Mushrooming print - What could cause this?

-

OK, so the one I printed using 3 perimeters printed perfectly.

The pulley height is 0.75 inches as I expect you intended it to be.

My conclusion is that when you slice with the interior being "All perimeters" rather than infill that differential cooling causes massive distortions.

Can you try reslicing with three perimeters and something like 42% (more or less

) infill and see what you get?

) infill and see what you get?

-

If it helps, this is the recommended setting for Voron parts, some are structural and some are for the look.

- ABS

- Nozzle: 0.4mm

- Layer height: 0.2mm.

- Extrusion width: 0.4mm, forced.

- Infill percentage: 40%

- Infill type: grid, gyroid, honeycomb, triangle, or cubic.

- Wall count: 4.

- Solid top/bottom layers: 5.

- Supports: NONE.

Not mentioned but I also run the material cooling fan low.

-

in my humble opinion, this is a combination of issues, like others said.. temps seem too hot, over extrusion maybe..

BUT none of that explains the absolutely incredible geometrical deviation from your design. This is not shrinkage lol, not in this way, not in such amounts. And then it switches to reverse-shrinkage? heh...

If it was bowden related, you would expect similar defects within each layer, not a continuous geometry change over many layers.

I have a sneaking suspicion, that something is screwed up with the geometry settings of your delta. Arm length in the FW perhaps wrong.. anything related to M666 and M665

Do you have a log of what you did to the machine? Was it working well before your changes? -

- 3 drive motors tested and all good

- 3 axis travel tested, all good

- Z probe repeatability: 0.065mm and 0.061mm (two different tests, 10 probes each in center)

- Flatness of travel after mesh - to be tested

- Calibrate flow from scratch - to be done

- Temp calibration TBD

I had the same train of thought as @pjl , and found this sentence in the guides:

Bed should be at right angles to the towers in both X and Y directions

Actually, this isn't essential, because RepRapFirmware can compensate for bed tilt. Unfortunately, auto calibration can't easily distinguish between bed tilt and differences in tower separation. One approach to getting the bed level is to mount it on 3 equal-length spacers attached to the lower horizontal frame. If you are using metal corners, the horizontal frame should be at right angles to the towers. If you do need to make any adjustment, you can stack washers or shims on top of one or two of the spacers.

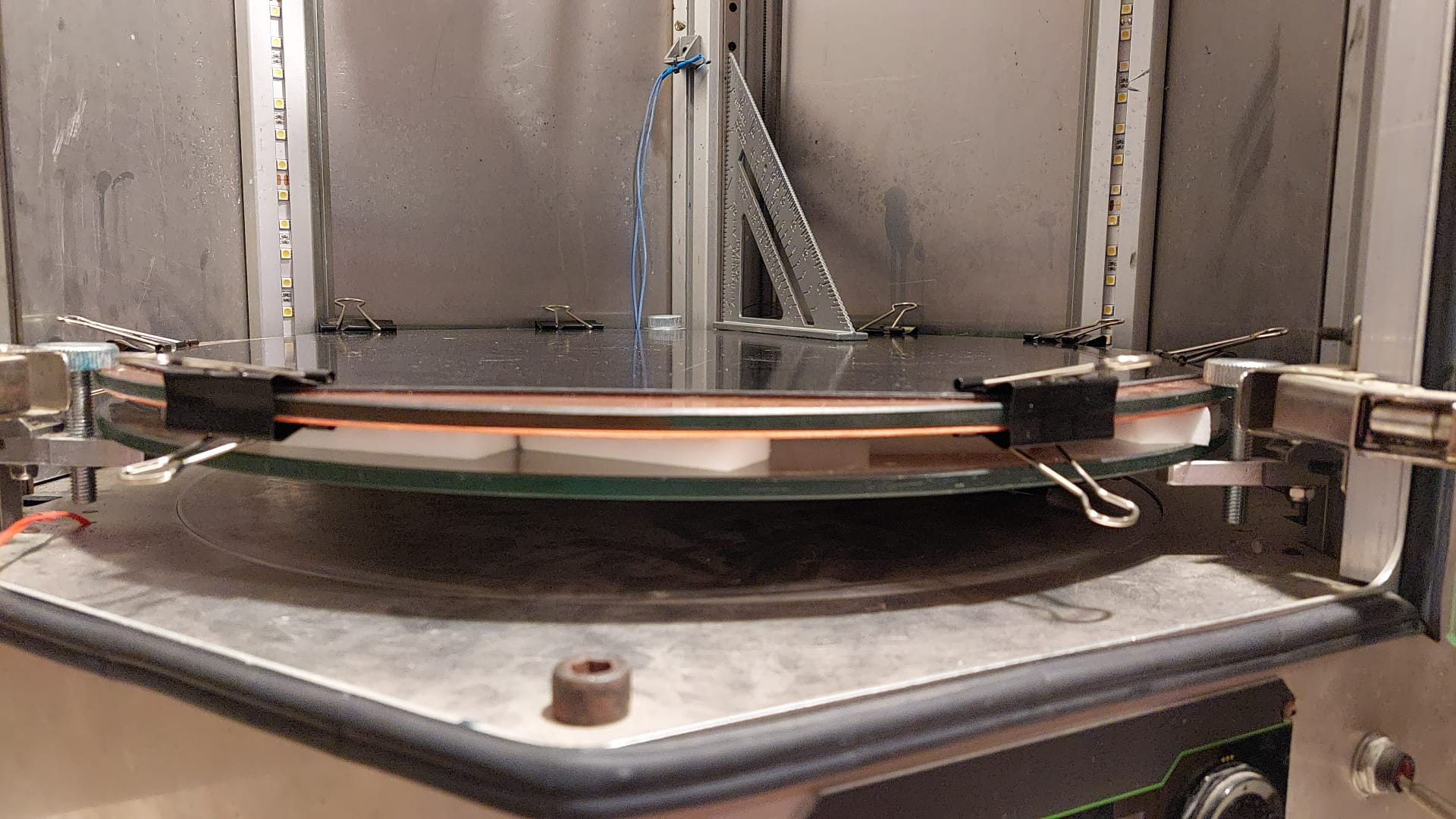

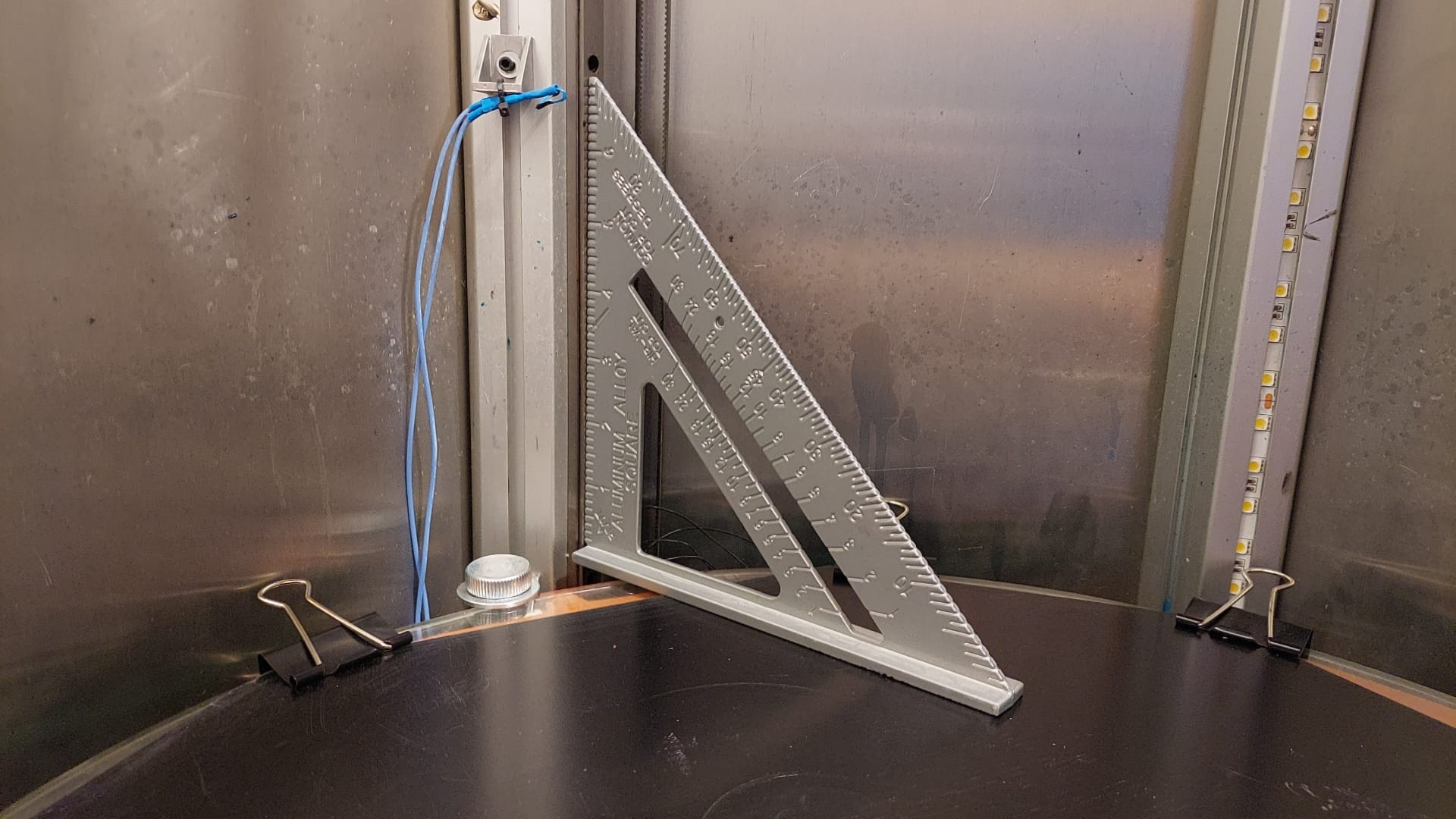

This is actually NOT the case in my printer: the bed flatness must be calibrated by hand every time you need to access the electronics (see pic1 below) and I always just assumed the mesh probing will take care of it.

Running M665 I get:

M665 Diagonals 511.070:511.070:511.070, delta radius 172.890, homed height 341.889, bed radius 160.0, X 0.399°, Y 1.141°, Z 0.000°An angle deviation of 1.141° means a position deviation of ~5mm, which is just not possible in my printer (the tower tops and bottoms are held in place by two laser cut sheets).

This confirmed my suspicion that I was wielding the G30 command without understanding its power and limitations.

Steps taken now:

- Bed perpendicular-ed to towers with a carpenter's square (see below, it's what I had...)

- bed.g changed to 4 factor calibration (was 6 factor)

Printing test file now, will update!

-

Happy to report that:

- Changing to 3-parameter calibration removed almost all of the waviness

- Reducing extrusion temp from 250°c to 230°c eliminated the warping near the edge in test parts

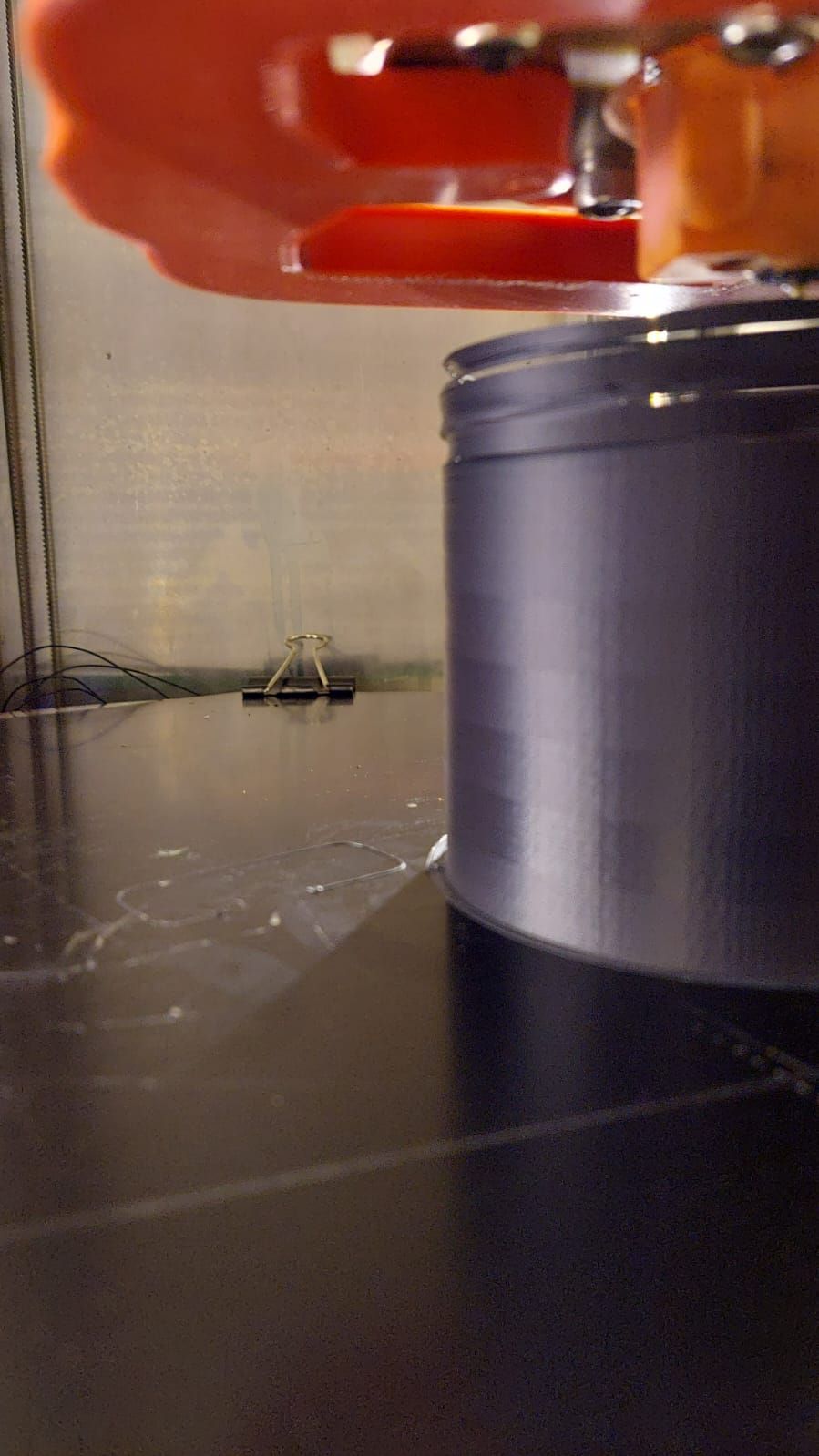

- I did indeed find that the socket was coming loose at the edge of the print area as @o_lampe suspected (though I estimate that it was not an issue in the original pulley parts. [Video 1] and [[Video 2](Video 2)], "fixed" by removing excess grease (may redesign the sockets one day)

Original thin wall cylinder (spiral vase)

Same part printed after the fixes 1 & 2 above (the printing gap is due to the socket pulling out, fixed mid print)

Now printing the pulleys again...

-

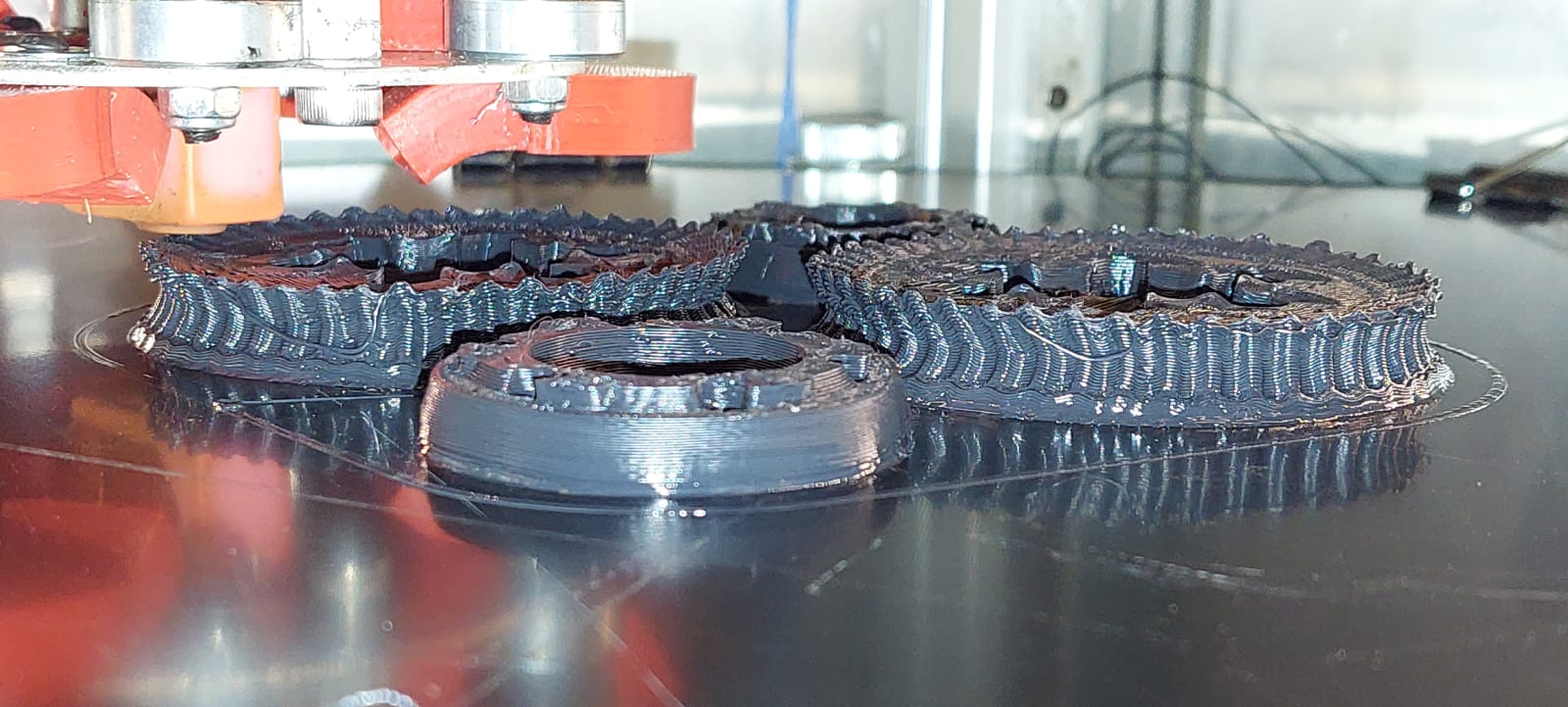

Pulleys do not seem impressed with all the improvements.

Now trying with part cooling fan on at 50% (even though this is ASA).

-

@leav

It looks like your component cooler is a hot air gun. Try it with a very easy to print PLA.If that then looks good, you know that you have to work on the settings of the ASA, but the printer is OK.

-

@leav said in Mushrooming print - What could cause this?:

Pulleys do not seem impressed with all the improvements.

Have you tried reslicing with only 3 perimeter walls and 50% infill like I did?

I got them to print prefectly when I made that change even though they printed distorted with completely-filled with perimeter walls like yours.

-

Also, can you please post the GCODE for just one pulley centered on the bed?

-

@norder said in Mushrooming print - What could cause this?:

@leav

It looks like your component cooler is a hot air gun. Try it with a very easy to print PLA.If that then looks good, you know that you have to work on the settings of the ASA, but the printer is OK.

You don't know the half of it. Here's a macro shot of the pulley teeth printed with the part "cooler" on, the shrinking is even worse.

Now printing 3 perimeters @ 42% infill in ASA, but I'll bust out my first ever roll of PLA after that.

@alankilian said in Mushrooming print - What could cause this?:

@leav said in Mushrooming print - What could cause this?:

Pulleys do not seem impressed with all the improvements.

Have you tried reslicing with only 3 perimeter walls and 50% infill like I did?

I got them to print prefectly when I made that change even though they printed distorted with completely-filled with perimeter walls like yours.

Doing that now, will update (I went for 18% infill).

@alankilian said in Mushrooming print - What could cause this?:

Also, can you please post the GCODE for just one pulley centered on the bed?

Here you go - This includes a single thick-walled pulley plus a 3-perimeter 18% infill version which I am now printing.

-

Im super sure that is not a slicing propblem. Definetley is mechanic. In my pinion you have a problem on your X Y movement. The variation Z is not a problem on the Z axis, it is the variation on the Z axis wich is doing some variation on your X and Y

I would check on the axis movment, you have a problem there. -

@leav said in Mushrooming print - What could cause this?:

... but I'll bust out my first ever roll of PLA after that ...

PLA is not my filament either.

At that time the printer came with a sample and I got some samples when I ordered filament.

And I won a 1kg roll of PLA in the color piggy pink, it's such an ugly color... but it's great for printing little piggy banks.

I almost only print ABS and Nylon, but I also have a few more exotic ones here, such as PP and PC etc.

You have to try everything.At first I was firmly convinced that it was a problem with the printer geometry, but since the two round surfaces of the gear wheel are the same size... I'm starting to ponder.

Have you ever had reasonable and true-to-size printouts with this ASA filament ?

If this is really solely due to the shrinking of the filament, then it belongs at the top of the list of the worst filaments ever.P.S.:

What speaks AGAINST a "shrinking of the filament" is this layer that is not on the underlying layer.

The nozzle has therefore completely passed the underlying perimeter.

I think that a complete layer in the area didn't take so long that it shrunk so extremely under the nozzle ?

I would like to see a video of the print.

Google Translate

--- Original Text ---PLA ist auch nicht mein Filament.

Damals war beim Drucker eine Probe dabei und ich habe einige Samples bekommen als ich mir Filament bestellt hatte.

Und eine 1kg Rolle PLA in der Farbe Schweinchenrosa habe ich mal gewonnen, es ist so eine hässliche Farbe... aber sie ist ideal um kleine Sparschweine zu drucken.

Ich drucke fast nur ABS und Nylon, habe aber auch noch ein paar Exoten hier wie zB PP und PC etc.

Man muss ja alles mal ausprobieren.Ich war ja auch erst fest davon überzeugt das es sich um ein Problem der Drucker-Geometrie handelt, aber da die beiden runden Flächen des Zahnrades gleich groß sind... komme ich langsam ins grübeln.

Hattest Du mit diesem ASA Filament denn schon einmal vernünftige und maßhaltige Ausdrucke ?

Wenn das wirklich alleine an dem schrumpfen des Filaments liegt, dann gehört es ganz oben auf die Liste der schlechtesten Filament ever.P.S.:

Was GEGEN ein "schrumpfen des Filaments" spricht, ist dieser Layer der nicht auf dem darunter liegenden Layer liegt.

Die Düse ist also komplett an dem darunter liegenden Perimeter vorbei gefahren.

Ich denke das ein kompletter Layer in dem Bereich nicht so lange gedauert hat das er unter der Düse so extrem zusammen geschrumpft ist ?Von dem Druck würde ich gerne mal ein Video sehen.

-

I have printed part of the GCODE you posted using PLA by adjusting the temperatures to 60C for the bed and 205C for the extruder and it is printing perfectly on my SeeMeCNC Rostock Max V3.2 using a Duet2/Ethernet and 3.4.0beta5+1 (Because I'm lazy and haven't updated in a while.)

I have to leave the house and I don't know what the end-of-print GCODE will do so I'm stopping this print.

It does tell you that your GCODE is perfectly able to be printed and will produce an acceptable part using the Duet firmware.

-

@norder said in Mushrooming print - What could cause this?:

I would like to see a video of the print.

A picture is worth a thousand words, but a GIF can hold a thousand pictures.

Since this happened with two different brands, I think there must be something wrong with my temperature settings?

- ABS from eSun and ASA from Polymaker

- Happened both @ 230°c and 250°c

- Bed @ 110°c

- Chamber temp reaches ~50°c and stabilizes there

Those seem pretty standard settings from what I've seen around. Maybe my temperature calibrations are off?

-

@leav That's incredible!

I've started to read about this filament and it sounds like difficult stuff to work with.

I hope you get things tuned in perfectly and can make great prints with is.

-

@leav

That's unbelievable.

It shrinks like shrink tubing.

Insanity.They gave you a rubber band instead of ASA.

And the ASA is from Polymaker... Polymaker makes the best Nylon on earth, the PolyMide CoPA. It can easily be printed with a bed temperature of 50°C and WITHOUT housing.

It is my most expensive filament in the range and it later withstands temperatures of over 180°C without becoming soft.

The only thing where it's a diva... it MUST be dry... bone dry !

And they make such an ASA? (cry)

I can't and don't want to believe that.

I have an ASA+ from PrimaSelect which I print with a 70°C bed without an enclosure, and the results are perfect.

I strongly assume that the PLA print will then give you a perfect result.

It is normal that filaments that shrink very much often detach from the print bed. But you didn't have any problems with that ?

You used 250°C nozzle, 110°C bed and 50°C housing for the ASA, you write.

Polymaker recommends 75°C to 95°C bed temperature.

I would say your print bed might be too hot at 110°C !?

Try 250°C nozzle, 85°C bed and only close the housing and don't heat it additionally.

Possibly the fan to 15% from the 2nd layer.

So the result should be better.I watched some videos about the Polymaker ASA and nobody had the same problems with the filament as you have.

For me, Polymaker is one of the best filament manufacturers in the world, so I can't believe that they should have brought such a scrap filament onto the market.

I don't have an ASA from Polymaker myself, but I do have other plastics and they are all absolutely top-notch.Google Translate

--- Original Text ---Das ist ja Unfassbar.

Es schrumpft wie ein Schrumpfschlauch zusammen.

Wahnsinn.Die haben Dir anstatt ASA ein Gummiband geliefert.

Und das ASA ist von Polymaker... Polymaker macht das beste Nylon auf Erden, das PolyMide CoPA. Es läßt sich locker mit 50°C Betttemperatur und OHNE Umhausung drucken.

Es ist mein teuerstes Filament im Sortiment und es hält später Temperaturen von über 180°C stand ohne weich zu werden.

Das einzige wo es eine Diva ist... es MUSS trocken sein... Knochentrocken !

Und die stellen so ein ASA her ? (heul)

Ich kann und will das nicht glauben.

Von PrimaSelect habe ich ein ASA+ welches ich mit 70°C Bett ohne Umhausung drucke, und die Resultate sind perfekt.

Ich nehme stark an dass dann der PLA Druck bei Dir zu einem perfekten Resultat kommen wird.

Normal ist es ja so, dass Filamente die sehr stark schrumpfen, sich auch sehr oft vom Druckbett lösen. Aber damit hattest Du wohl keine Probleme ?

250°C Nozzle, 110°C Bett und 50°C Umhausung hast Du für das ASA genommen, schreibst Du.

Polymaker empfiehlt 75°C bis 95°C Betttemperatur.

Ich würde sagen, Dein Druckbett könnte zu heiß sein mit 110°C !?

Versuche mal 250°C Nozzle, 85°C Bett und die Umhausung nur schließen und nicht zusätzlich beheizen.

Eventuell den Lüfter auf 15% ab dem 2. Layer.

Das Resultat müsste demnach besser werden.Ich habe mir einige Videos zu dem Polymaker ASA angesehen und dort hatte niemand solche Probleme mit dem Filament wie Du sie hast.

Polymaker ist für mich einer der besten Filament Hersteller dieser Welt, daher kann ich es nicht glauben dass sie so ein Schrott-Filament auf dem Markt gebracht haben sollen.

Ich selber habe kein ASA von Polymaker, aber dafür andere Kunststoffe und alle sind absolut top. -

Happy to update (click to see the GIF):

Printing settings:

- Polymaker ASA @240°c

- Bed at 75°c

- Chamber still heated up to ~50°c (It's passively heated by the giant bed, not much I can do to reduce it)

- Fan at 15% for the entire print, except the first 4 layers

Results:

- Perfectly straight pulley teeth

- Slight deformation on the bottom pulley wall (touching the bed), I think I need to enable cooling there as well, just a bit.

I would like to thank everyone here for your help, it's been amazingly helpful to have so many experienced people chime in and help me improve my printer and my my understanding.

Though the main culprit turned out to be simply a overly hot print bed, I also improved the way I calibrate my printer and removed a different error I have had for years.

Special shoutout to @Norder and @alankilian! Thanks so much!

-

@leav

Great... congratulations.

This problem was somehow exciting, so you wanted to know what the problem was.

So the filament didn't contract, it just melted and the walls collapsed.That it shrinks in the middle and not at the top and bottom... that didn't fit together.

If a filament were to shrink so extremely, it would detach from the print bed very quickly.

This is why some nylon (PA) and polycarbonate (PC) filaments etc. are so difficult to print because they contract and loosen on the print bed.If you have new filaments, focus primarily on the temperatures specified by the manufacturer.

Then print a heat tower to determine the ideal temperature for this particular spool of filament.

To adjust this filament even more precisely...

Determine the perfect flow, measure the diameter of the filament, measure the thickness of the printed walls, etc pp.And if you really want to know

then a shrinkage test print would be the order of the day, simply print a 5mm -10mm high cross in the X-Y direction, which you can still measure with your caliper, i.e. 100mm to 150mm length of the struts.

then a shrinkage test print would be the order of the day, simply print a 5mm -10mm high cross in the X-Y direction, which you can still measure with your caliper, i.e. 100mm to 150mm length of the struts.

Remove the finished printed cross from the print bed and let it cool down completely to room temperature !!! and then measure the difference and then enter it in the slicer so that the next print is printed "larger" by this value in order to obtain dimensionally accurate printed parts.

But I only do that if the dimensions of the component are important and you might be building different printed plastics and other materials together.

Otherwise I omit the specification in the slicer, since it is generally only a few tenths of a millimeter (depending on the size of the printed part and the type of filament).

In the slicer (PrusaSlicer) I have a page for comments for each filament, where I write down the values to transfer them to the slicer if necessary so that they are calculated.An example: ABS-X from Minadax (one of my favorites) I would have to slice at 100.5% magnification to get exact prints.

The ASA+ from PrimaSelect, which I mentioned and linked here, would have to be printed with 100.7% oversize.All these tests should be done with every filament, even an ABS from company A is different from an ABS from company B.

Maybe this information will help you to have more fun and less trouble with 3D printing in the future!?It would be great if you could send one last photo.

Maybe even a cog with the problem and a current cog next to it.

I would be interested in the end result, because the GIF doesn't show how well the print has become.

The top should also be visible.

Thanks !Sorry for the long text... I often write entire novels... one of my problems

Google Translate

--- Original Text ---Super... Gratuliere.

Dieses Problem war schon irgendwie spannend, da wollte man wissen woran es nun gelegen hat.

Das Filament hat sich also nicht zusammengezogen sondern es ist schlichtweg geschmolzen und die Wände sind eingestürzt.Das es sich in der Mitte schrumpft und Oben und Unten nicht... dass passte nicht zusammen.

Wenn ein Filament so extrem schrumpfen würde, dann würde es sich sehr schnell vom Druckbett lösen.

Deswegen sind manche Nylon (PA) und Polycarbonat (PC) Filamente etc. so schwer zu drucken, weil sie sich auf dem Druckbett zusammen ziehen und sich lösen.Wenn Du neue Filamente hast, richte Dich in erster Linie an die Temperaturen die der Hersteller vorgegeben hat.

Dann drucke einen Heattower um die ideale Temperatur für speziell diese Filamentrolle zu ermitteln.

Um dieses Filament noch genauer einzustellen...

Ermittle den perfekten Fluss, mit Filament-Durchmesser messen, die Stärke der gedruckten Wände messen etc pp.Und wenn Du es dann wirklich wissen willst

dann wäre ein Schrumpf-Testdruck angesagt, dazu einfach ein 5mm -10mm hohes Kreuz in X-Y Richtung drucken, welches Du mit Deinem Messschieber noch messen kannst, also 100mm bis 150mm länge der Streben.

dann wäre ein Schrumpf-Testdruck angesagt, dazu einfach ein 5mm -10mm hohes Kreuz in X-Y Richtung drucken, welches Du mit Deinem Messschieber noch messen kannst, also 100mm bis 150mm länge der Streben.

Löse das fertig gedruckte Kreuz vom Druckbett und lasse es komplett auf Raumtemperatur abkühlen !!! und messe dann die Differenz und trage sie dann im Slicer ein damit der nächste Druck um diesen Wert "größer" gedruckt wird, um masshaltige Druckteile zu erhalten.

Das mache ich aber nur, wenn die Maße des Bauteils wichtig sind und man ggf verschiedene gedruckte Kunststoffe und andere Materialien zusammen baut.

Ansonsten lasse ich die Angabe im Slicer weg, da es im Allgemeinen nur wenige Zehntel-Millimeter sind (Je nach Größe des Druckteils und Art des Filaments).

Im Slicer (PrusaSlicer) habe ich für jedes Filament eine Seite für Anmerkungen, dort notiere ich die Werte um sie bei Bedarf im Slicer zu übertragen damit sie mit berechnet werden.Ein Beispiel: ABS-X von Minadax (einer meiner Favoriten) müsste ich mit 100,5% Vergrößerung slicen um exakte Ausdrucke zu erhalten.

Das ASA+ von PrimaSelect, welches ich hier mal erwähnt und verlinkt hatte, müsste mit 100,7% Übergröße gedruckt werden.Diese ganzen Tests sollte man bei jedem Filament machen, selbst ein ABS von Firma A ist anders wie ein ABS von Firma B.

Vielleicht helfen Dir diese Infos um in Zukunft mehr Spaß und weniger Ärger beim 3D-Druck zu haben !?Es wäre toll wenn Du noch ein letztes Foto schicken könntest.

Vielleicht sogar ein Zahnrad mit dem Problem und ein aktuelles Zahnrad daneben.

Mich würde das End-Resultat interessieren, denn in dem GIF ist es nicht so gut zu erkennen wie gut der Druck jetzt geworden ist.

Die Oberseite sollte auch zu sehen sein.

Danke !Sorry für den langen Text... ich schreibe oft ganze Romane... einer meiner Probleme

-

Addendum

I have a 20mm x 20mm test cube here with four walls of different thickness.

0.4mm, 0.8mm, 1.2mm and 1.6mm thickness.

With this you can quickly determine the flow or balance your own values in terms of stability and accuracy.I had forgotten... you should also determine your own pressure advance value for each filament.

I'm sure I've forgotten something... that's how it is with age.

Unfortunately, it was not possible to upload a 3mf version, so it became a binary stl.

I hope you can do something with it and that it helps you.

(see link below)Google Translate

--- Original Text ---Nachtrag

Ich habe hier mal ein 20mm x 20mm Testwürfel mit vier unterschiedlichen dicken Wänden.

0,4mm, 0,8mm, 1,2mm und 1,6mm Stärke.

Damit kann man schnell mal den Fluss ermitteln bzw seine eigenen Werte ausbalancieren was Stabilität und Genauigkeit angeht.Ich hatte noch vergessen... man sollte für jedes Filament auch seinen eigenen Pressure Advance Wert ermitteln.

Ich habe garantiert noch etwas vergessen... so ist das mit dem Alter.

Eine 3mf Version hochzuladen, das ging leider nicht, also ist es ein binäres stl geworden.

Ich hoffe ihr könnt damit etwas anfangen und es hilft euch weiter. -

@leav

It still puzzles me, why it was able to collaps at 100% infill? But I'm glad you found a solution.