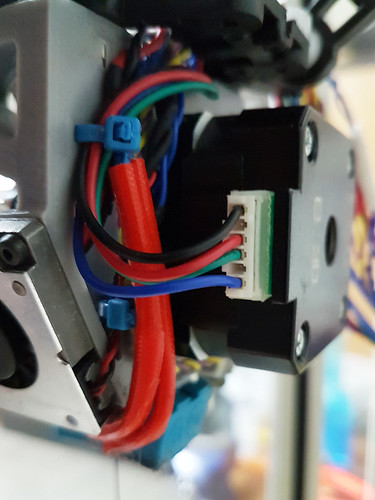

E3D Pancake stepper motor

-

so when I test the pairs I get 2.3-2.5ohms each

here is my config.g

; CoreXY sample config file for dc42 Duet firmware

M111 S0 ; Debug off

M550 PBig-D ; Machine name (can be anything you like)

M551 Preprap ; Machine password (used for FTP connections)

ns)

;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address

;*** Wifi Networking

M552 S1 ; Enable WiFiM555 P2 ; Set output to look like Marlin

;M575 P1 B57600 S1 ; Comms parameters for PanelDue; Machine configuration

M569 P0 S0 ; Drive 0 goes forwards (change to S0 to reverse it)

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

; If you use an endstop switch for Z homing, change Z0 to Z1 in the following line, and see also M558 command later in this file

M574 X1 Y2 Z1 S0 ; set endstop configuration (X and Y and endstops only, at low end, active high)

M667 S1 ; set CoreXY mode

M350 X64 Y64 Z64 E64 I0 ; Set 16x microstepping with interpolation

M92 X400 Y400 Z1600 ; Set axis steps/mm

M92 E1643:1643 ; Set extruder steps/mm

M906 X800 Y800 Z800 E800 ; Set motor currents (mA)

M201 X1000 Y1000 Z300 E4000 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z500 E1500 ; Maximum speeds (mm/min)

M566 X800 Y800 Z24 E1200 ; Maximum jerk speeds mm/minute

M208 X290 Y285 Z320 ; set axis maxima (adjust to suit your machine)

M208 X-10 Y0 S1 ; set axis minima (adjust to make X=0 and Y=0 the edges of the bed)

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves; Z probe

M558 P1 X0 Y0 Z0 ; Analog Z probe, also used for homing the Z axis

;G31 Z2.47 P500 S1 ; Set the probe height and threshold (put your own values here)

; The following M557 commands are not needed if you are using a bed.g file to perform bed compensation

;*** Adjust the XY coordinates in the following M557 commands to suit your build and the position of the Z probe

;M557 P0 X30 Y25 ; Four...

;M557 P1 X30 Y155 ; ...probe points...

;M557 P2 X250 Y125 ; ...for bed...

;M557 P3 X250 Y25 ; ...levelling

;M557 P4 X150 Y95 ; 5th probe point for levelling; Thermistors and heaters

;*** You can use S and B parameters to define the parameters of the thermistors you are using

M305 P0 T100000 B4388 R4700 H0 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 T100000 B4388 R4700 H0 L0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M305 P2 T100000 B3974 R4700 H0 L0 ; Put your own H and/or L values here to set the second nozzle thermistor ADC correction

M301 H1 P10 I0.10 D100 T0.50 S1.0 ; PID settings for extruder 0

M301 H2 P10 I0.10 D100 T0.50 S1.0 ; PID settings for extruder 1

M570 S120 ; Increase to allow extra heating time if needed

M307 H0 A86.7 C612.7 D6.0 B0

M307 H1 A406.3 C166.4 D10.3 B0; Fans

M106 P0 T50 H1

M106 P1 T50 H1

M106 P2 T50 H1; Tool definition

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a dual-nozzle build, un-comment the following 3 lines

;M563 P1 D1 H2 ; Define tool 1

;G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures;*** If you are using axis compensation, put the figures in the following command

M556 S78 X0 Y0 Z0 ; Axis compensation here

T0 ; select first hot end -

Have you tried a different motor connected to that motor output on the Duet, or that motor connected to a different motor output, in case the problem is a faulty driver?

-

Maybe also try 16X micro stepping instead of 64X (but don't forget to divide your steps per mm by 4)? Dunno - just a long shot.

-

That motor requires a really high current to get it to move. Try between 1200 - 1400ma, going off of memory.

Here's the E3D thread for it. https://forum.e3d-online.com/index.php?threads/nema17-slimline-rated-current.2720/

I ran it at 1200, but didn't care for it as the connector could come loose. It never popped off while printing, but was well on its way there a couple times, and I didn't want it to pop loose and kill a driver.

-

no good, any there suggestions?

is there a way I can skip E0 and use E1?

-

no good, any there suggestions?

is there a way I can skip E0 and use E1?

Yes, put M584 E4 in your config.g file, earlier than the M906 command.

-

Probably not helpful, but if that E3D motor is a lot of trouble consider this one https://www.omc-stepperonline.com/hybrid-stepper-motor/nema-17-bipolar-18deg-13ncm-184ozin-1a-35v-42x42x20mm-4-wires-17hs08-1004s.html instead it's only $6.60, its 13 Ncm but smaller size and I drive it at 650mA with titan extruders, yes its 1.8 degrees but running a geared extruder 0.9 degrees is overkill plus needs to be bigger to achieve the same torque (and apparently uses more than double the current!).

-

Hello Sharpie, I run it at 900ma with x16 microstepping and seems to perform well.

This is how it came wired:

Are you testing it alone or already assembled with the extruder? Maybe the gears are not aligned and that's why it stalls.

Long shot, but worth asking.Hope it helps.

-

It turned out to be a bad driver on the motherboard, when I plugged into E1 the moved as expected =(

But at least we are online.

-

If you've had your Duet for less than six months, ask your supplier to repair the board (replace the short driver) under warranty.