How is warranty service provided?

-

Been using this printer without fail. Turned it on and do my warm up and noticed the bed had stopped heating.

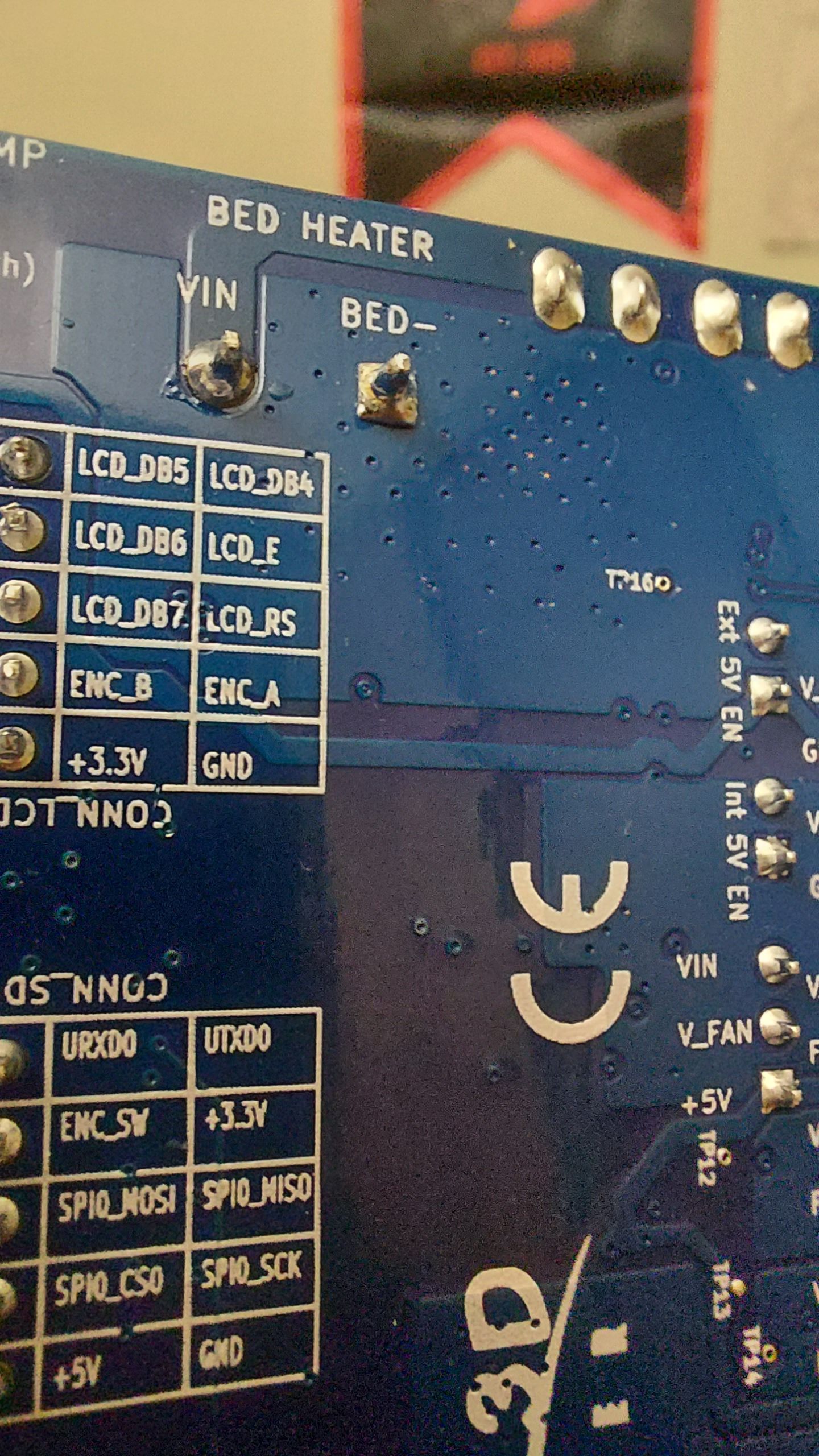

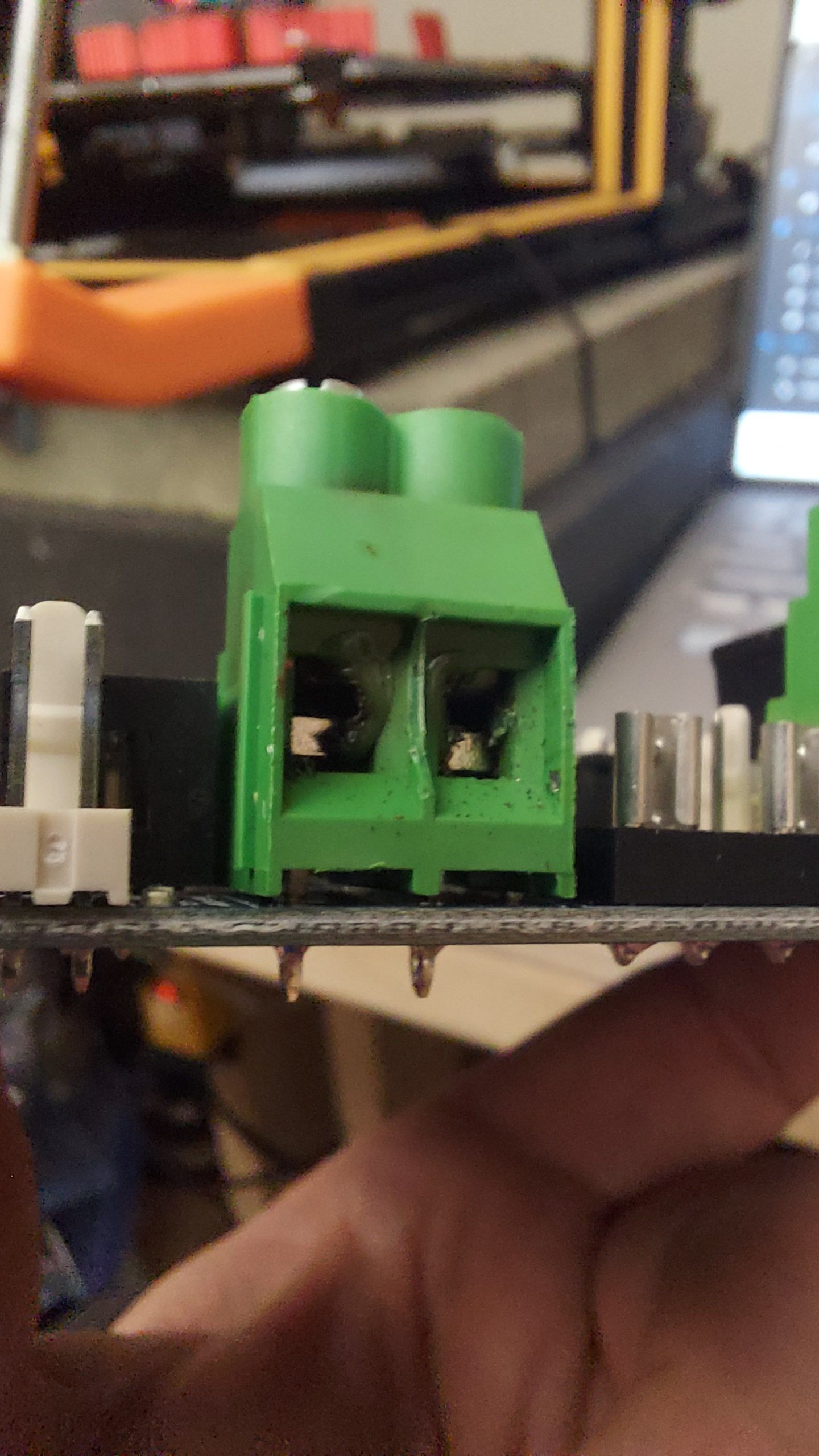

15A fuse is blown and terminal melted.

Running a home business, so any prompt help would be appreciated.

Thanks guys.

-

In short you post your problem here to get an admin to approve a warranty replacement and contact your reseller to process it.

If you include the purchase date and reseller name it might get you one step closer.

-

This seems to be caused by a loose terminal connectoion.

Did you use ferrules to connect the bed wires? -

Where and when was the Duet purchased?

Terminals heating up like that are usually due to a poor connection causing increase resistance. Were ferrules used on the bed wiring ends?

-

@Phaedrux I purchased it for this printer through Digitmakers in Canada earlier this year.

Yes, ferrules were used. Checked the bed connections, they are good as well.

-

Ali at digitmakers has emailed the link for warranty repair.

-

It seems to me to be just a bad terminal block that finally gave in. The 15a fuse blew before any major damage was done.

There are just two soldered connections on the bottom. I could easily desolder them and replace the terminal, and solder a new one in place.

Nothing else was/is wrong with this board.

-

@RyanP Are you sure the bed hasn't shorted out? With a blown fuse, as well as the melted terminal, it strikes me that something was pulling some serious current. What bed is it, or what machine is this on? What voltage is the machine running on? If possible, test the resistance of the bed.

You can replace the screw terminal; see here for replacements https://duet3d.dozuki.com/Wiki/Connector_and_spare_part_numbers#Section_Screw_Terminals

You will need a big soldering iron to desolder/resolder these terminals. They go into some large tracks.

Ian

-

I agree with droftarts, no reason for the fuse to blow if there was just a poor connection.

I am a little suspicious of the semiconductor right next to the connector - TR2 marked 'bed heat'. Might just be detritus coming off the bubbling connector but might bear looking into. -

Don't disagree with any of this. Just don't know IF there was a short. I was using this printer all weekend.

Btw, Creality Ender 5 Plus, original bed.

-

How do the solder points on the bottom side of the board look?

-

Clean and shiny.

-

How would you like to proceed? Do you want to try replacing the terminals yourself, or is Digitmakers able to do a warranty exchange?

Either way, definitely check the resistance of the bed and double check for any potential shorts so that it doesn't happen again.

-

@RyanP, a side note for the future, you may want to look into adding a solid state relay or an external power mosfet for the bed.

This will offload the high currents from your duet.

IIRC, there is an official duet web page that discusses this option but I can't find it at the moment.

-

-

Perfect guys.

@Phaedrux regarding unit. Digitmakers simply directed me to the online warranty submission. I have completed all of that but don't know how the approval process works.

Basically I simply want my largest printer back up and running, for the next week and a half so I can fill more orders.

-

I'm starting a Hevo build. As I go through that I will be doing small, more intermediate settings and mods to my printers. One major thing I am waiting until the Christmas rush is over is to do the 3.x firmware update. Figured I'd to all three current printers during the Hevo build.

-

@RyanP In that case consider this your approval. Include a link to this thread when you submit your form.

-

@Phaedrux said in How is warranty service provided?:

@RyanP In that case consider this your approval. Include a link to this thread when you submit your form.

I supplied this link in the form from the get go, I just don't know what the next step is.

-

@RyanP said in How is warranty service provided?:

I'm starting a Hevo build.

My only printer is HEVO and it's reliable and served me very well. I like its simplicity. The main design change I made was switching from bowden to a direct extruder. Couldn't get decent print quality with that 600mm bowden tube despite many attempts and design variations.

If I would build another one, I would probably look for a linear rail based design, at least for the X axis, with the expectation that it will be stiffer than the current dual 8mm steel rods.