Extruder control grayed out

-

I can't use the extrusion control in the web control for some reason. It remains grayed out even though I have my extruder fully preheated to 235 degrees, but it stays gray and wont let me click on it. I'm so close to having this printer working again but this one has me stumped. I've even tried commenting out the 2nd extruder heater settings to bring it down to one heater and it still wont work. Suggestions? Here are my config settings.

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jun 22 2021 17:08:13 GMT-0700 (Pacific Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Dbot XL" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z1500.00 E420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z150.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z250.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1500 E800:800 I50 ; set motor currents (mA) and motor idle factor in per cent

M84 S60 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X500 Y480 Z500 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop Inverted

M574 Y2 S1 P"!ystop" ; configure active-high endstop for high end on Y via pin ystop Inverted

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F90 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-45 Y0 Z1.5 ; set Z probe trigger value, offset and trigger height

M557 X45:450 Y15:420 S60 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 R0.590 C256.5 D3.61 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S140 ; set temperature limit for heater 0 to 140C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C

;M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

;M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

;M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;M143 H2 S300 ; set temperature limit for heater 2 to 300C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

;M563 P1 D1 H2 F0 ; define tool 1

;G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

;G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

-

Can you send a photo of the DWC console?

Did you select a tool? (I have a "T0" in my config.g)

What version of firmware are you running?With V3.3 I run the hotend temp up, and at about 100C the Retract button becomes active and at about 150C the Extrude button becomes active.

Here's my config.g (for a delta) if you want to look at stuff.

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Mar 09 2021 13:21:24 GMT-0500 (Eastern Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"alan" ; set printer name M665 R132.5 L291.06 B132.5 H400 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards ; Testing external driver ;M569 P5 S1 T4:4:4:4 ; physical drive 5 goes forwards ;M584 X0 Y1 Z2 E3 U5 ; set drive mapping ;M350 X16 Y16 Z16 E16 U16 I1 ; configure microstepping with interpolation ;M92 X100.00 Y100.00 Z100.00 U100.00 E91.00 ; set steps per mm ;M566 X1200.00 Y1200.00 Z1200.00 U1200 E1200.00 ; set maximum instantaneous speed changes (mm/min) ;M203 X18000.00 Y18000.00 Z18000.00 U18000E1200.00 ; set maximum speeds (mm/min) ;M201 X1000.00 Y1000.00 Z1000.00 U1000E1000.00 ; set accelerations (mm/s^2) ;M906 X1000 Y1000 Z1000 E800 U1000I30 ; set motor currents (mA) and motor idle factor in per cent M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z100.00 E91.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop ; Z-Probe M558 P1 C"zprobe.in" H5 F60000 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z-0.1 ; set Z probe trigger value, offset and trigger height M557 R132 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4388 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4385 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0.7 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings M501 ; Load config-overrides.g T0 ; Select tool zero ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M912 P0 S3.5 ; MCU temperature calibration M591 D0 P3 C"e0_stop" S1 ; Configure filament monitor -

I have tool 0 clicked on.

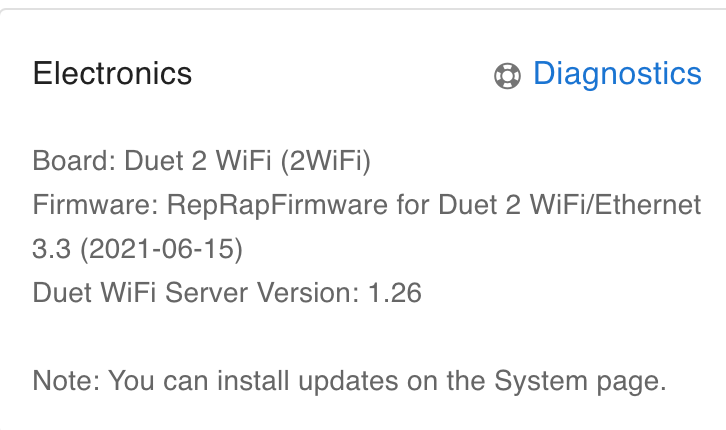

here is a picture of my firmware stuff from the web control page.

-

@jasonpgr I see "Status" = "Printing" What's going on there?

Can you show us the status page?

-

@jasonpgr said in Extruder control grayed out:

; Tools

M563 P0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0CYour M563 is missing a D0 to add a drive to the tool

-

as for the status, I was attempting a print when I took that screenshot to see if it would extrude under those conditions. Turns out thats a nope on that one. moved through all the motions, just no turning of the extruder motor.

So just to clarify, in my config file where it reads

M563 P0 H1 F0 ; define tool 0

it should actually read

M563 P0 H1 F0 D0 ; define tool 0

is that correct?

-

@jasonpgr said in Extruder control grayed out:

M563 P0 H1 F0 D0 ; define tool 0

That's what I have in my config.g

-

@jasonpgr said in Extruder control grayed out:

is that correct?

Correct, assuming that your first defined extruder drive is intended to be used with T0