Creating a new IDEX 3D Printer with Duet 2 WIFI

-

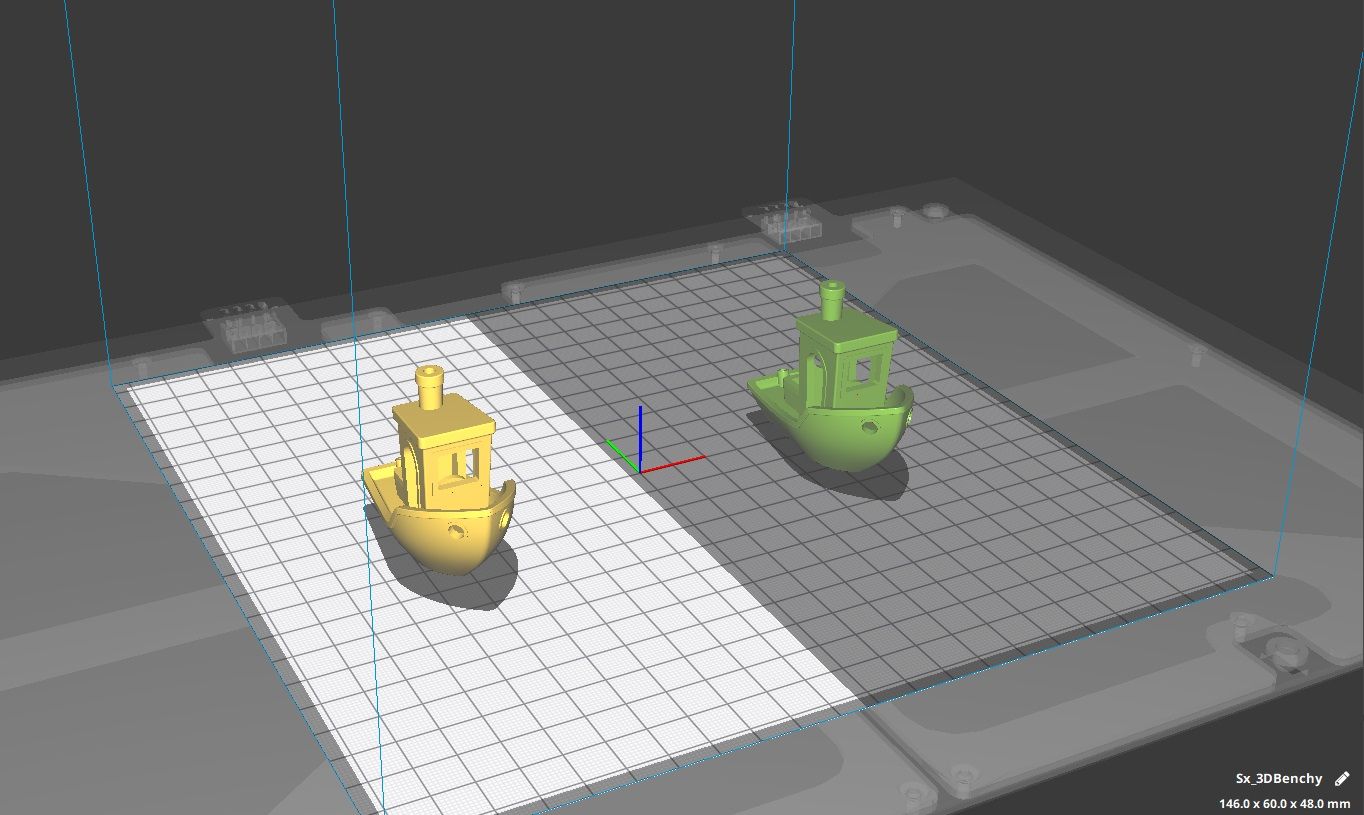

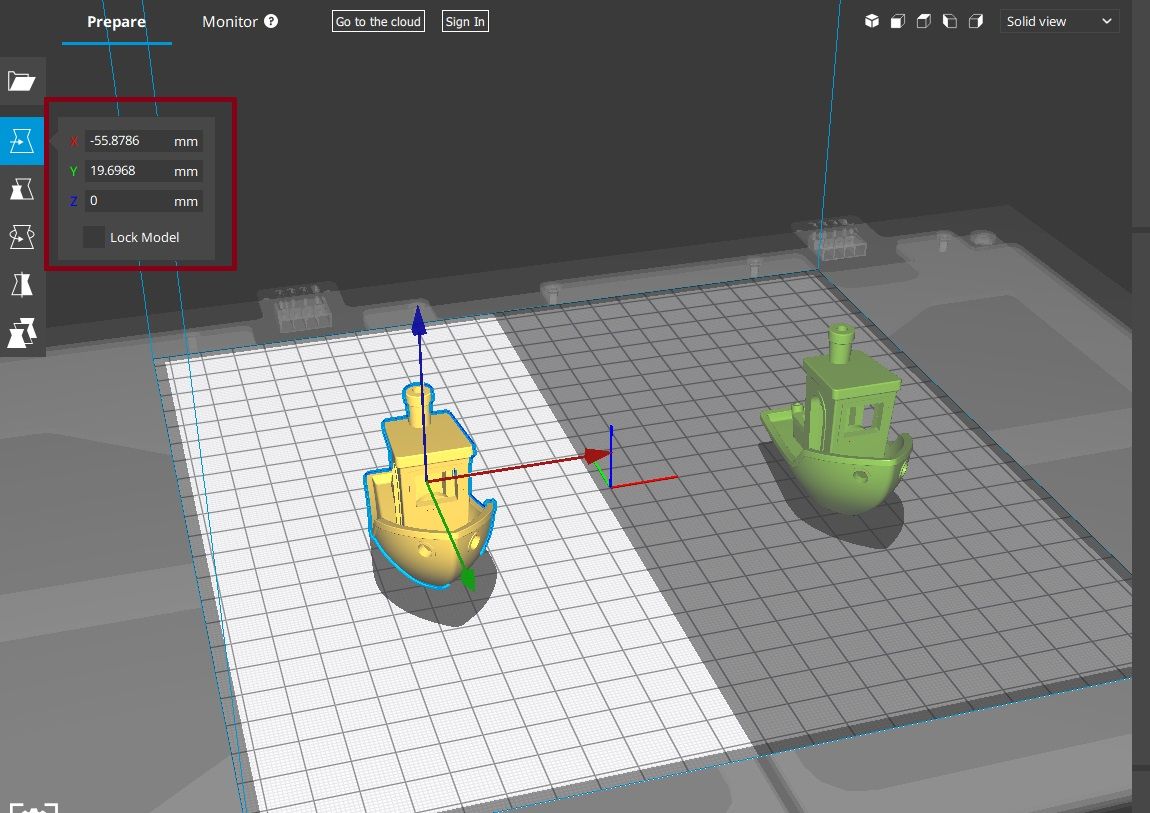

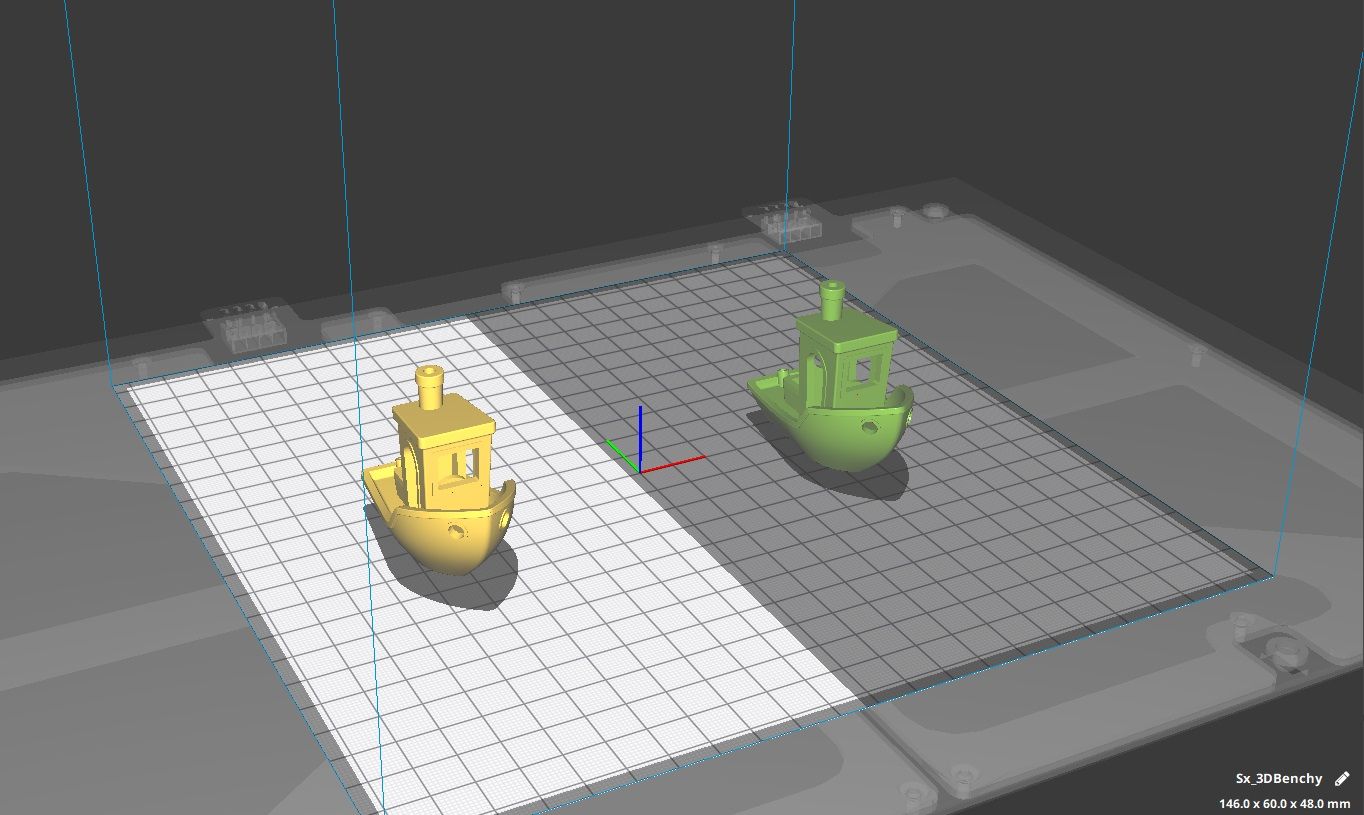

@sebkritikel I understand you well, the cura slicer is constantly updated and new features appear in it. Unfortunately, this method is not entirely convenient for ordinary consumers. the bcn3d slicer is much better for these purposes, since in it you can directly see the process of creating a duplicate and mirror copy.

Unfortunately, the bcn3d technical support did not provide me with a solution for my printer, they offered me to use the Marlin software with which I do not agree at the moment as I want to use the duet motherboard.

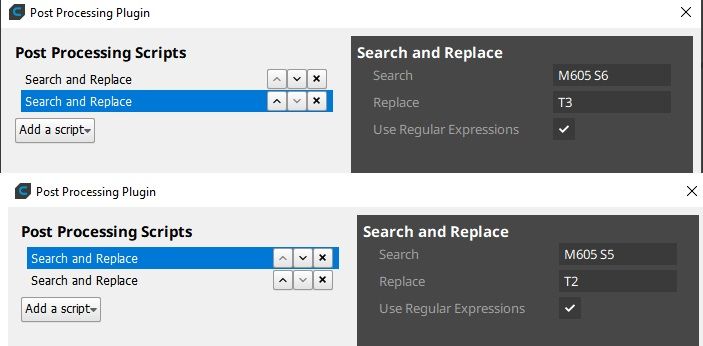

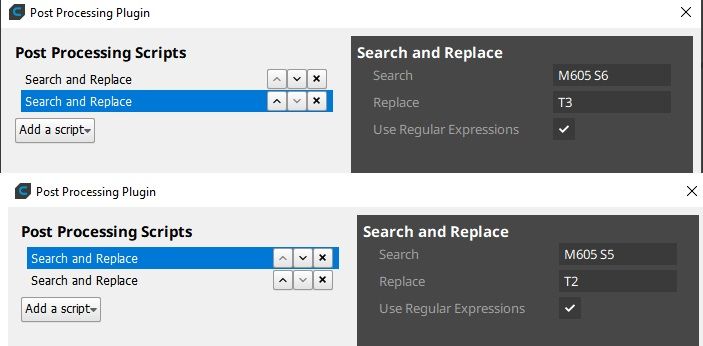

I even managed to fix the work of this slicer to some extent. when choosing duplicate mode it adds M605 S5 when choosing mirror M605 S6. using post processing - find and replace I was able to fix it on T2 or T3.

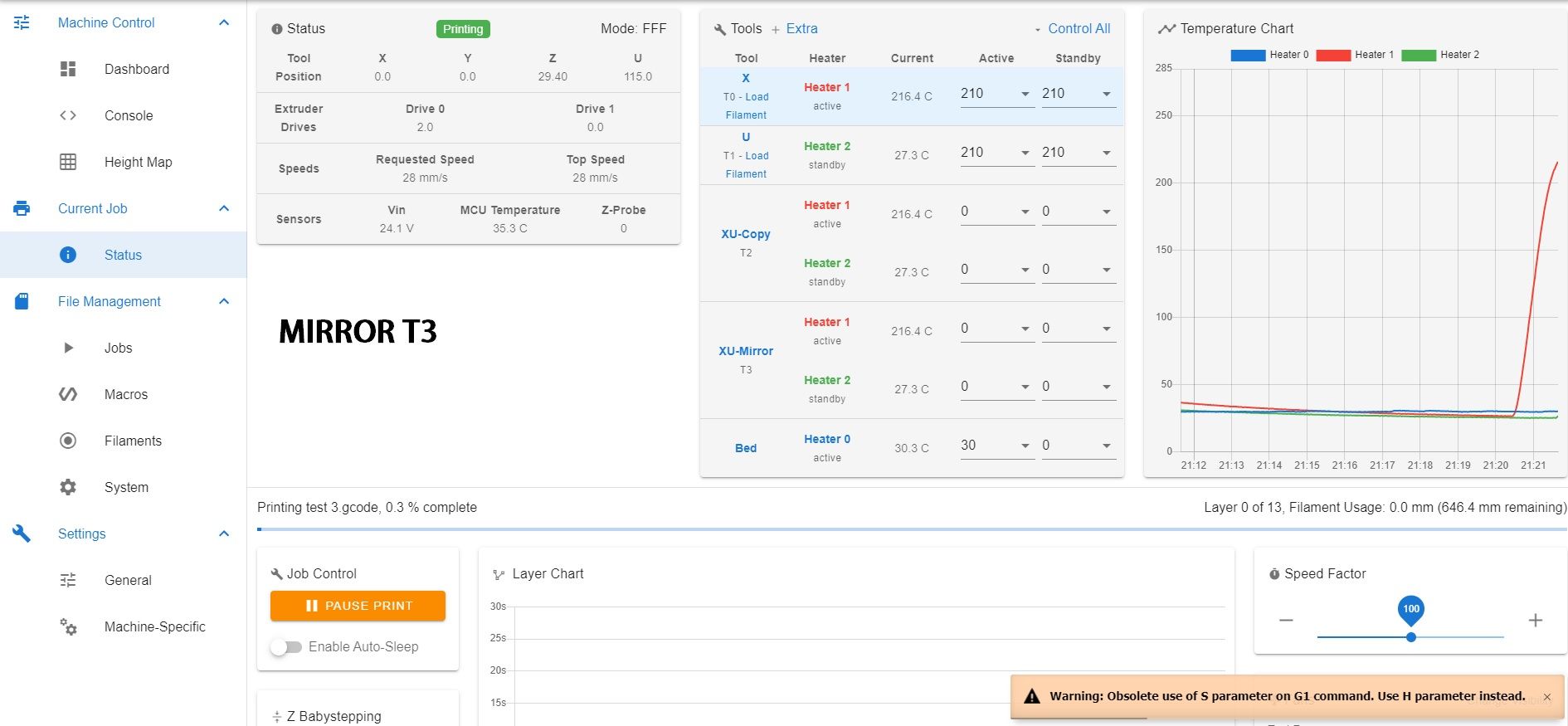

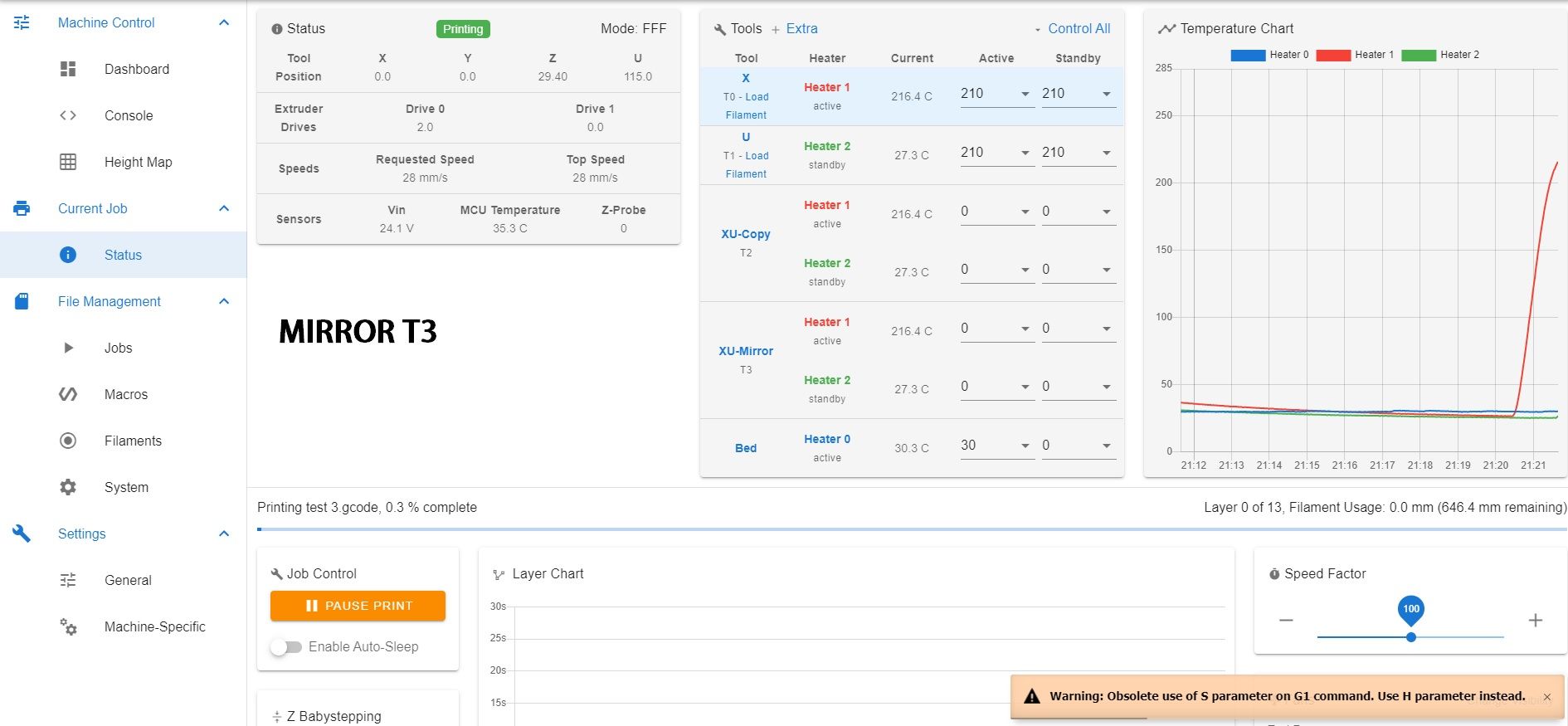

As for the kinematics, everything works perfectly when selecting 1 extruder (command T0) the first extruder is running, the heater turns on, the cooling turns on and the process continues. when extruder 2 (T1) is selected, 2 extruders are used and everything works fine too.but the following problems arose. when you select the duplicate or mirror mode, only one extruder heats up - left, but both extruders come in motion.

Most likely I made a mistake somewhere in the tools. Although I did absolutely as stated in the description. -

; Divers

;M564 H0

; General preferences

m80 ; Power ON

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DE-TechArt IDEX V1" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0

M569 P1 S1 ; physical drive 1

M569 P2 S1 ; physical drive 2

M569 P3 S1 ; physical drive 3

M569 P5 S1 ; physical drive 4

M569 P6 S1 ; physical drive 5

M584 X0 Y1 U3 Z2 E5:6 ; set drive mapping

M350 X16 Y16 U16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X100 Y100 U100 Z1200 E970:970 ; Set steps per mm

M566 X620 Y620 U620 Z80 E500:500 P1 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 U12000 Z1700 E3600:3600 ; Set maximum speeds (mm/min)

M201 X1900 Y1900 U1900 Z150 E800:800 ; Set accelerations (mm/s^2)

M906 X850 Y850 U850 Z600 E300:300 I20 ; Set motor currents (mA) and motor idle factor in per cent; Axis Limits

M208 X115 Y115 U115 Z295 ; Set axis maxima

M208 S1 X-115 Y-115 U-115 Z0 ; Set axis minimum; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 U2 S1 P"!e0stop" ; configure active-high endstop for low end on U via pin ustop; Z-Probe

M558 P1 C"!^zprobe.in" H8 F6500 T5000 ; Set Z probe type to inverted, unfiltered piezo and the dive height + speeds

G31 P900 X0 Y0 U0 Z-0.82

M557 X-58:58 Y-58:58 S40:40 ; Define mesh grid; Heaters

M308 S0 P"e5temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120CM308 S1 P"duex.e2temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin duex.e2temp

M950 H1 C"duex.pwm1" T1 ; create nozzle heater output on duex.pwm1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limitM308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"duex.fan8" Q500 ; create fan 0 on pin duex.fan8 and set its frequency

M106 P0 S0 H-1 C"Blower X"; set fan 0 value. Thermostatic control is turned off

M950 F1 C"duex.fan7" Q500 ; create fan 1 on pin duex.fan7 and set its frequency

M106 P1 S0 H1 T45 C"Fan X" ; set fan 1 value. Thermostatic control is turned onM950 F2 C"fan0" Q500 ; create fan 2 on pin fan0 and set its frequency

M106 P2 S0 H-1 C"Blower U"; set fan 1 value. Thermostatic control is turned off

M950 F3 C"fan1" Q500 ; create fan 3 on pin fan1 and set its frequency

M106 P3 S0 H2 T45 C"Fan U" ; set fan 3 value. Thermostatic control is turned onM950 F4 C"duex.fan5" Q500 ; create fan 4 on pin duex.fan6 and set its frequency

M106 P4 S1 H-1 C"LED" ; set fan 4 value. Thermostatic control is turned offM950 F5 C"duex.fan6" Q500 ; create fan 4 on pin duex.fan6 and set its frequency

M106 P5 S1 H-1 C"LED" ; set fan 4 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 X0 F1 S"X" ; define tool X tool 0 uses extruder 1, heater 1 and fan 1

G10 P0 X0 Y0 Z0 R0 S0 ; set tool 0 axis offsetsM563 P1 D1 H2 X3 F3 S"U" ; define tool U tool 1 uses extruder 1, heater 2 and fan 3

G10 P1 X0 Y0 U0 Z0 S0 R0 ; set tool 1 axis offsetsM563 P2 D0:1 H1:2 X0:3 F1:3 S"XU-Copy" ; define tool X+U copy mode

G10 P2 X0 Y0 U-113 S0 R0 ; set tool offsets and temperatures

M567 P2 E1:1 ; set mix ratio 100% on both extrudersM563 P3 D0:1 H1:2 X0:3 F1:3 S"XU-Mirror" ; define tool X+U mirror mode

G10 P3 X5 Y0 U-5 S0 R0 ; set tool offsets and temperatures

M567 P3 E1:1 ; set mix ratio 100% on both extruders; Miscellaneous

M501 ; load saved parameters from non-volatile memory; CPU temp calibration

M912 P0 S-11; Automatic power saving

M911 S22 R23 P"M913 X0 Y0 U800 G91 M83 G1 Z3 E-1 F1000" ; Set voltage thresholds and actions to run on power loss; tfree0.g

M83 ; relative extruder movement

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement;tfree1.g:

M83 ; relative extruder movement

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G1 H1 X-120 F5000

G90 ; absolute axis movement;tfree2.g:

M83 ; relative extruder movement

G1 E-2 F3600 ; retract 2mm

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement;tfree3.g:

M83 ; relative extruder movement

G1 E-2 F3600 ; retract 2mm

M106 S0 ; turn off our print cooling fan

G91 ; relative axis movement

G1 Z3 F500 ; up 3mm

G90 ; absolute axis movement

G28 X U ; home the X and U carriages

M579 U1; tpost0.g

M106 R2 ; restore print cooling fan speed

M116 P0 ; wait for tool 0 heaters to reach operating temperature

M83 ; relative extruder movement

G1 E2 F3600 ; extrude 2mm;tpost1.g:

M106 R2 ; restore print cooling fan speed

M116 P1 ; wait for tool 1 heaters to reach operating temperature

M83 ; relative extruder movement

G1 E2 F3600 ; extrude 2mm;tpost2.g:

M106 R2 ; restore print cooling fan speed

M116 P2 ; wait for tool 2 heaters to reach operating temperature

M83 ; relative extruder movement

M567 P2 E1:1 ; set tool mix ratio

M568 P2 S1 ; turn on mixing

G1 E2 F3600 ; extrude 2mm from both extruders;tpost3.g:

M106 R2 ; restore print cooling fan speed

M116 P2 ; wait for tool 2 heaters to reach operating temperature

M83 ; relative extruder movement

M567 P2 E1:1 ; set tool mix ratio

M568 P2 S1 ; turn on mixing

G1 E2 F3600 ; extrude 2mm from both extruders

M579 U-1 -

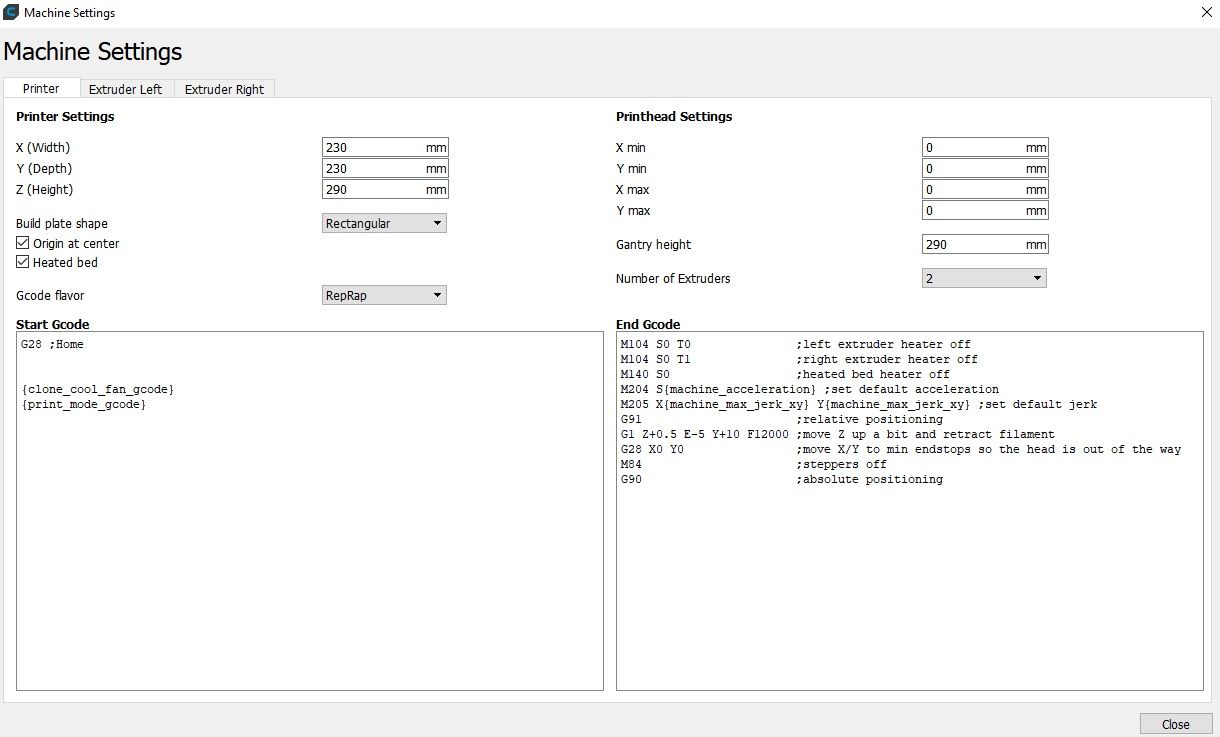

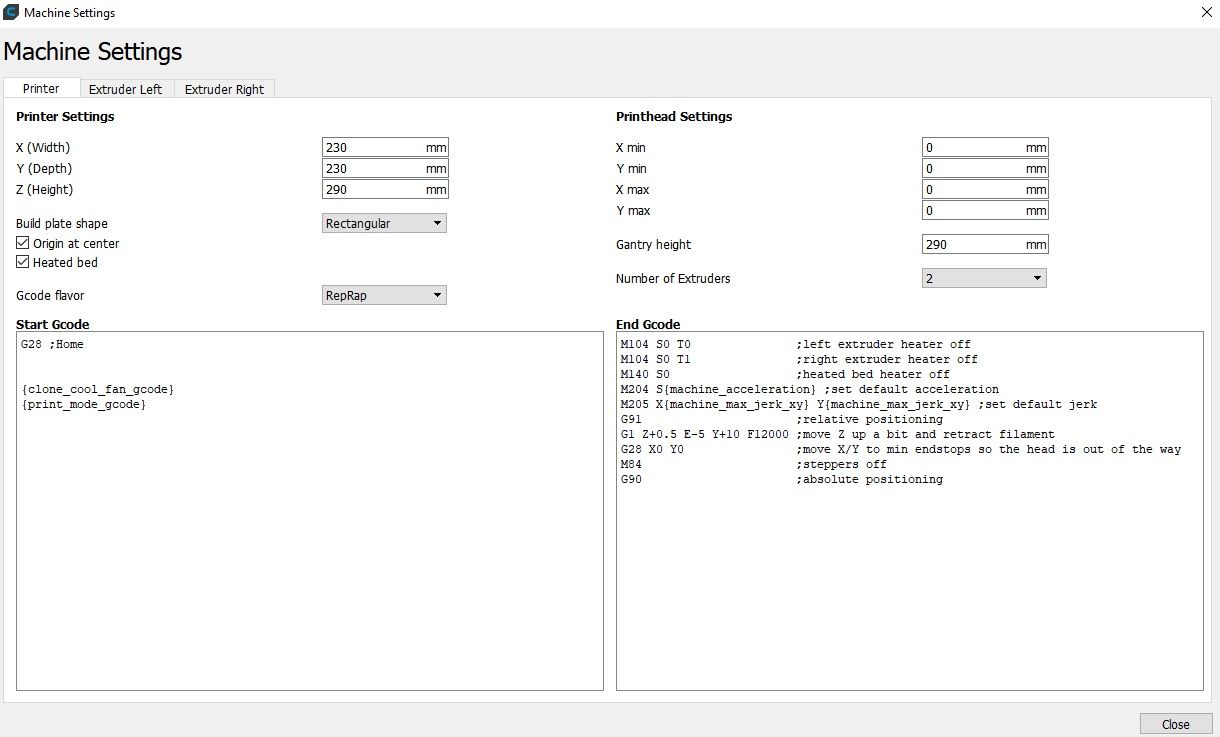

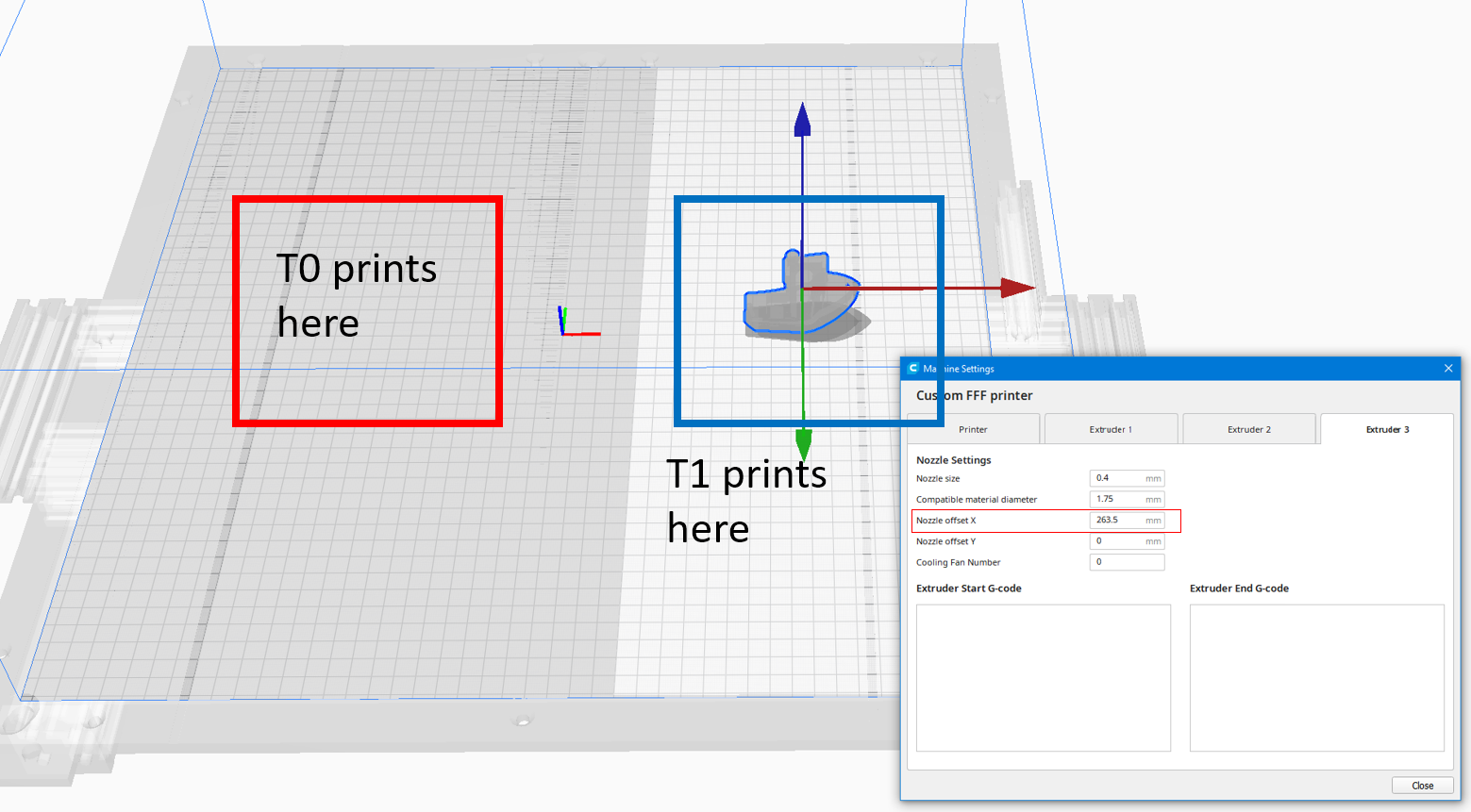

@sebkritikel, as I understand it you have configured RRF to make X0 Y0 the centre of the bed, which is good. Have you also configured Cura so that it knows that X0 Y0 is the centre of the printable area?

-

@dc42 Yes, I adjusted the center of the bed everywhere.

-

@dc42

M563 P2 D0:1 H1:2 X0:3 F1:3 S"XU-Copy" ; define tool X+U copy mode

G10 P2 X0 Y0 U-113 S0 R0 ; set tool offsets and temperatures

M567 P2 E1:1 ; set mix ratio 100% on both extrudersM563 P3 D0:1 H1:2 X0:3 F1:3 S"XU-Mirror" ; define tool X+U mirror mode

G10 P3 X5 Y0 U-5 S0 R0 ; set tool offsets and temperatures

M567 P3 E1:1 ; set mix ratio 100% on both extrudersIn these settings, I selected the correct value and both extruders take their desired position.

-

Your tool offsets for T2 and T3 are wrong. You should have equal but opposite X and U offsets in the G10 commands. For example if the lower limit printable by the X tool is -150 then the X offset should be half of that, so -75. Likewise the U offset should be half the maximum positive printable U value, which in this example would be half of +150.

-

@dc42 said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

Your tool offsets for T2 and T3 are wrong. You should have equal but opposite X and U offsets in the G10 commands. For example if the lower limit printable by the X tool is -150 then the X offset should be half of that, so -75. Likewise the U offset should be half the maximum positive printable U value, which in this example would be half of +150.

So I did at the beginning. but when using bcn3d slicer i had to adjust my firmware.

I myself move my model sideways from the center.

I am not saying that this is correct, but at least it works

This is now set up so that the two extruders do not touch each other while running. -

@dc42 said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel, as I understand it you have configured RRF to make X0 Y0 the centre of the bed, which is good. Have you also configured Cura so that it knows that X0 Y0 is the centre of the printable area?

Your comment made me stop and think, and in some ways I have myself to blame for some frustrations! Haha

Yes, Cura knows that X0, Y0 is the center of the printable area... HOWEVER while initially playing with duplication mode, I my G10 to:G10 P2 X0 Y0 U-263.5 S0 R0Rather than, what would probably be more appropriate:

G10 P2 X131.75 Y0 U-131.75 S0 R0Combine that with my fiddlings with Standard Cura, and I think I would be set. I think @DE-TechArt is on the right path with BCN3D Cura (Nicely done!!!)

(Reading further, I believe that is exactly how I should have set the G10 parameter)

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel I understand you well, the cura slicer is constantly updated and new features appear in it. Unfortunately, this method is not entirely convenient for ordinary consumers. the bcn3d slicer is much better for these purposes, since in it you can directly see the process of creating a duplicate and mirror copy.

Unfortunately, the bcn3d technical support did not provide me with a solution for my printer, they offered me to use the Marlin software with which I do not agree at the moment as I want to use the duet motherboard.

I even managed to fix the work of this slicer to some extent. when choosing duplicate mode it adds M605 S5 when choosing mirror M605 S6. using post processing - find and replace I was able to fix it on T2 or T3.

As for the kinematics, everything works perfectly when selecting 1 extruder (command T0) the first extruder is running, the heater turns on, the cooling turns on and the process continues. when extruder 2 (T1) is selected, 2 extruders are used and everything works fine too.but the following problems arose. when you select the duplicate or mirror mode, only one extruder heats up - left, but both extruders come in motion.

Most likely I made a mistake somewhere in the tools. Although I did absolutely as stated in the description.Nicely done - I forgot BCN3D Cura also had post processing.

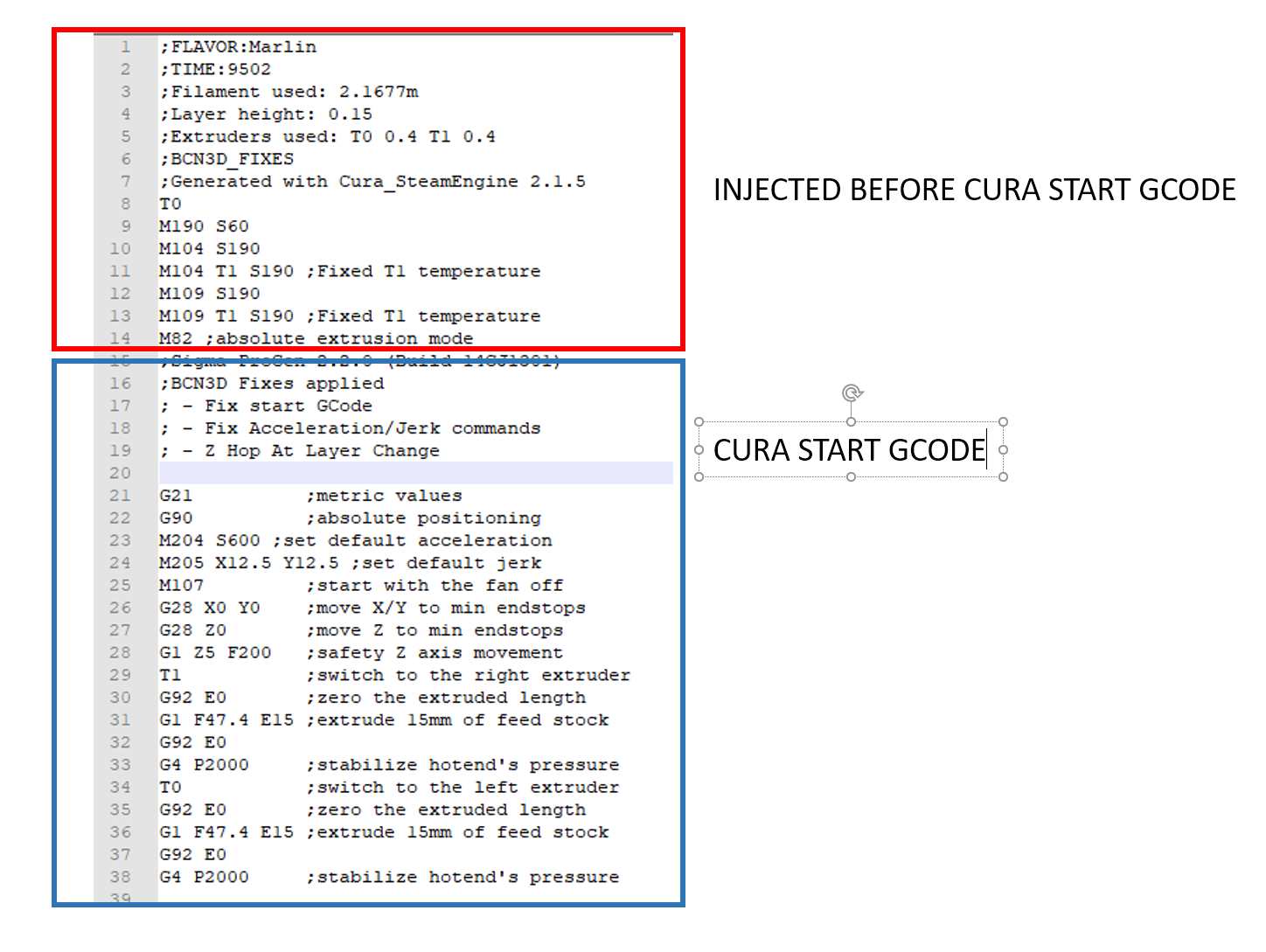

Can you upload a GCODE file of a print? I cannot recall specifically the details, but BCN3D might generate additional temperature commands for specifically T0 and T1 prior your start GCODE being injected into the file.

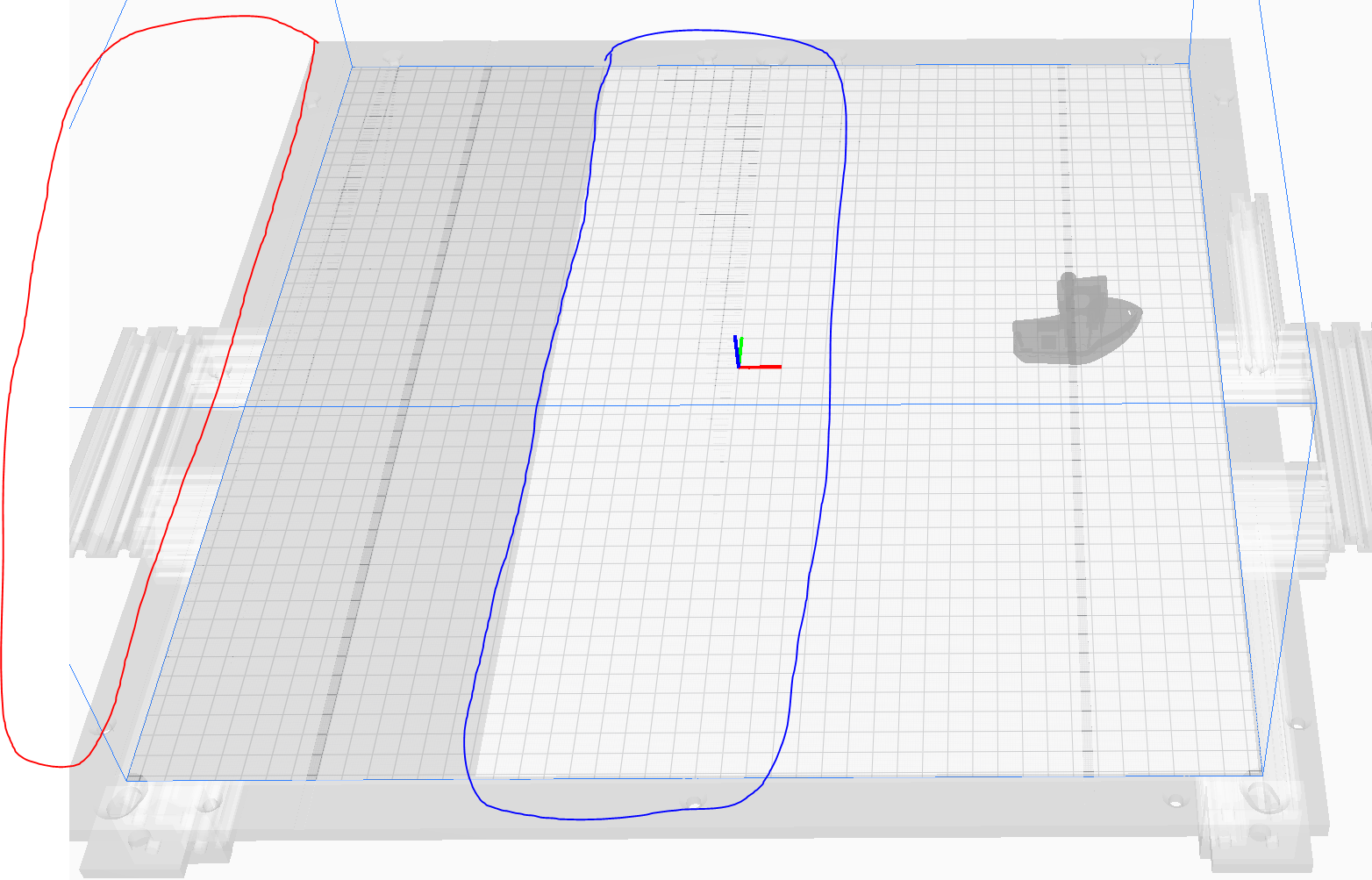

I'm not sure where the area in the red box is being created... perhaps the BCN3D Sigma(x) profile JSONs?

-

@sebkritikel said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@dc42 said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel, as I understand it you have configured RRF to make X0 Y0 the centre of the bed, which is good. Have you also configured Cura so that it knows that X0 Y0 is the centre of the printable area?

Your comment made me stop and think, and in some ways I have myself to blame for some frustrations! Haha

Yes, Cura knows that X0, Y0 is the center of the printable area... HOWEVER while initially playing with duplication mode, I my G10 to:G10 P2 X0 Y0 U-263.5 S0 R0Rather than, what would probably be more appropriate:

G10 P2 X131.75 Y0 U-131.75 S0 R0Combine that with my fiddlings with Standard Cura, and I think I would be set. I think @DE-TechArt is on the right path with BCN3D Cura (Nicely done!!!)

(Reading further, I believe that is exactly how I should have set the G10 parameter)

Important corrections to the above post - I got to a somewhat decent point with Cura removing some of my crazy steps from many posts back. G10 P2 X131.75 Y0 U-131.75 S0 R0 does make sense, however with Cura and my next step, keeping it at G10 P2 X0 Y0 U-263.5 S0 R0 is ideal.

Why?

Goes back to my comment on creating the third tool (T2, extruder 3 in Cura). You want the X offset to be equal to the U-263.5 (in this case, in order to work with Cura, it needs to be positive 263.5)

This allows Cura to block off half the build plate - mimicking the true build volume defined via G10. We cannot accidentally extend into a model into an area of the buildplate that we couldn't actually use - much like the BCN3D Cura preview.

If we kept Cura at 263.5, but used G10 P2 X131.75 Y0 U-131.75 S0 R0, T1 would actually print at the center of the bed, with T0 pretty much staying at the X endstop.

If we set the machine to G10 P2 X131.75 Y0 U-131.75 S0 R0, and then Cura to 131.75, Cura would give us an extra 131.75mm in width that we don't actually have available.

@dc42 said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

Your tool offsets for T2 and T3 are wrong. You should have equal but opposite X and U offsets in the G10 commands. For example if the lower limit printable by the X tool is -150 then the X offset should be half of that, so -75. Likewise the U offset should be half the maximum positive printable U value, which in this example would be half of +150.

So, in summary - this approach to G10 makes total sense, but you run into the slicers being dumber than the machine - no surprise there! By splitting the offset (-75 and 75 for example), you lose some of the benefits afforded by having dedicated T2 or T3 defined in Cura.

-

@sebkritikel

T0;FLAVOR:RepRap

;TIME:1438

;Filament used: 1.43706m

;Layer height: 0.2

;POSTPROCESSED

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T0

M190 S30

M104 S210 starts heating 1 extruder.

M109 S210

M82 ;absolute extrusion mode

G28 ;HomeM83 ;relative extrusion mode

;LAYER_COUNT:18

;LAYER:0

M107

G0 F3000 X20.413 Y22.145 Z0.2

;TYPE:SKIRT

G1 F1500 X19.834 Y22.342 E0.02441T1

;FLAVOR:RepRap

;TIME:476

;Filament used: 0m

;Layer height: 0.2

;POSTPROCESSED

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T1

M190 S30

M104 T1 S210 starts heating 2 extruder.

M109 T1 S210

M82 ;absolute extrusion mode

G28 ;HomeM83 ;relative extrusion mode

;LAYER_COUNT:13

;LAYER:0

G1 F1500 E-2

T1

M109 S210

M107

G0 F4500 X16.774 Y15.058 Z0.2

;TYPE:SKIRT

G1 F1800 X16.435 Y15.567 E0.02441T2

;FLAVOR:RepRap

;TIME:1440

;Filament used: 1.43709m

;Layer height: 0.2

;POSTPROCESSED

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T0

M190 S30

M104 S210

M104 T1 S210 ;Fixed T1 temperature Switching on 1 extruder again and no mention of a second extruder.

M109 S210

M109 T1 S210 ;Fixed T1 temperature

M82 ;absolute extrusion mode

G28 ;HomeT2 ;enable duplication mode

M83 ;relative extrusion mode

;LAYER_COUNT:18

;LAYER:0

M107

G0 F3000 X-36.514 Y21.344 Z0.2

;TYPE:SKIRT

G1 F1500 X-37.022 Y21.685 E0.02442T3

;FLAVOR:RepRap

;TIME:652

;Filament used: 0.646357m

;Layer height: 0.2

;POSTPROCESSED

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T0

M190 S30

M104 S210

M104 T1 S210 ;Fixed T1 temperature Same.

M109 S210

M109 T1 S210 ;Fixed T1 temperature

M82 ;absolute extrusion mode

G28 ;HomeT3 ;enable mirror mode

M83 ;relative extrusion mode

;LAYER_COUNT:13

;LAYER:0

M107

G0 F3000 X-42.99 Y14.305 Z0.2

;TYPE:SKIRT

G1 F1500 X-43.498 Y14.646 E0.02442 -

also i noticed the following:

when you select mirror or duplicate mode, only the heater 1 of the extruder is turned on, then printing starts. 2 extruder stays cold. then after several printed layers, 1 extruder stops heating and printing continues with cold extruders.

I think that the error is that I used the instructions for creating an idex 3D printer for RRF 2.0 firmware -

I don't know how the BCN version of Cura works. The instructions we give for setting up duplication and mirror mode assume a regular slicer. In the slicer, you centre your model around X0 Y0 as usual. Then the X and U offsets applied to T2 and T3 move the X print left of bed centre and the U print right of bed centre.

It may be possible to use the BCN slicer, but I can't tell you how. If that slicer puts a unique G- or M- code in the file to select duplication or mirror mode then you may be able to use that to run a macro to select the correct tool and offsets.

-

@dc42 Yes, there is still room for play, but now there is another problem. heating does not work 2 extruder. after printing several layers, the heater of the First extruder turns off

-

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@dc42 Yes, there is still room for play, but now there is another problem. heating does not work 2 extruder. after printing several layers, the heater of the First extruder turns off

Most likely either the GCode file you are printing is turning it off, or the heater is entering the Fault state. What state does the web interface show that heater to be in?

-

@dc42 The malfunction message does not appear. Only reports that extruder 1 has a low temperature.

-

@sebkritikel which firmware version do you use in your printer? could you share yours with me

tpost.g, tfree.g and Tools? -

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel which firmware version do you use in your printer? could you share yours with me

tpost.g, tfree.g and Tools?I may be able to post much later (in 12 hours). I am using 3.2-beta2, but have also used 3.1.1, 2.05.1, etc.

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel

T0... snip ...

G0 F3000 X-42.99 Y14.305 Z0.2

;TYPE:SKIRT

G1 F1500 X-43.498 Y14.646 E0.02442This is the challenge, as many of these codes we cannot easily change

Here are the lines we do not need in RRF on the DuetT2

;FLAVOR:RepRap

;TIME:1440

;Filament used: 1.43709m

;Layer height: 0.2

;POSTPROCESSED

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T0

M190 S30

M104 S210

M104 T1 S210 ;Fixed T1 temperature

M109 S210

M109 T1 S210 ;Fixed T1 temperature

M82 ;absolute extrusion mode

G28 ;HomeT2 ;enable duplication mode

now that T2 has been called, we need to define the print temperature here

M83 ;relative extrusion mode

;LAYER_COUNT:18

;LAYER:0

M107

G0 F3000 X-36.514 Y21.344 Z0.2

;TYPE:SKIRT

G1 F1500 X-37.022 Y21.685 E0.02442In RepRapFirmware, we do not need to call T0 and T1 multiple times to set the temperature. It is as easy as this:

T2 M190 S120 M104 S250 M109 S250We called T2

We set the bed temperature

We set the print temperature

Cura says to wait until we reach temperatureTake a look at C:\Program Files\BCN3D Cura YOUR VERSION\resources, there must be a JSON there that creates those extra start gcode lines. May be a good idea to search the github page to try and find them? I don't know where those extra lines are generated in the code.

What is happening now is, you create the file and start the print.

BCN3D Cura says select T0 and set its temperature

Then it sets the T1 temperature

Finally it selects T2 - which is a "new" tool, but Duet and RRF was not given a temperature for T2. T2 of course includes the heaters and extruders from both hotends, but must be given a temperature - which currently is not happening in BCN3D Cura. -

This post is deleted! -

@sebkritikel

Yes, you are right there is one file that describes the sequence of our printer

C:\Program Files\BCN3D Cura 3.2\resources\definitions

File fdmprinter.def"print_mode_gcode":

{

"label": "Print Mode GCode",

"description": "GCode to enable selected print mode.",

"type": "enum",

"options":

{

"": "Regular",

"M605 S6 ;enable mirror mode": "Mirror",

"M605 S5 ;enable duplication mode": "Duplication"

},

"default_value": "",

"value": "'' if print_mode == 'regular' else 'M605 S6 ;enable mirror mode' if print_mode == 'mirror' else 'M605 S5 ;enable duplication mode'",

"enabled": false,

"settable_per_extruder": false,

"comments": "BCN3D setting"in the next line I found commands that surrender for mirror and parallel modes in Marlin and replaced them with T2 and T3

"T3 ;enable mirror mode": "Mirror", "T2 ;enable duplication mode": "Duplication"now when mirror mode is selected, g-code is configured with the correct T3 code without post processing.

But I just can't find those commands that add unnecessary commands at the beginning of the g-code.

;FLAVOR:RepRap

;TIME:1412

;Filament used: 1.13875m

;Layer height: 0.2

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T0

M190 S30

M104 S210

M104 T1 S210 ;Fixed T1 temperature

M109 S210

M109 T1 S210 ;Fixed T1 temperature

M82 ;absolute extrusion modeT3 ;enable mirror mode

M83 ;relative extrusion mode

;LAYER_COUNT:101

;LAYER:0

M107

G0 F3000 X-36.732 Y9.588 Z0.2Technical support bcn3d Sorry, refuses to help(((

-

@DE-TechArt said in Creating a new IDEX 3D Printer with Duet 2 WIFI:

@sebkritikel

Yes, you are right there is one file that describes the sequence of our printer

C:\Program Files\BCN3D Cura 3.2\resources\definitions

File fdmprinter.def"print_mode_gcode":

{

"label": "Print Mode GCode",

"description": "GCode to enable selected print mode.",

"type": "enum",

"options":

{

"": "Regular",

"M605 S6 ;enable mirror mode": "Mirror",

"M605 S5 ;enable duplication mode": "Duplication"

},

"default_value": "",

"value": "'' if print_mode == 'regular' else 'M605 S6 ;enable mirror mode' if print_mode == 'mirror' else 'M605 S5 ;enable duplication mode'",

"enabled": false,

"settable_per_extruder": false,

"comments": "BCN3D setting"in the next line I found commands that surrender for mirror and parallel modes in Marlin and replaced them with T2 and T3

"T3 ;enable mirror mode": "Mirror", "T2 ;enable duplication mode": "Duplication"now when mirror mode is selected, g-code is configured with the correct T3 code without post processing.

But I just can't find those commands that add unnecessary commands at the beginning of the g-code.

;FLAVOR:RepRap

;TIME:1412

;Filament used: 1.13875m

;Layer height: 0.2

;Generated with Cura_SteamEngine 3.2.0

M141 S50

T0

M190 S30

M104 S210

M104 T1 S210 ;Fixed T1 temperature

M109 S210

M109 T1 S210 ;Fixed T1 temperature

M82 ;absolute extrusion modeT3 ;enable mirror mode

M83 ;relative extrusion mode

;LAYER_COUNT:101

;LAYER:0

M107

G0 F3000 X-36.732 Y9.588 Z0.2Technical support bcn3d Sorry, refuses to help(((

Yes, I would expect BCN3D to be of no help, since they would want you to buy a Sigma or Epsilon

haha

hahaNice job on the JSON.

Unfortunately, I think those lines are created somehow by the BCN3D fork of CuraEngine, so not as easy as changing a JSON sadly.

https://github.com/Ultimaker/CuraEngine/pull/640

https://github.com/Ultimaker/Cura/issues/1819

https://github.com/Ultimaker/CuraEngine/issues/676