Differential Screws, 11 Lenses, Harmonic Gear (robot series)

-

For the 6 Axis Robot project https://forum.duet3d.com/topic/17421/robotic-kinematics/211?_=1607408460374 I need to DIY harmonic gears (strain wave gearing, AKA trademarked harmonic drive). To produce it, little precise movements (differentail screws) and optical quality control (1:1 lenses) are prerequisites, as well as more elaboration of the teststation.

Differential Screws

Differential screws allow small movements, for an introduction please see https://en.wikipedia.org/wiki/Differential_screw

For a description how to fabricate differential screws for endstop usage with a lathe, please see Mark Rehorst's blog: https://drmrehorst.blogspot.com/2020/03/a-new-z-axis-optical-endstop-design-for.html?m=1Differential screw use cases:

- calibrate 3D printer, CNC machine, print bed, endstops

- focus optical lenses for quality check or manufacturing, measuring with a camera

- small router or drill bit movements for manufacturing small details like pulley/gear/spline teeth

- press

1:1 Lenses

1:1 lenses are lenses or objectives which are assembled face-to-face. If they have the same focus length, the image is transmitted in pixel size resolution to the image sensor. Which means 1.4 µm resolution for an OV5647 based raspberry camea. An introduction is in https://www.raspberrypi.org/forums/viewtopic.php?t=59889

1:1 lens use cases are:

- quality control (for harmonic gear e.g. quality of teeth and cross roller housing)

- optical absolute encoder

Harmonic Gears

Harmonic Gears (AKA strain wave gear, AKA trademarked harmonic drive) are gears with zero backlash and gear ratios between typically 1:50 to 1:166. They are expensive to buy, so I DIY them. An alternative is to buy them used for about 200$, this may be cheaper than to DIY, because manufacturing is very labour intensive. A second alternative is to DIY cycloidal gears, which is probably easier to manufacture.

Harmonic gear use cases:

- gear at the 6-axis-robot axes

- CNC index rotary table

- astronomy telescopes

Absolute Optical Encoder

Using the 1:1 Lenses and reading optical location information like I prepared in https://github.com/JoergS5/OpticalEncoder it should be possible to read a rotation position with high precision: the 600 dpi printout are 40 µm resolution for every dot, and 1:1 lenses can calculate by the dot position to even better precision. For a 100 mm diameter encoder ring around the hinge (perimeter 314 mm, 600 dpi are 23.622 dots/mm, 7400 ppr) the resolution is about 3 arcminutes per dot, with 1:1 lens maybe 10...20 better resolution.

Absolute Encoder use cases:

- know axes' positions of 6 axis robot immediately

- hence no endstops or homing needed

- if fast enough, give feedback for closed loop into 1HCL

- measure position errors and correct in firmware's kinematics calculation

- other length or rotational measurement (e. g. measure stepper precision)

Holding Brakes

A minor topic is to implement holding brakes, which are not meant for slow down, but to hold arm positions or screw positions.

Brakes use cases:

- hold robot arms in position when the steppers are powered off

- hold differential screws in position

- hold position if high force is applied to an actuator who shall stay at it's position

Toolchanger

Current planning is to attach a toolchanger to the 6th axis of the robot following the design of Jubilee. I am currently not sure whether I shall attach it vertical or 90 degree rotated, but probably the second choice.

-

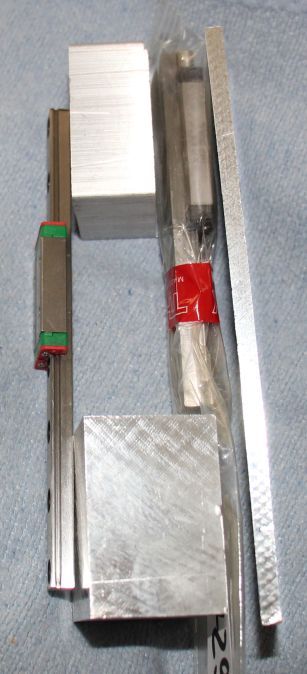

The first differential screw has dimensions 17x10x4 cm and has a stroke of about 3 mm with precision 0.125 µm for one full step.

The following screw pitches are used:

- M5x0.80 (metric screw 0.80 pitch for one rotation)

- MF5x0.75 (metric fine screw 0.75 pitch for one rotation)

- resulting in 0.05 mm movement with one rotation, meaning 0.125 µm for one full step of a 1.8 stepper with 1:2 belt gear.

The following raw material is needed for 1.8 stepper with 1:2 gear:

- top aluminium block 50 x 40 x 20 mm

- bottom aluminium block: 50 x 40 x35 mm

- long flat aluminium block: 130 x 40 x > 5 mm

- linear guide with length between 50 and 100 mm, as stable as possible

- linear guide 120 to 150 mm long for stepper movement

- 40 teeth pulley with 5 mm inner diameter

- 20 teeth pulley on stepper

- short closed belt (currently 80 teeth, but this is too long, 50 teeth is too short)

- stepper Nema 17 200 steps, highest possible detent torque

- aluminium or steel shaft 120 mm long, 5 mm diameter, not hardened

- aluminium angle for stepper-linear guide connection

- F625 ball bearing (flange 5x16x5)

- two 5 mm washers between pulley - ball bearing - adjusting ring

- aluminium angle for ball-bearing guide connection

- adjusting ring with 5 mm inner diameter

- a few screws (which one depends on the linear guides and adapter)

- tension spring (optional)

- for nice looking, 3D printed housing later

- optional plate at bottom to avoid tilting if it shall stand isolated

The following tools are needed

- tool to grind the shaft down to 4.9 on one side and 4.91 on the other

- cutting iron M5x0.80

- cutting iron MF5x0.75

- screw tap M5x0.80 long

- screw tap MF5x0.75 long

- screw tap M3, M4, depending on linear guides

- drill bit 4.2 mm for hole to cut core holes of M5 and MF5

- drill bit 2.5 mm for core hole M3 (if needed for linear guide)

- drill bit 3.3 mm for core hole M4 (if needed for linear guide)

- optional cone sinks for 3 or 4 mm holes

- cutting oil, abrasive paste and lubricating oil

- holders for screw taps and cutting irons

Things to think about while building:

- the right linear guide must have enough room between rail and lower block for about 3 mm movement

- the left linear guide may not touch the upper block

- both rails is not mounted in the middle, because this would conflict with the long screw.

- blocks and gap between are about 1/3 each, middle has more space to contain the pulley and holding mechanism, resulting here in 5+7+5 cm height

-

@joergs5 @mrehorstdmd did a great write up on differential screws, here: https://drmrehorst.blogspot.com/2020/03/a-new-z-axis-optical-endstop-design-for.html?m=1

Ian

-

@droftarts I didn't know this blog, I'll read it, thank you!

I've read the blog now, his build has a different goal. I'll describe my build and use cases here. Mark's descriptions how to design a good endstop with differential screws is very good.

-

@joergs5 it’s a great blog, really good stuff on machine design. Thanks Mark!

Ian

-

This post is deleted! -

I had my personal disaster yesterday: having gauge blocks, I measured the exactness of the caliper. It's 0.1 mm off every time ;-( (calibrated to 0, same error for 6 mm or for 30 mm). The micrometer screw below is much more exact, in the region 1/100 mm.

Everything I built (every hole) is wrong... Now I understand why I have so many problems, the biggest problem was wrong measuring of shaft diameters, resulting in play of pulleys.

-

I have one of those unbranded ones for quick measurements and using as an adjustable scriber, but also a Mitutoyo one for precision work.

The unbranded / no-name ones sometimes list accuracy as 0.1, though some claim 0.01

-

@rjenkinsgb I put a lot of effort to punch and to drill exactly, but if the starting measuring is wrong, this was worthless. Same with doing lathe work to make own threads. But I start anew, new game - learned something! (There is a book: measure twice, cut once). Mitutoyo have a good reputation.

-

@joergs5 One advantage of being older is that, when I served my apprenticeship back in the 60s and 70s nothing was digital. So I learned to read a vernier scale. https://en.wikipedia.org/wiki/Vernier_scale

I do have calipers with digital readout for quick measurements when accuracy isn't too important, but when it matters, and when I can't use a (non-digital) micrometer, I resort to my 40+ year old non-digital vernier calipers. Another advantage is that they don't need batteries.

Ultimately, when measurements are absolutely critical, the only way to be sure is to calibrate the instrument at a nominal value close to that which you are going to measure, take the reading, then re-check the instrument calibration. If it hasn't drifted, then you can have a reasonably high degree of confidence that the measurement is correct. But few of us have the time or inclination to do that.

-

@joergs5 Those Harbor Freight $10 calipers are crap.

I spent about $40 for a good one: https://www.amazon.com/iGaging-ABSOLUTE-Digital-Electronic-Caliper/dp/B00INL0BT

Measurements are accurate, battery lasts over a year, the battery cover doesn't fall off and get lost if you look at it sideways. -

@deckingman @mrehorstdmd thanks for feedback, I agree with both of you. There's still a lot to learn...

My father gave me his lathe as a gift and I produced the first threaded spindle. I wondered why I could not produce an even diameter for the whole length. Until I was aware that the shaft bent while turning, more at the beginning, then less.

-

@joergs5 said in Differential Screws, 11 Lenses, Harmonic Gear (robot series):

@deckingman @mrehorstdmd thanks for feedback, I agree with both of you. There's still a lot to learn...

My father gave me his lathe as a gift and I produced the first threaded spindle. I wondered why I could not produce an even diameter for the whole length. Until I was aware that the shaft bent while turning, more at the beginning, then less.

You do have a lot to learn!. When I bought my lathe, I wondered how much I would remember from the last time I used one which was over 40 years ago. Fortunately, I remembered most of it

For turning shafts, a centre in the tails stock will give you support at both ends and prevent that bending. Do an internet search for "live centre" and you'll see what I mean. For especially long shafts or especially thin ones, another steady in the centre can be great help, because even with both ends supported, they can tend to bed away from the cutting tool in the centre. Either a fixed or travelling steady (Google "travelling lathe steady" and you'll see what I'm talking about).

-

@deckingman thank you for your hints. Using the lathe is a useful next step to DIY needed parts.

-

@joergs5 said in Differential Screws, 11 Lenses, Harmonic Gear (robot series):

@deckingman thank you for your hints. Using the lathe is a useful next step to DIY needed parts.

I'm finding the same thing. For info, I've just made a set of 6 threaded heat breaks out of stainless steel, with the heat break section having a wall thickness of 0.3 - 0.4mm. That was a challenge.

-

@deckingman yes, I check your videos and blogs regularly, it's always interesting. I saw a video about Bondtech CHT today and thought, why not make my own nozzle in the future?

I tried thread cutting yesterday with M3 again and failed, it broke. I cannot remove the broken part. I have an impression what you have achieved!

-

@joergs5

bye! I follow you step by step on the work you are doing! I am waiting to see the differential screw reducer, to understand how it should be built! me to learn how to use a lathe, or watched the videos of (delfino brunelli) on you tube! he has a lathe from the early 1900s, rearranging by him with high precision is what he does with that lathe is amazing! I consider it the best I've seen among many! -

@tony73 said in Differential Screws, 11 Lenses, Harmonic Gear (robot series):

delfino brunelli

hello Tony, the youtube channels are worth a lot, thanks for the hint. I discovered "Huygens Optics", "Applie Science", "CNC Kitchen" and many others, it's a real gold source. Especially Huygens Optics is really impressive!!

I am currently developing the forward kinematics for the robot, so I make a little pause for the differential screw. But I am training using the lathe, damaged some parts, but it's getting better!

Interestingly, the forward kinematics of the robot allows as many axes as one wishes, from 1 to 10 or more axes, without problem. The inverse kinematics is the problem... (but I have ideas).

-

@deckingman said in Differential Screws, 11 Lenses, Harmonic Gear (robot series):

So I learned to read a vernier scale.

Vernier calipers go well with a sliding rules and Rapidographs .

I often watch the youtube channel of Nero 3D (a Canadian in his thirties) and I found it interesting that he refers to his digital calipers as 'vernier'.

-

@zapta said in Differential Screws, 11 Lenses, Harmonic Gear (robot series):

@deckingman said in Differential Screws, 11 Lenses, Harmonic Gear (robot series):

So I learned to read a vernier scale.

Vernier calipers go well with a sliding rules and Rapidographs .

Yes. I'm old enough to remember going to school before calculators were invented. As well as using books of log tables, we had slide rules. When I went to college, calculators were just coming on to the market but few people could afford to buy them. The first college exams I sat, calculators were banned but slide rules were permitted.