Have you ever observed this layer thickness problem?

-

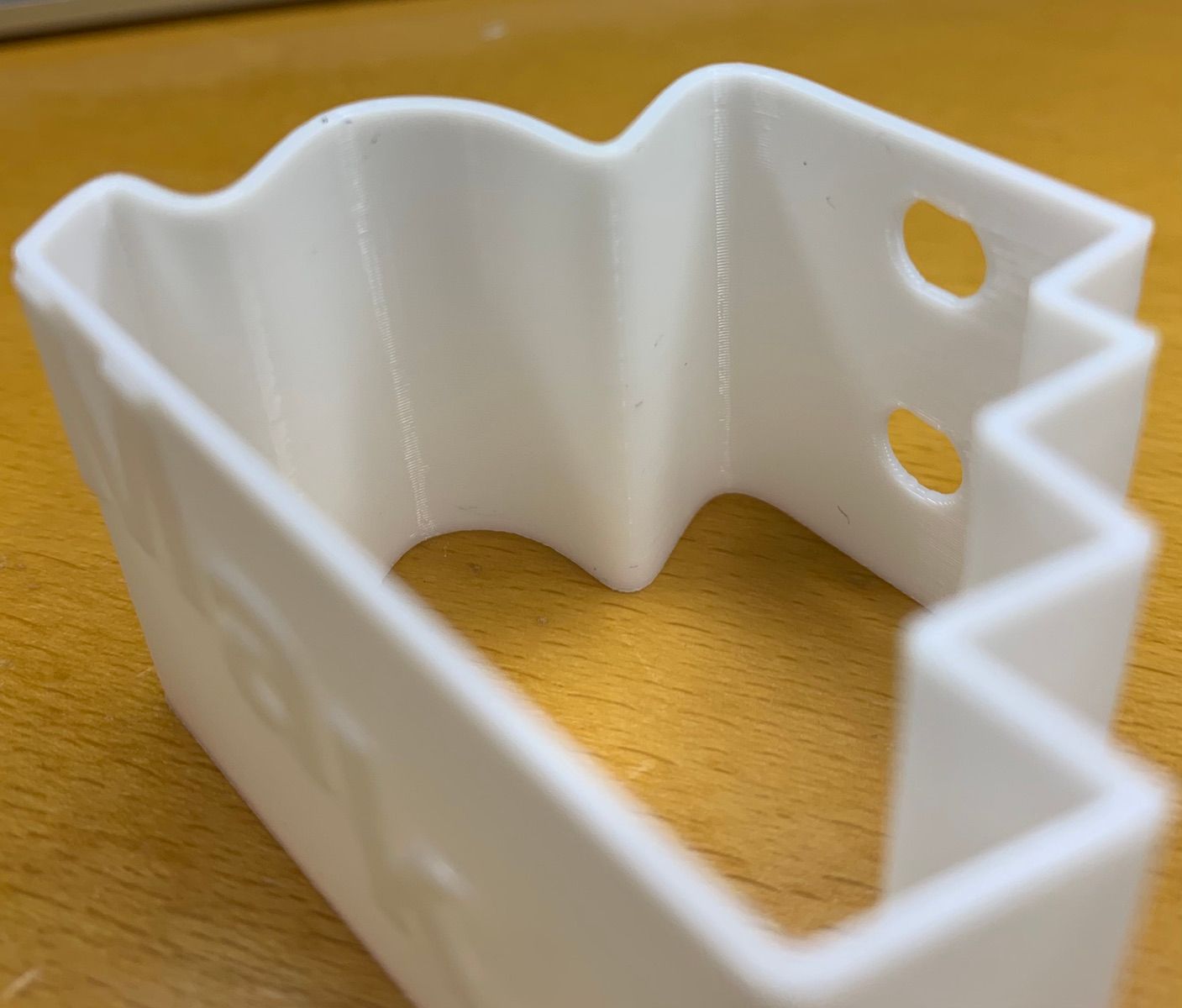

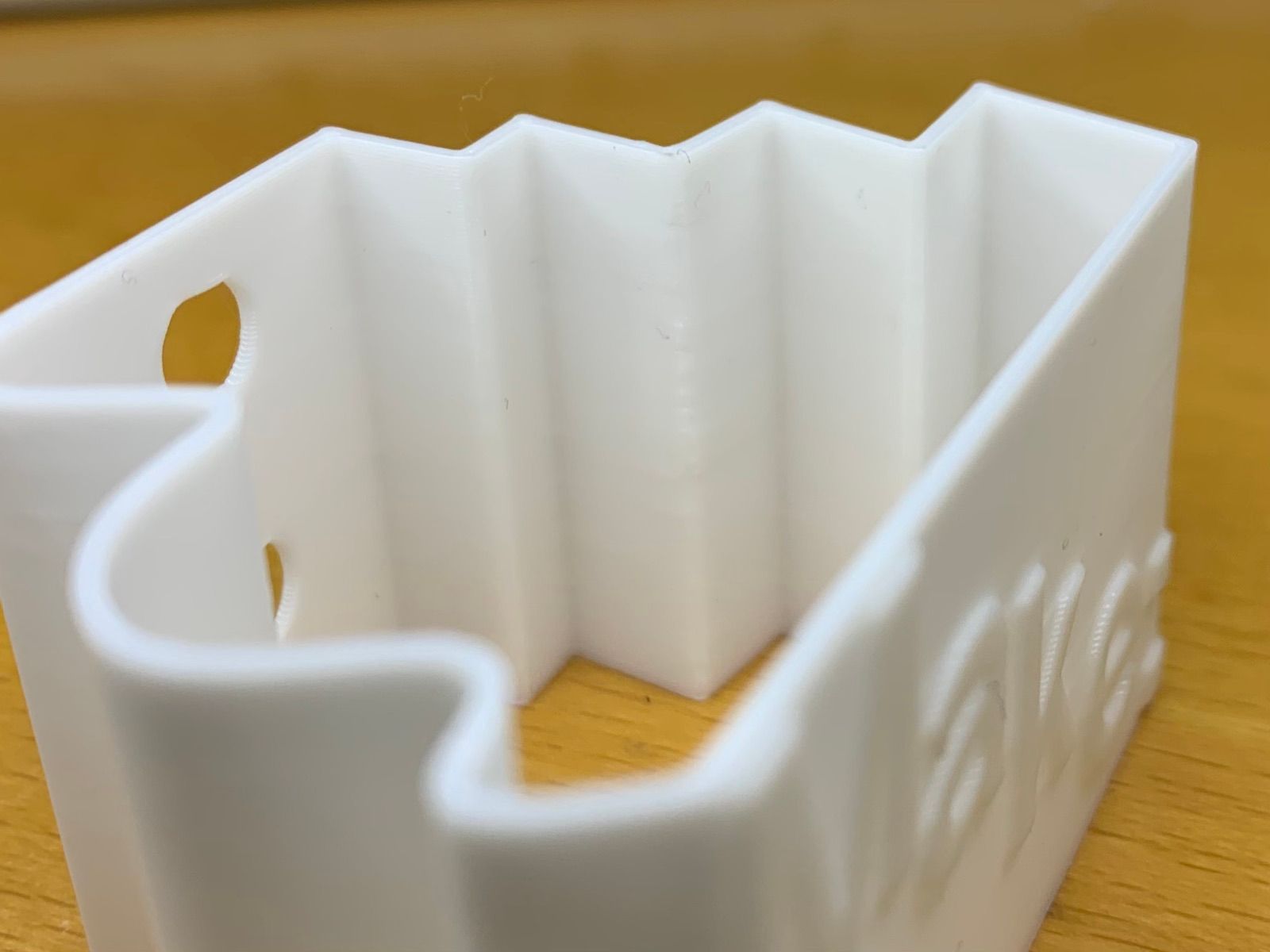

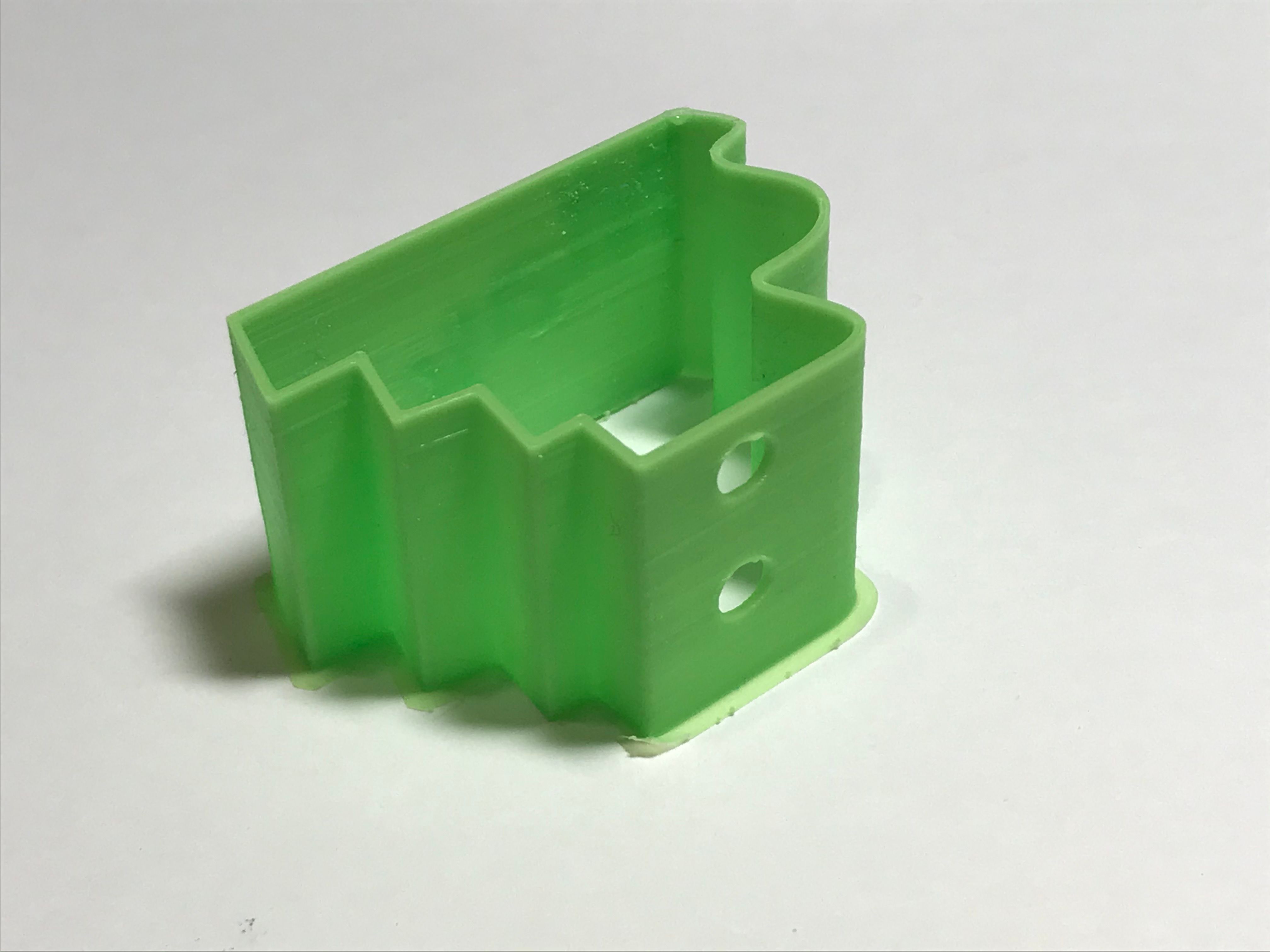

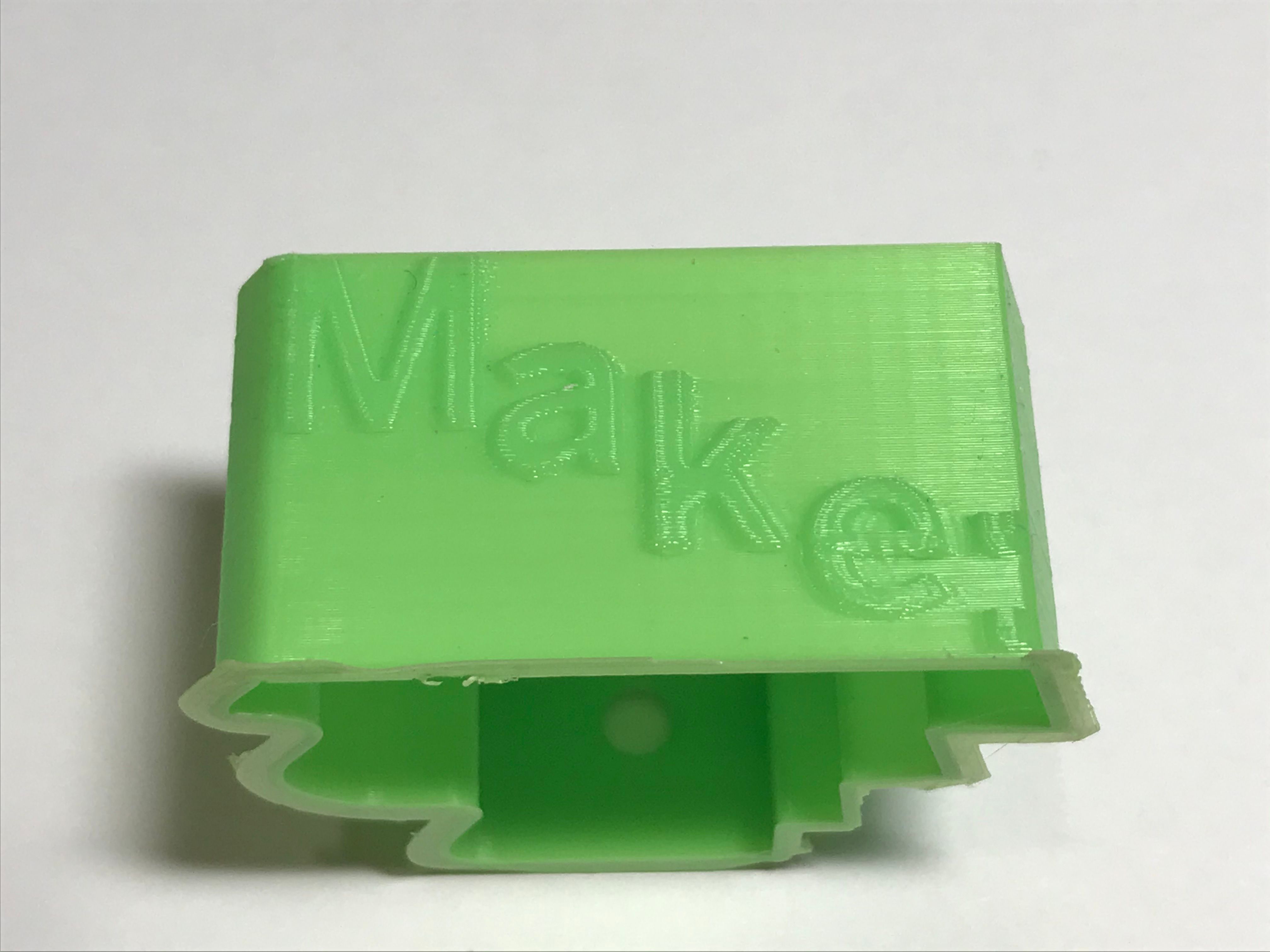

I also did some test prints:

I played around with lightning and tried to establish a "bad angle" to see all the inconsistencies of FDM but it's hard to capture.

-

@argo That's very good. It means I have to go back to my printer and look for more mechanical issues....

-

@drmaestro said in Have you ever observed this layer thickness problem?:

The wall thickness changes depending on the features on the object, so when there is a hole, the wall is thicker

Your picture in RepRap forum from 2017 show no signs of thicker walls, but an offset. I agree with @deckingman about the inner/outer perimeter first theory. I printed 'outer first' and saw the shift towards the outer face. (when direction changes)

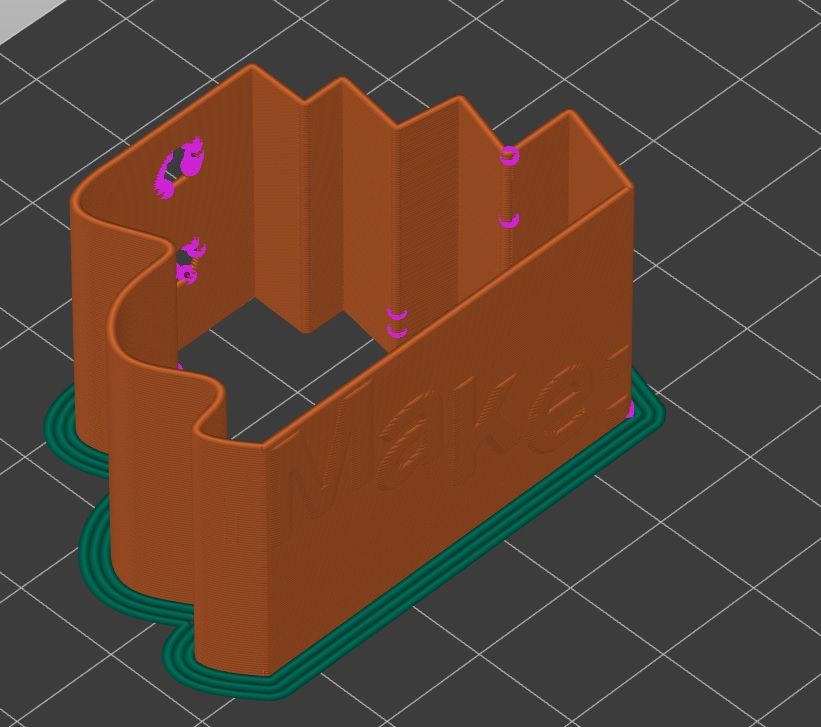

link textYour 0.8 slice is different than mine. I only see one perimeter and retractions.

But the print showed a loss of quality all around the part, where there's a gap/hole. It can't be explained by bad retraction settings alone or backlash-offset.

If you see different thickness now it's probably another problem? Maybe related to scaling up the part?

-

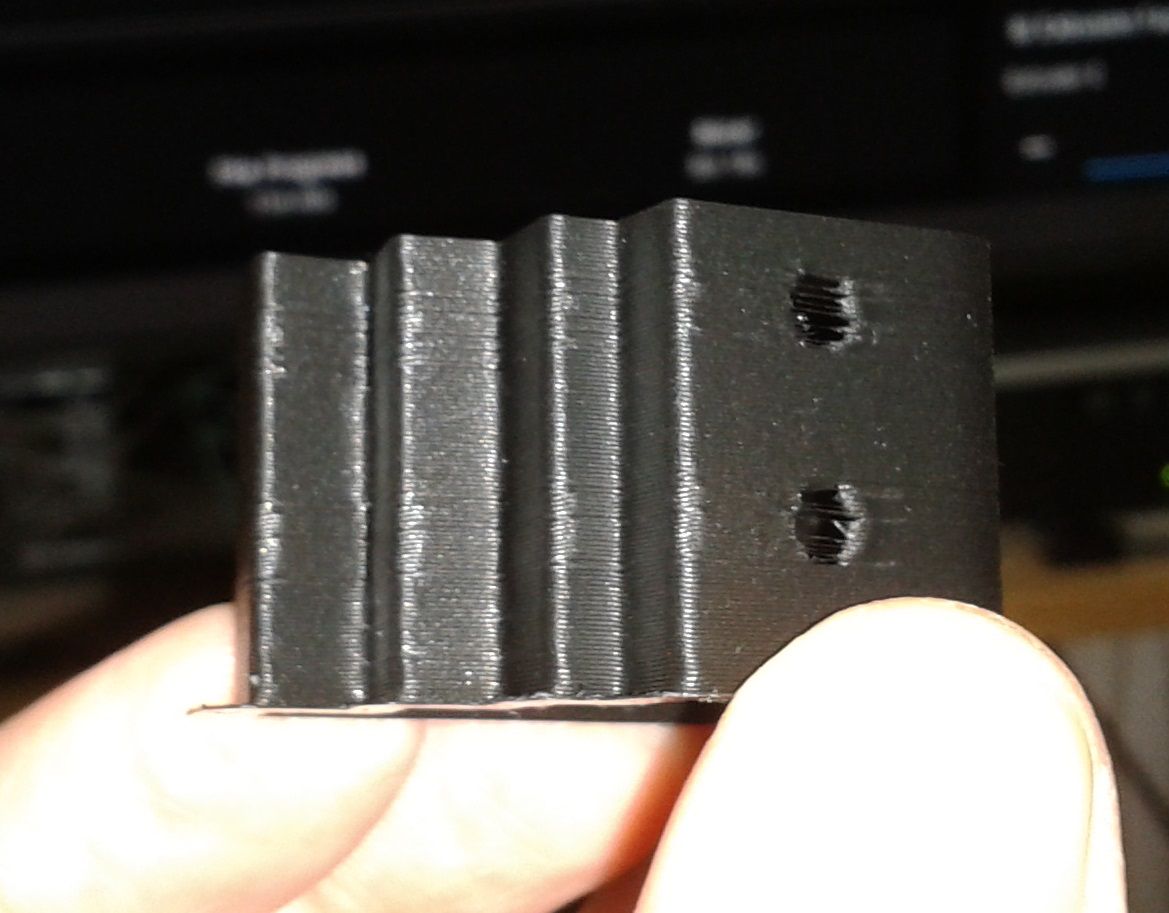

@dc42 @o_lampe @deckingman I've rebuilt the Y carriage, removed the twist that I used for smooth side of the belt on smooth idler, replaced the idler with a toothed one, retensioned. Here's a comparison of the object post-modifications:

It turns out you were right, there should be something related to backlash on my setup. While I still have the artefacts, thery are not as prominent as they were previously. I may still have some ğrpblem on the X axis, which I'll also replace with another solution.

-

I asked user @Hiroaki to print one on his RRF2.x printers.

-

The problem has a distinctly "hysteresis" feel about it. That is to say, that travelling in one direction does not result in the same path as movement in the other direction. Belt tension would be an easy culprit for this problem, but as such, it's the first one to be resolved.

Here's what I suggest. Isolate travel direction as the problem - Print a simple thin walled square (50x50 should do), go CW for 10-20 layers, then CCW for 10-20 layers. If hysteresis is the problem you should get the same bands appearing with direction change. I imagine you'll need to generate this code manually to control the travel direction.

If this occurs, you'll need to look for anything that gives you some uncontrolled movement - it could be as subtle as flexibility in the hot end, or a pulley (or many pulleys in the case of a CoreXY) that move slightly on their shaft. Remember you're looking for problems that add up to a total of a fraction of a line width - so perhaps 0.1mm or less.

Best of luck.