Duet3 6CH + 3CH expansion board - Missing steps.

-

This is diagnostics from Duet3 board

Supply voltage: min 24.0, current 24.3, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.2, under voltage events: 0 Driver 0: position 74917, standstill, reads 2634, writes 6 timeouts 0, SG min/max 0/250 Driver 1: position 2790, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/237 Driver 2: position 545, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/254 Driver 3: position 0, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/266 Driver 4: position 0, ok, reads 2639, writes 2 timeouts 0, SG min/max 0/1023 Driver 5: position 0, ok, reads 2639, writes 2 timeouts 0, SG min/max 0/1023If SG min 0 means that motors stalling, than all my motors are stalling.....

-

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

Driver 0: position 74917, standstill, reads 2634, writes 6 timeouts 0, SG min/max 0/250 Driver 1: position 2790, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/237 Driver 2: position 545, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/254 Driver 3: position 0, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/266

Also this looks like B.S. these are my Z motors, how they could have different positions?

Driver 0: position 74917, standstill, reads 2634, writes 6 timeouts 0, SG min/max 0/250 Driver 1: position 2790, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/237 Driver 2: position 545, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/254 Driver 3: position 0, standstill, reads 2635, writes 6 timeouts 0, SG min/max 0/266 -

@dc42

Motor is E3D-Online came with TitanAqua extruder. Temperature is 270c, I think for ABS is more than enough ...

... -

@evomotors When I've seen hiccups on extruders, it's always been retract/unretract moves that cause it, because the extruder moves much faster doing those moves than it does during printing. For example, during print moves the extruder moves are typically in the order of 5% of the carriage move (depending on nozzle size and layer height of course). So if you printed at say 100mm/sec, then the extruder speed would typically be about 5mm/sec. I note that you use firmware retraction and have it sec to 1800mm/sec.

So just as a test, try halving that to 900mm/sec which ought to cure the hiccups. If it does, but the print quality is not improved, then you know it's not a firmware issue. -

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@dc42

Like I say if I plug in extruder to main (Duet3) board, extruder works as it should.Please can you provide the following:

- A photo of a print, done with the extruder connected to the main board, running RRF 3.2.

- The config.g file you used to produce the print in #1.

- A photo of the same print, done with the extruder connected to the EXP3HC, running RRF 3.2 on both boards.

- The config.g file you used to produce the print in #3, along with M122 reports for both the main board and the EXP3HC [EDIT: taken when the print has completed].

- The GCode file you used to produce the prints.

I will then try to replicate and investigate this issue.

As @deckingman says, it is most likely retractions and reprimes that are causing the hiccups, however unless your steps/mm for that extruder is very high then I would not expect to see a significant number of hiccups on a 3HC.

-

@evomotors The other thing that strikes me as odd (although it should help with hiccups) is that you steps per mm for the extruder looks low (I have 6 Bondetch BMGs). Mine are all around 410 - 415 and Bondtech suggest using 415 but yours is set to 344. How did you arrive at that figure?

I hesitate to suggest this but it seems to me that you might be having extrusion problems due to incorrectly calibrated extruder, which might appear as missed steps and that the hiccups are a "red herring". (But that does not explain why the extruder connected to the main board appears to act differently - unless you change the steps per mm as well as the driver number when swapping between boards)?

-

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors When I've seen hiccups on extruders, it's always been retract/unretract moves that cause it, because the extruder moves much faster doing those moves than it does during printing. For example, during print moves the extruder moves are typically in the order of 5% of the carriage move (depending on nozzle size and layer height of course). So if you printed at say 100mm/sec, then the extruder speed would typically be about 5mm/sec. I note that you use firmware retraction and have it sec to 1800mm/sec.

So just as a test, try halving that to 900mm/sec which ought to cure the hiccups. If it does, but the print quality is not improved, then you know it's not a firmware issue.Firmware retraction speed is in mm/min not mm/s, so my 1800 is equal to 30mm/s

-

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors When I've seen hiccups on extruders, it's always been retract/unretract moves that cause it, because the extruder moves much faster doing those moves than it does during printing. For example, during print moves the extruder moves are typically in the order of 5% of the carriage move (depending on nozzle size and layer height of course). So if you printed at say 100mm/sec, then the extruder speed would typically be about 5mm/sec. I note that you use firmware retraction and have it sec to 1800mm/sec.

So just as a test, try halving that to 900mm/sec which ought to cure the hiccups. If it does, but the print quality is not improved, then you know it's not a firmware issue.Firmware retraction speed is in mm/min not mm/s, so my 1800 is equal to 30mm/s

Yes I know. But that's still around 6 times faster than what you'll see doing print moves when printing at 100mm/sec carriage speed where the extruder would be running at about 5 mm/sec. Hence my suggestion to try it at 900mm/min (15mm/sec).

-

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors The other thing that strikes me as odd (although it should help with hiccups) is that you steps per mm for the extruder looks low (I have 6 Bondetch BMGs). Mine are all around 410 - 415 and Bondtech suggest using 415 but yours is set to 344. How did you arrive at that figure?

I hesitate to suggest this but it seems to me that you might be having extrusion problems due to incorrectly calibrated extruder, which might appear as missed steps and that the hiccups are a "red herring". (But that does not explain why the extruder connected to the main board appears to act differently - unless you change the steps per mm as well as the driver number when swapping between boards)?

Extruder is calibrated using single perimeter cube, this calibration method always works best for me.

I did not change steps per mm when swapped boards.

You could be correct about "red herring". I maybe just afraid of the reported hiccups as I had very bed experience with extruder connected to the tool board in RRF3.1. I previously posted pictures of a 2 benchy (same gcode), one is printed with extruder connected to Tool Board and another with extruder connected to the Duet3 and the difference is like day and night.

-

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors When I've seen hiccups on extruders, it's always been retract/unretract moves that cause it, because the extruder moves much faster doing those moves than it does during printing. For example, during print moves the extruder moves are typically in the order of 5% of the carriage move (depending on nozzle size and layer height of course). So if you printed at say 100mm/sec, then the extruder speed would typically be about 5mm/sec. I note that you use firmware retraction and have it sec to 1800mm/sec.

So just as a test, try halving that to 900mm/sec which ought to cure the hiccups. If it does, but the print quality is not improved, then you know it's not a firmware issue.Firmware retraction speed is in mm/min not mm/s, so my 1800 is equal to 30mm/s

Yes I know. But that's still around 6 times faster than what you'll see doing print moves when printing at 100mm/sec carriage speed where the extruder would be running at about 5 mm/sec. Hence my suggestion to try it at 900mm/min (15mm/sec).

Sure, I will change it to 900mm/min for my next print.

-

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors When I've seen hiccups on extruders, it's always been retract/unretract moves that cause it, because the extruder moves much faster doing those moves than it does during printing. For example, during print moves the extruder moves are typically in the order of 5% of the carriage move (depending on nozzle size and layer height of course). So if you printed at say 100mm/sec, then the extruder speed would typically be about 5mm/sec. I note that you use firmware retraction and have it sec to 1800mm/sec.

So just as a test, try halving that to 900mm/sec which ought to cure the hiccups. If it does, but the print quality is not improved, then you know it's not a firmware issue.Firmware retraction speed is in mm/min not mm/s, so my 1800 is equal to 30mm/s

Yes I know. But that's still around 6 times faster than what you'll see doing print moves when printing at 100mm/sec carriage speed where the extruder would be running at about 5 mm/sec. Hence my suggestion to try it at 900mm/min (15mm/sec).

Sure, I will change it to 900mm/min for my next print.

I'm not expecting that it will have much effect on your print - might cause a minor blob at the end of print moves but nothing drastic. However, it should reduce or eliminate the hiccups. So if you still have print issues, it means that it something other than step pulse frequency issues with expansion boards.

For info, even with 3.1.1. I do not see any hiccups on either of my 2 expansion boards, each of which has 3 BMGs connected and which use 16X micro-stepping and around 410 steps per mm. - and that is also running 1800 mm/min firmware retraction (but I do see hiccups if I chnage to 32x micro-stepping). That doesn't really help your situation but adds weight to the argument that your issue might not be related to firmware.

-

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors When I've seen hiccups on extruders, it's always been retract/unretract moves that cause it, because the extruder moves much faster doing those moves than it does during printing. For example, during print moves the extruder moves are typically in the order of 5% of the carriage move (depending on nozzle size and layer height of course). So if you printed at say 100mm/sec, then the extruder speed would typically be about 5mm/sec. I note that you use firmware retraction and have it sec to 1800mm/sec.

So just as a test, try halving that to 900mm/sec which ought to cure the hiccups. If it does, but the print quality is not improved, then you know it's not a firmware issue.Firmware retraction speed is in mm/min not mm/s, so my 1800 is equal to 30mm/s

Yes I know. But that's still around 6 times faster than what you'll see doing print moves when printing at 100mm/sec carriage speed where the extruder would be running at about 5 mm/sec. Hence my suggestion to try it at 900mm/min (15mm/sec).

Sure, I will change it to 900mm/min for my next print.

I'm not expecting that it will have much effect on your print - might cause a minor blob at the end of print moves but nothing drastic. However, it should reduce or eliminate the hiccups. So if you still have print issues, it means that it something other than step pulse frequency issues with expansion boards.

For info, even with 3.1.1. I do not see any hiccups on either of my 2 expansion boards, each of which has 3 BMGs connected and which use 16X micro-stepping and around 410 steps per mm. - and that is also running 1800 mm/min firmware retraction (but I do see hiccups if I chnage to 32x micro-stepping). That doesn't really help your situation but adds weight to the argument that your issue might not be related to firmware.

I reduced retraction speed to 900 mm/min and even changed E micro-stepping to 8x . I still see hiccups and still under extrusions specifically after retractions moves. And I don't see this issue when E motor is connected to Duet 3 board. I wonder if I have the same issue if E motor is connected to expansion or tool board (both 3.1 and 3.2) and I'm the only one with this issue, it could be related to faulty Duet 3 board?

-

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

........................ I wonder if I have the same issue if E motor is connected to expansion or tool board (both 3.1 and 3.2) and I'm the only one with this issue, it could be related to faulty Duet 3 board?

I'm beginning to think that way myself - especially as I can run my 6 BMGs on expansion boards without any hiccups and even with an older firmware (providing I use 16x micro-stepping or less).

But I'm just an end user like you. I suggest you work through the steps that DC42 has asked you to do - he's the one you who will decide if it's a hardware issue and who can authorise a warranty replacement if that is what is required.

-

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

........................ I wonder if I have the same issue if E motor is connected to expansion or tool board (both 3.1 and 3.2) and I'm the only one with this issue, it could be related to faulty Duet 3 board?

I'm beginning to think that way myself - especially as I can run my 6 BMGs on expansion boards without any hiccups and even with an older firmware (providing I use 16x micro-stepping or less).

But I'm just an end user like you. I suggest you work through the steps that DC42 has asked you to do - he's the one you who will decide if it's a hardware issue and who can authorise a warranty replacement if that is what is required.

I added another Z axis few days ago and now I don't have free driver on the main board any longer to prove my point.

Do you think it would work when 3-Z motors connected to Duet3 and 4th Z to Expansion? e.g. (M584 X0.4 Y0.5 Z0.0:0.1:0.2:1.0 E0.1)

-

Yes, that would work

As long as you get your CAN/driver numbers correct -

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

........................ I wonder if I have the same issue if E motor is connected to expansion or tool board (both 3.1 and 3.2) and I'm the only one with this issue, it could be related to faulty Duet 3 board?

I'm beginning to think that way myself - especially as I can run my 6 BMGs on expansion boards without any hiccups and even with an older firmware (providing I use 16x micro-stepping or less).

But I'm just an end user like you. I suggest you work through the steps that DC42 has asked you to do - he's the one you who will decide if it's a hardware issue and who can authorise a warranty replacement if that is what is required.

I added another Z axis few days ago and now I don't have free driver on the main board any longer to prove my point.

Do you think it would work when 3-Z motors connected to Duet3 and 4th Z to Expansion? e.g. (M584 X0.4 Y0.5 Z0.0:0.1:0.2:1.0 E0.1)

Possibly ..........but you might fall foul of one or other of the following limitations.

-

Endstop switches and Z probes connected to the main board cannot control motors on an expansion board. This is planned to be fixed in release 3.4.

-

If you use a Z probe then the Z motors must be connected to the main board. This is planned to be fixed in release 3.4.

Link to the full list of limitations is here https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

-

-

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

@deckingman said in Duet3 6CH + 3CH expansion board - Missing steps.:

@evomotors said in Duet3 6CH + 3CH expansion board - Missing steps.:

........................ I wonder if I have the same issue if E motor is connected to expansion or tool board (both 3.1 and 3.2) and I'm the only one with this issue, it could be related to faulty Duet 3 board?

I'm beginning to think that way myself - especially as I can run my 6 BMGs on expansion boards without any hiccups and even with an older firmware (providing I use 16x micro-stepping or less).

But I'm just an end user like you. I suggest you work through the steps that DC42 has asked you to do - he's the one you who will decide if it's a hardware issue and who can authorise a warranty replacement if that is what is required.

I added another Z axis few days ago and now I don't have free driver on the main board any longer to prove my point.

Do you think it would work when 3-Z motors connected to Duet3 and 4th Z to Expansion? e.g. (M584 X0.4 Y0.5 Z0.0:0.1:0.2:1.0 E0.1)

Possibly ..........but you might fall foul of one or other of the following limitations.

-

Endstop switches and Z probes connected to the main board cannot control motors on an expansion board. This is planned to be fixed in release 3.4.

-

If you use a Z probe then the Z motors must be connected to the main board. This is planned to be fixed in release 3.4.

Link to the full list of limitations is here https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

So looks like I'm stuck... I cannot connect my extruder to main board without changing printer (reverting to 3Z screws).

-

-

Can you explain this?

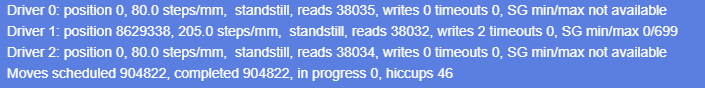

This is from expansion board diagnostics:

According to it extruder completed all 904822 requested steps, and if I calculate this in mm it would be 904822 / 205 = 4413.77 mm.

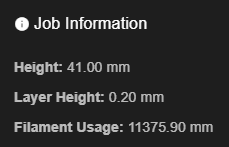

This is job information:

According to it , the filament usage should be 11375.9 mm.And print looks and weights exactly like it 2.5 times lighter.

So it looks like expansion board is not missing steps, it looks like Duet 3 board is not sending all steps to it.

-

Or this is some other "Moves"?

-

That figure is moves, not steps. Each move normally has many steps. Try looking at the reported driver 1 position instead. If will have started from 0 when the machine was last powered on or reset.