Duet3/PI issue - DCS is not started

-

My Raspberry Pi 4 Model B no longer sees the Duet3 board via the 26 pin ribbon cable.

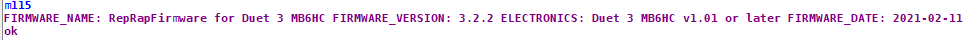

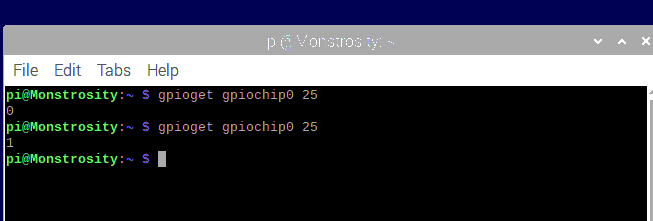

In a nutshell, I do not see 3.3v on pin 22 to signal the PI. I did all the troubleshooting via the below thread and had the same results at all steps. This includes the v3.2.2 firmware via m115 and the voltage measurement checks. I tried multiple 26 wire ribbon cables, 2 raspberry PI 4B and multiple new SD card images.

It worked fine through 3 Benchy prints and when I cycled the power before the 4th, I got the DCS is not started error.

Let me know what info you would like. I have the Duet3 connected via USB and YAT.

Thanks!

https://forum.duet3d.com/topic/21640/duet3-dcs-is-not-started

-

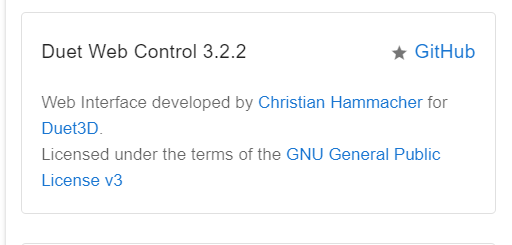

I have the Duet3 running in stand alone mode. Info:

M115 from YAT:

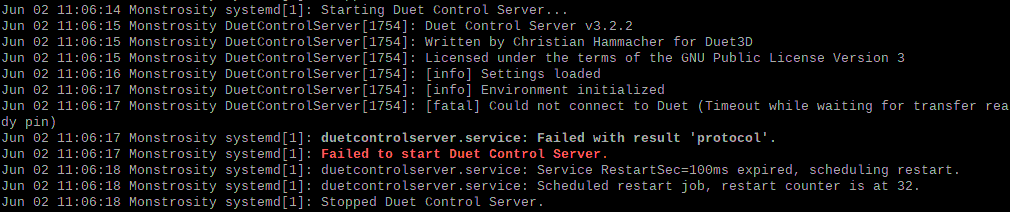

Back to SBC Mode and info:

sudo journalctl -u duetcontrolserver -ef

gpioget gpiochip0 25

config.g

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Fri May 21 2021 17:05:16 GMT-0500 (Central Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Monstrosity" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S0 ; physical drive 0.2 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M584 X0.0 Y0.1 Z0.3:0.4 E0.2 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z1600.00 E404.62 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z120.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ;Dual Z M671 X-140:140 Y15:15 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis ; Axis Limits M208 X-130 Y-155 Z0 S1 ; set axis minima M208 X130 Y155 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z0 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds m558 A10 R1 S0.006 ; Additional Mesh requirements ;********************************************************************************************************* G31 P500 X17.75 Y38.1 Z.995 ; set Z probe trigger value, offset and trigger height ;********************************************************************************************************* M557 X-100:130 Y-100:155 P2 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 ;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H0 R0.884 C317.6 D3.43 S1.00 V24.2 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.275 C244.1 D5.68 S1.00 V24.2 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F1 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P1 C"HotHead" S0 H1 T45 ;M106 P0 C"HotHead" S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F0 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency ;M106 P1 C"Print Cooler" S1 H1 T35 ; set fan 1 value. Thermostatic control is turned on M106 P0 C"Print Cooler" S0 H-1 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue T0 ; Sets Tool0 as default -

Thanks, taking a look to see if there is anything else we'd like you to try.

-

@toy4x4 please email email warranty@duet3d.com and cc the reseller that you purchased from. You will receive a reply with a link to a form to fill in within 24h.