Duet2 Beginner with RRF Config Tool

-

Here's a config.json file you can load into the config tool to play around with that is set to use RRF3 and has 2 tools and a BLtouch configured.

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 15 2021 21:59:06 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X230 Y210 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"e1temp" Y"thermistor" T100000 B3950 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1:2:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F1 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first toolI didn't know some details for your printer so I left them default, so you'd need to change the details to suit.

-

This is a ton of great information, thank you. I do want to update to RRF3 however I have a cpl more questions.

If you do wish to update the firmware to RRF3 and start with a fresh config from the tool here's how.

If you still have access to DWC. Upload these 3 zip files, one at a time in the system tab. Don't extract them. Reboot after each. Use M115 to verify the firmware has been applied.

I dont know IF I still have access or not...I have never turned this board on before to be honest. It's straight from the box. I can connect it to my pc via usb but getting the ethernet to work will be a nightmare because my roommate, who is a software engineer for our ISP, has an overly complicated network setup in our house, and I dont want to hear him crying right now.

Can I simply connect the board via usb and have access to DWC? -

@printerdad said in Duet2 Beginner with RRF Config Tool:

Can I simply connect the board via usb and have access to DWC?

You can't access DWC over USB

You could however connect directly over ethernet from your PC/Laptop

https://forum.duet3d.com/topic/22019/connect-ubuntu-pc-directly-to-duet-ethernet-without-a-router/3?_=1615846598333 -

This may help

https://duet3d.dozuki.com/Guide/1.)+Getting+Connected+to+your+Duet/7

The board will use DHCP by default so it shouldn't be too difficult to connect to any network that will serve an IP address.

If not, the direct connect method described by @jay_s_uk can be useful.

-

so much great info, thanks guys. I have a lot of tinkering to do now!

-

@Phaedrux said in Duet2 Beginner with RRF Config Tool:

Here's a config.json file you can load into the config tool to play around with that is set to use RRF3 and has 2 tools and a BLtouch configured.

How do I use this file?

-

nvm i copied and pasted into a new .json

-

Should have been able to download it and then upload it into the config tool. If it was opening as a text file in a browser window file > save as.. probably would do it.

-

New questions, I need help with the config tool again. I am setting up my fans, and i want my extruder fans to turn on only when the extruder is heating.

Do I- Fan0 set to thermostatic control, yes. Monitor E0, threshold 45C?

or - Fan0 set to thermostatic control, no. Under tools page, select fan0 for the E0's fan?

whats the difference? It wont let me assign fan0 to any E in tools, if I have thermostatic control turned on for that fan0.

Also, I assume the extruder XYZ offsets are the distance away from 0,0,0, when the printer is homed to XYZ? Why would there be a Z offset?

thanks, Dad

- Fan0 set to thermostatic control, yes. Monitor E0, threshold 45C?

-

Did the config I provided not have all the fans assigned as well? Should have been fan0 as the part cooling fan for tool0 and fan1 as the part cooling fan for tool1. And fan2 as the heatsink fan tied to the heaters.

@printerdad said in Duet2 Beginner with RRF Config Tool:

Also, I assume the extruder XYZ offsets are the distance away from 0,0,0, when the printer is homed to XYZ? Why would there be a Z offset?

Yes, usually tool0 would be 0,0,0 and tool1 would have an offset in XYZ from there. There is Z because the tools aren't always are the same height.

-

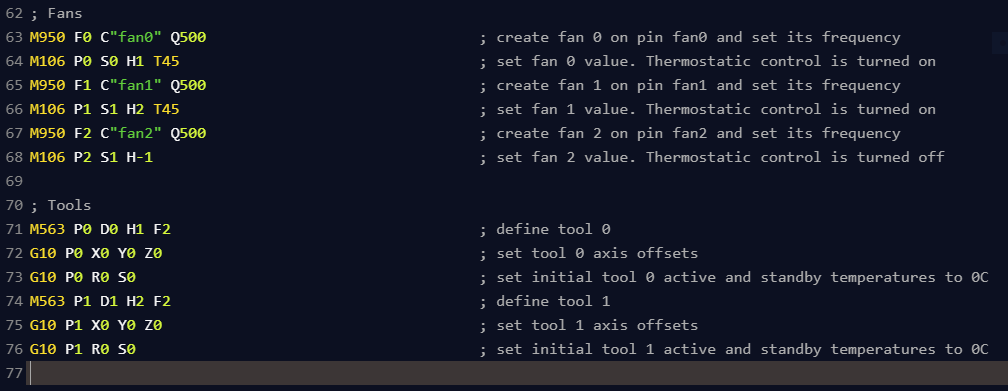

This is my fan setup:

fan0, heatsink E0

fan1, heatsink E1

fan 2, parts cooling fan for both -

In which case your fan and tool section in config.g would look like this

; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H2 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F2 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F2 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C -

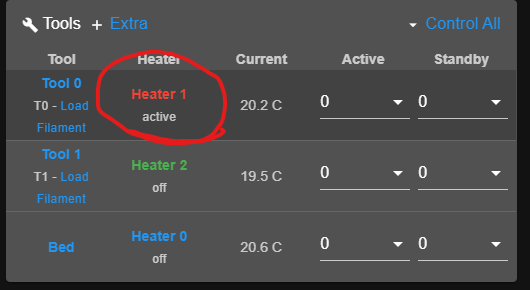

Ok Ive got 3.2.2 installed with the new configuration files, installed using dwc. Here are a couple problems Im having.

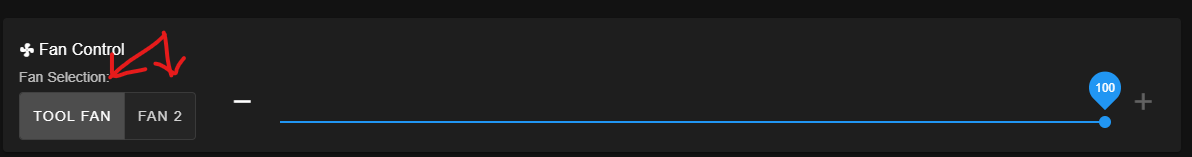

ToolFan and Fan2 are both operating the same fan, which should be Fan2.

Fan2 starts at 100% upon power on, which should be 0.

Not sure why ToolFan is even listed as it has thermostatic control. (I have 2 tool fans)

Also, Tool0 starts as active upon power on, but tool1 does not. Seems odd.

This is a screenshot of my config.

Thanks guys, Dad

-

TOOL FAN and FAN2 are the same thing in your case.

TOOL FAN will control the fan of the currently selected tool. IF you had multiple tools with separate fans, you would see TOOL FAN, FAN1 and FAN2 (as an example). Tool fan would control either fan1 or fan2 depending on which tool was selected at the time.

If you wish you can hide the fans you don't want to see by clicking on the change visibility button.

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H-1To have fan2 start off, change the S value in the M106 command from S1 (on) to S0 (off). Like so:

M106 P2 S1 H-1toM106 P2 S0 H-1Tool0 starts as active at power up because there is likely a T0 at the end of your config.g to select the first tool. You can only use a single tool at a time, the others will be in standby or inactive. It would be up to your slicer to send the tool change commands to switch between them as needed.

-

I do have 2 tool fans though, fan0 and fan1. I have two extruders each with their own heat sink fans. Fan2 is a parts cooling fan, not a tool fan.

The fan slider is operating my parts cooling fan.Also, If S0 or S1 is the command for fan start on/off then why is only one fan starting on, when two of them have S1 in the gcode?

-

There is some confusion on terminology here.

Fan0 and Fan1 are the heatsink fans, correct. They are thermostatically controlled for each heater.

Fan2 is the parts cooling fan, also called tool fan. Same thing.

The fan0 and fan1 will only start at full power when the temperature is reached. They are off until then.

-

i see, I assumed the heatsink fans were tool fans considering they are attached to the tools.

-

Tool fan because it's a fan controlled for the tools operation, ie cooling the part. Or maybe clearing chips away. Or maybe it's not even a fan at all.

The heat sink fan is controlled by the heater, not the tool directly. Though in this case the heater is assigned to the tool.

The M563 command defines the tool. Which tool number it is, what extruder drive it gets, which heater, which fan.