massive overextrusion, E-Steps are calibrated

-

Also, are you measuring 100mm of filament going INTO the extruder or 100mm of filament coming OUT of the extruder?

(I'm not implying you're an idiot, just trying to check non obvious things since SOMETHING strange is going on and we're not nailing it down yet.)

-

@Phaedrux: It is with hotend attached.

@alankilian: Measuring Filament going into extruder.

One Idea came to my mind: as it is extruding right, when doing a do a "G92 E0" followed by "G1 E100" from console.

Could it be that there is something buggy with the DWC extrusion factor when used, that it calculates twice or something like that.

Is the DWC extrusion factor also used when doing a "G1 E100" from console, or only when printing a file ?

-

do you have something like non linear extrusion enabled?

-

This post is deleted! -

@Veti said in massive overextrusion, E-Steps are calibrated:

do you have something like non linear extrusion enabled?

What exactly do you mean ? Which commands / Gcodes ? So far only tested absolute and relative extrusion. No Volumetric / Advanced Pressure printing tested nor activated.

-

-

@Veti said in massive overextrusion, E-Steps are calibrated:

https://duet3d.dozuki.com/Wiki/Gcode#Section_M592_Configure_nonlinear_extrusion

No M592 in config or Gcode of 3D printed file found.

-

@Enpixa Just to rule out something changing the config.g values, send the following after resetting the Duet:

M92 M350 M221

which should respond with something like (my settings):Steps/mm: X: 80.000, Y: 80.000, Z: 800.000, E: 612.000 Microstepping - X:16(on), Y:16(on), Z:16(on), E:16(on) Extrusion factor(s) for current tool: 100.0%Then send again once you have started a file printing. If there's a gcode somewhere changing these settings, the firmware should report it.

Just as a sense check, I looked at the snippet of gcode you posted. It shows a 12.5mm move with a 0.75mm extrusion move (roughly). For 1.75mm filament this is:

π(1.75/2)^2 x 0.75 = 1.8mm^2For a 0.4mm nozzle (0.4mm extrusion width; yours may be bigger) with a layer height of 0.3mm, for this distance you should be extruding (again, roughly):

0.4 x 0.3 x 12.5 = 1.5mm^2 of filamentSo it looks (from this tiny fragment of gcode) that the extrusion commanded is in the right ballpark; I'd guess you have an extrusion width of 0.5mm, which gives 1.875mm^2 of filament. However, check the settings in your slicer for the first layer, as they are often different from other layers.

Ian

-

@droftarts said in massive overextrusion, E-Steps are calibrated:

M92 M350 M221

Hello Droftarts, thx alot. Always the same result.directly after starting, after homing, while printing, after printing/aborting:

27.1.2021, 19:23:00 M92 M350 M221 Steps/mm: X: 80.040, Y: 80.040, Z: 800.960, E: 415.800 Microstepping - X:16(on), Y:16(on), Z:16(on), E:16(on) Extrusion factor(s) for current tool: 100.0% -

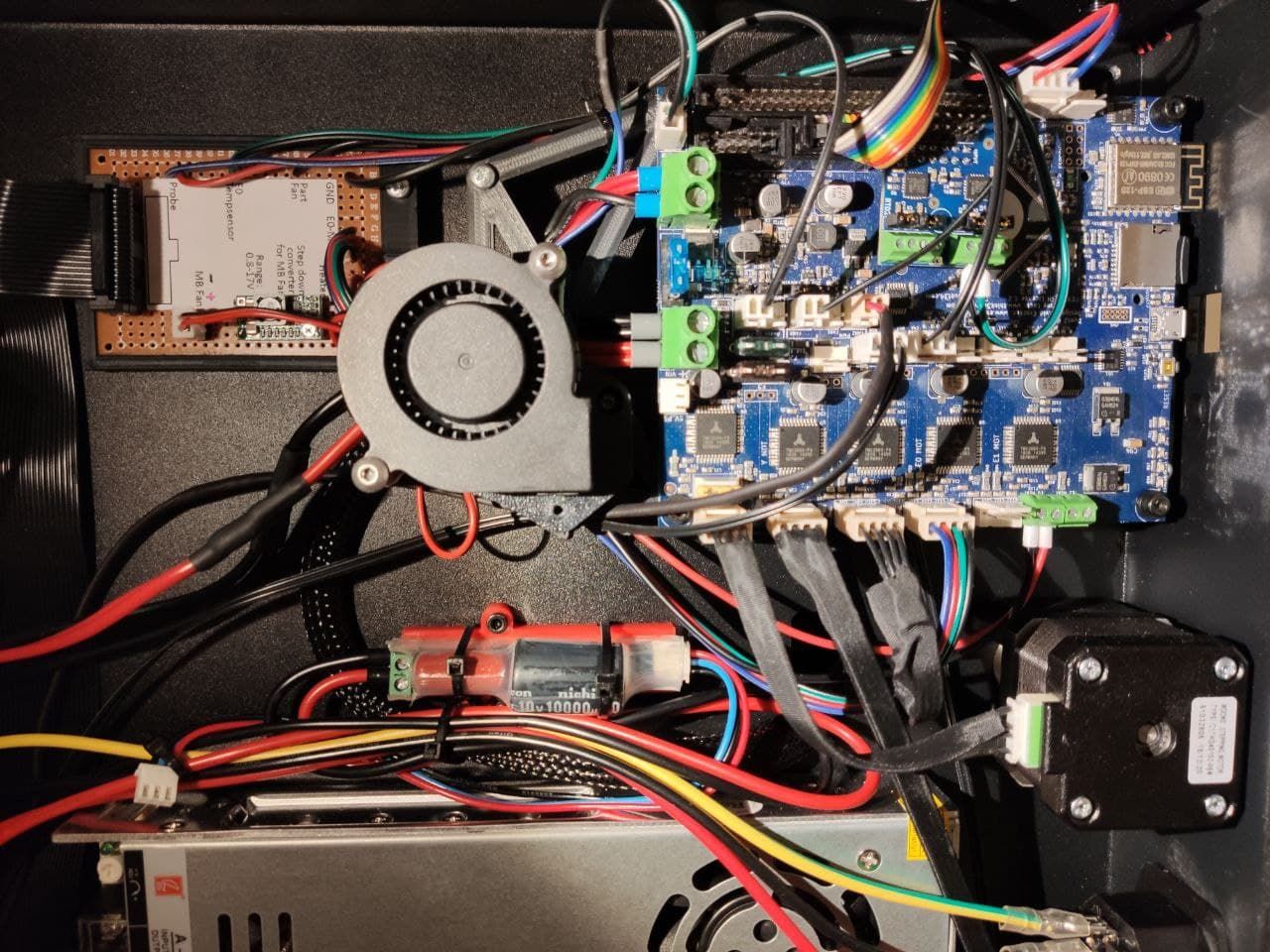

Little Update: Meanwhile i replaced the Duet Wifi mainboard with another one i had here in my shelf. Rewired everything.

The whole story again. Reinstalled Firmware 3.2 completely new. ( Also DWC 3.2 etc. ) Also used another SD-Card. deleted all folders before. The only thing i copied was the config-files to sys folder from the "old" board.

Did new PID for heater.

Checked again, 100mm is moved when doing the G1 E100.

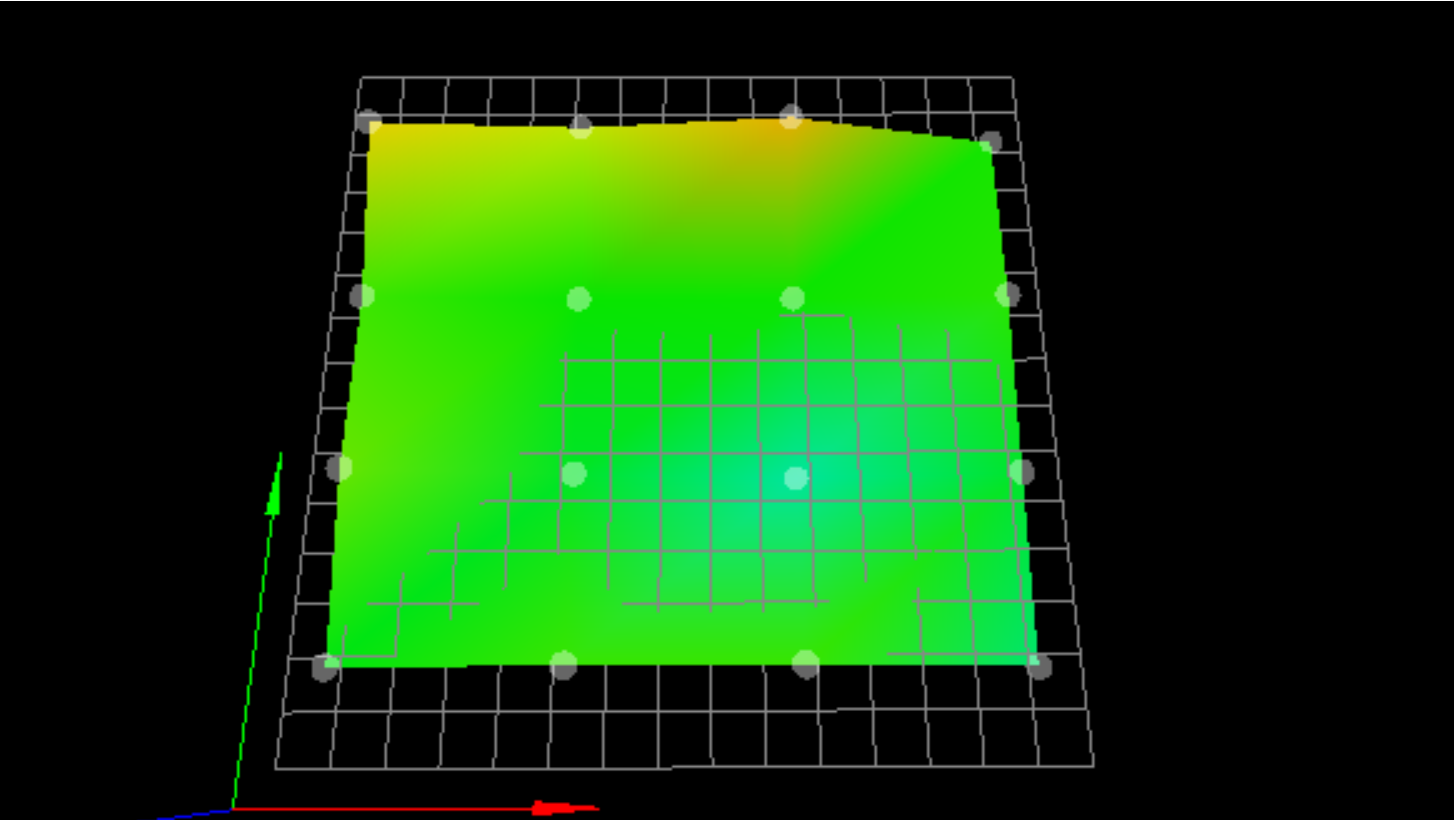

Heightmap doesnt look too bad:

Checked nozzle distance to bed again with the good old "paper-method" using standard 80g paper. Nozzle is barely touching the paper. Really only slightly, it doesnt bend nor really scratches it. just a little feel of.. there could be paper

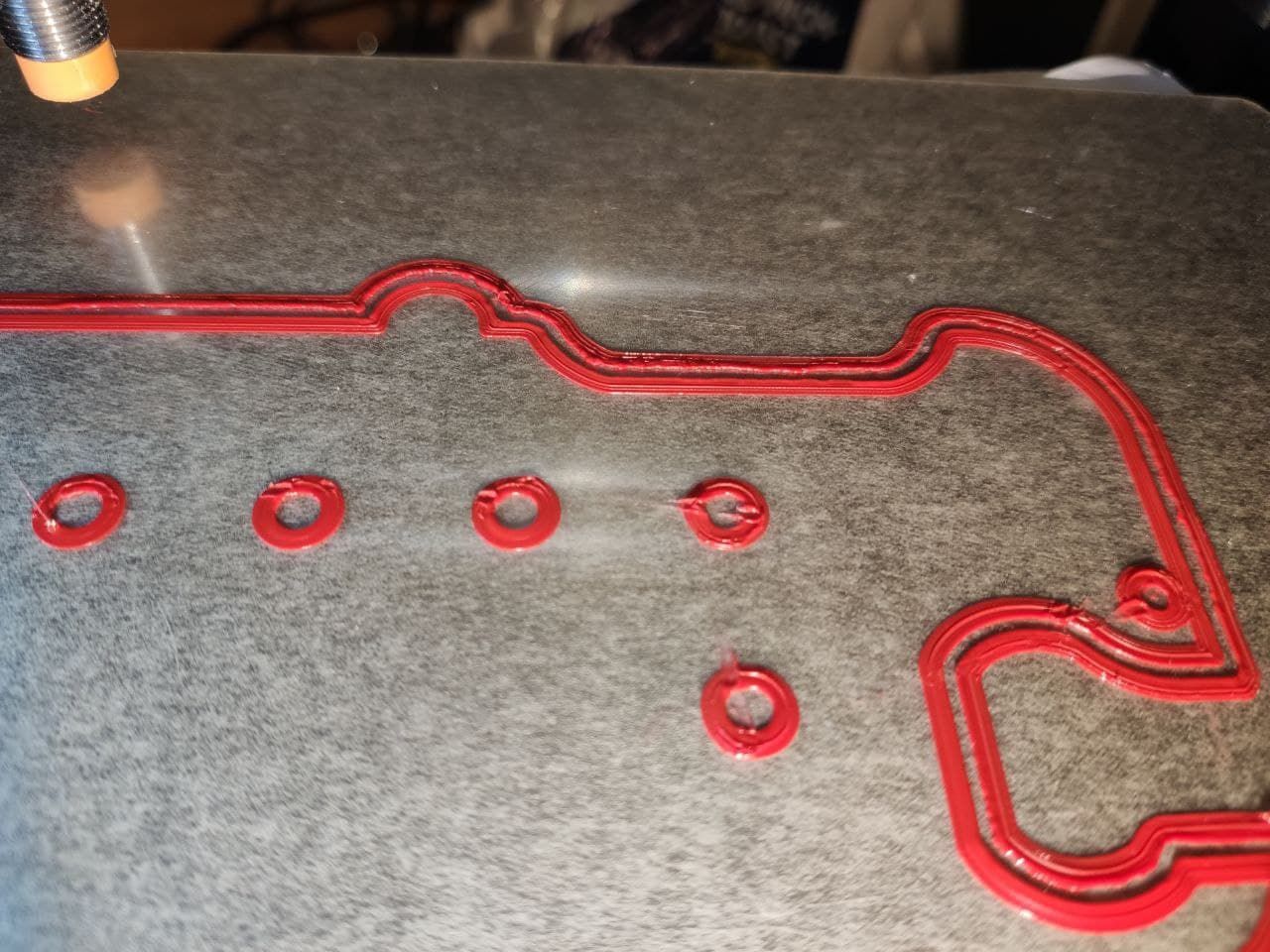

Print result at 100% Flow: same old story.

i am going crazy !

-

Try a fresh config from the configurator.

-

Some more checking:

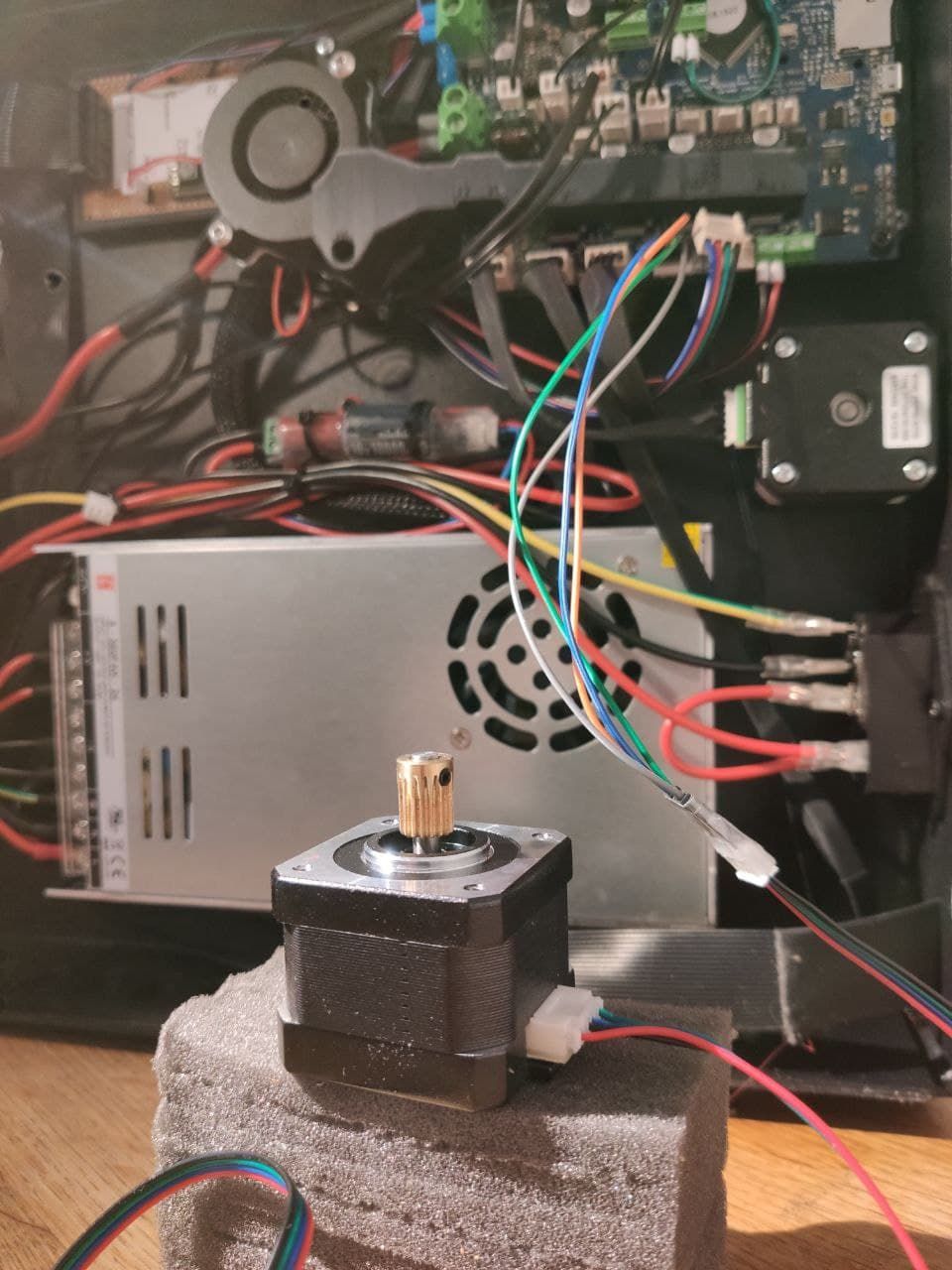

Now disconnected the stepper from the printers daughter-board on top of the extruder Carriage and connected the stepper directly to the Duet Wifi to double check that there is no issue with the connections or daughtboard. Checked. Seems to perform the same. So connected back to daughterboard again.

Also send some "G1 E7.7" ( trial and error for a full 360° revolution value) which gives a full revolution at the bare stepper. Sent via console, working. fine.

Then wrote a little gcode file for execution:

M83; relative extrusion M302 P1 ;allow cold extrusion G92 E0 ;extruder 0 G1 E7.7 F200 M118 S"Round 1" G4 P4000 G1 E7.7 F200 M118 S"Round 2" G4 P4000 G1 E7.7 F200 M118 S"Round 3" G4 P4000printed via DWC:

Works fine:

Video of executing that file: video_2021-01-28_15-52-49.mp4Performs like it should. No "over-extrusion" or double revolution seen here. Maybe this helps to get a step closer to the origin of the

over-extrusion problem. -

maybe we could send you a known good sliced g code and you can print that to rule out any misconfiguration in the slicer

-

@Veti said in massive overextrusion, E-Steps are calibrated:

maybe we could send you a known good sliced g code and you can print that to rule out any misconfiguration in the slicer

Hello Veti, that would be very nice !

Here is a link to the file i am doing all my tests with atm:

iphone_halterung_V26.stlIf someone could slice that proper for further testing. Would be great ! thx alot.

-

1611847978080-iphone_halterung_v26.txt

rename to zip and extract.

-

@Veti said in massive overextrusion, E-Steps are calibrated:

1611847978080-iphone_halterung_v26.txt

rename to zip and extract.

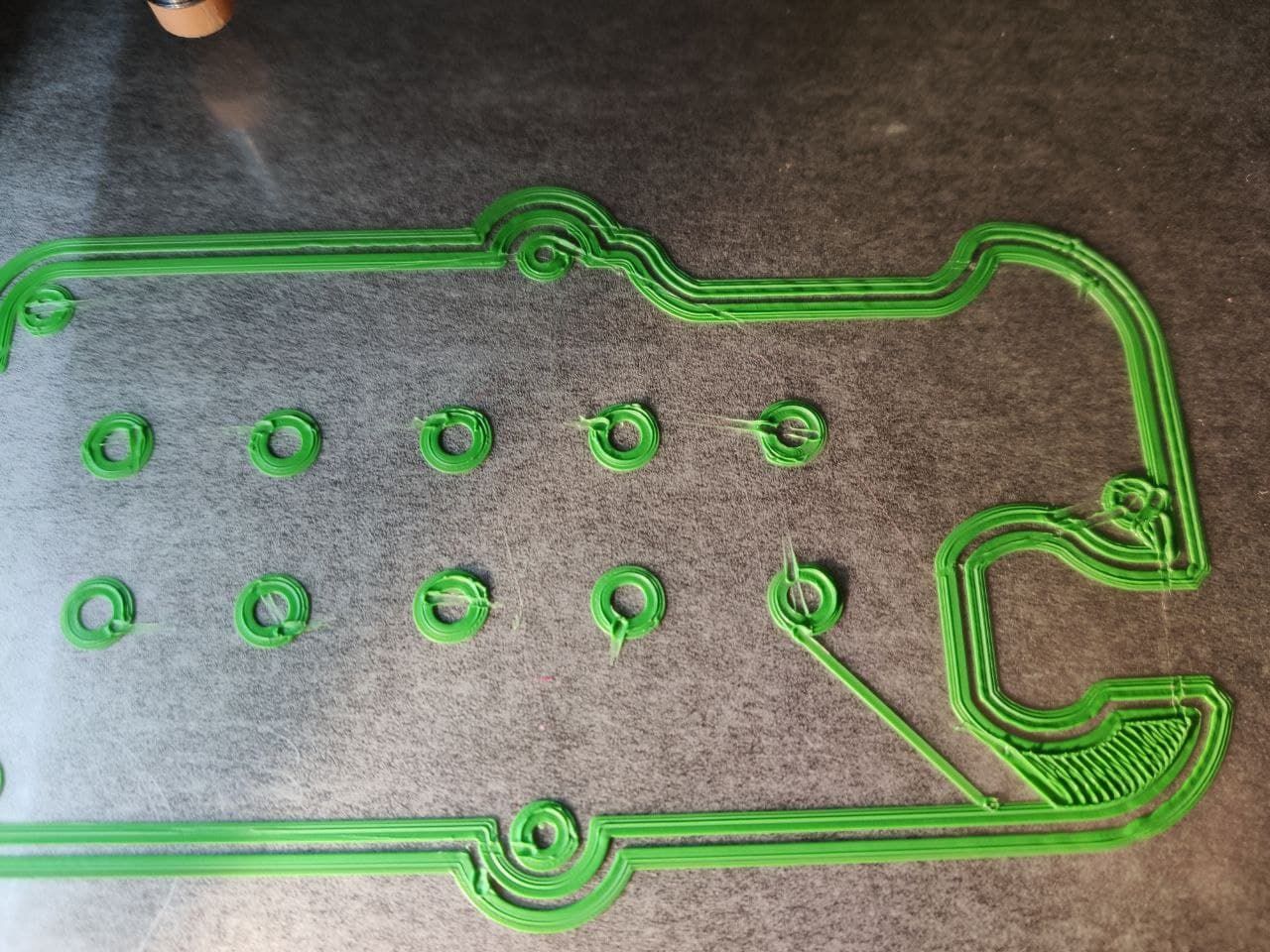

Veti, thx alot. Here comes the result of your gcode printed:

-

@Enpixa said in massive overextrusion, E-Steps are calibrated:

Checked nozzle distance to bed again with the good old "paper-method" using standard 80g paper. Nozzle is barely touching the paper. Really only slightly, it doesnt bend nor really scratches it. just a little feel of.. there could be paper

Did you measure the paper thickness with calipers or a micrometer? What do you set Z to when it's just brushing the paper? 0? 0.1? If the printer thinks it's at Z 0, and it's just brushing a piece of paper that's 0.1mm thick, then your first layer should look UNDER extruded (because your distance is too great.)

As an alternative to standard paper, I buy cigarette rolling papers. They are usually about 0.02mm thick, and tear VERY easily. If I put that paper under my nozzle and move to Z0, it should tear the paper. If I move to Z0.02, I should be able to slide the paper out without tearing (but still feel resistance.)

At Z0.01, I can slide it out if I'm very careful and go slow, but it feels like it really wants to tear.

(I realize that the above info likely isn't going to help you solve your issue, and might even result in it appearing worse. I've just noticed that people very frequently associate a piece of paper with "z = 0" when it's not.)

i am going crazy !

That depends: Were you crazy before you started having this issue?

-

Some random ideas based on likely far-fetched things, but that haven't been asked yet:

I've noticed all your pictures are using red filament. I'm guessing it's the same spool? What is the brand and type of filament? Is it 1.75mm?

Have you tried a different spool of filament?

Have you measured the filament thickness to validate it's really 1.75 (or within 0.05mm)? It's not unheard of for people to get filament that's way off.

When measuring, use calipers to measure the thickness of the filament in multiple directions. For example, it might be 1.73 measured one way, and 1.77 measured at a 90 degree angle.

-

In Germany we have a saying: "It is the same in green"..... fits perfect to my print result

Meanwhile tried it with 4 different filaments. ( All from "high quality" filament companies.

Meanwhile tried it with 4 different filaments. ( All from "high quality" filament companies.

Will measure tomorrow, have my calipers in office. But the filaments work on my other printers fine.

-

Taking more guesses (and they really are guesses at this point.)

The shape that it's starting to print in your tests: are the X and Y dimensions of the outline accurate? In other words, if the shape is supposed to be 100mm wide and 50mm long, it the outline on the build plate 100mm wide and 50mm long? (Just validating that your X and Y steps/mm are accurate. If they are set too low, the shape would be smaller than it's supposed to be, and it would appear over-extruded.)

What is the height of that first layer? 0.2mm?

Try reversing the order of M92 and M350 in your config.g (so that M350 appears BEFORE the M92.) That way, you define what "a step" is before you define how many steps are in a millimeter. (I don't think this will solve your problem, but it's good practice anyway.) Also, "I1" in your M350 turns interpolation on (the comment in your config.g says "without interpolation", but the command is enabling it.)