Mesh compensation results backwards

-

Hmm... Curious.

Some Z axis movement error perhaps?

What is your Z axis setup? What is the Z axis movement for one full stepper step - not a micro-step?

Frederick

-

@fcwilt

So I'm not exactly sure how to move a single step, but mechanically this is how I am setup:

Dual 1.8° steppers w/ TR8*2 lead screwsM350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation M92 X201.2499 Y201.2499 Z1601.584008 C100 E421.1332199:690 ; T8x2 1-Start Lead ScrewWhen I perform a single rotation of the Z motor my Dial Gauge reads 2mm at bed center, which is expected. It reads the same when moved to the lead screws and moved one full rotation.

Maybe I need to perform some tests for repeatability?

-

Great.

That's what I needed to know. You have plenty of resolution even at full steps. A 1.8 degree stepper has 200 steps per revolution. You have 2mm of movement per full revolution. Which means one full step moves 2mm / 200 or 0.01mm.

I have heard tell of inexpensive lead screws having poor linearity (moving the same amount for each revolution) . I don't know how common that may be. You could easily use the dial gauge to measure that at different Z positions if you have a 123 block or something to perform the same function.

I get my lead screws from these folks: McMaster Carr

Frederick

-

Thank you for your help up until now. I'll continue to do some testing later this week to see if this is motor-related.

I got my Lead Screws from ZYLTech a few years ago. Never thought to look at McMaster. I suspect if there were variations I should see those in my layer lines, which I don't normally have an issue with since upgrading to these. However the anti-backlash nuts are brass and could have some play. I do my best to keep them greased.

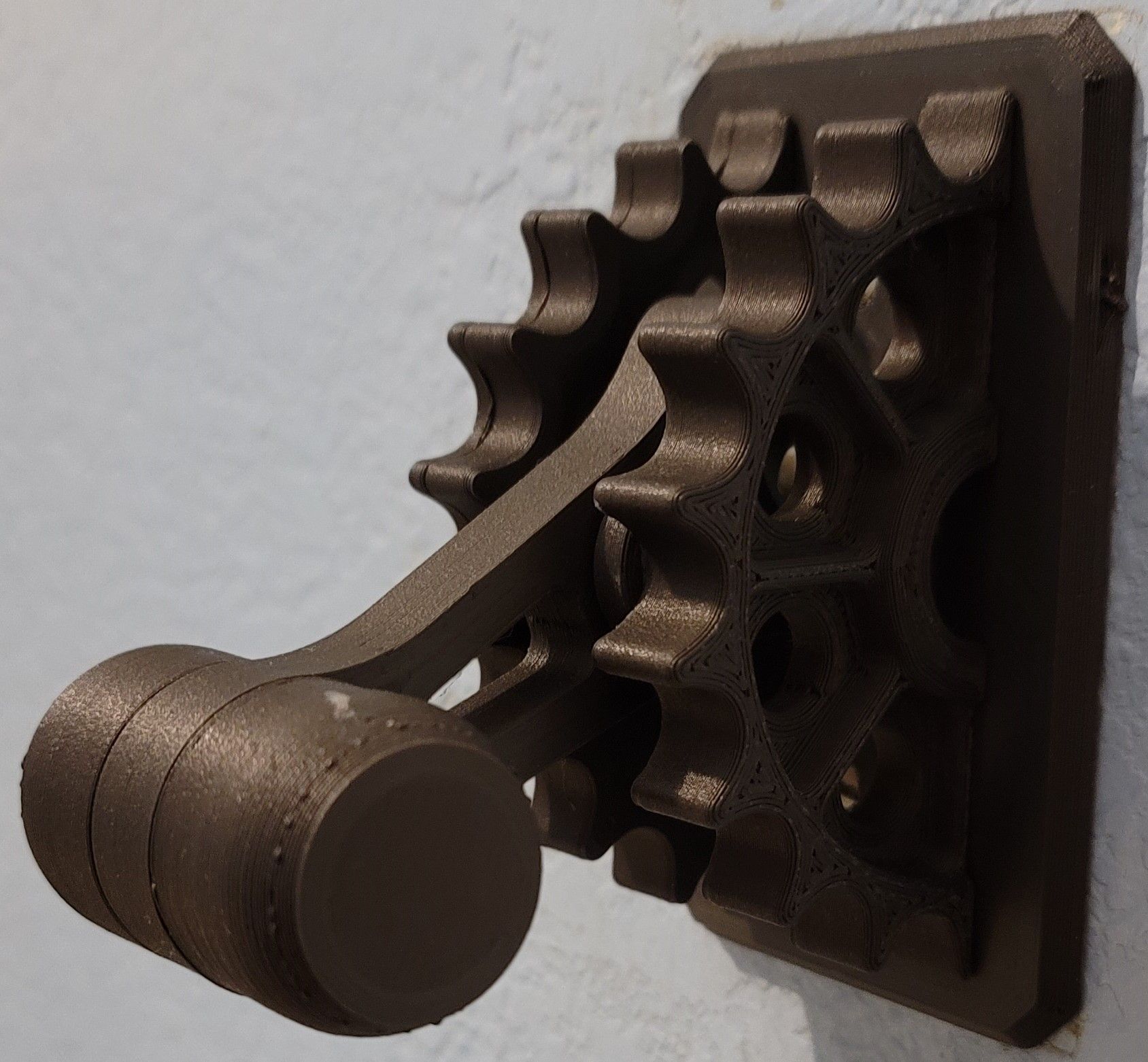

I am thinking there may be some play in my Tool Carrier. I know that I can get flex up to 0.14mm when I put some pressure on it, but it does want to return back to 0. Today looking into this further I dove the tool into the bed and found it didn't want to return to its normal height. So I docked and undocked it and picked it up again, the tool height was back to normal. I'm suspecting that it's shifting in the kinematics and even though it's a ball bearing and has no scoring it's not able to return. This would not explain the BLTouch variation, but maybe a factor when it comes to printing.