Mesh compensation results backwards

-

In your MyMeshCompStep1 file you have

if var.probezOne - var.probezTwo <= 0.005Ignoring any floating point errors:

if var.probezOne = 1.006 and var.probeTwo = 1.000 then var.probezOne - var.probezTwo = 0.006 and the test fails.

if var.probezOne = 1.000 and var.probeTwo = 1.006 then var.probezOne - var.probezTwo = -0.006 and the test succeeds.

In both cases the difference is 0.006.

I don't understand what you are testing for.

Also the number returned by G30 S-1 does not have a fixed relationship to the probe Z Trigger Height setting.

Thanks.

Frederick

-

@gamefanatic3d said in Mesh compensation results backwards:

I believe the Duet may have just been having a moment as I was getting a homing error with negative values when performed the first homez.g after startup. Any future homing would be successful. This appears to have cleared itself up as easily as it came with me doing nothing to the system other than turning it off and back on a few times...

Have you tried a homez.g without the conditional gcode?

-

@phaedrux said in Mesh compensation results backwards:

@gamefanatic3d said in Mesh compensation results backwards:

Have you tried a homez.g without the conditional gcode?I started off without the conditional code and only added it due to a recommendation by @fcwilt.

-

@fcwilt said in Mesh compensation results backwards:

In your MyMeshCompStep1 file you have

if var.probezOne - var.probezTwo <= 0.005Ignoring any floating point errors:

if var.probezOne = 1.006 and var.probeTwo = 1.000 then var.probezOne - var.probezTwo = 0.006 and the test fails.

if var.probezOne = 1.000 and var.probeTwo = 1.006 then var.probezOne - var.probezTwo = -0.006 and the test succeeds.

In both cases the difference is 0.006.

I don't understand what you are testing for.

Also the number returned by G30 S-1 does not have a fixed relationship to the probe Z Trigger Height setting.

Thanks.

Frederick

I'm attempting to get a height value from the BLTouch that represents the difference from Z-0 which I am interpreting to be in direct relation to when I run my G30.

In this case, I'm interested in the return values so I can better understand what is happening and see the variations. I'm not so sure how much it matters on the macro as it's not what's actually coming up with the heightmap values, I'm just using it to test my theory and why I can manually set my values in the heightmap vs using the BLTouch and the G29. -

Thanks.

I just got back from testing on my printer. I setup the M557 to probe a 3x3 grid. I placed a 1mm thickness gauge at the point at the center of the grid. I created the height map. Below are the values. As you can see the 1mm thickness gauge is showing as a positive value which is as it should be.

-0.243, -0.082, 0.013 -0.217, 1.115, 0.050 -0.195, -0.053, 0.027Here I used a larger and thicker object leaving it in place at the center of the bed so it's thickness was affecting the Z=0 Datum. As you can see the center point is now reading near 0 and all that other points are reading low by appx the thickness of the object.

-3.311, -3.171, -3.068 -3.306, 0.001, -3.036 -3.278, -3.145, -3.065So all I can think of is your Z=0 Datum is off.

Frederick

-

Going with where you are headed I did 3 heightmaps. All will use the same points and were done with the bed at 70°C.

Map1

Normal height map-0.050, -0.086, 0.053 0.067, 0.007, 0.090 0.251, 0.020, -0.019Map2

Normal level with 0.8 feeler gauge put in after in the middle:-0.031, -0.124, -0.038 0.061, 0.836, -0.013 0.242, -0.035, -0.120Map3

0.8 feeler gauge in place when G30 performed:-0.927, -0.969, -0.847 -0.833, -0.004, -0.807 -0.653, -0.874, -0.904Now taking a look at just the difference between Map1 and Map2 we can see the obvious and expected difference at the middle point. I am a little plagued by the right values being nearly 0.1mm difference. I now wonder if this is my probe or my hardware.

When I run my Dial Guage out from the middle I get a negative value of ~ -0.14 after setting its Z-0 at my middle probing point. This is about what I expect based on my manual leveling.

-

Hmm... Curious.

Some Z axis movement error perhaps?

What is your Z axis setup? What is the Z axis movement for one full stepper step - not a micro-step?

Frederick

-

@fcwilt

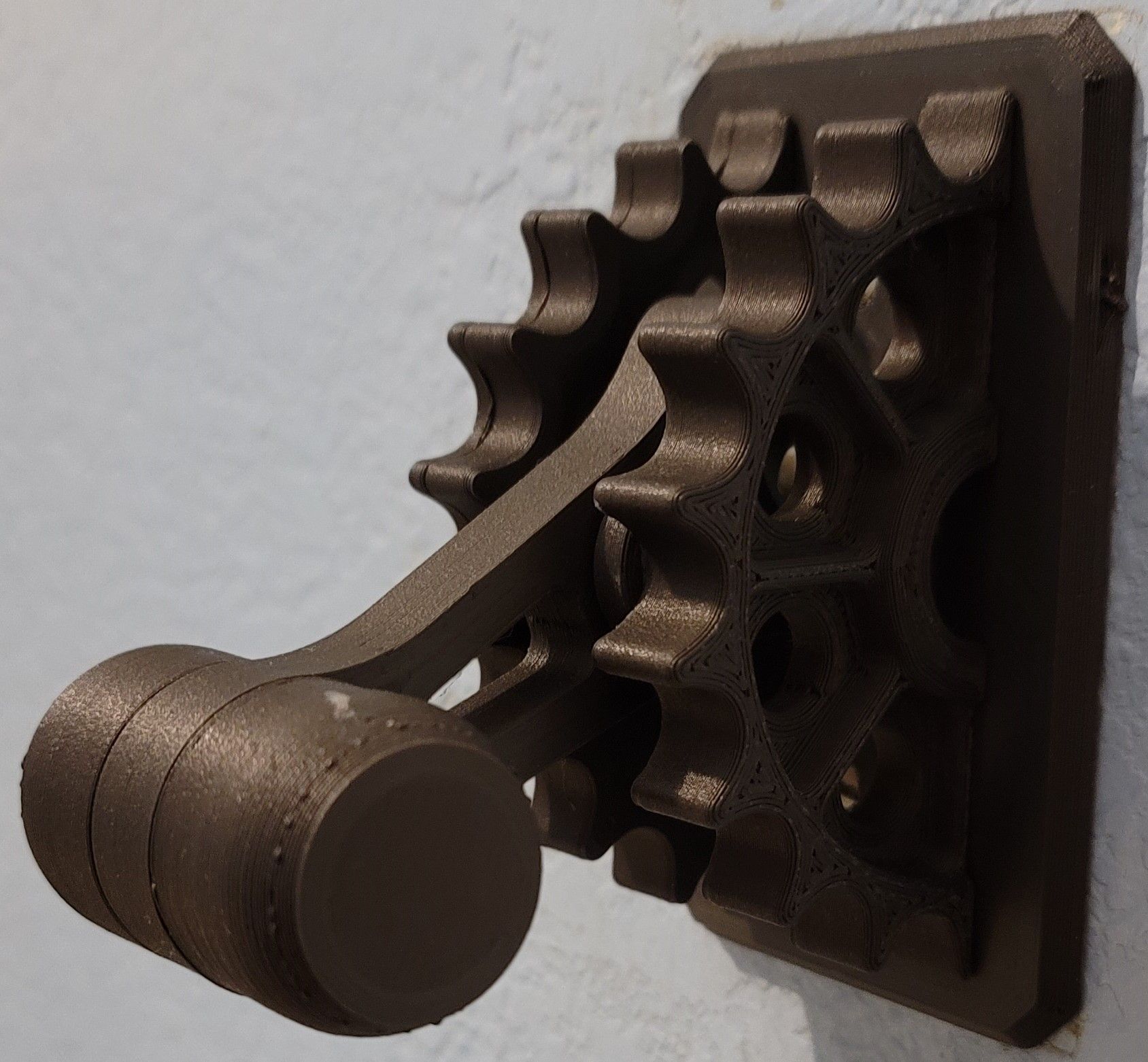

So I'm not exactly sure how to move a single step, but mechanically this is how I am setup:

Dual 1.8° steppers w/ TR8*2 lead screwsM350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation M92 X201.2499 Y201.2499 Z1601.584008 C100 E421.1332199:690 ; T8x2 1-Start Lead ScrewWhen I perform a single rotation of the Z motor my Dial Gauge reads 2mm at bed center, which is expected. It reads the same when moved to the lead screws and moved one full rotation.

Maybe I need to perform some tests for repeatability?

-

Great.

That's what I needed to know. You have plenty of resolution even at full steps. A 1.8 degree stepper has 200 steps per revolution. You have 2mm of movement per full revolution. Which means one full step moves 2mm / 200 or 0.01mm.

I have heard tell of inexpensive lead screws having poor linearity (moving the same amount for each revolution) . I don't know how common that may be. You could easily use the dial gauge to measure that at different Z positions if you have a 123 block or something to perform the same function.

I get my lead screws from these folks: McMaster Carr

Frederick

-

Thank you for your help up until now. I'll continue to do some testing later this week to see if this is motor-related.

I got my Lead Screws from ZYLTech a few years ago. Never thought to look at McMaster. I suspect if there were variations I should see those in my layer lines, which I don't normally have an issue with since upgrading to these. However the anti-backlash nuts are brass and could have some play. I do my best to keep them greased.

I am thinking there may be some play in my Tool Carrier. I know that I can get flex up to 0.14mm when I put some pressure on it, but it does want to return back to 0. Today looking into this further I dove the tool into the bed and found it didn't want to return to its normal height. So I docked and undocked it and picked it up again, the tool height was back to normal. I'm suspecting that it's shifting in the kinematics and even though it's a ball bearing and has no scoring it's not able to return. This would not explain the BLTouch variation, but maybe a factor when it comes to printing.