Compatible Layer Heights

-

Having a bit of z banding on the Duet 2 Wifi DBot re-build and I think it's mostly related to a bent lead screw but it's got me thinking. Which layer heights are compatible with my setup? I think it's anything that's divisible by 3 wouldn't require microstepping, but unfortunately I can't find anything definitive on it.

I'm using the 3 lead screw 1 stepper setup with T8x2 lead screws (single start, 2mm per revolution).

Z stepper has 20t pulley

Driven pulleys on the lead screws are 60t pulleys.Thanks in advance for any help.

This is my config:

M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Big-Boy" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S0 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 F1 P0 ; TOFF Adjustment M569 F1 P1 ; TOFF Adjustment M569 F2 P2 ; TOFF Adjustment M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z4800.00 E400.00 ; set steps per mm M566 X600.00 Y600.00 Z30.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) - Jerk M203 X60000.00 Y60000.00 Z250.00 E5000.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z250.00 E3000.00 ; set accelerations (mm/s^2) M906 X1700 Y1700 Z1700 E600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X380 Y390 Z700 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin !xstop M574 Y2 S1 P"!ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin !ystop M574 Z1 S1 P"!zstop" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin !zstop ; Z-Probe ;M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed ;M557 X15:0 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 R0.559 K0.372:0.000 D4.69 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 R2.385 K0.403:0.338 D4.62 E1.35 S1.00 B0 V24.7; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; select Tool 0 ; Custom settings are not defined M308 S10 Y"mcu-temp" A"MCU" ; defines sensor 10 as MCU temperature sensor M308 S11 Y"drivers" A"Duet stepper drivers" ; defines sensor 11 as stepper driver temperature sensor M308 S12 Y"drivers-duex" A"Duex stepper drivers" ; for Duet 2 WiFi/Ethernet with DueX2/5, defines sensor 12 as DueX2/5 stepper driver temps -

undefined imadunatic marked this topic as a question

undefined imadunatic marked this topic as a question

-

Let's do the math.

The steppers are likely 200 full steps per revolution.

Given the pulleys, 600 full steps will produce one revolution of the lead screw, yielding 2mm advance.

If printing at 0.4mm layer height, 120 full steps will produce the required 0.4mm advance.

If printing at 0.3mm layer height, 90 full steps will produce the required 0.3mm advance.

If printing at 0.2mm layer height, 60 full steps will produce the required 0.2mm advance.

If printing at 0.1mm layer height, 30 full steps will produce the required 0.1mm advance.

For micro-stepping just do the multiplication.

You are in good shape for printing at all the most common layer heights.

It's late and I am short on sleep - I hope I've done the math correctly.

Frederick

-

@imadunatic A simplified version of what @fcwilt has said .. .. with your 3:1 gearing, you have 300 full steps per mm, which is 30 full steps per 0.1mm which is 3 full steps per 0 01mm. So you can use any layer height to two decimal places without having to rely on micro-stepping for positional accuracy. The layer height would only need to be divisible by 3 if you went to 3 decimal places (please tell me you are not trying to do that).

-

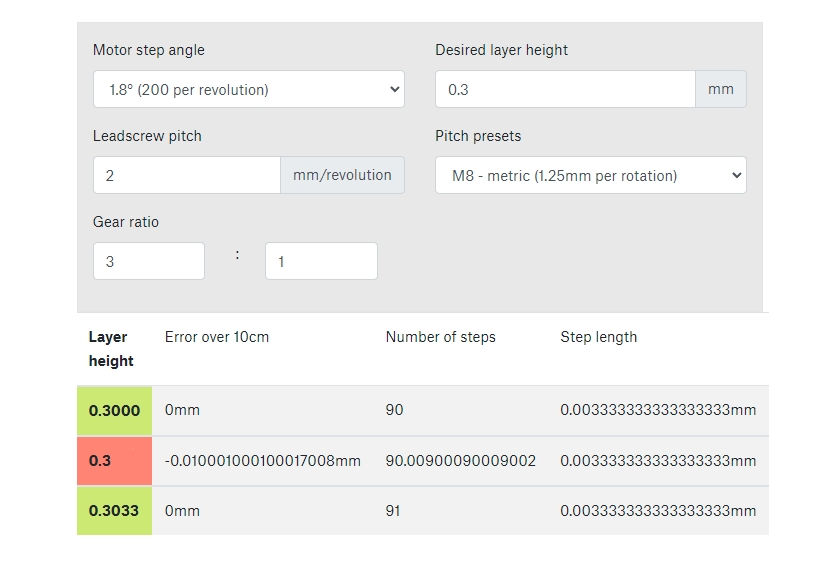

Thanks for the help! I thought this was too simple since the reprap calculator gave some funk-o answers but it makes sense if you forget about the calculator. I will base my profiles around tenths of a mm and forget about it.

@deckingman said in Compatible Layer Heights:

The layer height would only need to be divisible by 3 if you went to 3 decimal places (please tell me you are not trying to do that).

Definitely not going to 3 decimal places. I'm not pushing anywhere near the amount of plastic you are, but all of my tuning is being done with a .8mm nozzle because this printer will mostly be for larger prints and time is of the essence on a 2 day print!

-

undefined imadunatic has marked this topic as solved

undefined imadunatic has marked this topic as solved

-

@imadunatic Yes forget that calculator - something very weird going on with the second row of figures (1 decimal place). The other thing I hate about it is that it mentions "pitch", rather than "lead". For a single start thread, that's OK but if you had a 2 start 8mm x 2mm pitch screw, the lead would be 4mm and that's the value that you would have to use rather than the pitch.

Most people don't know the difference between pitch and lead but it's really, really important. You might find this video that I made some time back interesting https://www.youtube.com/watch?v=o_0xdrKUYVU