Part Fan and Tool fan on DWC does the same thing

-

Morning All. Bit lost.

The config was built using the config tool.

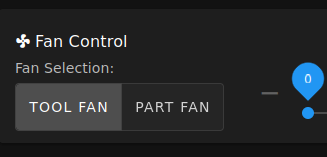

On my DWC dash I have 2 fan selectors.

They both control the same fans, the part cooling fans, does not matter which one I select same fans run, same percent etc.

The tool fan has been configured for thermostatic control so IMO should not even be visible as it is being controlled by the Mini 5+ in my case.Checked my other printer, again running a Mini 5+ and that is the same, 2 selectors they both control the part fan.

Checked my code but nothing jumps out!

Current firmware is Firmware: RepRapFirmware for Duet 3 Mini 5+ 3.3RC2 (2021-05-11) with Duet Web Control 3.2.2

Config.g

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Disco V0.1" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 P192.168.0.8 S1 ; enable network and acquire dynamic address via DHCP M553 P255.255.255.0 M554 P192.168.0.1 M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D3 V0 ; physical drive 0.0 goes forwards M569 P0.1 S1 D3 V0 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M584 X0.1 Y0.0 Z0.2 E0.3 ; set drive mapping M350 X32 Y32 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z400.00 E420.00 ; set steps per mm M566 X300.00 Y300.00 Z60.00 E400.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z900.00 E3000.00 ; set maximum speeds (mm/min) M201 X2500.00 Y2500.00 Z1200.00 E4000.00 ; set accelerations (mm/s^2) M906 X425 Y425 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X120 Y120 Z120 S0 ; set axis maxima ; Endstops M574 X2 S1 P"io4.in" ; configure active-high endstop for high end on X via pin io4.in M574 Y2 S1 P"io5.in" ; configure active-high endstop for high end on Y via pin io5.in M574 Z1 S1 P"io6.in" ; configure active-high endstop for low end on Z via pin io6.in ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:90 Y15:90 S20 ; define mesh grid ; Bed Heater M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 ;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H0 B0 R1.266 C265.2 D6.02 S0.50 V23.9 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Dragon ;M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M308 s1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Part Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Tool Fan" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"out5" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 C"Cooling" S1 H1 T45 ; set fan 2 name and value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous ;M575 P1 S1 B57600 ; enable support for PanelDue M575 P1 S2 B57600 ; enable support for BTT T0 ; select first toolHelp would be appreciated.

Regards,

Paul. -

@paulhew

What if you update DWC too? -

@o_lampe Thanks for the reply.

The other Printer is running "Duet Web Control 3.3.0-rc1" and that has the issue also.

Just tried to update using the Pi to pull the updates on the other printer and no change in version. -

@paulhew AFAIK, that's just the way it is. I seem to remember reading an explanation somewhere. Can't remember exactly but I think the only time you get different behaviour is if you have multiple tools, each with their own dedicated fan. I think (but could be wrong) that the "part fan" will alwys be the be the same as the current active tool.

-

I think you're expecting "tool fan" to be the hotend heatsink fan, but that's not the case. The "tool fan" slider will control the part cooling fan of the currently selected tool. So if you have multiple tools, that will always control just the fan of the currently selected tools, while the "Part fan" slider will control a particular physical fan, which in this case you have named "part fan".

Thermostatically controlled fans do no show up as a slider.

If you want, you can hide the "tool fan" slider by changing it's vsibility.

-

@paulhew said in Part Fan and Tool fan on DWC does the same thing:

M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Tool Fan" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

Perhaps change the name of this one to heat sink fan to differentiate.