Printing problem with filament or set up?

-

Hello ok i have been working on my E3D Bog Box printer for the few weeks by replacing the rumba board and other things which go with it over for the Duet wifi board and now have it installed with the latest software (DWC 3.2.2). The printer is a dual head but at this time i am only using one head to figure this stuff out because i have never used g code before or have i built a 3D printer as well. So at this point i have the mother board in and wired up and somewhat working. it will print but not well sometimes.

I have several things here i would like to see if any one can help me get to where i need to be.

- i have printed the 100mm Round cube and here is the print file

100mm_Rounded_Cube.gcode 30JUN2021.gcode

-

i have printed the Make robot as well and here is the this file1_MAKE_Robot_V6.gcode 30JUN2021 B.gcode

-

i do not where to find or look for the codes i need to figure out how to change the filament feed rate into the extruder. on the DCW i can extrude like 1, 5, 10 15 mm/S but how can make do 6 or 7 mm/s feed rate?

-

i am using G29 S1 to engage bed compensation, how to make this happen every time print without me doing this every print?

-

the filament i am using is clear PLA 1.75" 210-220 C

when the printer stops and moves to different location to start printing again the filament keeps coming our the extruder and this is causing a mess with the prints which is why i am asking #3 above.

Thank you for your time.

-

oh yes you might need to see some files as well.

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue May 25 2021 18:51:26 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"big Print 1" ; set printer name

;M669 K1 ; select CoreXY mode; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y320.00 Z1600.00 E274.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E270.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X250 Y200 Z290 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S2 ; configure Z-probe endstop for high end on Z; Z-Probe

;M558 P1 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

M558 P5 C"e0stop" H5 F120 T3000 ; Z probe connected to E0 endstop input

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X33 Y26 Z1.5 ; set Z probe trigger value, offset and trigger height

M557 X15:250 Y15:200 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R160 S220 ; set initial tool 0 active and temp 240C and standby temperature to 160C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue May 25 2021 18:51:26 GMT-0400 (Eastern Daylight Time)

M561 ; clear any bed transform

G29 ; probe the bed and enable compensation

RepRapFirmware height map file v2 generated at 2021-06-30 10:05, min error -0.931, max error 0.116, mean -0.343, deviation 0.195

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum

15.00,250.00,15.00,200.00,-1.00,20.00,20.00,12,10

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0

0, -0.391, 0.081, -0.043, -0.407, -0.400, -0.209, -0.586, -0.212, -0.297, -0.377, -0.565

0, -0.313, -0.019, -0.141, -0.427, -0.296, -0.216, -0.226, -0.240, -0.260, -0.322, -0.596

0, -0.086, -0.036, 0.001, -0.063, -0.426, -0.298, -0.306, -0.186, -0.273, -0.418, -0.522

0, 0.116, -0.271, -0.145, -0.116, -0.637, -0.173, -0.285, -0.247, -0.289, -0.418, -0.526

0, -0.026, -0.192, -0.289, -0.281, -0.233, -0.225, -0.337, -0.396, -0.314, -0.460, -0.479

0, -0.058, -0.345, -0.293, -0.192, 0.090, -0.186, -0.409, -0.407, -0.377, -0.509, -0.702

0, 0.028, -0.416, -0.423, -0.352, -0.314, -0.240, -0.416, -0.495, -0.408, -0.501, -0.558

0, -0.143, -0.517, -0.570, -0.592, -0.584, -0.331, -0.421, -0.429, -0.592, -0.579, -0.678

0, -0.249, -0.394, -0.619, -0.409, -0.417, -0.288, -0.522, -0.551, -0.584, -0.749, -0.931let me know if this is enough or you need something else.

-

@testpro said in Printing problem with filament or set up?:

i do not where to find or look for the codes i need to figure out how to change the filament feed rate into the extruder. on the DCW i can extrude like 1, 5, 10 15 mm/S but how can make do 6 or 7 mm/s feed rate?

If you want to extrude at specific speeds and distances manually you can command the extruder directly with G1 E10 F300 for example. G1 is the move axis command. E is the axis you want to move, In this case the extruder of the currently selected tool, 10 is the amount you want to move it in mm, and F300 is the feed rate in mm/min.

Calibrating the extruder steps per mm here if you haven't already done so: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

That box doesn't look too bad.

@testpro said in Printing problem with filament or set up?:

i am using G29 S1 to engage bed compensation, how to make this happen every time print without me doing this every print?

You can add the G29 S1 to your slicer start gcode after the printer has been homed with G28.

@testpro said in Printing problem with filament or set up?:

when the printer stops and moves to different location to start printing again the filament keeps coming our the extruder and this is causing a mess with the prints which is why i am asking #3 above.

That sounds like you need to tune retraction.

-

@phaedrux

sorry for the long delay in responding to you. My Father in law passed.ok i have printed the bottom of the carriage for the hot ends and extruders. i now have it installed with two now v6 Gold extruders form E3d. after reassembled the extruder was skipping here and there during a trial print so i checked the extruder rate, the tension on the pivot arm which pushed against the filament and loosened it some. I notice my extruders motors can handle 1.7 amps but were set for 0.8 amps so i set them for 1.2 amps and the extruder runs fine but leaves me to believe maybe the temp for silk PLA filament is not high enough? it is 220C as stated.

so now i am trying to get something to print and not having much luck. I am using OVERTURE filament 1.75 silk Blue PLA.

bed temp 100C hot end is 220 C.

at this point i am trying to print the box again ( it did good last time) but now i can not get it to stick to the surface or bed. it keeps curling up or just comes out of the extruder and will not stick.

i have tried hair spray, some golden brown tape that came with the printer, past and blue apainters tape and nothing sticks to the bed.

i believe i have a problem with z probe. with just the glass or glass and hairspray on the bed the print looks like the bed is uneven. but we have bed compensation on. i have been fighting this for a week. it seems to be the z probe sometimes sees the glass and other times does not.

so i am just tired of trying to get something to print or stick to the bed. this is a major pain.

-

Sorry to hear that.

1.2 amps on the extruder sounds ok.

For the filament, I would suggest getting some plain white/natural color PLA. silk filaments have additives that can make it behave a little different than pure PLA which can make tuning a bit maddening.

For the probe, what kind is it? IR probe? If so glass can be a bit problematic because it's transparent to IR so would need to be able to detect the actual bed surface. When you add hair spray etc to the bed it can block the IR and you can end up with a patchy heightmap. What does your heightmap look like now? Post a photo. You could also try placing a piece of plain white paper on the bed and probing on that to compare.

Bed temp of 100c might also be too hot for PLA. Try 65c instead.

-

@phaedrux

thank youok will check on what you stated above. Now the extruder will not extrude. the wheel is turning but the filament is not. yes the wheel is dirty or clocked at this point. so now i have got to figure this out as well.

i have some Plain Green PLA from the same place. this should work correct?

-

@testpro are you able to push the filament through by hand while hot? Is your hotend cooling fan working? Can you try a cold pull to try and remove a clog?

Heat to printing temp and try to force the filament through by hand. If it doesn't make it through turn off the heat and let it cool completely. Then raise the temp to 85c when it reaches the temp try to firmly and steadily pull the filament out. If it still won't release raise temp to 90 and try again. Eventually it should come out with an imprint of the nozzle tip. If it comes out tattered and not cleanely. Reheat to print temp and try again.

Plain green should be fine.

-

@phaedrux

ok i have removed the steel tip and heated it and got everything out. tip not longer clogged. i got some filament in the blue tube in the cool zone (where the fan runs all the time). i am thinking when the tip was to close to the bed it forced extra filament up into the blue tube and caused a drag on the filament. to replaced the tube and put the hot end back with tip. So now can extrude 5mm/s with no skipping.now with the green PLA only and bed temp set at 60 C print 220 C, we are printing the base for the cube and the first layer down looks smooth and nice but when second and third layer come it looks like we are getting small waves in the base. Also when it starts the building the walls around the border they arre getting really wavy as well. I am thinking this has something to do with the Z probe but not really sure.

we have slowed done the extrusion rate the speed of the printer plus we have been playing with the retraction/detraction setting as well. it looks better but still needs some work.

So here are some photos and i am going to send some screen shots of my setting for the file as well so you can see what we have here.

-

@testpro

i do not know how this us supposed to look when printing so here are some photos of the printer printing the first layer. what do you think?

-

You see those places where the lines of the filament are touching?

That's what you want.

Those gaps suggest the nozzle is too far from the bed at those places which may be related to a mesh compensation problem.

Please bring up your height map in the DWC and post a screen shot of it here.

Thanks.

Frederick

-

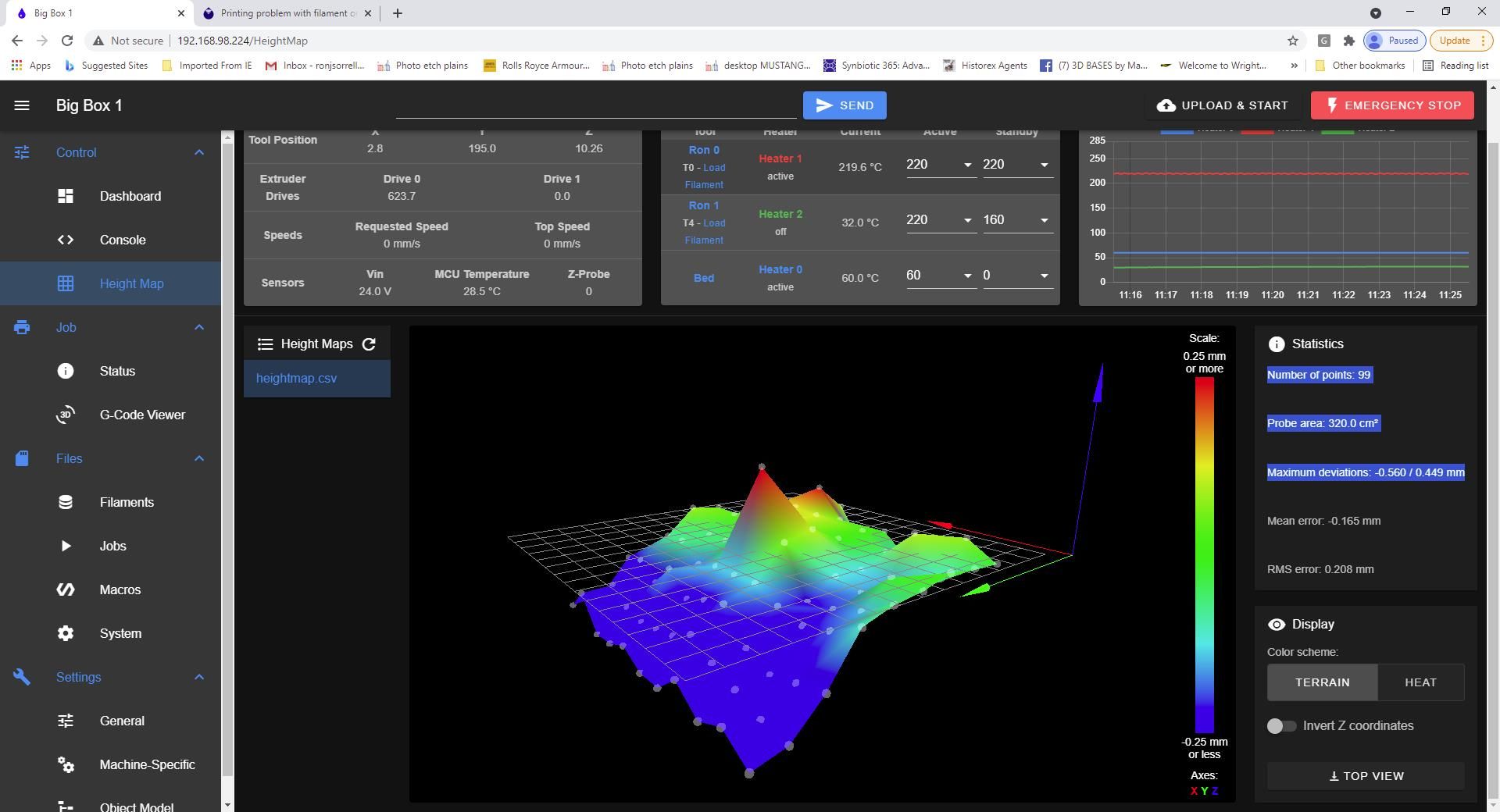

Screen shots of Prusa slicer set up and height map as requested.

-

@testpro said in Printing problem with filament or set up?:

Screen shots of Prusa slicer set up and height map as requested.

I was thinking you could post a .jpg or .png like this:

As to your configuration files just copy and paste into </> tags like this:

; --- home Z --- G1 Z-399 F1200 H1 ; move until endstop switch is activated G1 Z15 F600 ; backoff a bit G1 Z-20 F600 H1 ; move until endstop switch is activated -

undefinedfcwilt

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Big Box 1" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes backwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.47 Y361.26 Z1599.10 E185.0:291.30 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S120 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y200 Z300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S1 ; configure Z-probe endstop for high end on Z; Z-Probe

;M558 P1 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

;G31 P500 X-16.1 Y26 Z0.297 ; set Z probe trigger value, offset and trigger height

;M557 X16.1:300 Y5:174 S20 ; define mesh grid

M558 P5 C"e0stop" H5 F120 T3000 ; Z probe connected to E0 endstop input

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X16.1 Y26 Z0.6

; set Z probe trigger value, offset and trigger height

M557 X15:250 Y15:200 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 1 to 285C

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S285 ; set temperature limit for heater 2 to 285C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H1:2 T45 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1:2 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1:2 T10 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 S"Ron 0" D0 H1 F0 ; define tool 0

G10 P0 X-16.1 Y26 Z5 ; set tool 0 axis offsets

G10 P0 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C

M563 P4 S"Ron 1" D1 H2 F0 ; define tool 1

G10 P4 X16.1 Y26 Z5 ; set tool 0 axis offsets

G10 P4 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss```

undefined -

; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Big Box 1" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes backwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X160.47 Y361.26 Z1599.10 E185.0:291.30 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S120 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X300 Y200 Z300 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z2 S1 ; configure Z-probe endstop for high end on Z ; Z-Probe ;M558 P1 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds ;G31 P500 X-16.1 Y26 Z0.297 ; set Z probe trigger value, offset and trigger height ;M557 X16.1:300 Y5:174 S20 ; define mesh grid M558 P5 C"e0stop" H5 F120 T3000 ; Z probe connected to E0 endstop input ;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved G31 P500 X16.1 Y26 Z0.6 ; set Z probe trigger value, offset and trigger height M557 X15:250 Y15:200 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 285C M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S285 ; set temperature limit for heater 2 to 285C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H1:2 T45 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1:2 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1:2 T10 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 S"Ron 0" D0 H1 F0 ; define tool 0 G10 P0 X-16.1 Y26 Z5 ; set tool 0 axis offsets G10 P0 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C M563 P4 S"Ron 1" D1 H2 F0 ; define tool 1 G10 P4 X16.1 Y26 Z5 ; set tool 0 axis offsets G10 P4 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

Thanks.

That height map is pretty bumpy.

What sort of build surface or system are you using?

You might want to change your M557 command by replacing the S20 with P20.

That will give you a denser grid better able to cope with a bumpy build surface.

And create your height map with the bed at temp - if you aren't already doing that.

Frederick

-

What sort of build surface or system are you using?

i have a E3D Big Box printer that sat in my boss office for the past 6 years. it has a black bed with a piece of glass on top for the build surface. the bed is original to the printer. We use hair spray to help the print stick. It is a vary smooth surface but the bed does have a hump in the middle compared to the bed sides.

You might want to change your M557 command by replacing the S20 with P20.

That will give you a denser grid better able to cope with a bumpy build surface.

ok i will make this change.

And create your height map with the bed at temp - if you aren't already doing that.

the bed and hot end both are on for that procedure.

ok send a new map when done. thanks

-

@phaedrux said in Printing problem with filament or set up?:

For the probe, what kind is it? IR probe? If so glass can be a bit problematic because it's transparent to IR so would need to be able to detect the actual bed surface. When you add hair spray etc to the bed it can block the IR and you can end up with a patchy heightmap. What does your heightmap look like now? Post a photo. You could also try placing a piece of plain white paper on the bed and probing on that to compare.

So seeing your heightmap and your description of the bed I think you may be experiencing what I described. Assuming it's an IR probe.

Have you tried doing a mesh with plain paper on the bed yet?

The first layer looks under extruded and the rest of the layers look over extruded, so I think you are printing the first layer too high and your flow rate is also too high.

Fixing the probe mesh with a piece of paper should help get your first layer distance better.

If you've already calibrated the steps per mm for the extruder you can probably reduce the flow rate in the slicer from 100% to 90 or 95%

-

at this point i am trying to get a better a level on bed by using the metal standoffs for small adjustments and getting the four corners of the bed to the same height and then yes the paper on the bed and run mesh compensation again.

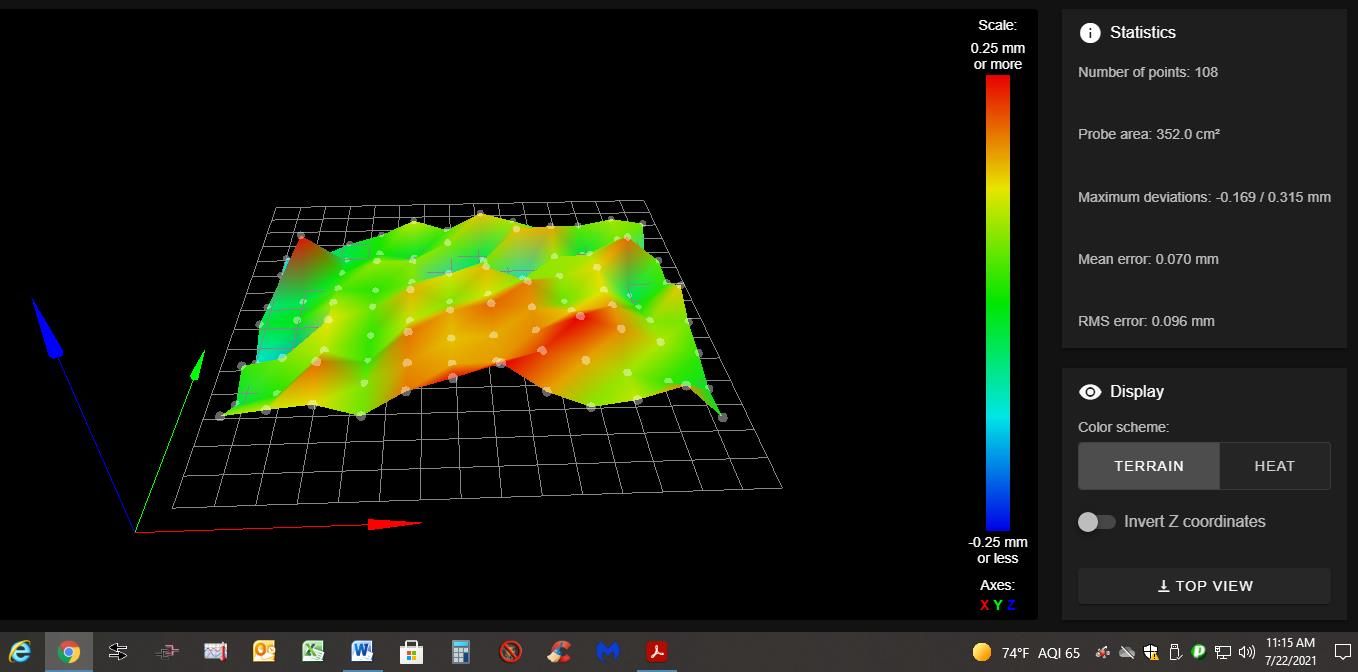

for right now the mech map is looking somewhat better. i no longer have red.

so if i can do a better job leveling the bed maybe this issue will go away with the mech compensation. so more level bed and paper on bed to run mech compensation and i hope this issue goes away.

you have stated:

The first layer looks under extruded and the rest of the layers look over extruded, so I think you are printing the first layer too high and your flow rate is also too high.

At this point the first layer has the lines touching and not separated. But when i run the cube base, just the first layer only i can see where first layer gets thin where the nozzle is too close and then i see where the extruded lines are perfect little lines and not touching and the nozzle is too far away from the bed. So this is what i am trying to over come so i can get a perfect first layer which is even.

Fixing the probe mesh with a piece of paper should help get your first layer distance better.

yes i am hopping so. doing this today.

If you've already calibrated the steps per mm for the extruder you can probably reduce the flow rate in the slicer from 100% to 90 or 95%

yes i have calibrated mm per step but since then i have cut that number in half in the software and this is what i am getting at this point. so after i get the first layer to go down flat thin i will let the print run to do the 2 layers for the base and i am hopping there is no more sand waves on those layers.

i am having some trouble of finding where i need to change some of these settings in the software. Like flow rate you have mentioned above in the slicer for flow rate? i will to find that. i am figuring out with your guys help on what to change but where to change it in slicer or software and what setting to do it under.

that is where we are at this morning.

-

@testpro

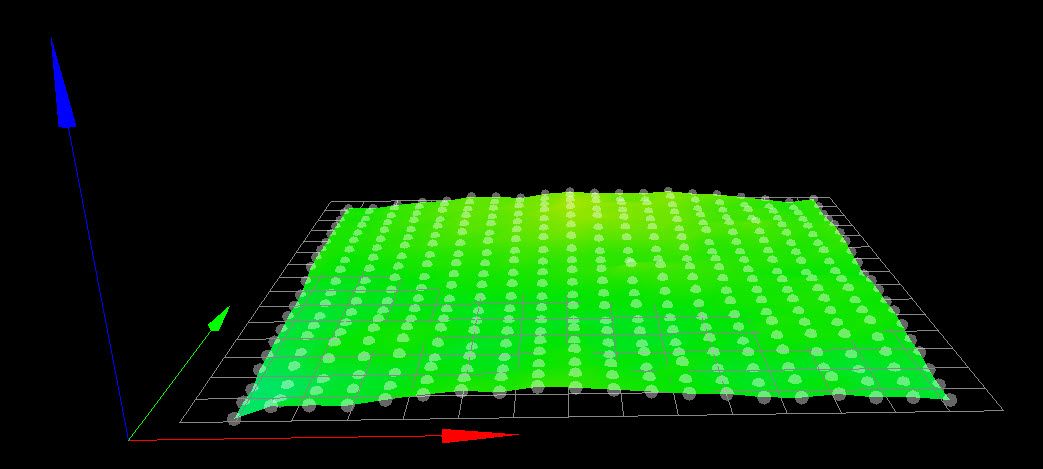

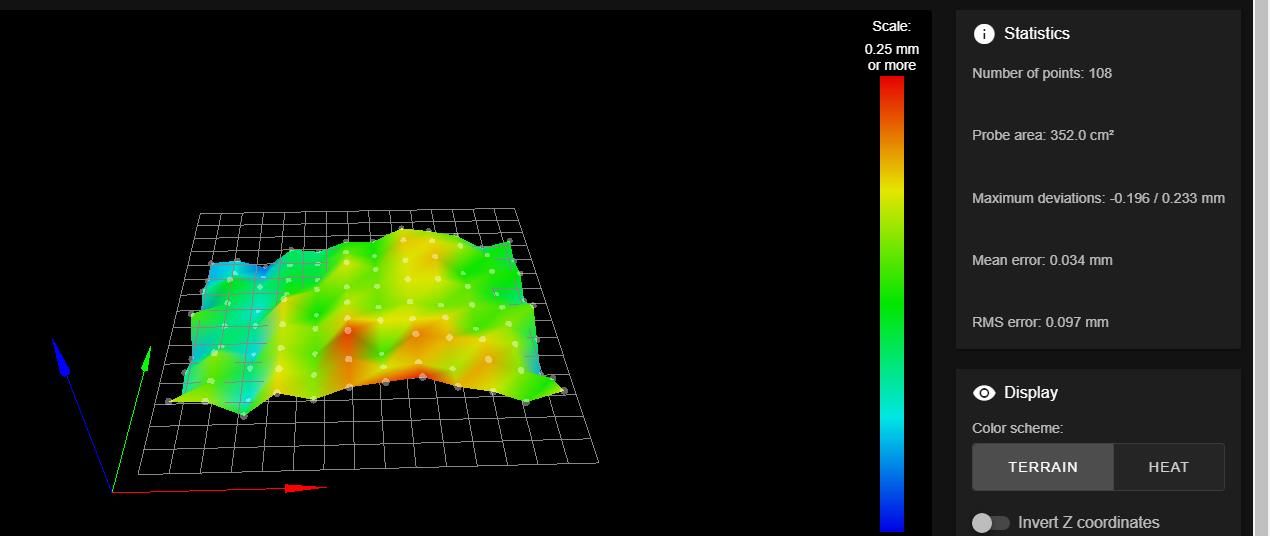

ok leveled the bed to the point where all four corners of the bed are within .2 MM.the height map with paper on bed:

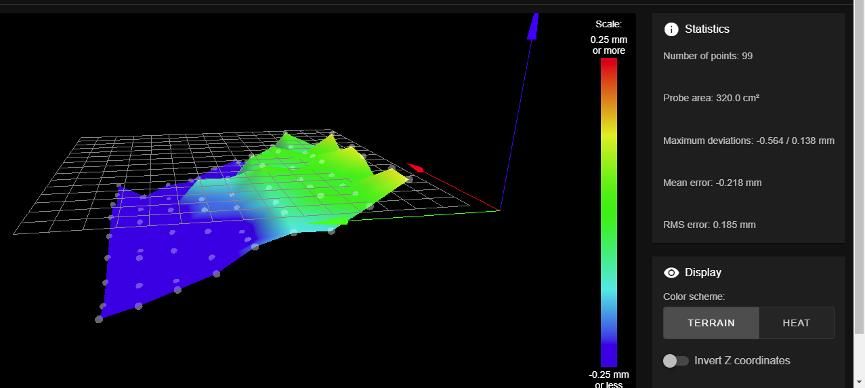

Next i put tape on the bed and performed another height map:

note this one has neg reading of -0.196 too 0.233 mm for a 0.429 mm

so the compensation needs to travel 0.429 mm in total for compensation. But the point to point is really not that much. so now i print the base layer and in some places you can see where it is to thin. so still not keeping up. so either the compensation is not working fast enough or the probe is giving bad measurements.

so now going to run the first layer base twice in a row with no changes and if they look different then the probe is bad.

also as a side note the heat map on the bed is not even either. this can be some of the problem?

-

You can test if the probe is reading correctly:

- move the probe to the center of the bed.

- execute a G30

- move the nozzle to the center of the bed

- jog down until the nozzle is just touching the bed

- verify the position reported is Z=0

I find it easier to move to Z=1 and then use a 1mm thickness gauge to verify the gap.

Also remember you need to execute a single G30 at some fixed XY location to set the Z=0 datum before issuing the G29 to create the height map.

Some folks suggest picking the fixed XY location from one of the G29 probe points.

I just use the center of the bed.

Frederick