Read chamber's temp

-

Hi,

I use a Duet3 mini 5+ with RRF3 and I just want to read the temp inside my printer.

So I just put a thermistor at the top of the printer and I added in the config file :M308 S2 P"temp2" Y"thermistor" T100000 B4725 A"Chamber"

But the sensor is not in "Extra" on DWC and when I send "M308 S2" the console tell me : "Error: M308: Sensor 2 does not exist"

I tried with an other thermistor but nothing new and then I try to switch the pins temp0 and temp2 and I could see the temp of the extruder on temp2.

So I assume that my gcode is wrong but I don't know what could I change.Thanks in advance for your help !

-

@aodrennn Try sending the full M308 line on it's own, and see if it generates an error. Otherwise, please post your full config.g and response to M122.

Ian

-

@droftarts

Waw, it works now ... thank you but why i have to send the command after I wrote it in the config.g ?

Do I have to resend the command everytime I turn on my printer or it was just the first time ? -

@aodrennn Send

M98 P"config.g"to run config.g and report any errors. Could be there's a typo in the command in config.g, usually curly quotes used instead of straight quotes.Ian

-

@droftarts

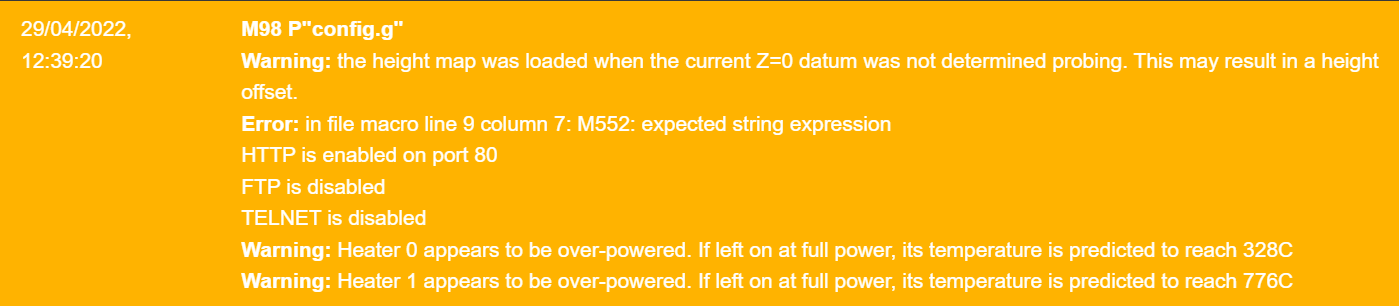

Here is the answer of the M98

I don't see anything bad but i'm not an expert ... tell me if ther is something wrong.

Thanks a lot

-

@aodrennn Nothing in there related to M308, so not sure. Did you reset the Duet after adding the M308 line?

There are a couple of other errors, though. Post your config.g and response to M115. You can cut and paste text from DWC into the forum, rather than posting images of text, btw. Format any code with the 'Code' style to aid readability, using the '</>' icon in the message composition window.

Ian

-

@droftarts

Thanks for the tip, yeah I reset my card every time I change anything in the config.gSo here is the M115 :

FIRMWARE_NAME: RepRapFirmware for Duet 3 Mini 5+ FIRMWARE_VERSION: 3.3 ELECTRONICS: Duet 3 Mini5plus WiFi FIRMWARE_DATE: 2021-06-15 21:46:20And here the config :

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"GigaRat" ; set printer name M669 K1 ; CoreXY G29 S1 ; Set Units to Millimeters ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D3 ; physical drive 0.0 goes forwards M569 P0.1 S1 D3 ; physical drive 0.1 goes forwards M569 P0.2 S1 D3 ; physical drive 0.2 goes forwards M569 P0.3 S1 D3 ; physical drive 0.3 goes forwards M569 P0.4 S1 D3 ; physical drive 0.4 goes forwards M569 P0.5 S1 D3 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.154 Y80.154 Z798.56 ; set steps per mm M906 X1000 Y1000 Z800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X280 Y260 Z280 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure active high endstops M574 Y2 S1 P"io3.in" ; configure active high endstops M574 Z1 S2 ; configure Z-probe endstop for low end on Z M671 X-4.5:150:304.5 Y-4.52:305:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:280 Y20:280 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out5 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ;; Run Bed PID Tune!! Bellow is an example for a 300x300 bed M307 H0 A303.1 C356.7 D1.4 S1.00 V24.0 B0 ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Hotend Fan" S0 H1 T45 L255 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M950 H1 C"out1" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set the maximum temperature in C for heater ; EVA 2 / BMG / E3D V6 M92 E409 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) M906 E800 ; set extruder motor current (mA) and idle factor in per cent M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" ;; Run Heater PID Tune!! M307 H1 A751.5 C196.6 D4.7 S1.00 V23.9 B0 ; Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch M950 S0 C"io2.out" ; Create a servo pin on io7 M558 P9 C"io2.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X24.5 Y-46 Z3.5 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed T0 ; Pressure Advance M572 D0 S0.035 ; PanelDue M575 P1 S1 B57600 ;Température Chambre M308 S2 P"temp2" Y"thermistor" T100000 B4725 A"Chambre" ;M950 F2 C"out5" T2 ; create fan 0 on pin out3 and set its frequency ;M106 P2 T40:60 H2 ; set fan 0 name and value. Thermostatic control turned on for Hotend -

@aodrennn Not sure why the M308 command isn't working. The order of your config.g is a bit strange; you are defining the tool with M563 P0 D0 H1 F1 before the heater H1, and heater H1 which references temperature sensor S1 before M308 S1 is defined. Put the temperature sensor configuration first, then heater, then tool. Also move the chamber temperature configuration before the 'T0' which enables the tool; maybe that's messing with it.

Also, change:

G29 S1 ; Set Units to Millimeters(this is the bed map error)

to

G21 ; Set Units to Millimetersand

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

to

M552 S1 ; enable network and acquire dynamic address via DHCP

(This is the M552 error)Ian

-

@droftarts

Yeah I took the config.g from the Ratrig tutorial so I didn't wrote it and I just changed with my parameters and then it worked good so I didn't search deeper.

But it's nice to can correct that now, so thank you again for your time and your help !

See you ;))