Normalizing Temperature Sensors Across Machines

-

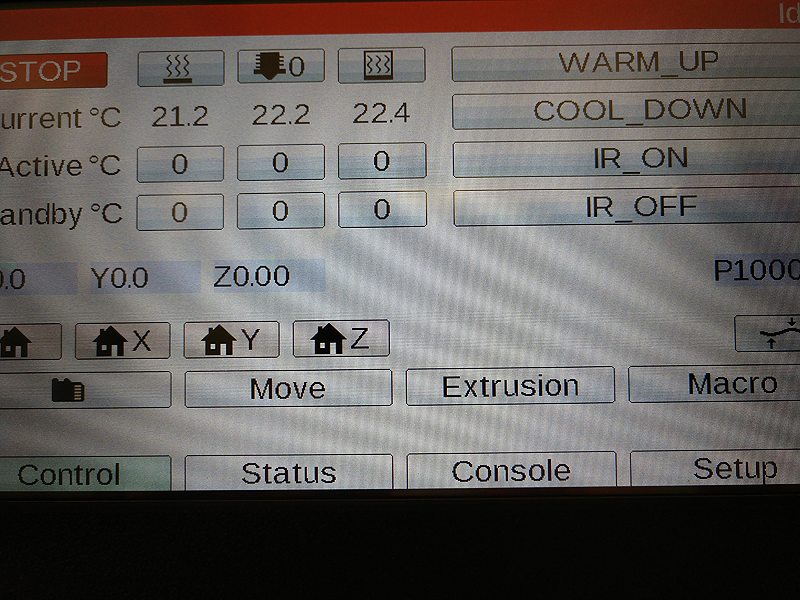

Hello - I have 10 printers using the Duet 3 6HC boards running version 3.3 firmware. They are production printers and typically run the same programs.

The PT1000, PT100 and standard thermistors across the 10 machines vary due to typical accuracy tolerance bands.

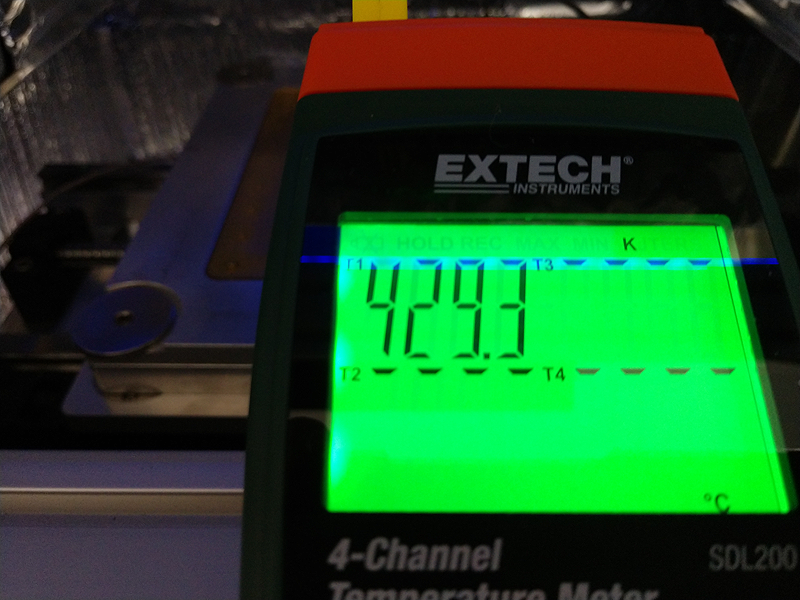

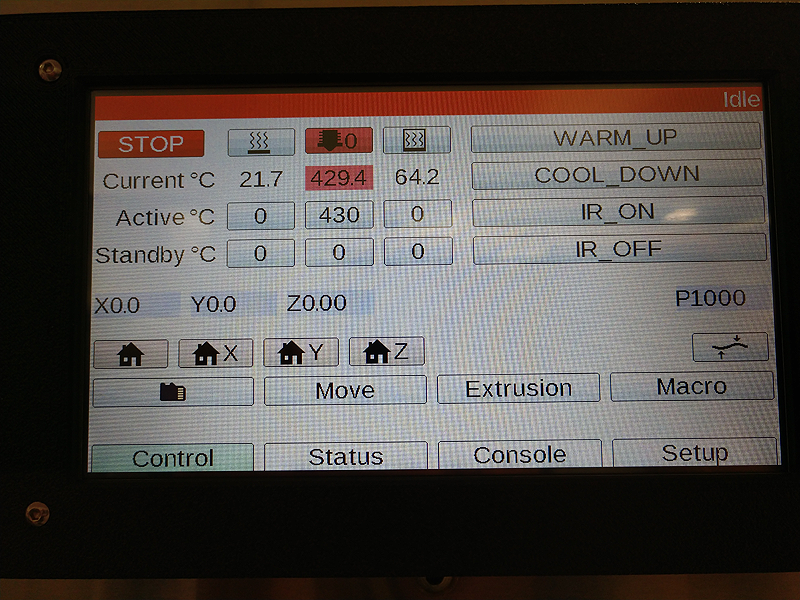

I'm using an external temperature gauge that has been calibrated which allows me to record the +/- variances of the in machine temperature reading to the external gauge value.

Is there a method to provide an offset to the respective temperature input?

-

-

@stephen6309 Thanks for the URL

I'll start here and see how the temperatures report.I may still need to provide an offset +/- to fully align with an external sensor. Is there a method for this?

The above URL was for thermistors, is there something for the PT100 sensors?

-

@tmreith good quality PT100 sensors used with the temperature daughter board and a 4-wire cable should be accurate to withing about 0.4C. If you use a 2-wire cable then the readings will be affected by the resistance of the cable and any connectors in it. So if you want accuracy, use a 4-wire cable.

-

@stephen6309 Thanks!

I had success using the manual calibration method. I used a resistance decade box to feed values into the Duet. Resistance to desired temperature values are drawn from respective NTC Thermistor R-T Table Sheets. Resistance decade box output was verified with a calibrated FLUKE multimeter to confirm resistance value. Then using M308 Snn Hhhh and M308 Snn Lvvv to dial in the Duet. -

@tmreith The problem with this approach is that the R-T sheets are only at best rough, for temperatures very different than 25C, unless they are individually measured for the sensor. Tiny process variations in manufacture result in beta variations. Over the range 25C - 300C, even a tiny beta change can result in a pretty big temperature offset. Commercial thermistors are adjusted to have exactly the right resistance at 25C, and are excellent in a range near there. Going to a sensor such as Pt100 or Pt1000 gives much better interchangeability over a wide range.

-

@mendenmh Thanks for your input. The purpose of sending fix values into the Duet mainboard is to normalize behavior across multiple machines. The thermistors we are using are with 1% of each other.

Maybe I got lucky, but all 10 machines are within 1-2 max degrees of each other.

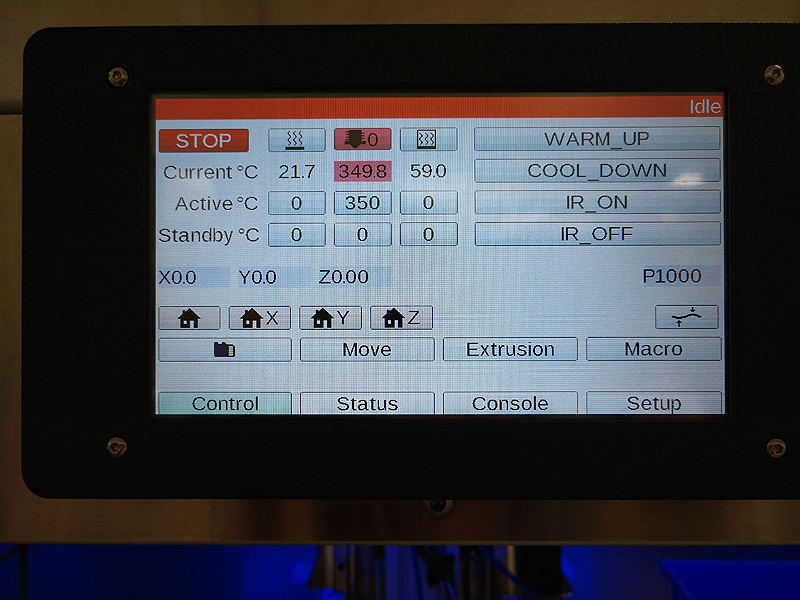

We used a calibrated meter along with external contact sensors to check actual temperatures to the internal sensors connected to the Duet .

-

@tmreith related github issue:

https://github.com/Duet3D/RepRapFirmware/issues/624