Vertical lines vs. geared extruders

-

I don't understand ..... here is an example of a perfect print and yet there is talk about improving it. Given enough magnification you can find fault in anything. Shouldn't the question be 'how does this print look if I look at it with the unaided mach1 eyeball?' I bet you can't see those artefacts without some sort of magnification. Even if you could the fact that you have layer lines is way way way more obvious. Worry about them if you need to worry about something.

I would be tickled pink and purple if I could achieve a print quality like that ! -

@luke-slaboratory did you test your orbiter with some cube at slow speeds like 30mm/s and 0.2mm per layer?

Can you please say more about your setup? I mean, is it a comercial orbiter or printed one? What stepper does it use? And what kind of printer do you have?The artifacts we discussed here and in another thread are more vissible at low speeds and thinner layer heights due less extrussion requires.

-

@jens55 problem is if you can see there you can see it by far distance in more slow "quality" prints and we are trying to find yet if it is extruder related or fw related

-

@ccs86 said in Vertical lines vs. geared extruders:

It depends on what you mean by "geared extruder". Are you talking about a dual drive gears, like Bondtech; or gear reductions like geared steppers, or printed gear reductions?

There's a sudden burst of reactions, but they mostly discuss the gear ratio. The math showed it would lead to very fine artifacts, but we've seen vertical lines with bigger gaps. Wondering, if they all run BMG dual drive? Anyone using a E3D Titan? They have a comparable gear ratio, but no dual drive...

I suspect the coarse gears of the BMG dual drive and how the idler gear is pressed into the main drive gear. They have 17 teeth at 7.4mm extruder drive diameter.

What would the math say about these with a classic 0.4 x 0.2 track?On my selfprinted Sherpa mini clone, I could make it run smoother by 'misaligning' the idler bracket shaft. A wider distance at the dual drive side and closer at the filament path. (+/- 0.1mm each)

Now the thumb screw presses the filament before the drive-teeth. -

I wonder how well microstepping works at these lower speeds and relatively high motor loading particularly with the use of these smaller motors? I seem to recall that there is a relatively large reduction in torque/holding power at the intermediate microstep positions. Perhaps the actual movement is not as smooth as you might expect?

-

@gloomyandy

Worst thing would be, if all the torque pulses from various sources come into sync and add up.

Filament-Tsunami -

Sure. I can certainly print more at .2mm layers. I typically print at volumetric limits, 25mm3/s for Jessie Filament with this setup, meaning if I go lower layer heights, the toolspeed will be significantly higher.

My printer these prints were off is a Stablebot core. Mechanics are Corexy. This is an injection molded orbiter with the 20mm extruder. Running .35A rms, x64usteps. Hotend is a slice magnum skeeter with .6mm vanadium nozzle. Klipper. 7k accel. Pressure advance enabled (tho this should only matter for the corners).

-

i think the bondtech style extruder gears are the main cause for those issues .

the tensioning mechanism on bondtech style extruder effects the backlash . more tension = gears fully engaged . less tensions = gears are separated , causing backlash .

too much tension and you're chewing the filament . -

@jens55 said in Vertical lines vs. geared extruders:

@ccs86, my BMG LGX uses 405 steps/mm and it has a 3:1 gear reduction build in and I agree that the steps are not easily visible although in a print you might still see an overall pattern. I think an extruder without gear reduction is around 120 or so steps per mm which is considerably coarser than your 709 steps/mm.

Here is my math .... please double check and correct me where/if I have made an error.

1 step = 1/120 mm of 1.75 mm filament

filament is (1.75 /2)^2 x 3.14 = 2.4 mm^3 volume of filament per mm.

Since each step is 1/120mm then each step is 0.02 mm^3 of filament

Printed filament (0.4x0.2) is 0.08 mm^3 volume per mm laid down

So we lay down 4 mm of filament for every full step of the extruder.

At a micro stepping rate of 16 we lay down 0.25 mm of filament or 4 microsteps per mm laid down.

This is certainly visible in itself but you have to keep in mind that each step has a flow curve associated with it which makes the individual steps more visible. Then you put all of this into a largish printed area (let's say 100mm x 100 mm) and even though the eye might have an issue looking at the individual line and see the flaws it is remarkably more accurate to see a pattern in a larger area and you will see this pattern.So to sum it up and even if my math is incorrect, I was going under the assumption of a standard extruder where the motor turns the gear that feeds the filament and you would see the steps. When reduced in a 3:1 gear reduction like the BMG, steps are much less visible. At 709 steps/mm

the end result would be even smoother.I think your math is correct, depending on your microstepping. I am pretty sure that 709 step/mm on the Sherpa mini is considering x16 stepping, not full steps of a 1.8* motor.

-

@hackinistrator said in Vertical lines vs. geared extruders:

i think the bondtech style extruder gears are the main cause for those issues .

the tensioning mechanism on bondtech style extruder effects the backlash . more tension = gears fully engaged . less tensions = gears are separated , causing backlash .

too much tension and you're chewing the filament .What issues?

Backlash in Bondtech gears only affects the idler's ability to drive the filament. Especially at lower flow rates, there is essentially no demand for the idler to drive. Only once the primary gear starts to slip on the filament is the idler gear truly loaded.

-

@ccs86 I agree. Low tension isn’t the problem, it’s high tension that causes cogging issues in the Bondtech-style gears. And as @gloomyandy (I think) pointed out, the lack of torque at some microsteps causes the movement to be delayed, then catches up as the micro stepping gains more torque towards the full step (or wherever there is more torque), which creates a pulsing in the extrusion.

I had a look on the Bondtech website to try and find correct tensioning advice, but couldn’t find any.

Ian

-

@droftarts said in Vertical lines vs. geared extruders:

@ccs86 I agree. Low tension isn’t the problem, it’s high tension that causes cogging issues in the Bondtech-style gears. And as @gloomyandy (I think) pointed out, the lack of torque at some microsteps causes the movement to be delayed, then catches up as the micro stepping gains more torque towards the full step (or wherever there is more torque), which creates a pulsing in the extrusion.

I had a look on the Bondtech website to try and find correct tensioning advice, but couldn’t find any.

Ian

That's a very interesting theory. Basically, regardless of micro-stepping setting, you have a periodic torque output, depending on distance from the closest full step. This would cause a similar (but inverse) plot of positional error of the extruder, given a constant filament force. If this is true, I can only see more mechanical reduction and/or smaller step angle to improve the situation.

-

@ccs86 said in Vertical lines vs. geared extruders:

@hackinistrator said in Vertical lines vs. geared extruders:

i think the bondtech style extruder gears are the main cause for those issues .

the tensioning mechanism on bondtech style extruder effects the backlash . more tension = gears fully engaged . less tensions = gears are separated , causing backlash .

too much tension and you're chewing the filament .What issues?

Backlash in Bondtech gears only affects the idler's ability to drive the filament. Especially at lower flow rates, there is essentially no demand for the idler to drive. Only once the primary gear starts to slip on the filament is the idler gear truly loaded.

you never truly know which side (primary or idler) is actually loaded and driving the filament with this set up .

if gears are fully meshed , it can be that the idler is the one loaded and driving the filament .i dont think its the microstepping torque spread issue , as i already tested extruders with 2 set-ups , one with bondtech style (not original , so there might be quality issues) and one with simple idler .

the simple extruder wins .

even prusa had many quality issues in mk3 since the move to bondtech . -

@hackinistrator said in Vertical lines vs. geared extruders:

you never truly know which side (primary or idler) is actually loaded and driving the filament with this set up .

if gears are fully meshed , it can be that the idler is the one loaded and driving the filament .I don't agree. The primary gear is always driving. Torque input comes in through the primary gear and that gear is always engaged in the filament. How could it not be driving?

The idler gear is always in contact with the filament too. So, it is either out of contact with the main gear and idling, or in contact and also driving.

-

@ccs86 lets say the the gear mesh is perfect - no backlash .

in this case , why do you think that only primary gear is driving ?

both spin at the same speed , it does not matter which one is directly connected to the motor .

in ideal world and perfect filament torque will be split 50/50 in this case . -

@hackinistrator said in Vertical lines vs. geared extruders:

@ccs86 lets say the the gear mesh is perfect - no backlash .

in this case , why do you think that only primary gear is driving ?

both spin at the same speed , it does not matter which one is directly connected to the motor .

in ideal world and perfect filament torque will be split 50/50 in this case .Read my post again.

-

@ccs86

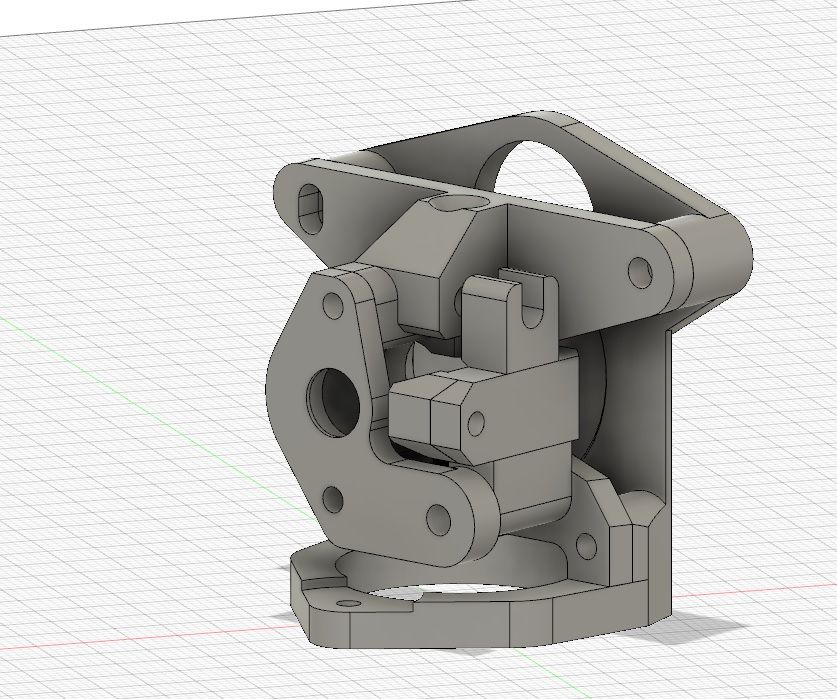

I've changed my 'Sherpa Mini Clone' to adjustable gears as you proposed. Will test it today...also allowed my stepper to be adjustable with the spur gear. That wasn't possible before, because the center hole wasn't oval.

I also beefed up a few strategic points, but that's not the point here.

-

@o_lampe HI!

How did it work?

-

@zabana

Surprisingly well!

I have some ringing, I try to dampen with input shaping, but that's another thread.

In the meantime I print at 90-100mm/s and 300-400mm/s travel speed. The result is 'sharper' than the same parts printed on my CoreXY. (shorter belts?)

I have an idea, how to drop the motor about 20mm to improve effector stability. But, that's again another thread. -

@o_lampe your sherpa mini clone reminds me of the superfly extruder and the Sailfin extruder... a lot of minimalized setups around now.