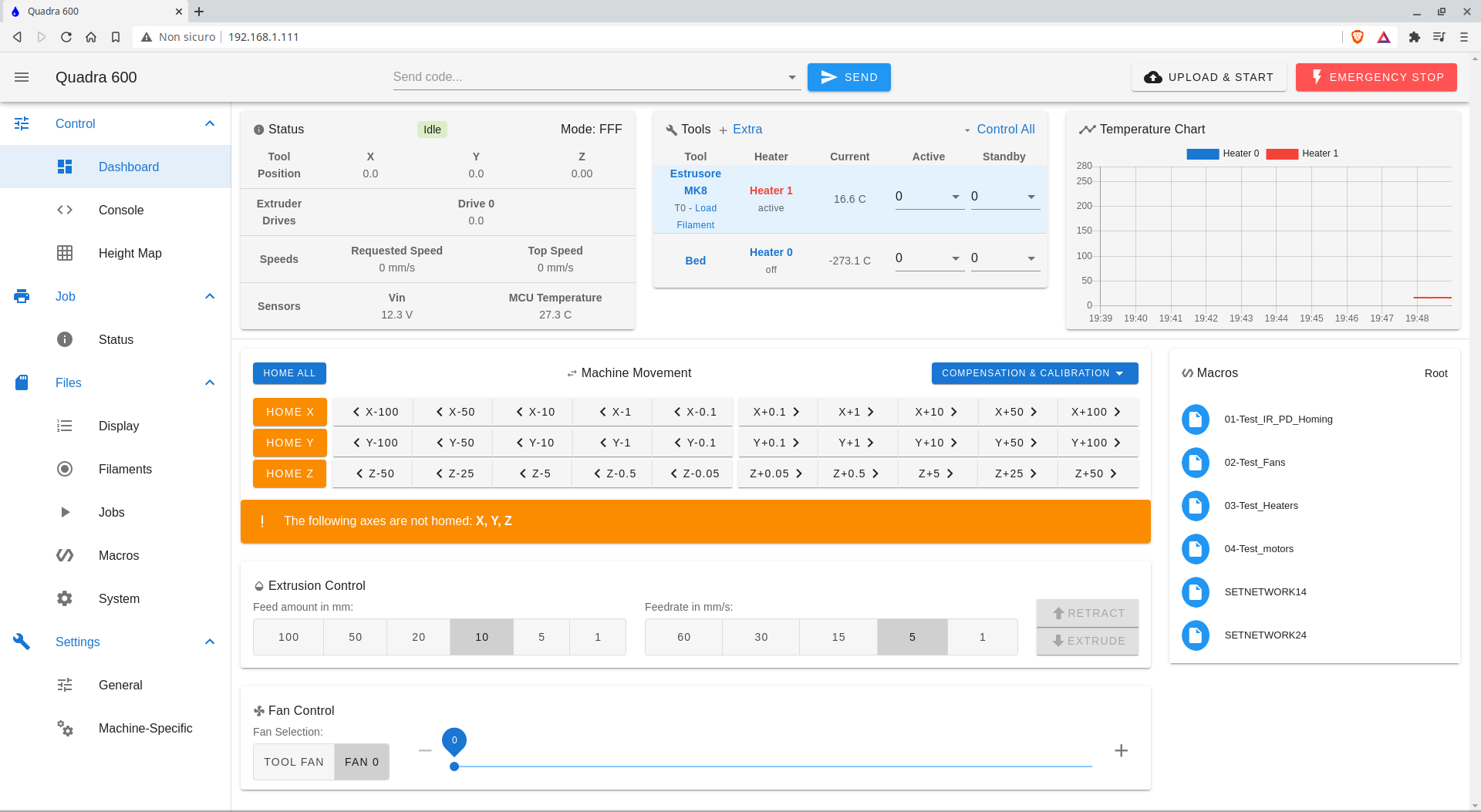

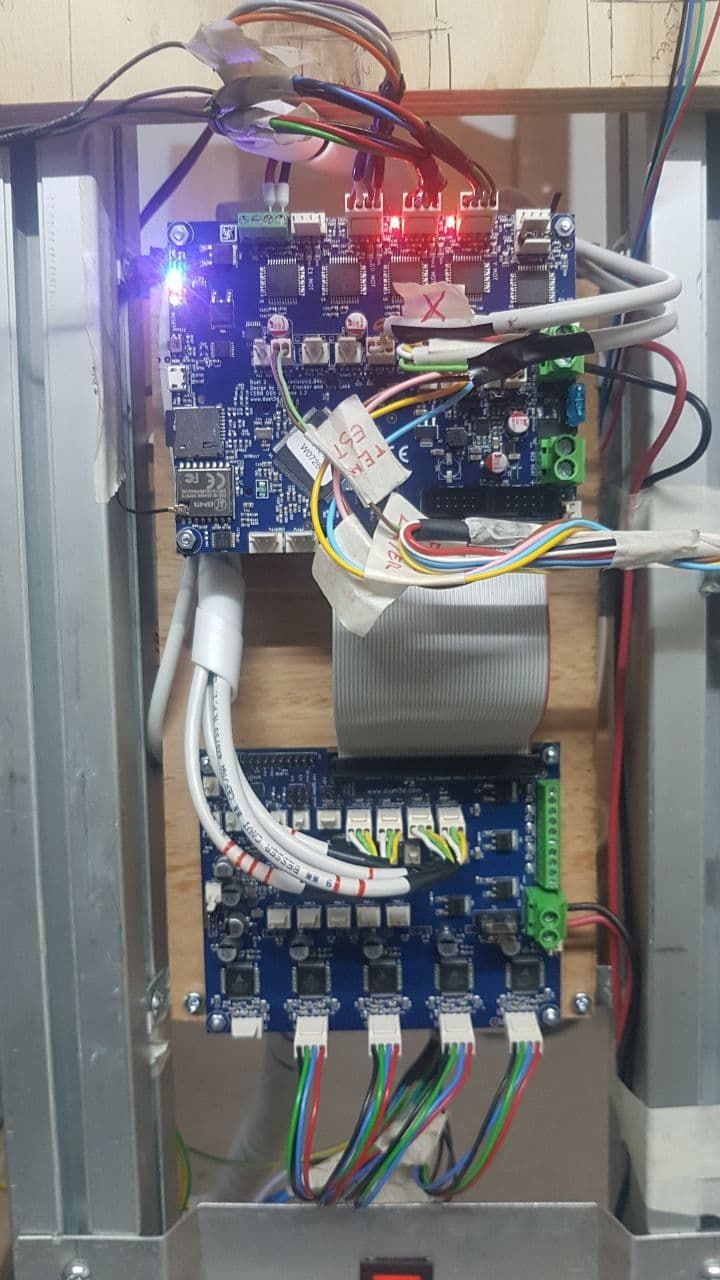

Duet2 wifi + Duex5 for large printer with 4 Z motors

-

By replacing the 12v power supply with the 24v, I hadn't connected anything.

Now I have reassembled the 12v and removed the display.

This is the wiring

M906 X800 Y800 Z800 E800 I30

No, I'm not sure of anything. first of all I wanted to understand how it works and fix things as you go. I'll need lots of suggestions ... -

there is the problem that if you connect the paneldue to the wrong header, the voltage will drop.

this seems to have happened for you.

you also did not follow the duex wiring guide. see

https://duet3d.dozuki.com/Wiki/Duex2_and_Duex5_Features#Section_Wiring -

Ok. the problem with the display was that I had connected both cables supplied ... one, to the PanelDue connector (4 wire cable), the other to the LCD connector (not sure why).

The supply voltage is now correct, even with the display on.

I connected the power supply as shown in the photo to the link you suggested (even if the power supply was 30 cm from the boards).

The next step is to understand how to properly set up the motors.

For now I want to try with the 12 volt power supply, waiting to receive the various components (hot-end and fans) at 24 volts. The Hot Bed is, for me, a problem ... in the end I think I will have to use a 220v relay (with 12 or 24volt coil) to power the hot-bed, as, with the current structure of the floor, I have a way to mount heaters. It doesn't matter ... at the moment! -

@bernardomattiucci said in Duet2 wifi + Duex5 for large printer with 4 Z motors:

I connected the power supply as shown in the photo to the link you suggested (even if the power supply was 30 cm from the boards).

there is a big warning on the page

Do not run separate ground wires from each terminal block back to the power supply unless the power supply is very close (less than 100mm) to the Duet 2 and Duex.

so 30 cm is more than 10cm

-

@Veti

Yes, you're right, but I just can't understand why. It does not matter. Now it is OK.The problem now is understanding why the PanelDue works but doesn't seem to interact with the rest of the electronics. Maybe I need to update it?

-

The PanelDue has also been updated.

Now I have to check the engine settings.

Tips? -

@bernardomattiucci said in Duet2 wifi + Duex5 for large printer with 4 Z motors:

Now I have to check the engine settings.

what engine settings?

-

I have to verify the correctness of the settings, both for the stepper motors and for the remapping of the motors.

I have 4 independent motors for the Z axis, each with its own optical sensor (which I am mounting now), placed more or less at the 4 vertices of the XY plane (the printing plane is fixed). I have to make the Z axis move in a coherent way .. reset it using the 4 sensors and manage it properly. -

That's quite easy with RRF3. All you need to do is connect your 4 z endstops, and then define the used pins in the M574 endstop configuration. And home Z as a single axis as normal.

-

Everything starts moving ... and if it weren't for the power supply fan, you wouldn't hear anything (or almost)!

very beautifull!

-

Good morning,

I got to the point where I have to set the zeroing of the Z axis considering the fact that I have 4 motors with 1 endstop each.

in my config.g I have inserted the following instructions:

M584 X0 Y1 Z5: 6: 7: 8 E3 M574 Z1 S1 P "duex.e2stop + duex.e3stop + duex.e4stop + duex.e5stop"and this is my homez.g:

G91 G1 H2 Z5 F6000 G1 H1 Z-607 F360 G92 Z0How should I proceed?

I'm following these directions:

https://duet3d.dozuki.com/Guide/Independent+Z+motors+and+endstop+switches+in+RRF2/18But it is not very clear to me what I actually have to do and I would not want to be wrong.

In order, the Z axes (Z1, Z2, Z3 and Z4) are positioned as follows:

Z1 = X0 Y0

Z2 = X0 Y600

Z3 = X600 Y600

Z4 = X600 Y0Can you give me some advice?

Thank you

EDIT:

Maybe I need to enter the command

M671 in my config.g?In my case it would be something like:

M671 X-115: -115: 715: 715 y130: 470: 470: 130; Z leadscrews are at

Z2 (-115.130) Z2 (-115.470), Z3 (715.470), Z4 (715.130) -

M584 X0 Y1 Z5: 6: 7: 8 E3

M574 Z1 S1 P "duex.e2stop + duex.e3stop + duex.e4stop + duex.e5stop"delete the spaces

there is no leadscrew location required for this as the endstops determine the position.

just the normal z homing will do it

-

@bernardomattiucci said in Duet2 wifi + Duex5 for large printer with 4 Z motors:

I'm following these directions:

https://duet3d.dozuki.com/Guide/Independent+Z+motors+and+endstop+switches+in+RRF2/18These are for RRF2.

I already linked the instructions for RRF3 above.

-

Good morning

It all seems to work quite well.

Now I just have to figure out how to solve a problem on the Y axis, mostly due to the type of "transmission" used and complete the settings ... before moving on to the print tests!This is the X axis test: https://youtu.be/UG27txKxALk