big problems with print bed and mesh

-

Yesterday I tried for quite a while to get the Y-axes of my printer straight. But somehow I can't do it.

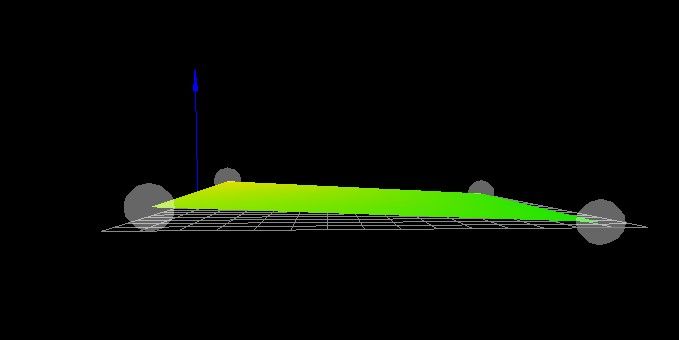

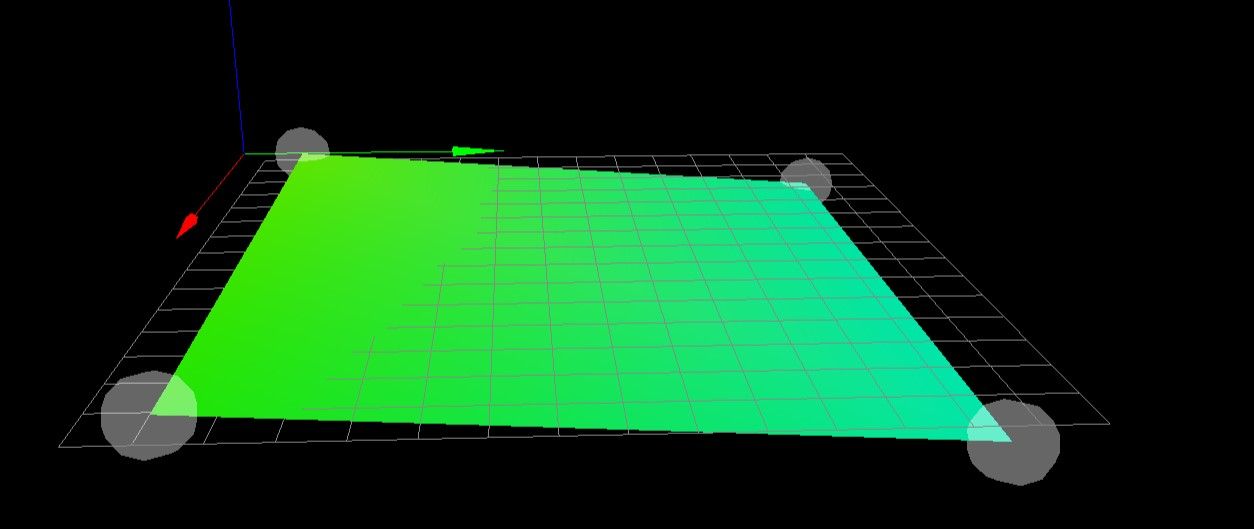

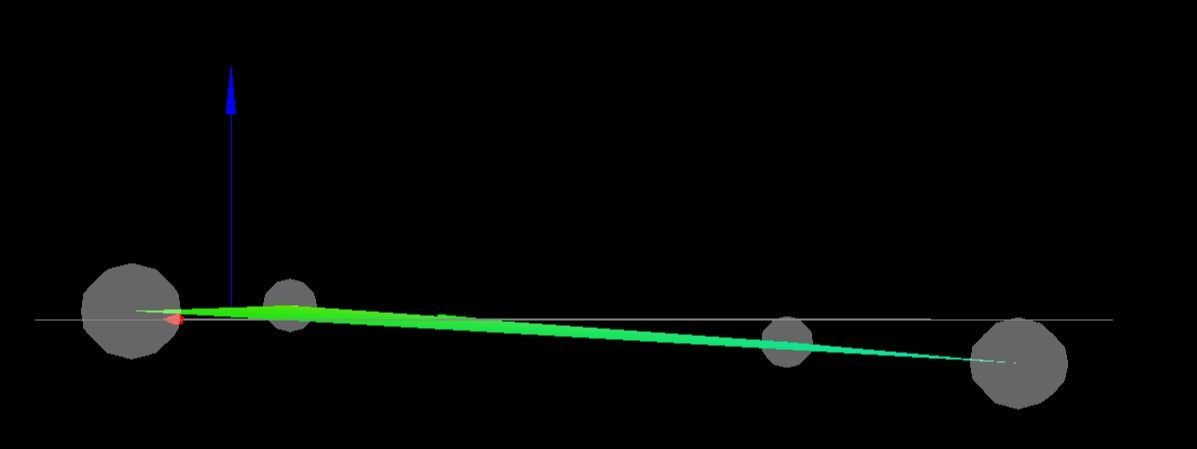

According to Mesh, my bed looks as if it were sloping at first and becomes straight from the middle (i.e. a kink in it). That is 100% not the case.So I made the bed like this

Then I tried to get the Y-axis further away from the bed at the front, but strangely enough, the measuring points at the front didn't "wander" after the change

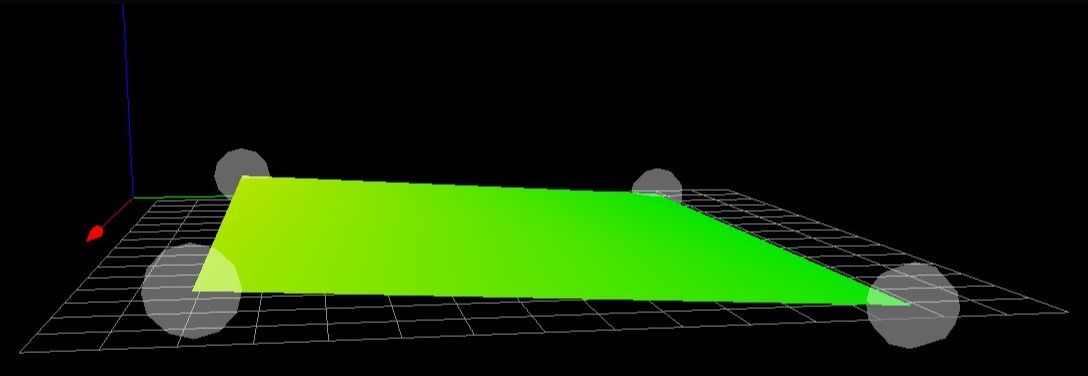

Then I simply put a sheet of paper under the spring steel plate and made the Z=0 centered in the front instead of in the middle. Then, as always, a G32 and then the mesh.

That was the result

My question is how can that be? I thought the bed aligns with the gantry. So according to my previous understanding, nothing should have changed because the ABL should have compensated for the 0.1mm from the blade?

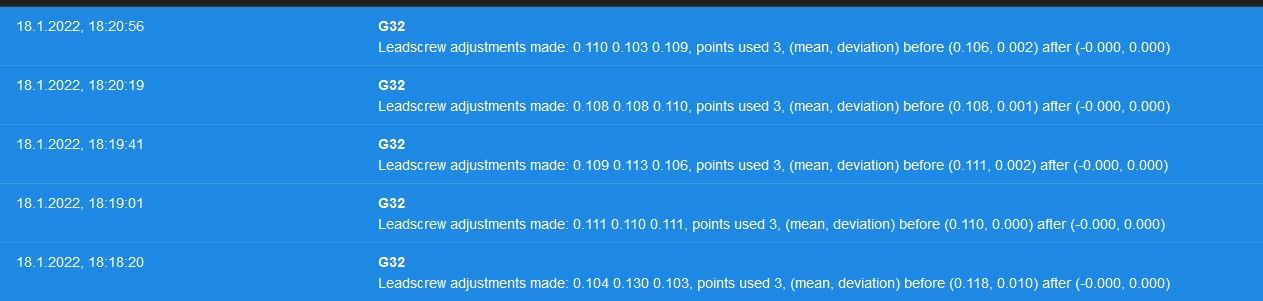

But it looks like that's not the case.Also, these results are weird...

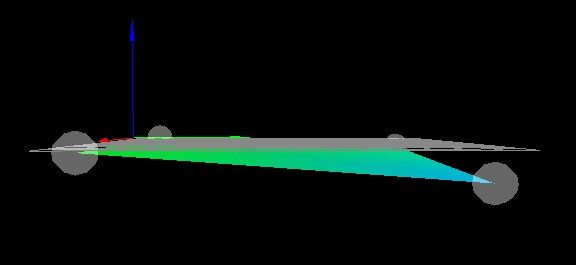

Here I made both Y-rails further down at the back (so the gantry closer to the bed unfortunately not quite uniform)

Then just back up to the right on the Y-rail (ganry further away from the bed)

Then again a little to the right in the back and up (this is where it gets weird)

It also seems to me that the two front spindles only compensate for the misalignment in X and the rear one only in Y. Shouldn't the front spindles be able to compensate for X and Y?

Hardware: Duet 3 6HC (FW 3.4.0beta7+7) + Duet 3HC (3x Z-axis [FW 3.4.0beta7+4])

-

What is your probe?

The mesh can only be accurate if the build is accurate. Often times when the mesh doesn't appear to match reality it's a case of either the probe being at a tilt such that the trigger height varies with XY position, or the XY motion platform isn't true to the bed platform, as in it has a twist.

Ensure the frame is square. Test your probe trigger height at multiple places on the bed with G30 S-1

-

@phaedrux said in big problems with print bed and mesh:

What is your probe?

The mesh can only be accurate if the build is accurate. Often times when the mesh doesn't appear to match reality it's a case of either the probe being at a tilt such that the trigger height varies with XY position, or the XY motion platform isn't true to the bed platform, as in it has a twist.

Ensure the frame is square. Test your probe trigger height at multiple places on the bed with G30 S-1

I have a kind of SuperPinda probe, the max deviation is 0.003mm when I do 20x in a row G30 S-1.

I also completely disassembled the frame and the Y-rails and fitted them together with a precision angle so that both Y-rails are almost exactly 90 degrees on both sides.

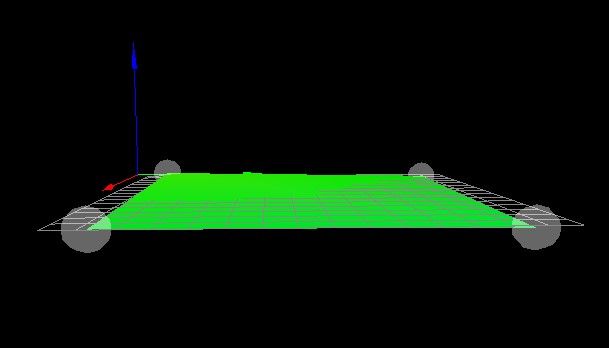

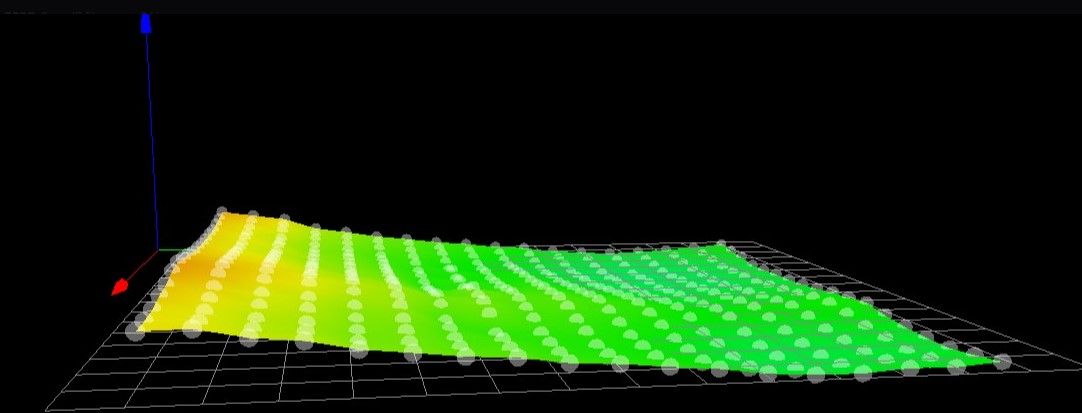

This is the newest mesh after aligning once 2:2 and once 18:18 mesh

Can a result like this also occur if the spindle position is not defined precisely enough?

-

@dogma2k Can you post the output from running G32, it might help to see what sort of corrections are being made.

-

@dogma2k said in big problems with print bed and mesh:

This is the newest mesh after aligning once 2:2 and once 18:18 mesh

Looks better to me, no?

-

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Mon Jan 25 2021 21:47:00 GMT+0100 (Mitteleuropäische Normalzeit) M561 ; clear any bed transform ;G29 S2 ; Clear Mesh Compensation Values M290 R0 S0 ; reset Babysetting G28 ; Home all axis ; Tufnol und Filaprint G30 P0 X25 Y87 Z-99999 ; BLTouch unten links (Offset => X25 Y45) G30 P1 X145 Y335 Z-99999 G30 P2 X265 Y87 Z-99999 S3 ; BLTouch unten rechts und Bett ausrichten (Offset => X283 Y45) G1 X145 Y184 F12000 ;G1 X145 Y20 F12000 G30 G1 X145 Y0 Z15 F12000 -

@gloomyandy

I don't really think it's better because my bed should actually be flat -

@dogma2k said in big problems with print bed and mesh:

I have a kind of SuperPinda probe, the max deviation is 0.003mm when I do 20x in a row G30 S-1.

20 in a row, meaning one after another, or 20 in a row of X Y points?

Test it at multiple points on the bed, is the result the same everywhere?

-

@phaedrux said in big problems with print bed and mesh:

@dogma2k said in big problems with print bed and mesh:

I have a kind of SuperPinda probe, the max deviation is 0.003mm when I do 20x in a row G30 S-1.

20 in a row, meaning one after another, or 20 in a row of X Y points?

Test it at multiple points on the bed, is the result the same everywhere?

I mean 20 in an row on after another at the same point but in a different place than last time.

or should I test at 3-4 other places? -

@dogma2k said in big problems with print bed and mesh:

or should I test at 3-4 other places?

Yes. Ideally test at the points you're using for leveling.

-

@phaedrux said in big problems with print bed and mesh:

@dogma2k said in big problems with print bed and mesh:

or should I test at 3-4 other places?

Yes. Ideally test at the points you're using for leveling.

ok give me some minues to heat the bed up

-

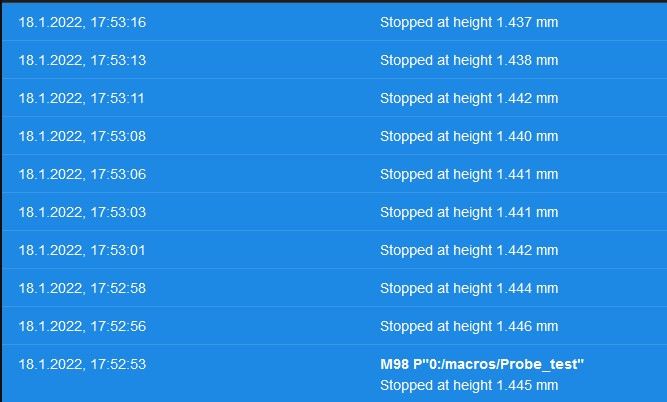

@Phaedrux

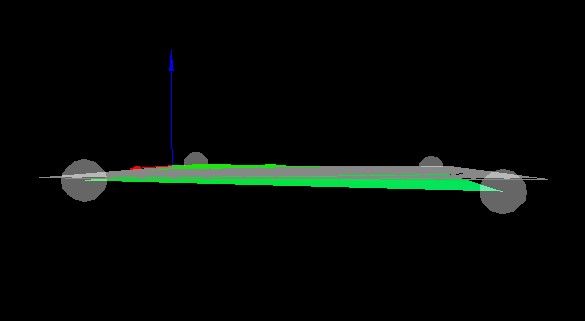

That's how something came upfront left

rear middle

front right

-

@dogma2k Can you try running G32 several times one after the other. Most folks find that they need to run more than one pass to get the bed level as the adjustments made are often an approximation. There are various scripts around to do this looking for the error to converge to a small value. But for now its worth just running multiple passes to see what happens to the numbers.

-

@gloomyandy

I did a G32 3x before measuring, then I was at 0.003 deviation. The mean doesn't get any less -

@dogma2k I was actually wanting to see what was happening to the adjustment values.

-

@gloomyandy

Ok, I misunderstood that, sorry, are 5x enough?

-

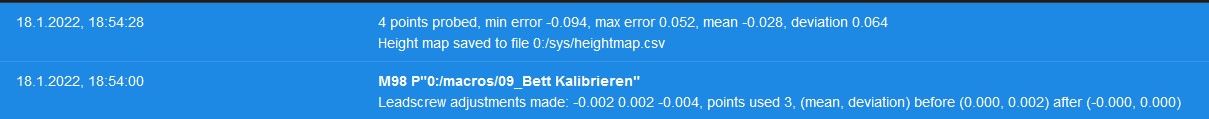

@dogma2k Thanks, that's interesting so it looks like you have a fairly constant offset from your zero point of about 0.1mm. You might want to try setting a z=0 point at one of the points that you use to probe the bed as part of your probing sequence. So for instance do a G30 probe with the probe positioned over one of the three points you are using as part of the G32, before you go on to do the actual three probes. Hopefully that will get rid of that constant offset.

-

@gloomyandy

I have now taken the middle rear position (same position as the P1 of the G30).

Somehow it hasn't gone away

-

@dogma2k Well it looks like it has resolved the constant offset issue at least (look at your mean error now and the adjustments being made). I suspect that the difference you are seeing in the mesh output is down to some sort of twist in the axis or the bed not being really flat or rails straight (the deviations you are seeing are not that large). What sort of print surface are you using? Although using four points for the mesh give you a rough idea of what is happening, you really need more points (like your second mesh above) to get a better idea of what is happening.

-

@dogma2k can I suggest running a ore detailed heightmap and checking the three locations where you are probing for your G32 bed levelling (taking probe offsets into account)?

Looking at your more detailed heightmap, you have a slight raised saddle up the middle (could be gantry sags?). I bet you'll find the three measurement points have a very similar mesh height, so the bed levelling is working correctly, based on the three measurement points you are using. However, it results in the heightmap 'kicking up' at the front of the machine.

I have a similar (though much worse!) saddle shaped heightmap on my machine. I always had the debate over whether to G32 based on four probe points at the corners (to get the bed level), or to do three points near the leadscrews to get the leadscrew locations level with each other and let the heightmap do the rest. In the end I chose option 2 as it makes G32 quicker