RRF 3.4 input shaping preview available

-

@owend I confirm there is a bug in the implementation of DAA. I hope to get time to fix it today.

-

I have updated the binaries at https://www.dropbox.com/sh/l020weqx7pijv84/AACFM3knhVXQ1hKu6NyKOfx6a?dl=0 again:

- Fixed a bug that caused incorrect movements when DAA input shaping was selected

- Fixed a bug that sometimes caused incorrect extrusion on CAN-connected extruders when pressure advance was used

- Fixed a bug that caused a filament error pause to lock up if the pause.g file used certain commands in combination, e.g. a M106 command followed by a tool change

- Increased Duet 3 MB6HC Ethernet task stack size by 50 words

- Fixed a bug that caused a crash when the slicer labeled objects using M486 and there were more than 20 (Duet 2) or 40 (Duet 3) objects on the build plate. Unlike the other ones, this bug is also present in RRF 3.3 stable and 3.4.0beta1.

I have tested that movement with DAA enabled is now working; however on my delta printer, when printing the test piece it's much less effective at reducing ringing than the other shaping methods. I have also tested with pressure advance set to 0.5.

-

@dc42

I got Duet3 + toolboard ver1.1 installed - Today i have upgraded to 3.4.0beta1-inputshaping (2021-07-11) - i have then used latest binaries to be able use accelerometer in SBC configuration. -when i try to G1 X-50 G4 S2 M956 P121.0 S1000 A0 G4 P10 G1 X50 F20000 i received Error: M956: Accelerometer not found but when i send M120 B121 in response i got : Accelerometer detected: yes, status: 00

Is this got any thing to toolboard still being: Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58)? is there any files to upgrade TOOL1LC to 3.4 firmware? -

@cadetc you don't need to upgrade the tool board firmware. I assume you have verified that you are running DSF 3.4.0b1 on the Pi. We are looking into a possible cause of the problem you are having with M956.

-

@dc42

Info copied from DWC : Machine specific-General :

Board: Duet 3 MB6HC (MB6HC)

DSF Version: 3.4-b1

Firmware: RepRapFirmware for Duet 3 MB6HC 3.4.0beta1-inputshaping (2021-07-11)Thanks,

-

@dc42 here the same error , accelerometer detected but when trying to perform a data collect, it says acceleromter not found

m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.0beta1 (2021-07-10 16:20:28) running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956BA-NA3TN-6J9DL-3S46S-99AUT Used output buffers: 1 of 40 (10 max) === RTOS === Static ram: 150904 Dynamic ram: 62912 of which 24 recycled Never used RAM 140352, free system stack 146 words Tasks: SBC(ready,0.7%,308) HEAT(delaying,0.0%,325) Move(notifyWait,0.0%,266) CanReceiv(notifyWait,0.0%,774) CanSender(notifyWait,0.0%,374) CanClock(delaying,0.0%,339) TMC(notifyWait,7.4%,59) MAIN(running,91.8%,922) IDLE(ready,0.0%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:40:04 ago, cause: software Last software reset at 2021-07-11 15:33, reason: User, none spinning, available RAM 137420, slot 0 Software reset code 0x0012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 Step timer max interval 172 MCU temperature: min 31.1, current 33.9, max 47.4 Supply voltage: min 24.0, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: position 41808, standstill, reads 41390, writes 20 timeouts 0, SG min/max 0/425 Driver 1: position -25728, standstill, reads 41390, writes 20 timeouts 0, SG min/max 0/995 Driver 2: position 3893, standstill, reads 41390, writes 20 timeouts 0, SG min/max 0/852 Driver 3: position 0, standstill, reads 41391, writes 20 timeouts 0, SG min/max 0/280 Driver 4: position 0, standstill, reads 41391, writes 20 timeouts 0, SG min/max 0/825 Driver 5: position 0, standstill, reads 41399, writes 12 timeouts 0, SG min/max 0/0 Date/time: 2021-07-11 16:13:58 Slowest loop: 56.12ms; fastest: 0.04ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, maxWait 1844035ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 13, completed moves 13, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 2 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet* is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: no data received === CAN === Messages queued 21655, received 30029, lost 0, longest wait 5ms for reply type 6024, peak Tx sync delay 169, free buffers 49 (min 48), ts 12021/12020/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === State: 4, failed transfers: 0, checksum errors: 0 Last transfer: 2ms ago RX/TX seq numbers: 29527/29527 SPI underruns 0, overruns 0 Disconnects: 0, timeouts: 0, IAP RAM available 0x2c7a4 Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.4-b1 Code buffer space: 4096 Configured SPI speed: 8000000Hz Full transfers per second: 39.59, max wait times: 49.2ms/0.0ms Codes per second: 0.04 Maximum length of RX/TX data transfers: 3196/800 m122 b121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 2108, free system stack 2789 words Tasks: Move(notifyWait,0.0%,153) HEAT(delaying,0.2%,117) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,2.8%,57) MAIN(running,92.0%,352) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0% Last reset 00:01:14 ago, cause: VDD brownout Last software reset data not available Driver 0: position 0, 859.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 11, reads 18391, writes 0, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/5, peak Rx sync delay 192, resyncs 0/0, no step interrupt scheduled VIN: 24.4V MCU temperature: min 37.5C, current 39.0C, max 39.0C Ticks since heat task active 2, ADC conversions started 74496, completed 74495, timed out 0, errs 0 Last sensors broadcast 0x00000002 found 1 6 ticks ago, loop time 0 CAN messages queued 492, send timeouts 0, received 339, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 0, other errors 0 === Filament sensors === Interrupt 5726621 to 0us, poll 9 to 432us Driver 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 m122 b121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 2108, free system stack 2789 words Tasks: Move(notifyWait,0.0%,153) HEAT(delaying,0.2%,113) CanAsync(notifyWait,0.0%,61) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(delaying,2.8%,57) MAIN(running,92.0%,352) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0% Last reset 00:43:34 ago, cause: software Last software reset data not available Driver 0: position 0, 859.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 23, reads 5309, writes 0, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/6, peak Rx sync delay 212, resyncs 0/0, no step interrupt scheduled VIN: 24.4V MCU temperature: min 38.8C, current 40.0C, max 40.3C Ticks since heat task active 129, ADC conversions started 2614124, completed 2614122, timed out 0, errs 0 Last sensors broadcast 0x00000002 found 1 134 ticks ago, loop time 0 CAN messages queued 8362, send timeouts 0, received 6006, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 0, other errors 0 === Filament sensors === Interrupt 5726621 to 0us, poll 9 to 433us Driver 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0regards

-

@frederik thanks, we have identified the cause. Fixing it will require a change to DSF on the Pi.

Meanwhile, you should be able to send the command to the Duet from an attached PanelDue if you have one, or via USB.

-

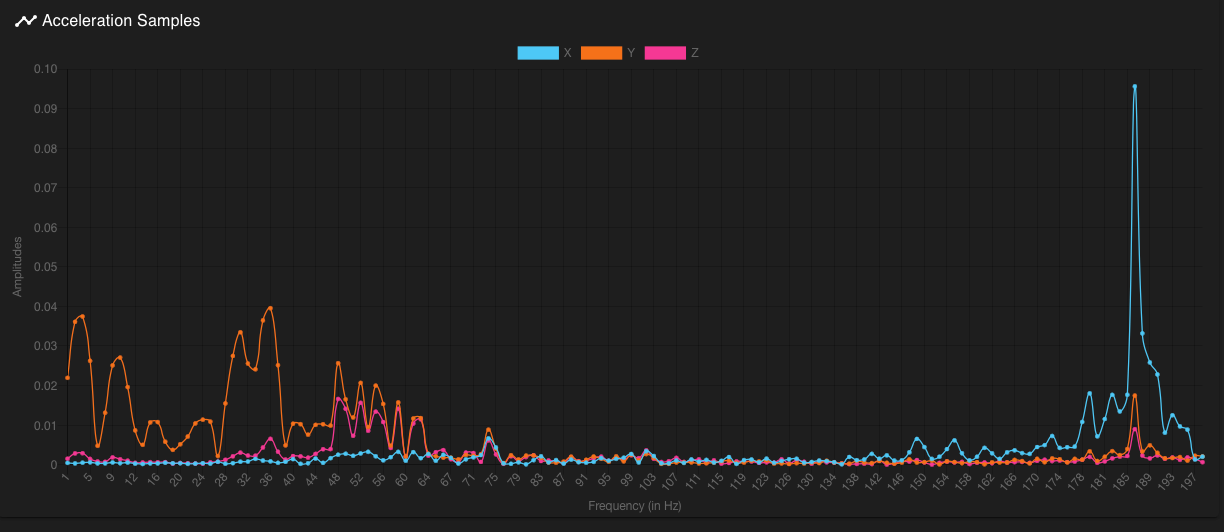

Measurement without input shaping (Y axis):

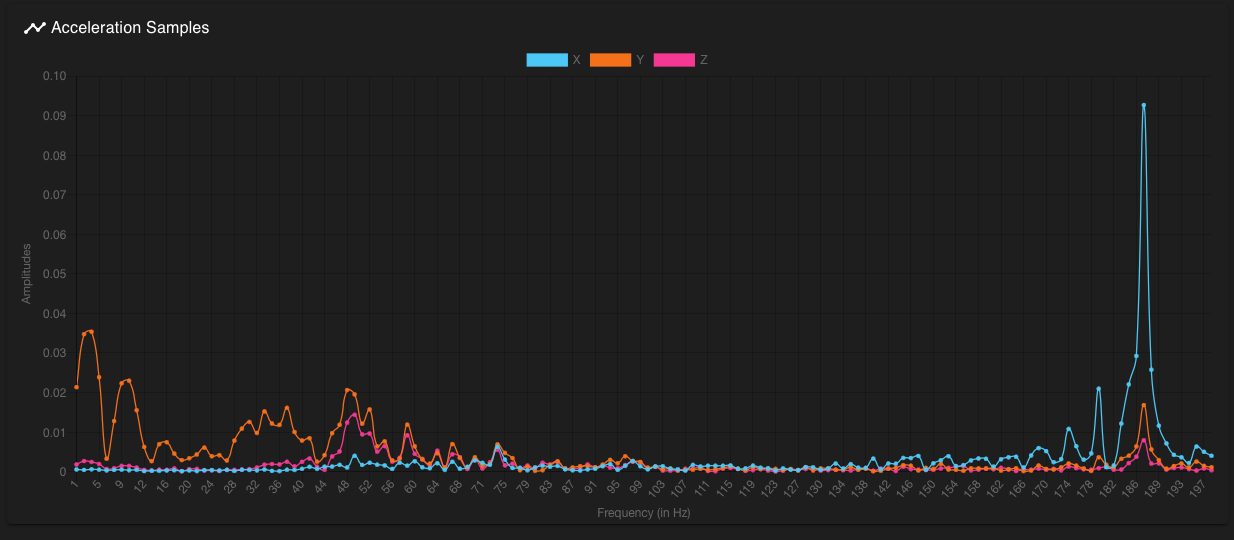

With ZVD input shaping:

The print results to also show that it is working.

I also have no issues with PA nor was it necessary to recalibrate PA.Is it planned to to be able to use different shapers and frequencies per axis or to use an "automatic frequency and shaper finder" in conjunction with the accelerometer (like Klipper does)?

-

@argo the automatic shaper recommendation generator is under development.

-

@dc42 I mis-typed, I meant that PA clunked unless I took it down to 0.04 (not 0.4), reducing it from my usual 0.12 value. Sorry about that.

I've grabbed the latest firmware and still have that same result of clunking with PA at or above 0.04 or so. My extruder is attached to E0 on the duet2, I have a pretty standard railcore setup, so I have z steppers on a duex5 but X/Y and E0 are on the duet2 wifi.

Aside from the PA clunking, everything else so far seems fine, things were printing ok with DAA, and now with zvdd in some quick tests.

-

@argo, as you have a fairly broad resonance, ZVDD will probably work better than ZVD.

-

@skrotz said in RRF 3.4 input shaping preview available:

@dc42 I mis-typed, I meant that PA clunked unless I took it down to 0.04 (not 0.4), reducing it from my usual 0.12 value. Sorry about that.

Interesting, my Duet WiFi powered delta normally runs at PA 0.2 and has been fine. My tool changer didn't have the correct extrusion with the earlier firmware, but that uses a tool board and it is running fine now with the later firmware.

-

@dc42 definitely some extruder weirdness for me that I don't get on 3.3.

I only had PA on briefly (the clunking is disconcerting) on a test print of a calibration cube but did notice this from M122:

=== Move ===

DMs created 83, segments created 35, maxWait 135339ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 11522, completed moves 11522, hiccups 511, stepErrors 2, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1my extruder motor is the standard LDO one in a filastruder railcore kit, used as a direct drive.

-

@skrotz thanks.The step errors are not right. Please can you connect a laptop to the Duet via USB, load a terminal emulator (e.g. YAT), and send M111 S1 P4. That will enable Move debugging. Then run that print. For each step error recorded you should get a few lines of DDA and DM printout in the terminal. Post those lines here.

Also please post the print file and your config.g.

-

Using the same frequency with ZVDD or other shaper is giving me worse results. I don‘t think I can just use the measured ringing frequency with shapers other than ZVD?

-

@dc42 it took a bit of finagling to get things hooked up to the PC, but so far even though I heard the clunking it didn't output anything on the terminal at that point even with the debug enabled. I may be able to try again later, is there anything else I could/should enable? an M122 after stopping showed "hiccups" but no stepper errors at that point. I only did a small amount of the print though, I had to stop as I think I injected something via the terminal at the wrong time and caused some problems.

I've included my config file and the gcode I'm printing.

-

@skrotz please can you try again, this time wait until M122 shows some step errors, as it did in your previous M122 that you posted here.

Some extduders do sound clunky when used with pressure advance, however it shouldn't be different in the latest 3.4 with input shaping compared to 3.3.

-

@dc42

Just an update.

Upgraded to the latest binary.

This time the print completed with no apparent missed step issues, or clunking including during sectioins using DAA.

No step errors in the M122 report, but a couple of hiccups.M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0beta1-inputshaping (2021-07-11 11:04:56) running on Duet WiFi 1.02 or later === MainDDARing === Scheduled moves 34420, completed moves 34420, hiccups 4, stepErrors 0, LaErrors 0, Underruns [0, 0, 6], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1Nothing of note shows up in the M111 debug log.

Too late in the night to evaluate the results in regards to print quality of each mode.

-

@dc42 There's definitely different behavior between 3.3 and 3.4 - no clunks on 3.3. I need to do a quick print on 3.3 with PA disabled to double check some strangeness I see with same on 3.4, then will try and collect the data again, I think I sorted out what went wrong previously with my 3.4 print (user error basically).

-

@dc42 ok I did a simple print of the xyz calibration cube on 3.3 with PA disabled, and it looks clean, but the same print on 3.4 shows some zits or bubbles in spots that don't show in the 3.3 print - it looks like it is overextruding sometimes before it changes direction, they occur in several spots on the "X" of the calibration cube. They are consistent in where they occur in 3.4, multiple prints show them in the same places. Something is definitely wonky with extrusion in general for me in 3.4, and made worse when PA is enabled.