E3D Toolchanger Issue, Print Shift Artifacts

-

Hi, it's a bit of a strech to post this here I'll be honest. But this is the forum I've had the most luck with in the past.

I'm getting unusable prints out of my machine as of late, so far I've had no luck at all in figuring out what's wrong.

Before looking at what I've tried, so as to not prejudice potential new ideas/poison the well. Take a gander at these images.

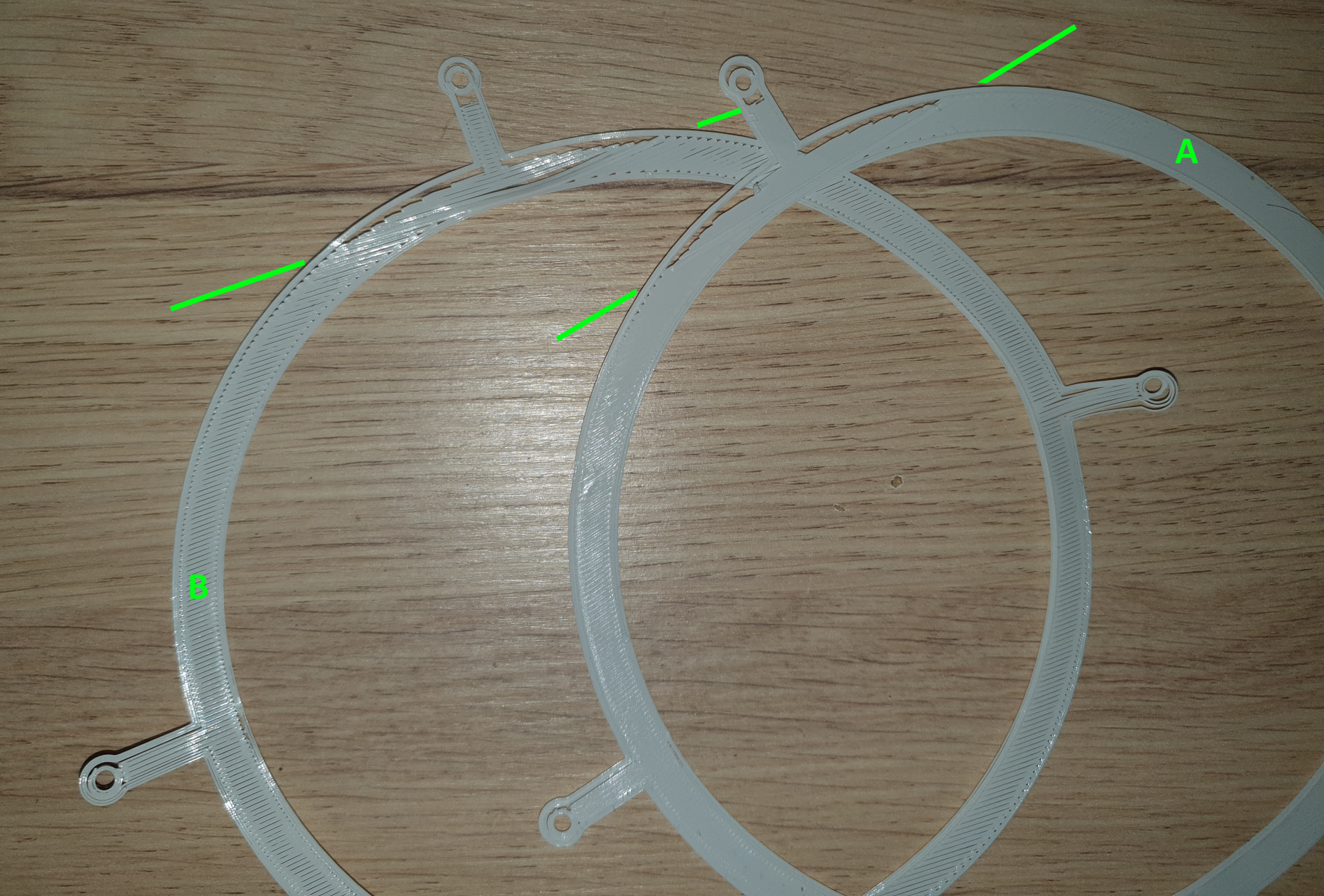

Simplified Test Print, section with green line is shifted. As is the circular mount hole, which should have been concentric.

Back and front of original part.

Macro shots.

Macro shot, different tool. Different polymer.

The Machine: 2019 E3D toolchanger, running Duet 2 Wifi + Duex 5, RRF3.4.

I rebuilt all the tools and updated the firmware in January this year, but it's been seemingly working fine.

Machine Troubleshooting:

- Checked bed is secure.

- Checked wiring harness doesn't impinge on tool causing a deflection.

- Checked no play in tool itself.

- Checked no obstructions in belt path.

- Checked no obvious wear on belts.

- Checked x-gantry is square to within the best tolerances of my measuring tools.

- Cleaned x-rail with alchohol to clean dust and... 'seasoned' with some silicone lubricant.

- Increased belt tension*[1]

*[1] - bit of a shot in the dark, wanted to see if I got any result. Not really. It did seem to do something,

Firmware Troubleshooting:

- Updated from RRF3.3 to 3.4

- Reduced max accel, jerk, and motor speeds back to what I used to have in my archieved RRF2.x config the machine originally shipped with.

Slicer Troubleshooting:

- Reduced Speeds

- Tried a different tool.

- Disabled z-hop for retraction. (noticed the issue in the basic test was occuring after a large move with retraction/z-hop)

Any ideas?

-

Loose grub screw on a motor pulley maybe?

-

@andywm I have had this problem also. It was based on the nozzle and/or tool being loose. If everything, including the nozzle / heating element/ heat break does not flex at printing temperature, check to see if the tool is being held securely by the tool head. The insert in the tool plate should be seated firmly. The small stepper that rotates the retaining pin may not be rotating far enough to retain the tool securely; it can rotate further than the original firmware written by e3d ( not a lot, but enough to possibly hold the tool more firmly.

FWIW - I noticed that you used silicone lubricant on the rail. This is not what e3d recommends; they use "Magnalube-G". Whichever lubricant you use, it's important that the little ball bearings roll (and circulate) and not slide on the rail. If they slide, they can develop flat spots.

BTW, which tool are you using?

Also, check out the posting on skewed prints on corexy.

https://forum.duet3d.com/topic/13397/skewed-prints-on-corexy -

Fair on the lubricant I'll buy a suitable one. It's just all I had on hand at the time.

All my tools are currently the Hemera tool, which is something I only did a few months ago. I didn't notice any play when testing that, but actually on this specific tool the press fit insert in the tool block did fall out once... I should possibly check that.

It'll have to be tomorrow now. But I'll test the print again on tool 2 and 3 to see if it's the same. If it's not then it'll have to be down to the tool.

As for the possibility of it being skewed. Me messing around with the belt tension might have introduced that honestly, but it did still seem square within about 0.1mm when measured it against the frame on both sides. I'd just settle for it not shifting for the moment.

-

I've tried with tools 1,2,3 all Hemera tools. They all produce exactly the same artifacts. So unless it's the gantry side that has the issue, I don't think this is play in the tool.

Here's a print from tool 3, notice how it's distortion in the top left quadrant exactly like the two I show with the annotated green lines.(made with tool 1)

and here's another of the original part without infill better showing perimeter distortion.

Going to have another play about with the mechanics of it today, belt tension, gantry squareness, etc.

-

@andywm did you try wiggling the tool on the head? Could be the locking shaft has slipped so isn't holding the tools as tightly?

I'd also be adoubke checking the pulleys and grubs screws. Definitely looks a backlash thing

-

I can cause them to deflect, but not without quite a bit of force.

What should I be checking with pulleys? I already have it on my list to check the grubs on the two motor ones in the back from @Phaedrux's suggestion when I get the back panel back off. Basically just that?

Unrelated, but I am also a bit worried about Z, I noticed plastic debris resting and tangled with the leadscrew nut.

-

@andywm sounds like the tool is being held okay then.

Yeah it would mostly be the grub screws on motor pulleys. Then check that all the idler mounts are solid and screwed in properly. As all the idlers are cantilevered it could be one of them has come loose and is flopping about a bit?

I get the plastic debris in the z axis in mine every now and again. Doubt it will be able to cause much wear so I'd just pull the plastic out with a pair of pliers

-

It was indeed a loose grub screw on one of the xy plane motors. Machine is printing well again.

Thanks all.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved

-