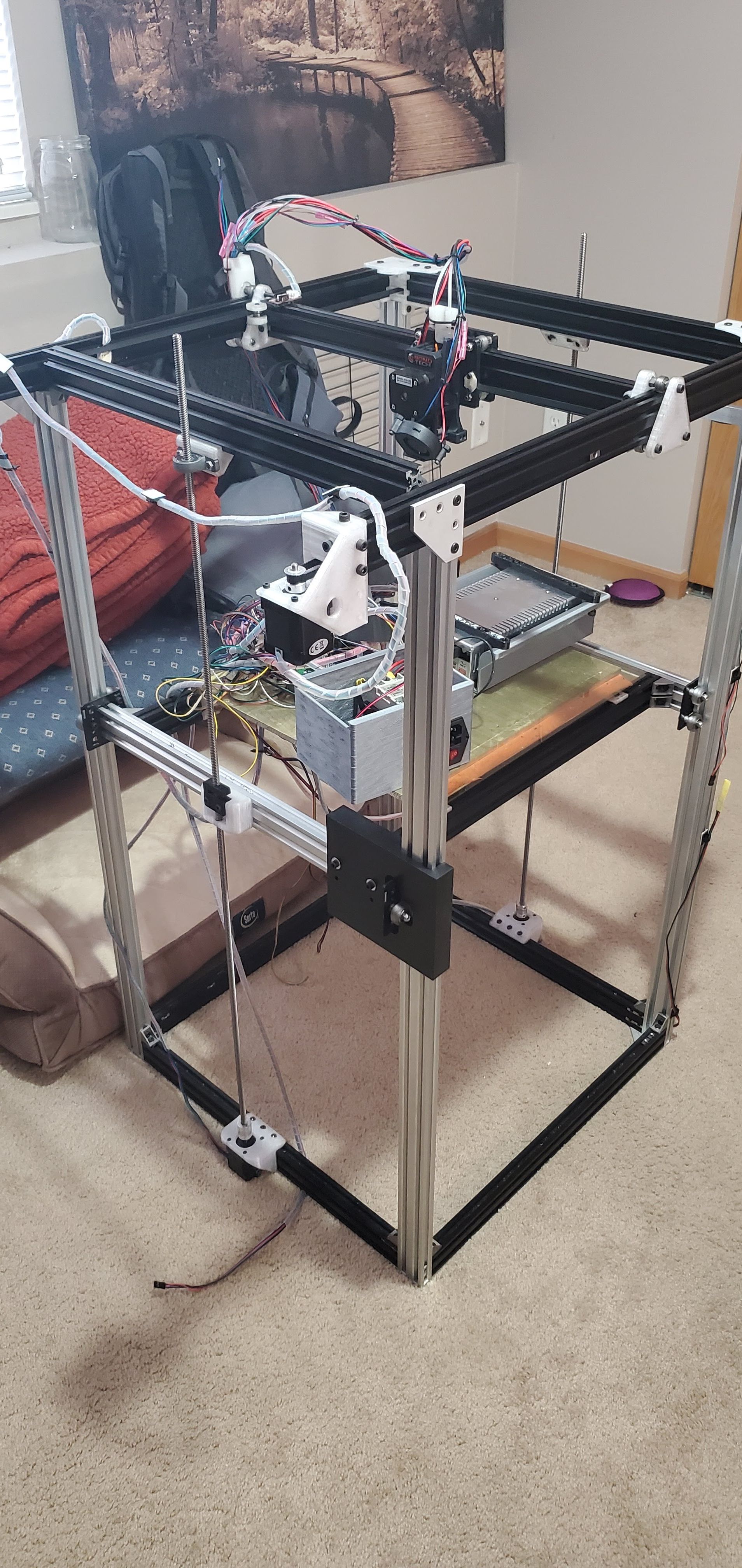

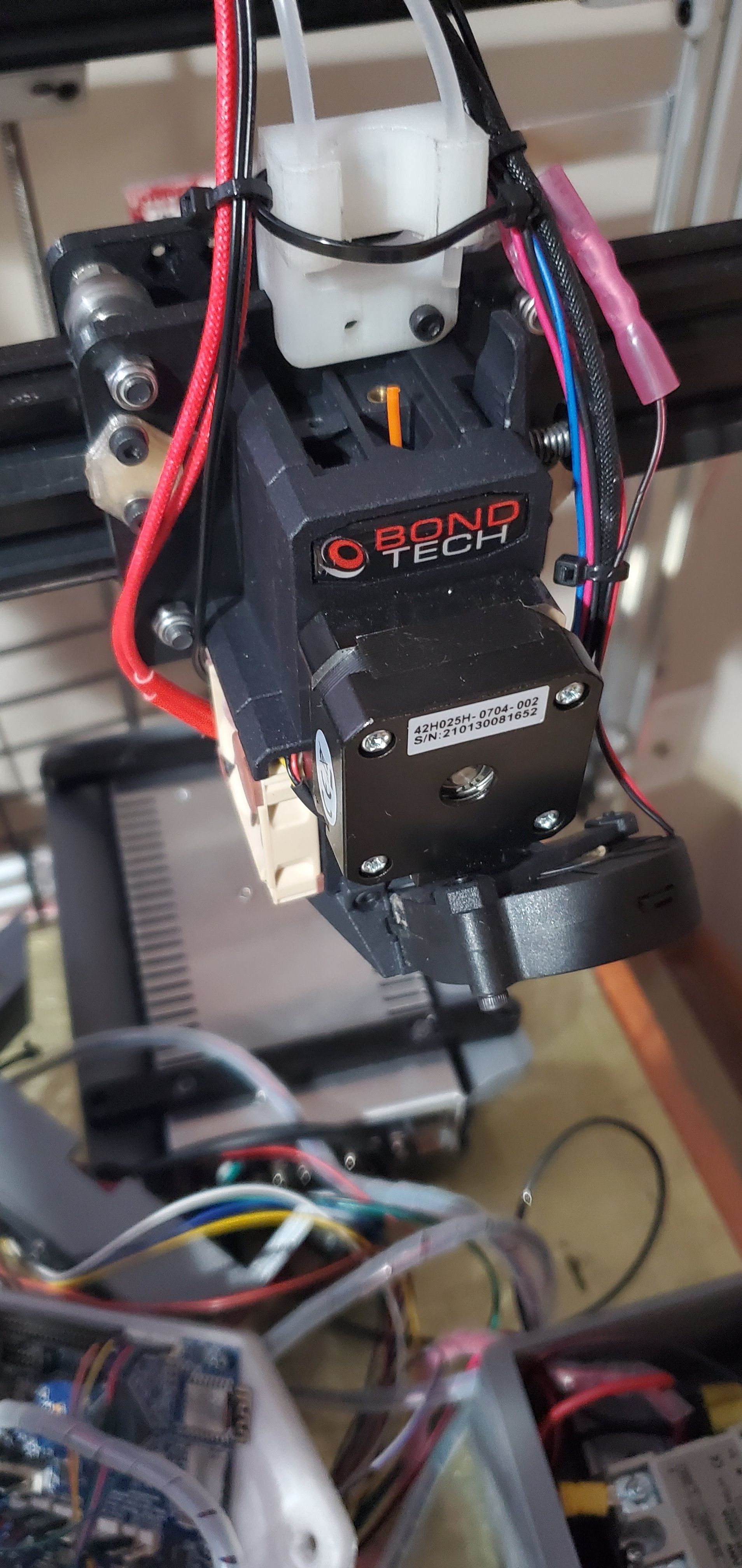

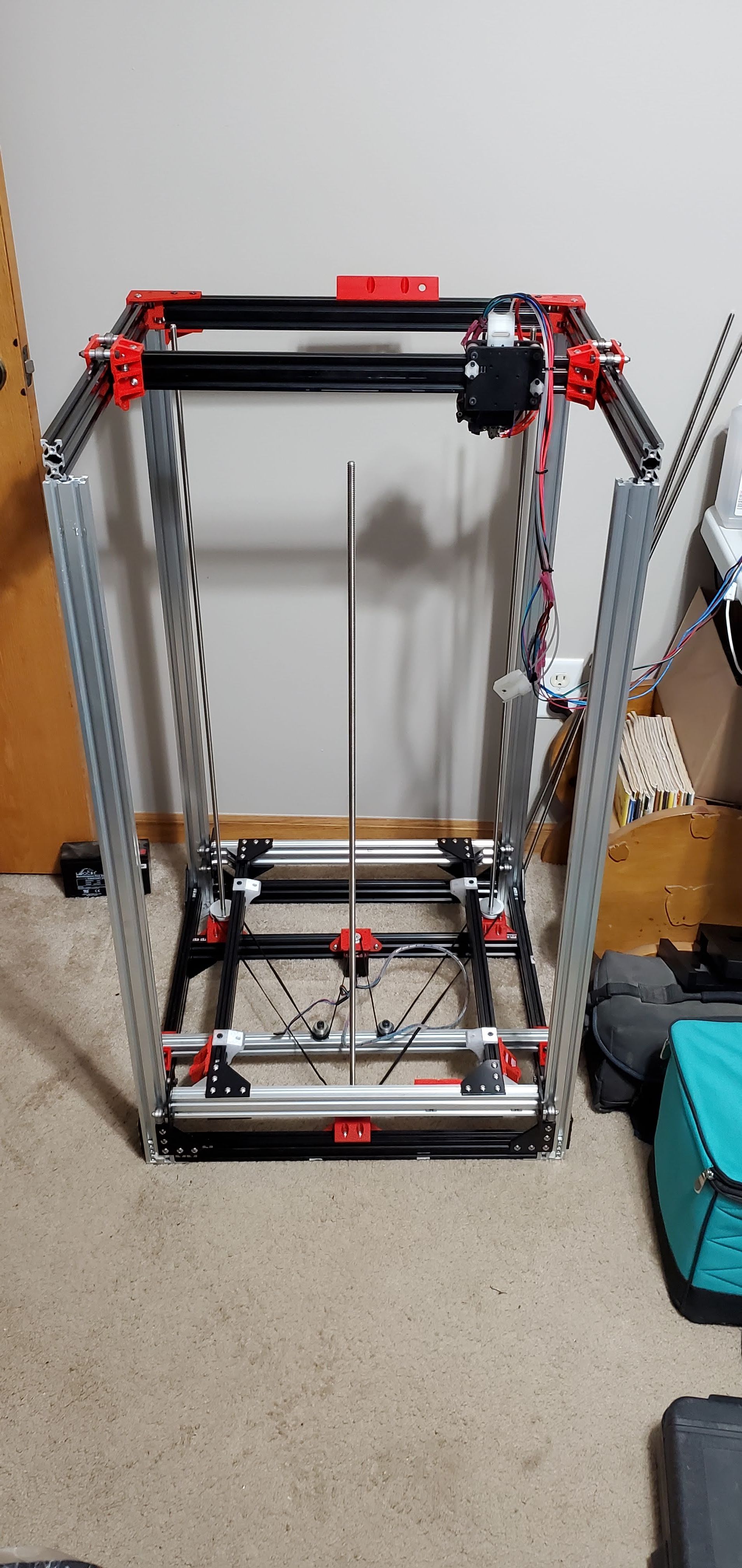

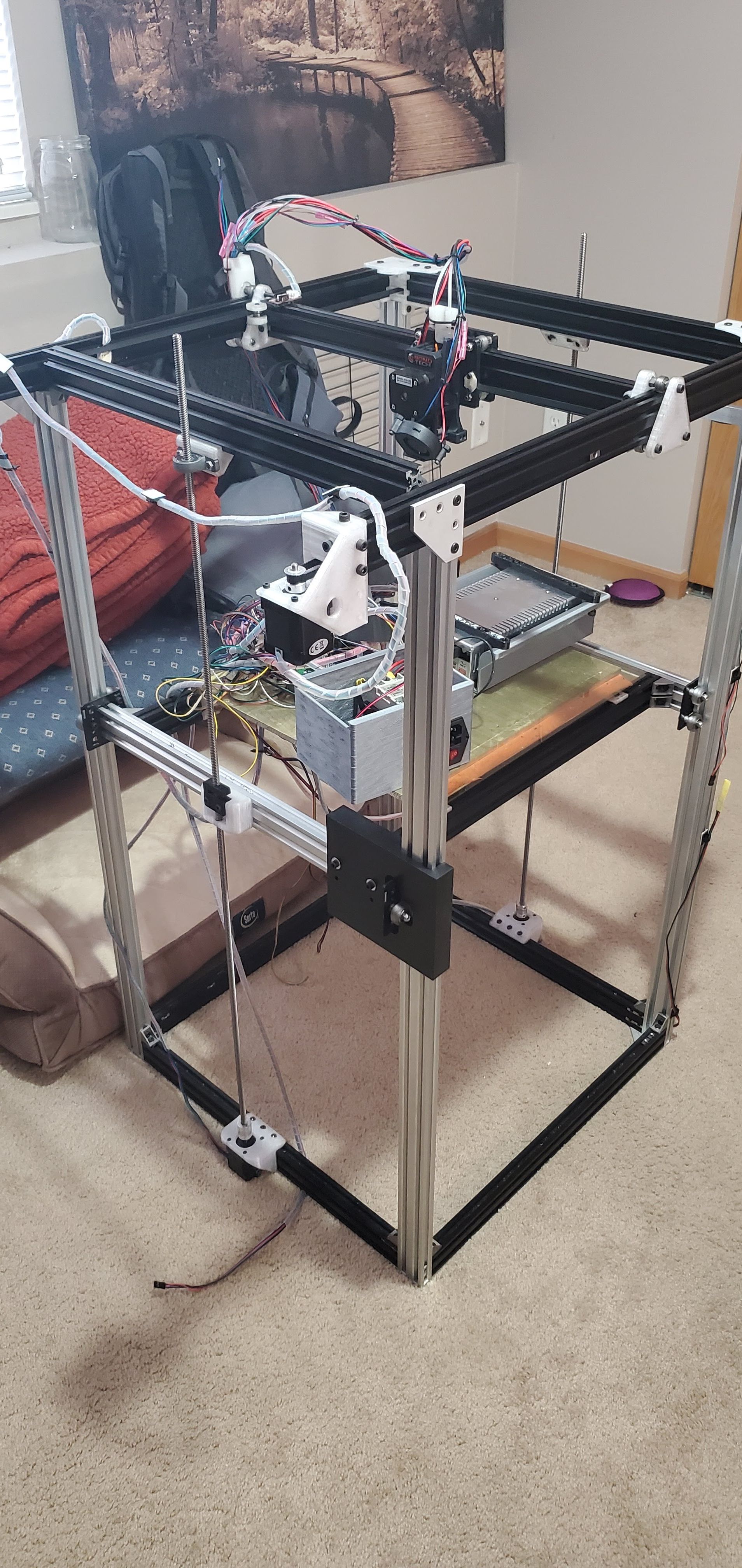

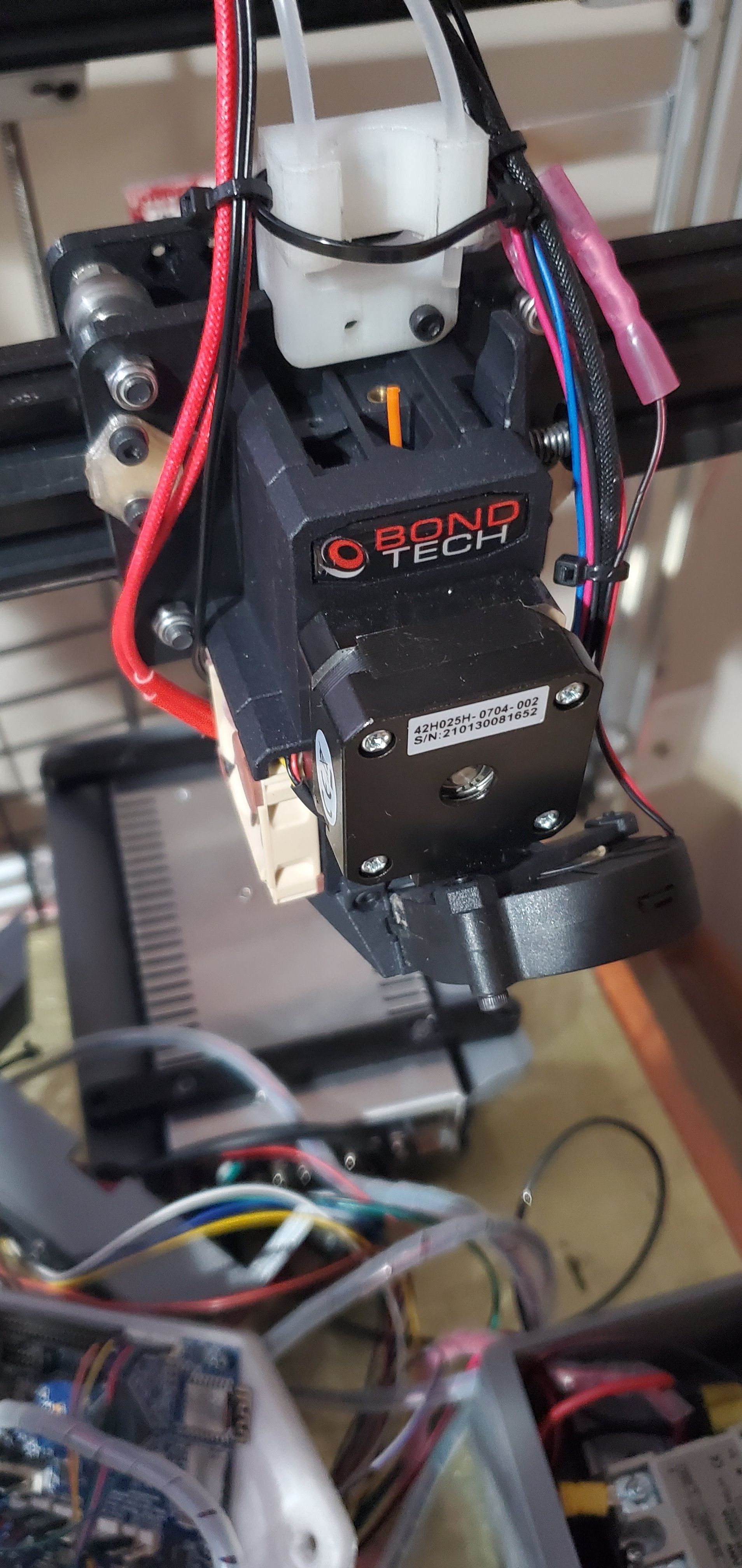

Long story short this printer started life about 4 years ago with our old 3DP manager, he never really finished it, the guys that took over the department toiled about 500 hours into it, bought a beautiful bond tech extruder and mosquito magnum hot end and never got it to print reliably. I picked it up for way less than a trip to the grocery store ("for parts") and originally had visions of pulling all the best components off for a voron build and leaving it's skeletal remains. But the last 2 weeks of research now has me pointed pointed me to saving this big boy (once I figured out where the inspiration for it's design came from) and trying to root cause it's issues.

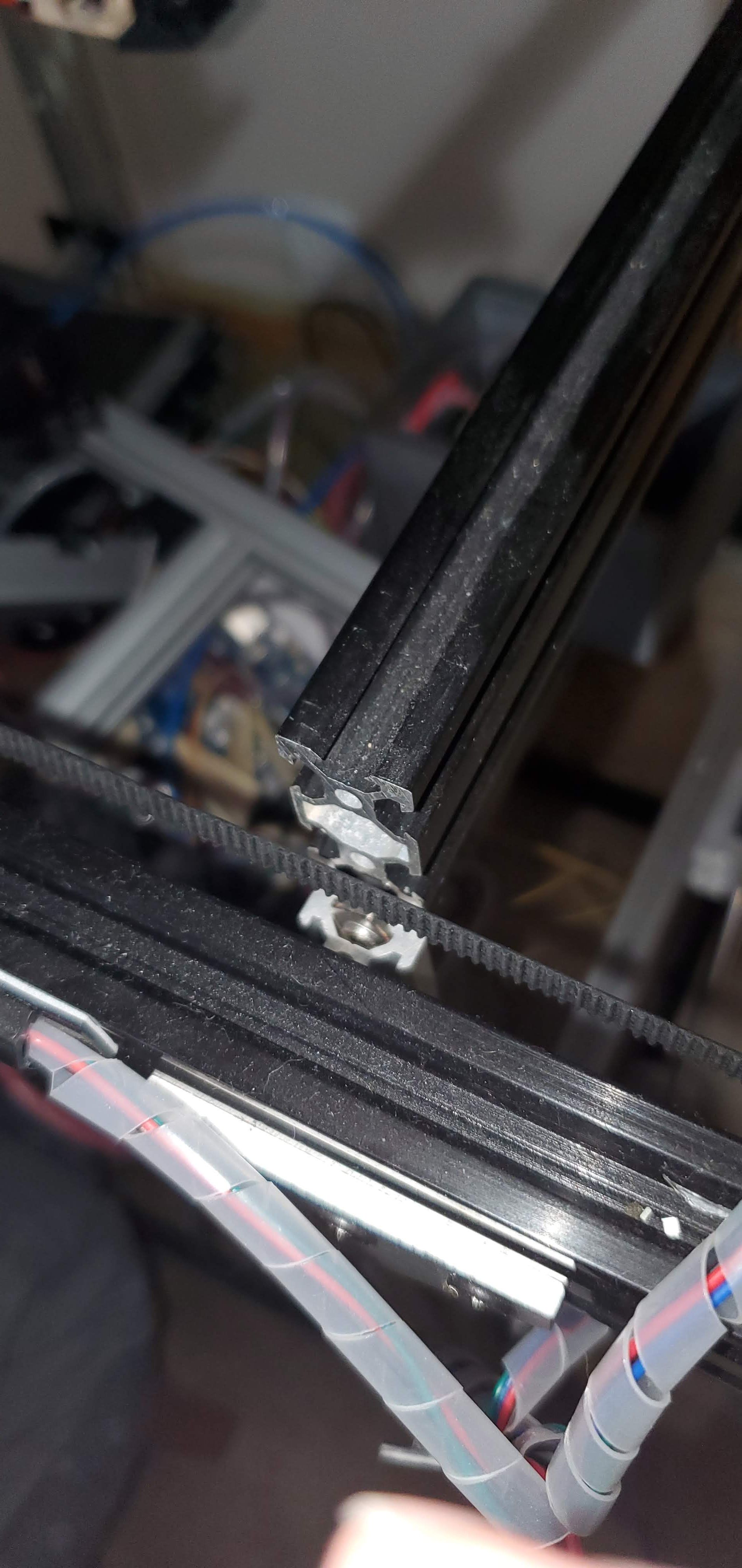

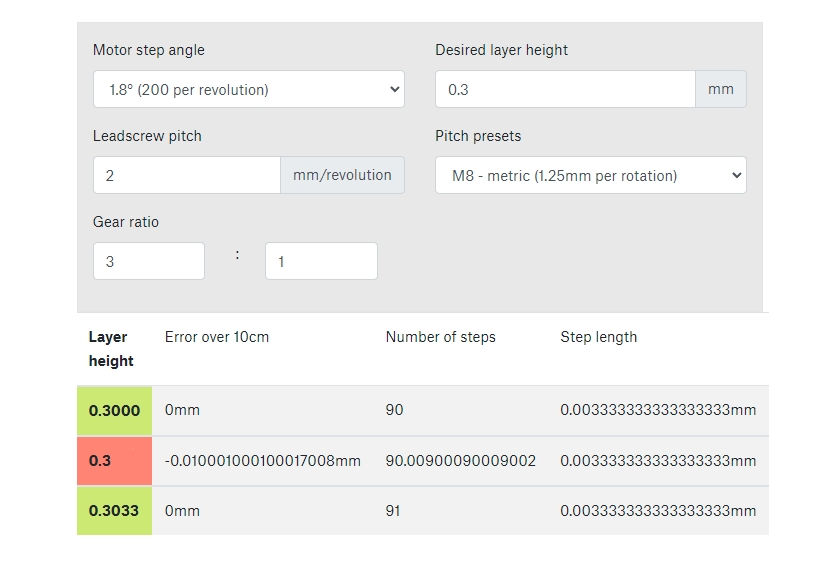

I'm brand new to these printers, but my first thought is that the Z is too tall to every be reliable. The bug that they never figured out was at some point the printer would either skip a step or the extruder would slip and it would make the best looking bowl of spaghetti you've ever seen over night. My assumption is that at this point, the extruder should be reasonably reliable with this set up, but I'm not sure the best way to monitor or debug this particular problem. I'm thinking of setting up a longer print, affix a dial indicator to the frame in view of a camera to monitor the Z movements and just let it run. When it starts making spaghetti, I can review the footage and see if I can pick up any sort of skip, stall etc. But I'm open to ideas and asking for any help anyone can provide.

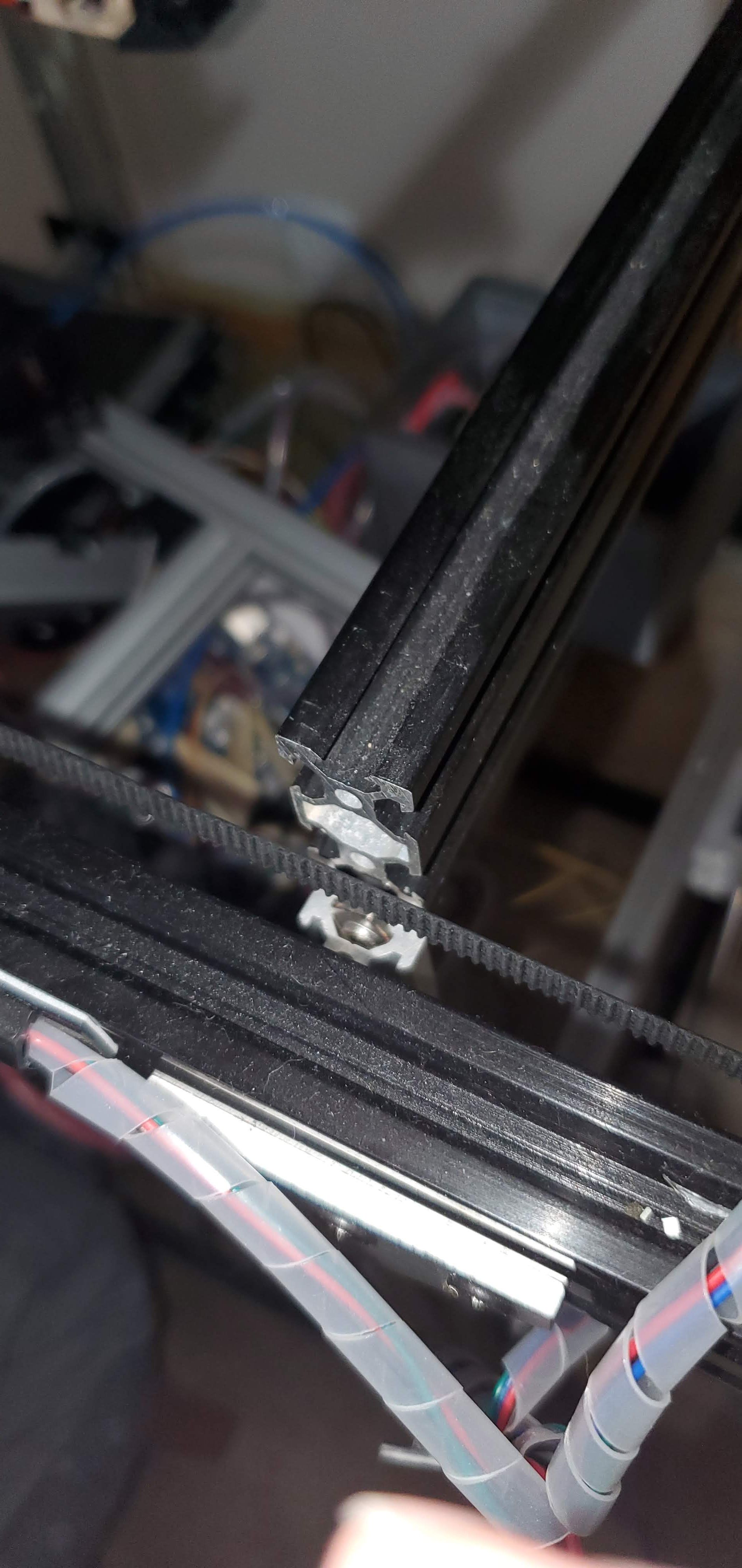

TLDR; I think this beast can be saved. My first thought is halve the Z height (unless I can get it running as is), add a 3rd lead screw (ala Phaedrux 3 screw mod) and possibly redo the wheel mounts with the 3 wheel mods that seem to be very popular.