M308 ADC Tuning Issue

-

@os1r1s The Blackbox looks like an interesting build!

I assume you are doing the semi-automatic calibration as explained here https://docs.duet3d.com/User_manual/Connecting_hardware/Temperature_connecting_thermistors_PT1000#semi-automatic-calibration? I can't see anything obviously amiss in your config.g.

If it is limited to the second tool, and causes the same issue no matter what temperature input it is connected to, it sounds like it may be more of a wiring issue. I checked with @dc42, and he suggested it might be one of the other connected temperature sensors that has an intermittent connection or short. Test by removing all temperature sensors on the thermistor ports, and tune the ADCs again individually. Or you could remove them individually during the second (L999) phase, and see if removing them causes the values to stabilise.

Ian

-

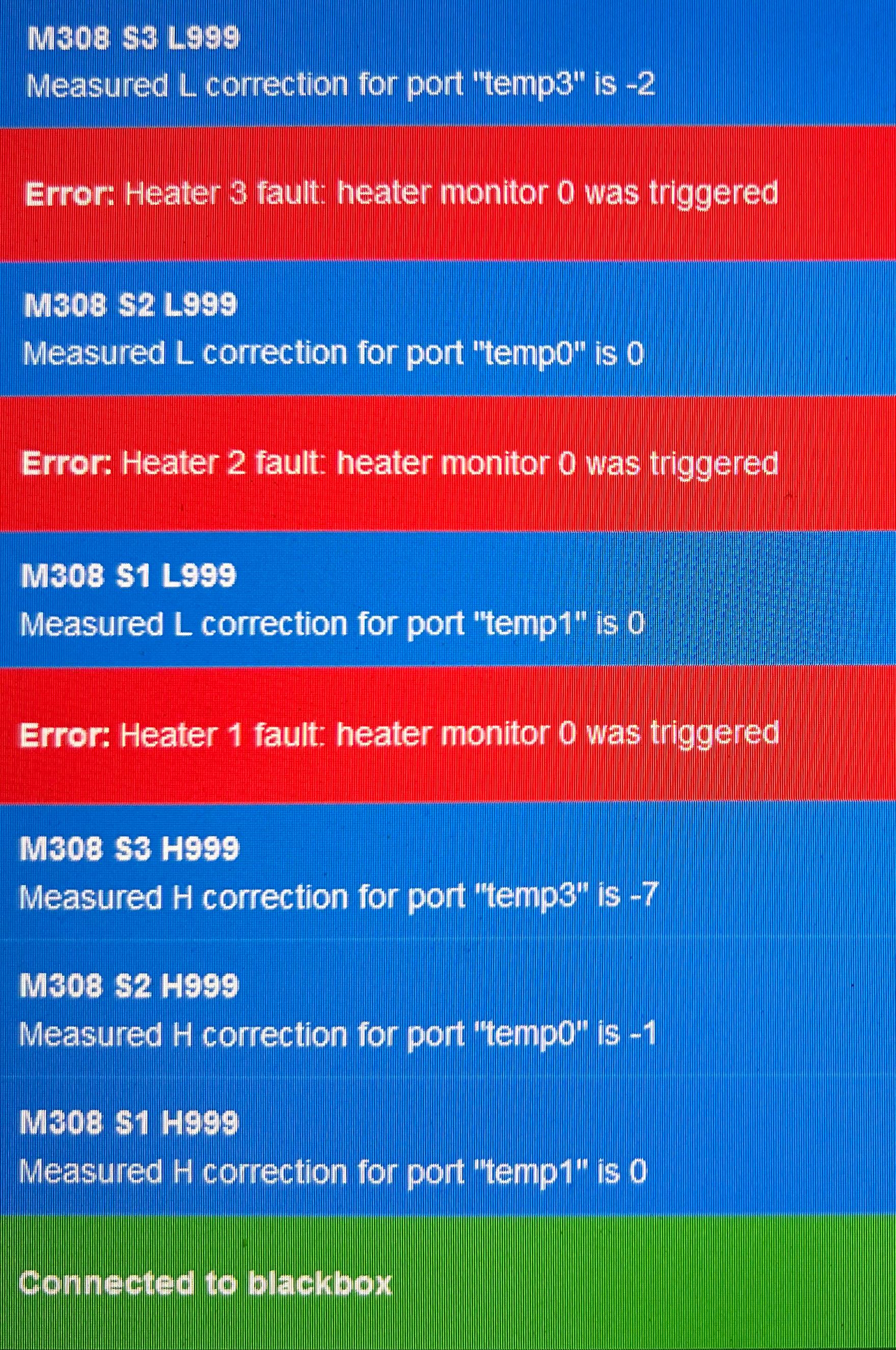

I removed the three thermistors plugged into temp1, temp0, and temp3 respectively (s1,s2,s3). Now it appears S1 and S2 are erratic. Keep in mind it is only erratic with the jumper. The normal temp seems relatively stable. Will post a picture I a bit.

-

@droftarts The blackbox has a bit of everything ... multiple hot ends, water cooling, a counterweighted bed, etc, etc. Its a bit of a crazy printer. I look forward to having it all working.

I am doing the calibration from that page. I made a short jumper (50mm) with a connector on it to do this calibration. It seems to be getting worse the more I do it. Is there a way to extract the values that M308 sets through the calibration? I'd like to view what the ones that are working properly are set to. Yesterday I reverted the 6hc and 3hc to firmware version 3.3 to see if that changed anything. It was before my test this morning with all unplugged.

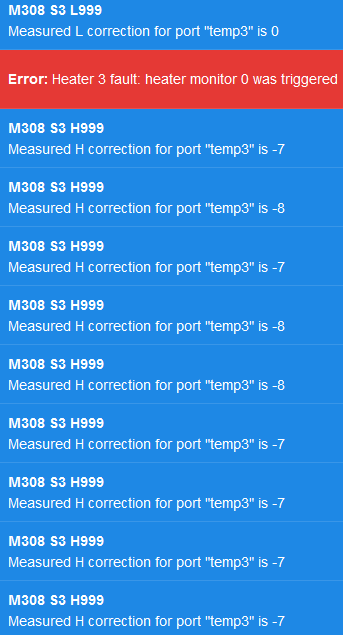

Below you can see the output in DWC of the tuning of the three thermistors plugged into the 6hc. What led me to this was chasing down some jamming that I was seeing when extruding. Filament from one nozzle drooled out while another came out more begrudgingly. I thought it prudent to set reset these. All 5 nozzles are E3D v6 with the standard thermistor and the 30w heat cartridge.

-

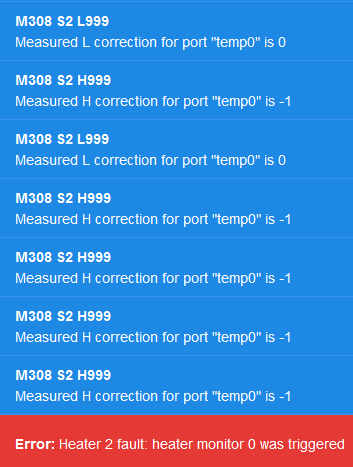

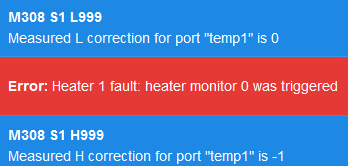

@os1r1s it looks like temp0 and temp1 are consistent (being different by 1 is not unexpected), but temp3 is not. How much does it vary if you run M308 S3 H999 multiple times?

-

@dc42 Thank you. I'll try running it multiple times in a row when I get home. To be clear, do you just want me to run the H999 phase or or both phases sequentially?

Also to be clear, when it is jumpered, should I expect the value to jump/be erratic? Or should I expect it just to show 2000? On some of ports on my 6hc and all the ports on my 3hc, they all show 2000 when jumpered. Is it possible that it is writing a value during the calibration that is then causing erratic readings when jumpered?

Is there a way to get from the firmware what the calibration value was set to via the M308 H/L command?

-

@os1r1s said in M308 ADC Tuning Issue:

I made a short jumper (50mm) with a connector on it to do this calibration.

Really, I'd use a proper jumper; there's usually at least one spare one you can use off the board, and I think the board is supplied with a couple. If the readings are moving around only when you use this jumper wire, I'd anticipate it has a poor connection/crimp somewhere.

Ian

-

@os1r1s said in M308 ADC Tuning Issue:

@dc42 Thank you. I'll try running it multiple times in a row when I get home. To be clear, do you just want me to run the H999 phase or or both phases sequentially?

Just the H999 phase, assuming the L999 phase gives consistent values (i.e. changing by no more than 1).

Also to be clear, when it is jumpered, should I expect the value to jump/be erratic?

If the H999 calibration has been done, it should show 2000. If the H999 calibration has not been done correctly, it might not.

Is there a way to get from the firmware what the calibration value was set to via the M308 H/L command?

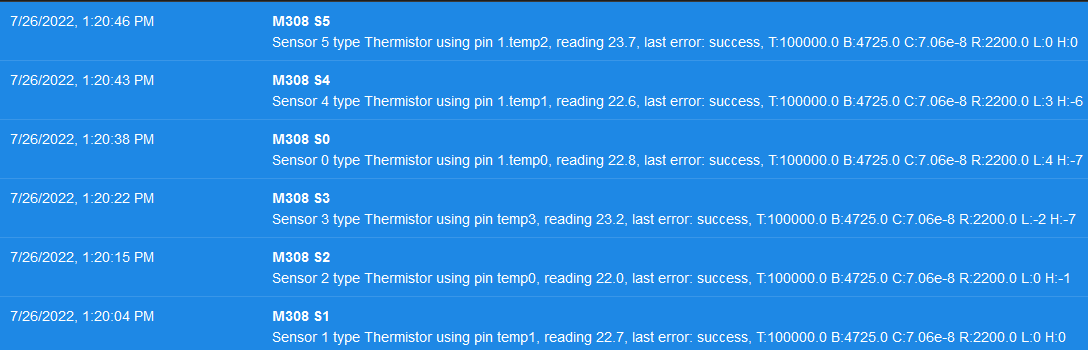

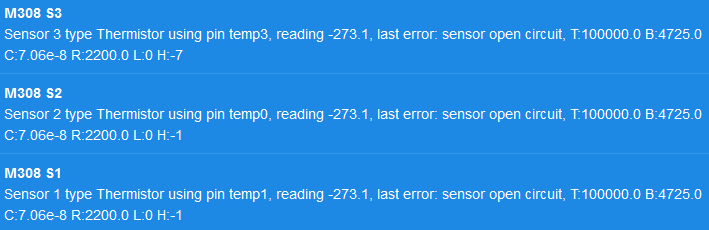

Yes, send M308 S# where # is the sensor number. The L and H values in use are displayed at the end of the reply.

-

@dc42 Here is a screenshot of running through all the temp sensors associated with thermistors. (S1,S2,S3 all on the 6HC, S0,S4,S5 on the 3HC) I will do the repeat test when I get home later today.

-

@droftarts Can you just use a normal 2 pin jumper on those ports? For some reason I thought it would not fit and therefore created one.

-

@os1r1s said in M308 ADC Tuning Issue:

@droftarts Can you just use a normal 2 pin jumper on those ports? For some reason I thought it would not fit and therefore created one.

Yes, just quickly checked!

Ian

-

@dc42 Here they are as requested. I used a normal pin jumper this time. I noticed that all three are now jumping when jumpered, but S3 is jumping once every 20-30 seconds vs every 4-5 on the others.

-

I just put a duet6hc from another printer I have in this one and it does the exact same thing. The L and H are different, but the 2000 is hopping all over the place. The duet3hc is unplugged so that I can see if the can connection is doing anything. Now I'm going to take it out of SBC mode and see if that changes anything.

-

I removed the SBC from the system and it still does the same thing.

I reverted the firmware to 3.2 and it still does the same thing.

To recap, I've tested this on two different 6hcs, 3.2, 3.3, and 3.4.1 versions of the firmware, with/without the SBC, with/without the 3HC connected. I'm at a loss here ...

Does anyone else calibrate their ADCs?

-

Last update for the night. I found a 100k resistor and a 220 ohm resistor in my cabinet. I went through and calibrated each temp port following the doc page. Below are the values I got. Now when I jumper the temp port it gives me a reading around 700C. I assume this is ok to proceed. All of the temps now are accurate at least to room temp. If there is anything else that you think I should do before running up the heaters, please let me know.

M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 H-15 L-8

M950 H1 C"out1" T1

M307 H1 B0 S1.00

M143 H1 S280M308 S2 P"temp0" Y"thermistor" T100000 B4725 C7.060000e-8 H-15 L-8

M950 H2 C"out2" T2

M307 H2 B0 S1.00

M143 H2 S280M308 S3 P"temp3" Y"thermistor" T100000 B4725 C7.060000e-8 H-8 L-5

M950 H3 C"out3" T3

M307 H3 B0 S1.00

M143 H3 S280M308 S0 P"1.temp0" Y"thermistor" T100000 B4725 C7.060000e-8 H-6 L-5

M950 H0 C"1.out0" T0 Q50

M307 H0 B1 S1.00

M140 H0

M143 H0 S100M308 S4 P"1.temp1" Y"thermistor" T100000 B4725 C7.060000e-8 H-6 L-5

M950 H4 C"1.out1" T4

M307 H4 B0 S1.00

M143 H4 S280M308 S5 P"1.temp2" Y"thermistor" T100000 B4725 C7.060000e-8 H-6 L-5

M950 H5 C"1.out2" T5

M307 H5 B0 S1.00

M143 H5 S280 -

@dc42 @droftarts Any additional thoughts on this? Using the manual process seems to have worked, but I am concerned about not being able to use the semi-automatic method.