Well this is something I haven't seen before

-

@jay_s_uk said in Well this is something I haven't seen before:

they probably match the pitch of your Z screws, indicating some sort of platform movement

He's using a belt driven axis

............the machine which is newly equipped with a 3 stepper, belt driven Z axis setup.

-

you might want to check https://forum.duet3d.com/topic/14607/slant-lines too

-

@arhi said in Well this is something I haven't seen before:

you might want to check https://forum.duet3d.com/topic/14607/slant-lines too

Excellent - thanks for the link.

Frederick

-

play with microstepping, use less microstepping ... on my setup the problem was that motor's microstepping was very inprecise, reducing microstepping / changing motor helped

-

@arhi said in Well this is something I haven't seen before:

play with microstepping, use less microstepping ... on my setup the problem was that motor's microstepping was very inprecise, reducing microstepping / changing motor helped

I know the folks at Zesty are struggling with the current Nimble (v3 I think) because it has issues and they are trying to fix them.

It happens that I am using a Nimble but it is an older unit - v1.2.

As a test perhaps I need to install an extruder right on the hotend mount to determine if the Nimble is the cause.

Reading those posts in the link you provided has given me a number of things to try.

Thanks much.

Frederick

-

@fcwilt it can easily be nimble

-

An entirely different approach to think about it:

Is it a single wall print with something like a gyroid infill? -

@arhi said in Well this is something I haven't seen before:

@fcwilt it can easily be nimble

I hope by fitting an extruder to the gantry I will be able to verify that.

The first print I posted was done at a layer height of 0.20.

These two were done at 0.15 and 0.10 - the appearance is quite different.

Frederick

-

I originally believed the issue is with layer height but then I tried same height but different extrusion speed (different print speed) and that's what made it different for me. I only had the issue with the combination of G5 (similar to zesty, supposedly better, higher gear ratio, better cable) and Mellow (PRC clone of mosquito hotend). Replacing mellow with e3dv6 and problem was gone, replacing G5 with BMG and problem was gone, but combo G5 and Mellow and I had the slanted lines, more or less pronounced depending on the print speed

-

Thanks for the additional information.

It seems the problems we have with our printers tend to be somewhat complex and not lending themselves to simple solutions.

Part of the fun I suppose.

Frederick

-

@fcwilt well I don't have it any more

- I removed the mellow from my printer, the original mosquito is purchased, arrived and sitting in usa waiting for someone to bring it here when they travel back to this middle of nowhere

- I removed the G5 from my printer and mounted the old dual flex3drive (I used dual flex3drive with hexagon hotends for year, it's what zesty nimble was designed from, and then I printed 2x G5 to test how the new design works but switched back to old dual setup that works awesome)

so I don't have any issues any more

... now, my toolchanger from e3d is sitting half assembled since january waiting for me to get my hand back in the operational state so I can finish assembling it ... and I expect whole new set of troubles when that happens as I will experiment with new hotends and new drives there (G5 again, hemera, mosquito... I have some of my own designs in the drawer for super high volume printing that are not tested yet... ) but till then..

... now, my toolchanger from e3d is sitting half assembled since january waiting for me to get my hand back in the operational state so I can finish assembling it ... and I expect whole new set of troubles when that happens as I will experiment with new hotends and new drives there (G5 again, hemera, mosquito... I have some of my own designs in the drawer for super high volume printing that are not tested yet... ) but till then..One thing I think I understood here is

G5+Mellow = problem

G5+E3Dv6 = OKThe difference mellow vs v6 is mellow need more force to extrude filament so it's possible G5 twists and bends and allow gears to not mesh ideally when high pressure is required. When I attach mellow on the dual flex3drive the rpoblem is not there but dual flex3drive is much "heavier design" so much stronger. Zesty is, like G5, a flimzy, bendy, twisty thing so it behaves more less the same with a difference that it has lower gear ratio than G5 so the pattern will be at different frequency compared to G5.

This is of course a total guesswork and might be totally off but makes sense to me

-

@arhi said in Well this is something I haven't seen before:

This is of course a total guesswork and might be totally off but makes sense to me

But it's educated guess work - that's the best kind.

Fortunately I only print functional parts so minor surface imperfections are not an issue.

I really like the idea behind the Nimble. Hopefully Zesty will get things sorted out on what is likely to be "version 4".

I've got a FlexDrive unit in a box somewhere BUT I think it may be a G5.

Thanks for your input - it really has been a help.

Frederick

-

But it's educated guess work - that's the best kind.

yeah ... but knowing how many times I was totally off ..

yeah ... but knowing how many times I was totally off ..Fortunately I only print functional parts so minor surface imperfections are not an issue.

same here, but some issues I really hate to have even if they don't affect what I do... like repeating patterns

.. they always show something is wrong

.. they always show something is wrongI really like the idea behind the Nimble. Hopefully Zesty will get things sorted out on what is likely to be "version 4".

I've got a FlexDrive unit in a box somewhere BUT I think it may be a G5.

I personally dislike zn 'cause of their behavior, not 'cause of the device... device's major issue is low print speed and low power due to missunderstanding of the fd they were basing their design on. I had a lot of issues with G5 that has nothing to do with this thread, it would just out of nowhere strip the filament and stop extruding, and the guy behind it was helping me solve that but I was not able to continue (personal crap) so we let it sit in the drawer till I'm able to test more..

G5 is the small & light (bit lighter than zn)

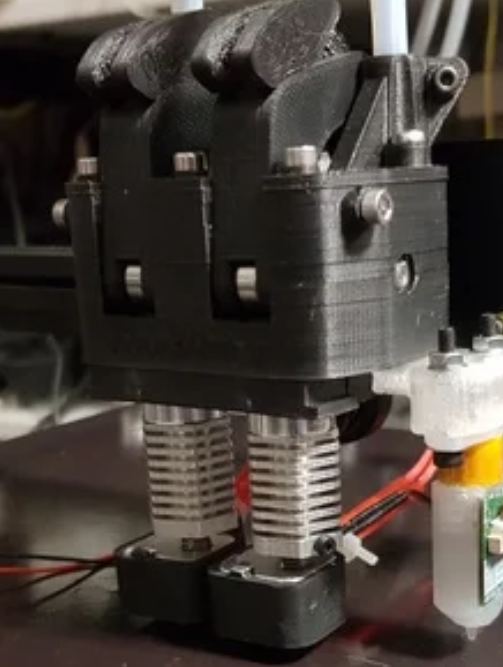

previous versions were bigger, the dual I use:

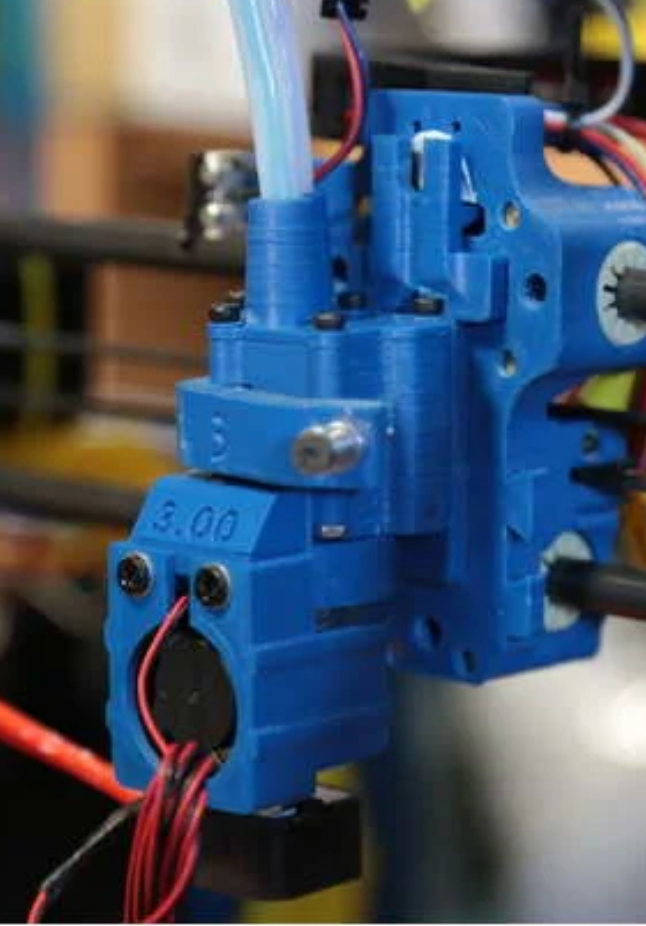

old single (heavier than G5 and ZN but much sturdier)

all f3d uses the same gearing inside (I only have 2 sets of gears, so I use them in different cases, all cases f3d make are fdm printable so easy to experiment) and I have slant lines only with G5 + Mellow

-

@arhi said in Well this is something I haven't seen before:

I personally dislike zn 'cause of their behavior, not 'cause of the device... device's major issue is low print speed and low power due to missunderstanding of the fd they were basing their design on.

Low speed? Please define low speed - in your world.

And I have no idea how "low power" applies - the power to do what?

And what does the "fd" refer to?

Thanks.

Frederick

-

@fcwilt said in Well this is something I haven't seen before:

I really don't want to make this into fd vs zn flame... I have both, don't really use them any more at all cause both have issues

Low speed? Please define low speed - in your world.

I can drive 3mm filament trough fd (flex3drive, old, not G5, having issues with G5 that are not resolved yet so can't reliably do anything with it attm) 300mm/sec, 0.6mm layer height, 0.7mm extrusion width trough 0.8mm nozzle easy. With 1.75mm filament I can do more but don't have a frame that will not vibrate itself apart if I go faster. I could not do even 1/4 of that with zn, actually reliably not even 1/5 of that.... in some "ordinary" terms, going .2mm layer .4mm nozzle, .48mm extrusion width ZN was for me reliable up to 50mm/sec and fd up to mechanical limitations of the frame - 300mm/sec

And I have no idea how "low power" applies - the power to do what?

power to push/pull filament, pull from spool trough a long ptfe tube, push into nozzle at high speed with high precision and reliability. I pull filament sometimes trough almost 6 meters of ptfe cable from the dry box, no matter how much ptfe is oversized and slippery it's a drag, especially with those 3.6 or 5kg spools on the other end

... I'm designing the new system for the toolchanger where the secondary extruder's will pull the filament from the box and maintain slack for the main extruder to not have to deal with that based on the principle old teartime up was doing... will share, once I finish it

... I'm designing the new system for the toolchanger where the secondary extruder's will pull the filament from the box and maintain slack for the main extruder to not have to deal with that based on the principle old teartime up was doing... will share, once I finish it -

Sounds like you might be doing things that most of us can only dream about.

For me printing at 90 mm/sec is "fast".

Thanks.

Frederick

-

@fcwilt said in Well this is something I haven't seen before:

Sounds like you might be doing things that most of us can only dream about.

Not really that hard, you use a big nozzle and push 100W into the hotend and it can pass through extreme amounts of plastic... problems are of different kind

- it is super unsafe, not sure what temp you need to melt the copper but I already killed some alu hotends with smaller, 80W heaters

- the khantal wire does not last too long so every 3-4 months I need to replace it

- the print quality is ... well ... acceptable for huge parts & building blocks that you will postprocess...

the dual fd I used cause I can run one custom hotend running 100W .8-1.2mm nozzle with 3mm filament on the input and one .4-.6mm nozzle in the same time and use small one for perimeter and big one for infill ... unfortunately that never worked the way I expected... slicers are still lot behind what is mechanically possible

For me printing at 90 mm/sec is "fast".

hm, wanhao duplicator i3, prints decent quality PLA at 100-110mm/sec, creality ender 5 by only switching to bmg and moving it on top of existing PRC hotend prints 120mm/sec PLA ... yes corners are rounded but you can fill the bed easy and you will reach 120mm/sec in most of the moves, you just need to get the accel up to 2000.... and yes, you need to move away from original 8bit board and use something else (in my case that was redeem and smoothieware, now I'm moving slowly to duet)

now, I don't, any more, need bigm nor fast prints so I'm on .3mm nozzle and "normal" hotends (e3dv6, hexagon, soon mosquito..) printing at "quiet" speeds

)(don't have external appt for 3d printing neither any more) ... but back in the day with my cubebot I had to push many many kg's of plastic every day

)(don't have external appt for 3d printing neither any more) ... but back in the day with my cubebot I had to push many many kg's of plastic every day  and fd solved me as with fd I could run at super high accelerations achieving high speeds

and fd solved me as with fd I could run at super high accelerations achieving high speedsbtw, what ppl rarely mention, one of the HUGE issues with fast printing is quality filament, for e.g. mitsubishi purchased dutch factory that makes AWSOME filament, e.g. one domestic company use them to make filament for them, they have special "high speed PLA", when you go over 120mm/sec printing with that filament looks better than anything else I tried (3d republika pla-x) .. at speeds below 120mm/sec you can tweak any filament to look decent, but when you go over, you really need good filament (they don't want to tell me what is different inside from regular PLA, but the cost is ~x2)

if you are interested I can find one of those hotends and take a few pics

... they are rather uninteresting (piece of copper turned on mini lathe, fire cement, khantal wire... ) but.. maybe when that project finally "expires" I can publish some of that work

... they are rather uninteresting (piece of copper turned on mini lathe, fire cement, khantal wire... ) but.. maybe when that project finally "expires" I can publish some of that workbig printed parts unfortunately are all very very very very nda-ed

as they are part of the special light tank (and also drilled, sanded, sanded, sanded, sanded, sanded, primed, sanded, sanded, coated, sanded, coated...)

as they are part of the special light tank (and also drilled, sanded, sanded, sanded, sanded, sanded, primed, sanded, sanded, coated, sanded, coated...)now as for ZN - I could not push it to go 90mm/sec with .35mm layer and .5mm extrusion width

-

-

lot of interesting things from back then... not too interesting to "high quality - high details" folks

anyhow, I'm much more interested in what will you find out to remove those slanted lines... lot of different approaches, as you can see on that other topic too... I even heard ppl had improvement using those TL-smoothers with TMC drivers. It makes no sense as TMC drivers should not have that problem around zero but ... I recently seen a super weird behavior on one old corexy laser cutter, problem ended up being "worn pulleys" and I was 90% sure there's no way a metal pulley would worn so much that it will affect movement ... but hell, they did so.. I'm collecting experiences on these weird issues ppl have

-

Well I designed and printed a test mount for a Bondtech BMG with a 25mm Stepper that I happened to have in inventory.

But when I went to fit it to the printer I found that I shouldn't trust my memory - a 20mm dimension should have been a 15mm dimension.

Such is life.

Anyway that discovery led to deciding to correct a few minor issues with a couple of existing, related parts.

One of those has been re-designed, the other is for tomorrow.

Then to print all three parts, mount the BMG and found out if it proves the Nimble is the cause.

Frederick