Extrusion problems that seem to appear random

-

Hey there, I have been trying to figure out this problem with seemingly random over extrusion for weeks, but i got nowhere. I am running a E3D v6 And a Titan extruder and using Prusament PLA at 220C. Does anyone have any ideas on what might cause this?

```

```

Config.gG90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Kossel XL" ; set printer name M665 R181.59 L300.187 B116 H441.06 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M912 P0 S-9.1 ; MCU temperature sensor calibration offset ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S1 D3 V50 ; physical drive 0 goes forwards M569 P1 S1 D3 V50 ; physical drive 1 goes forwards M569 P2 S1 D3 V50 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160 Y160 Z160 E817 ; set steps per mm M566 X600 Y600 Z600 E600 ; set maximum instantaneous speed changes (mm/min) (Jerk) M203 X15000 Y15000 Z15000 E3600 ; set maximum speeds (mm/min) M201 X2000 Y2000 Z2000 E1000 ; set accelerations (mm/s^2) M906 X830 Y830 Z830 E1450 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ;M572 D0 S0.2 ; Set Pressure advance (old 0.95) M592 D0 A0.0124929539412195 B0.00208450767751017 L0.2 ; Configure nonlinear extrusion ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"!^xstop" ; configure active-high endstop for high end on X via pin !^xstop M574 Y2 S1 P"!^ystop" ; configure active-high endstop for high end on Y via pin !^ystop M574 Z2 S1 P"!^zstop" ; configure active-high endstop for high end on Z via pin !^zstop ; Z-Probe M558 P5 R0.5 C"zprobe.in" H2.5 F240 T2500 ; set Z probe type to effector and the dive height + speeds M558 P5 R0.4 C"zprobe.in" H2.5 F240 T1500 G31 P1 X0 Y0 Z-0.25 ; set Z probe trigger value, offset and trigger height M557 R115 S45 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S90 ; set temperature limit for heater 0 to 90C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"fan0" Q65535 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"Part cooling Fan R" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q65535 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"Hotend Fan " S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q65535 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"Part cooling Fan L" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off ; Tools M563 P0 S"E3D V6" D0 H1 F0:1:2 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings M591 D0 P1 C"e0_stop" s1 ; filament monitor connected to E0_stop M81 C"pson" ; PSU off G29 S1 ; Load hight map ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first tool -

undefined Lee marked this topic as a question

undefined Lee marked this topic as a question

-

@lee Have you tuned your heaters, both nozzle and bed? That looks like PLA printed way too hot in spots. I would also make sure your heatsink fan is operating normally and your extruder hobb gear idler is tensioned properly. I would also make sure your slicer is not overwriting your M83 command. M83 in config.g is only processed when the machine is rebooted or config reloaded.

-

@lee said in Extrusion problems that seem to appear random:

M563 P0 S"E3D V6" D0 H1 F0:1:2 ; define tool 0

You have all 3 of your fans set as part cooling fans. I don't think that's what you want. I suspect your sliced gcode file is actually turning off your hotend heatsink fan as well.

Based on your fan config I think you want fan1 as the heatsink fan so change the tool definition to only use fan0 and fan2

M563 P0 S"E3D V6" D0 H1 F0:2

Also are you sure you want to use Q65535 as your PWM frequency for the fans? The default is 500.

-

This post is deleted! -

@phaedrux

First of all thanks for the help i found the problem yesterday. the problem was that the heartbreak and the nozzle weren't quite tightened against each other. But i dont quite get how what you are suggesting about changing in the config the fans 0,2 are the part cooling fans and fan 1 is the heatsink fan.

Would you be so kind an post the cahnges i would need to make. Thanks in advance -

@lee It's because M563 is only supposed to define the part cooling fans. remove your heat sink fan from the F parameter.

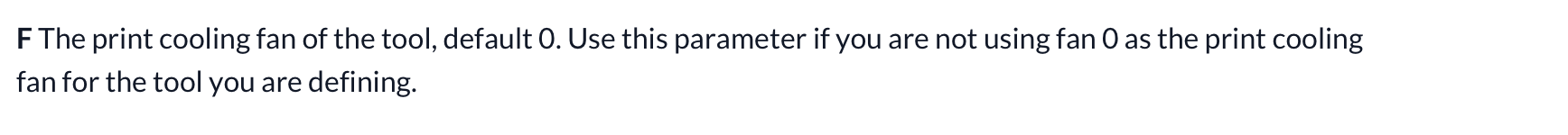

Relevant parameter for M563

Your heatsink fan is linked to a heater in your M106 command when you define your fan. for example:

M950 F1 C"121.out_2" Q10 M106 P1 C"Heatsink Fan" S0.8 H1 T45 ; assigns fan F1 to Heater 1 and sets thermostatic control temp ; Tools M563 P0 S"Extruder" D0 H1 F0 ; define tool 0 where part cooling fan is F0.In your case the M563 command should read as follows.

M563 P0 S"E3D V6" D0 H1 F0:2 -

@ctilley79 Thank you very much

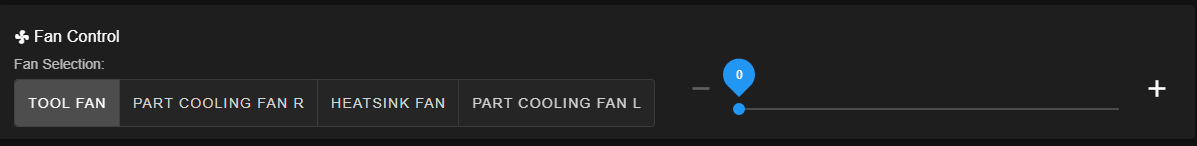

I now have this in my config```; Fans M950 F0 C"fan0" Q5000 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"Part cooling Fan R" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q5000 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"Heatsink Fan" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q5000 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"Part cooling Fan L" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0:2 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

I now have a new Fan (Heatsink Fan) in the control panel but i can't control it. I think this is right because this is the Heatsink fan, why would it show up as a controllable fan. -

@lee What firmware version are you running? I can't seem to duplicate the issue. I've got one printer on 3.3 and another on 3.4b7. If I recall, I had this issue on older firmwares. I've compared your config with mine, and it should work.

-

@lee said in Extrusion problems that seem to appear random:

but i can't control it.

It's a thermostatically controlled fan, so you can't manually control it.

-

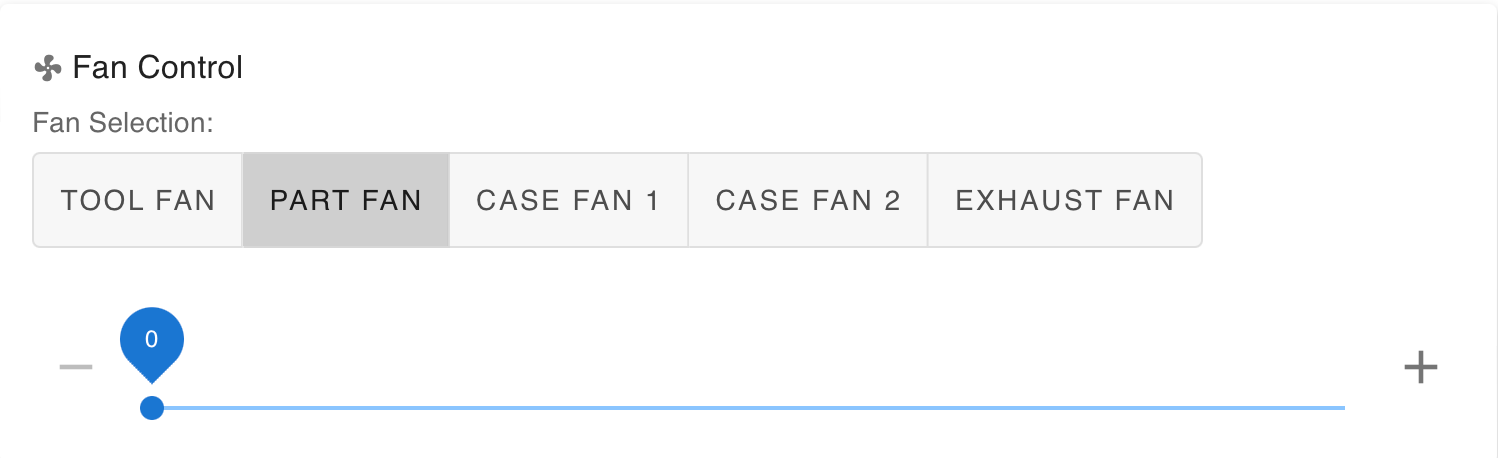

@phaedrux You didn't understand what he's saying. Thermostatically controlled fans shouldn't show up in DWC. They don't show up on my printers.

Look at my dashboard. Notice my heatsink fan is not in the list... because it shouldn't be....

-

yes it seems like something is out of sync.

I suggest uploading this zip file and seeing if it will update everything to 3.3 for you.

https://github.com/Duet3D/RepRapFirmware/releases/download/3.3/Duet2and3Firmware-3.3.zip

-

@phaedrux Ok I will try this and share my results

-

@phaedrux Yup that did it Thank you very much

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved

-

undefined Lee has marked this topic as unsolved

undefined Lee has marked this topic as unsolved

-

undefined Lee marked this topic as a regular topic

undefined Lee marked this topic as a regular topic