [[Video 2](Video 2)], "fixed" by removing excess grease (may redesign the sockets one day)

Original thin wall cylinder (spiral vase)

Same part printed after the fixes 1 & 2 above (the printing gap is due to the socket pulling out, fixed mid print)

Now printing the pulleys again...

-

Pulleys do not seem impressed with all the improvements.

Now trying with part cooling fan on at 50% (even though this is ASA).

-

@leav

It looks like your component cooler is a hot air gun. Try it with a very easy to print PLA.If that then looks good, you know that you have to work on the settings of the ASA, but the printer is OK.

-

@leav said in Mushrooming print - What could cause this?:

Pulleys do not seem impressed with all the improvements.

Have you tried reslicing with only 3 perimeter walls and 50% infill like I did?

I got them to print prefectly when I made that change even though they printed distorted with completely-filled with perimeter walls like yours.

-

Also, can you please post the GCODE for just one pulley centered on the bed?

-

@norder said in Mushrooming print - What could cause this?:

@leav

It looks like your component cooler is a hot air gun. Try it with a very easy to print PLA.If that then looks good, you know that you have to work on the settings of the ASA, but the printer is OK.

You don't know the half of it. Here's a macro shot of the pulley teeth printed with the part "cooler" on, the shrinking is even worse.

Now printing 3 perimeters @ 42% infill in ASA, but I'll bust out my first ever roll of PLA after that.

@alankilian said in Mushrooming print - What could cause this?:

@leav said in Mushrooming print - What could cause this?:

Pulleys do not seem impressed with all the improvements.

Have you tried reslicing with only 3 perimeter walls and 50% infill like I did?

I got them to print prefectly when I made that change even though they printed distorted with completely-filled with perimeter walls like yours.

Doing that now, will update (I went for 18% infill).

@alankilian said in Mushrooming print - What could cause this?:

Also, can you please post the GCODE for just one pulley centered on the bed?

Here you go - This includes a single thick-walled pulley plus a 3-perimeter 18% infill version which I am now printing.

-

Im super sure that is not a slicing propblem. Definetley is mechanic. In my pinion you have a problem on your X Y movement. The variation Z is not a problem on the Z axis, it is the variation on the Z axis wich is doing some variation on your X and Y

I would check on the axis movment, you have a problem there. -

@leav said in Mushrooming print - What could cause this?:

... but I'll bust out my first ever roll of PLA after that ...

PLA is not my filament either.

At that time the printer came with a sample and I got some samples when I ordered filament.

And I won a 1kg roll of PLA in the color piggy pink, it's such an ugly color... but it's great for printing little piggy banks.

I almost only print ABS and Nylon, but I also have a few more exotic ones here, such as PP and PC etc.

You have to try everything.At first I was firmly convinced that it was a problem with the printer geometry, but since the two round surfaces of the gear wheel are the same size... I'm starting to ponder.

Have you ever had reasonable and true-to-size printouts with this ASA filament ?

If this is really solely due to the shrinking of the filament, then it belongs at the top of the list of the worst filaments ever.P.S.:

What speaks AGAINST a "shrinking of the filament" is this layer that is not on the underlying layer.

The nozzle has therefore completely passed the underlying perimeter.

I think that a complete layer in the area didn't take so long that it shrunk so extremely under the nozzle ?

I would like to see a video of the print.

Google Translate

--- Original Text ---PLA ist auch nicht mein Filament.

Damals war beim Drucker eine Probe dabei und ich habe einige Samples bekommen als ich mir Filament bestellt hatte.

Und eine 1kg Rolle PLA in der Farbe Schweinchenrosa habe ich mal gewonnen, es ist so eine hässliche Farbe... aber sie ist ideal um kleine Sparschweine zu drucken.

Ich drucke fast nur ABS und Nylon, habe aber auch noch ein paar Exoten hier wie zB PP und PC etc.

Man muss ja alles mal ausprobieren.Ich war ja auch erst fest davon überzeugt das es sich um ein Problem der Drucker-Geometrie handelt, aber da die beiden runden Flächen des Zahnrades gleich groß sind... komme ich langsam ins grübeln.

Hattest Du mit diesem ASA Filament denn schon einmal vernünftige und maßhaltige Ausdrucke ?

Wenn das wirklich alleine an dem schrumpfen des Filaments liegt, dann gehört es ganz oben auf die Liste der schlechtesten Filament ever.P.S.:

Was GEGEN ein "schrumpfen des Filaments" spricht, ist dieser Layer der nicht auf dem darunter liegenden Layer liegt.

Die Düse ist also komplett an dem darunter liegenden Perimeter vorbei gefahren.

Ich denke das ein kompletter Layer in dem Bereich nicht so lange gedauert hat das er unter der Düse so extrem zusammen geschrumpft ist ?Von dem Druck würde ich gerne mal ein Video sehen.

-

I have printed part of the GCODE you posted using PLA by adjusting the temperatures to 60C for the bed and 205C for the extruder and it is printing perfectly on my SeeMeCNC Rostock Max V3.2 using a Duet2/Ethernet and 3.4.0beta5+1 (Because I'm lazy and haven't updated in a while.)

I have to leave the house and I don't know what the end-of-print GCODE will do so I'm stopping this print.

It does tell you that your GCODE is perfectly able to be printed and will produce an acceptable part using the Duet firmware.