Temperatures totally wrong 3.4 RC

-

@resam Are you using a part cooling fan? Is there any correlation between the temperature changes and the use of the part cooling fan? If you rerun the PID tuning for the hotend using the RC1 build and then test again does anything change? Take care as you may not be able to use the new PID parameters with 3.3 if you want to go back to that, so make sure you save the old settings before replacing them with the RC1 version.

-

@gloomyandy said in Temperatures totally wrong:

@thedragonlord It looks like you may be doing something with temperature settings in your tool files (you have global variables which seem to relate to temperature settings) so you should probably post any files that set/change temperatures and explain what it is you are doing.

It may also be worth creating a simple test print (that only uses one tool ideally) and posting the gcode file for that print and a screenshot of the graph and the DWC temperature readings showing what happens. It may be worth using a larger temperature change from the first layer to the second layer so that it is more obvious what is going on (5 degrees can be hard to spot on a graph).

It is probably worth running M105 in a console at various stages to see how the values there compare with those displayed in DWC.

You may also want to experiment with turning your part cooling fan off to see if that is having any impact on this problem (recent versions of the firmware have introduced a feed forward mechanism that attempts to compensate for the impact the cooling fan can have).

Did you check that your DWC version matches the firmware?

As told in a next post all worked fine until I've installed RC1...DWC matches the firmware, yes...unfortunately I have no time to make all the checks you asked me before, I downgrade the FW and wait until all will be fixed.

-

@thedragonlord @resam the heater parameters changed in 3.4 beta 7; see https://docs.duet3d.com/en/User_manual/Reference/Gcodes/M307/

I can’t find the note about it in the release notes (@dc42 ?), but in 3.4RC2 try sending M307 H# and see what parameters are reported. Then retune with M303 and see if that helps. I did this the other day, and temps were very stable in 3.4RC2.

Ian

-

@droftarts said in Temperatures totally wrong:

@thedragonlord @resam the heater parameters changed in 3.4 beta 7; see https://docs.duet3d.com/en/User_manual/Reference/Gcodes/M307/

I can’t find the note about it in the release notes (@dc42 ?), but in 3.4RC2 try sending M307 H# and see what parameters are reported. Then retune with M303 and see if that helps. I did this the other day, and temps were very stable in 3.4RC2.

Ian

I don't understand....if I'm not wrong M307 reports the actual PID values but M303 recalculatte them so how the two comands are related? I mean, what's the purpose to run M307 H# to see the actual PID parameters if running a M303 T# then will completely recalculate them?

-

undefined Phaedrux moved this topic from General Discussion

undefined Phaedrux moved this topic from General Discussion

-

Still no solution for this issue???

-

@thedragonlord did you retune the heaters? Like I said, in any release since 3.4beta7, the parameters have changed, and I believe the algorithm to determine PID has too.

My suggestion was to see what values you had currently, retune, and see what parameters you then get.

I’ve asked @dc42 to look at this thread.

Ian

-

@droftarts said in Temperatures totally wrong 3.4 RC:

@thedragonlord did you retune the heaters? Like I said, in any release since 3.4beta7, the parameters have changed, and I believe the algorithm to determine PID has too.

My suggestion was to see what values you had currently, retune, and see what parameters you then get.

I’ve asked @dc42 to look at this thread.

Ian

I7ve followed your advice and I've watched the values I had with M307 then retuned with M303, got different values but the issue are still "alive"....that's why I've asked if the issue has been solved...

-

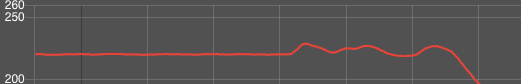

I have the same problem. From 3.4-b7 to 3.4-rc2_1 I have the temperature issue. This goes up about 10° and down again. But the funny thing is only at Z=2.1mm. With 3.4-b5 this is ok. I did everything PID. It's not on the slicer either, I've tested different ones.

On 3.4-b7 the temperature is constant up to Z=2.1mm and then it starts.

and this is on 3.4-b5 the temperature is constant throughout the printing

-

@TheDragonLord Sorry, I see from your first post that you are using the new M307 parameters. Though according to @dc42 even if you used the old parameters, the values are converted to the new parameters.

When you tuned the heaters, did you tune them with the nozzles close to the bed, ie within 1mm?

The fluctuation looks much more like it’s not dealing with the cooling fan being on, or somehow on tool change the heater tuning for the cooling fan being on is inverted, so it thinks the fan is on when it’s not, and vice versa.

Please post your tool change files, so we can see what is happening there.

Ian

-

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

-

@hernicz said in Temperatures totally wrong 3.4 RC:

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

I'll give it a try, thanks

-

@hernicz said in Temperatures totally wrong 3.4 RC:

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

It works thanks!

-

@thedragonlord You're welcome.

-

@thedragonlord Can you post the details of the heater settings that did not work along with the ones you have now that do work, DC42 may find them of interest. Do your new settings give a constant temperature during a print? Can you also confirm what version of RRF you are now running.

-

@thedragonlord as @gloomyandy said if the tuning is overcompensating for the fan, it would be good to understand why.

When tuning, does the cooling fan run at 100%?

Does the part cooling fan run at 100% when printing?

When each tool is parked parked, could the hot end fan be having an effect on nozzle cooling?

When each tool is parked, does the cooling fan continue to run?

When you reverted to RRF 3.3 and temperatures were stable, what M307 commands were used?

As requested before, please post your tool change macros so we can see what is going on. A sample Gcode file, or snippet of the commands sent at tool change, would also help.Ian

-

@droftarts said in Temperatures totally wrong 3.4 RC:

@thedragonlord as @gloomyandy said if the tuning is overcompensating for the fan, it would be good to understand why.

When tuning, does the cooling fan run at 100%?

Does the part cooling fan run at 100% when printing?

When each tool is parked parked, could the hot end fan be having an effect on nozzle cooling?

When each tool is parked, does the cooling fan continue to run?

When you reverted to RRF 3.3 and temperatures were stable, what M307 commands were used?

As requested before, please post your tool change macros so we can see what is going on. A sample Gcode file, or snippet of the commands sent at tool change, would also help.Ian

As I told before it's not related to a tool change because it doesn't work even with a single heater on. The fan isa always 100% in the tuning and during the print

-

@gloomyandy I wrote a post more than a month ago (maybe 2) about this. PID tuning is even worse when I did it with copper heatblock.

There might be some fix values in the PID tuning process or the heating control that totally sends temp off the chart.

I mean even if it's over target temp it still tries to compensate the part cooling fan by raising temperature, triggering heater fault after a while.

If you have a copper heatblock, at initial heatup it way overshots temp. The purpose of PID is to precisely reach target temp and sustain it in a changing environment. But when you use copper, heatup just doesn't slow down. It's like PID is hardcoded to aluminium heatblock.

I even tried manually adjusting the values with no luck, but even like this PID was far better than bang-bang.

-

@thedragonlord okay. Can you at least post the M307 you were using in 3.3? Then we might be able to reproduce the issue.

For now I’ll update the M303 instructions to say that if the feedforward isn’t working for the user, to tune heaters rather than tools, as @Hernicz suggests.

Without sufficient data and information to be able to understand the cause of issues and to reproduce them, it’s very difficult to resolve them.

Ian

-

@hernicz said in Temperatures totally wrong 3.4 RC:

If you have a copper heatblock, at initial heatup it way overshots temp. The purpose of PID is to precisely reach target temp and sustain it in a changing environment. But when you use copper, heatup just doesn't slow down. It's like PID is hardcoded to aluminium heatblock.

This is not true in my experience. I had E3D v6 copper block (with copper nozzle and titanium heatbreak) in my delta from new and had no problems with a number of v3.4 betas and RC1 & 2 on a MB6HC. All tuned fine (as tools, not heaters) and worked fine when tuned. So it's not the case that something fundamental in the tuning cannot accomodate a copper block.

I'm now using a Revo, so the concept of block dissapears somewhat, since there's heater - nozzle assembly without discrete block. FWIW, that has tuned fine too.

-

@hernicz this post? https://forum.duet3d.com/topic/26830/issues-with-pid-tuning-rrf-3-4-0-b7/

I’ll try and get @dc42 to look at all threads where PID tuning is an issue. If you spot more, please post them here. Maybe if they’re taken all together there may be a common issue that he can look at.

Ian