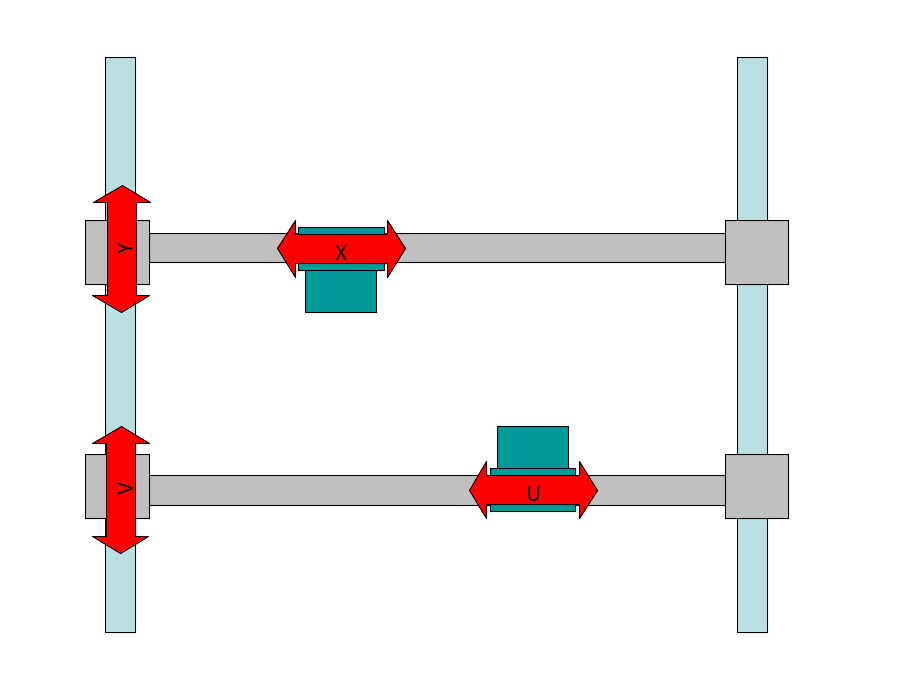

Core XY - Idex with two gantries

-

Hi folks, I'm new to the forum and so far I don't know anything about the Duet hardware or RRF. However, I have already built a couple of printers with Klipper FW.

I've thought of something for my next project, but I'm not sure whether it can be implemented at all. I've built a variety of printers so far, but I'm fascinated by the speeds some can get with their CoreXY systems. However, I want to build my next printer so that I can use two nozzles. There are already different solutions - two nozzles on one carriage or IDEX systems. But I was wondering if you can't combine the advantages of CoreXY and IDEX by letting two CoreXY systems fly over a print bed. I hope you know what I mean without being able to show you any pictures. So I actually mean a CoreXY system (gantry with carriage) for nozzle no.1 and another CoreXY system (gantry with carriage) for nozzle no.2. Both share the rails for Y. There are then a total of 4 motors - two for gantry no.1 and two for gantry no.2.Sounds like a lot of work and you can certainly ask yourself what that is all about. But I figured that this should make it possible to create a fast and lightweight IDEX system. Super fast mirror or doubling mode and also high printing speed with two materials.

What do you all mean? I would be happy about your opinions and of course whether you think that is possible.

-

I'm not following what you are describing.

Would this be just like two COREXY machines sitting next to each other with the Y-axis rails lined up?

Or would one rail be able to crash into the other rail if you were not careful because the print areas overlap?

If so, how would the belts be arranged to allow that?I've just looked, and it's been discussed here a few years ago. Maybe that will help.

And dc42 was involved in the discussions!

-

I saw the Hlidskjalf concept, which has both printheads on one gantry. Also a cool project, by the way. But what I mean are two separate gantries. I made a little sketch so that it might be a little clearer. I think the 4 timing belts would somehow cascade in height on top of each other.

-

@yeti-wst IDEXY has certainly been done before, although I don't recall seeing a IDEXY design based on CoreXY kinematics. RRF should be able to drive it without modification. It looks to me to be a good candidate for a Duet 3 or 3 Mini plus two tool boards. Alternatively a Duet 3 Mini plus the 2-driver add on could be used, but then there will be more wires to the tool heads.

-

Thanks for the feedback. Good to know that it is technically feasible.

I don't know yet whether it really makes sense to build it. I would be happy to receive further opinions.

-

@yeti-wst bear in mind that if you want to print two copies of something, the bed needs to be very flat and the gantries not sag because there is only one Z axis to do mesh bed compensation.

We're planning to allow that type of machine to print a GCode stream that moves the two heads independently. That could either be two separate objects, or two parts of a single large object.

A further extension would be to put two print heads on each gantry IDEX-style.

-

@dc42 I asked about this same idea a few months ago. Would there be any crazy things that would have to be done on the gcode side or is it possible that the tools are attached to the different sets of axis and that is how the machine understands which set to use? I understand the tool setup in m563 for Cartesian idex the 2nd tool is mapped to y u and z. Would it just be u v and z? Then home to max. I understand that the firmware doesn't support printing 2 different gcodes for the two gantrys but simple 2 color and multi material should work right?

-

@yeti-wst the belt layout would simply be the original crossover corexy belt path stacked instead of the fabutotum layout. Two more motors flipped over with the pulleys pointed down and bingo Bango.

-

For this kind of setup a Dual-Wire-Gantry basis might be easier to set up because it's stacking free for normal XY operations. You can then add U and V on the next layer. The only thing to consider is that one axis has double the "steps" through pulley setup; easy to address in the kinematics matrix though.

-

@oliof I considered Synchromesh. What are you talking about with the steps being double? All 4 pulleys would be the same size.

-

@breed that's specific to DualWire Gantry kinematics. It doesn't necessarily use wire. See https://reprap.org/wiki/Dualwire-Gantry_(DW-G).

Re: syncromesh: Always interesting. I dimly remember reports that it's prone to stretching, but I'm not sure if that was just early attempts that never got re-evaluated (similat to the infamous hackaday article that begat the idea that CoreXY is better than HBot in terms of racking, which the original author years later pedalled back on in the comments: The HBot was built on self printed pulleys and cheap belts, the CoreXY on machined pulleys and quality belts ... no wonder the second was better).

-

Hello to all 3d print addicted

Already in 2019 exactly this idea came to my mind and it did not left me. Some months ago I finished the mechanics side and the dual gantry corexy is running with just one gantry.

Currently I am struggling with the strategy to get the second gantry to life.

Already in 2017 titan robotics announced the "the cronus" which has 5 independent gantries. Every gantry has its own g-code (created by autodesk netfabb 2017). Practically I do not know how they achieved the synchronisation between the gantries and how to force each gantry to park and pause when he has finished its layer and has to wait for the others.

In general I think this is a totally underestimated technologie / strategy where we should put more effort into. -

@slaughter2k independent gcode streams will be an upcoming feature in RepRapFirmware v3.5

-

oh, that is very interesting.

Is there an estimation when 3.5 will be released? Is there already a beta for testing available? -

@slaughter2k probably best to check here, the feature seems to be under heavy development but maybe dc42 has a preliminary build https://forum.duet3d.com/topic/27895/beta-testers-for-multiple-motion-system-support