Solved z motors drives faster than the should

-

Hey everybody,

I have a little problem with my 4 z motors. When I would like to home the z motors, they drive up very loud, than x and y home normally and when the z motors drives down, i think they would be to fast. 2 z motors don't go further, blocking and making loude noise.

I'm using external stepper drivers (leadshine DM556) for the z motors with Expansion Breakout Board.

I think, I have set the stepper driver right.

Here you have two pictures.

![IMG_20200930_151412[1].jpg](/assets/uploads/files/1601471721577-img_20200930_151412-1.jpg)

![IMG_20200930_151138[1].jpg](/assets/uploads/files/1601471769466-img_20200930_151138-1-resized.jpg)

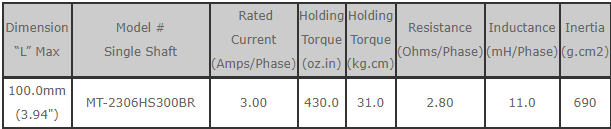

Motor data sheed

leadshine DM556 datasheet

DM556m.pdfconfig.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Sep 29 2020 15:16:53 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"3D Printer" ; set printer name ; Network M551 P"****" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P5 S1 R1 T2.5:2.5:5:0 ; physical drive 5 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M569 P6 S1 R1 T2.5:2.5:5:0 ; physical drive 6 goes forwards M569 P7 S1 R1 T2.5:2.5:5:0 ; physical drive 7 goes forwards M569 P8 S1 R1 T2.5:2.5:5:0 ; physical drive 8 goes forwards M584 X0 Y1:4 Z5:6:7:8 E3 ; set drive mapping M350 Y256:256 Z4:4:4:4 I0 ; configure microstepping without interpolation M350 X16 E16 I1 ; configure microstepping with interpolation M92 X448.00 Y241.37:241.37 Z1280.00:1280.00:1280.00:1280.00 E420.00 ; set steps per mm M566 X900.00 Y900.00:900.00 Z12.00:12.00:12.00:12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00:6000.00 Z180.00:180.00:180.00:180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00:500.00 Z20.00:20.00:20.00:20.00 E250.00 ; set accelerations (mm/s^2) M906 X1800 Y1800:1800 Z800:800:800:800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1280 Y2500 Z1500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop M574 Y2 S1 P"!ystop" ; configure active-high endstop for high end on Y via pin !ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:1265 Y15:2485 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; Tools M563 P0 S"Extruder" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S21 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossI don't find the problem.

Many thanks for your help!

Best regards

-

You have set your Z steps/mm to 1280 in config.g, however you have set the steps/rev to just 400. That combination implies your leadscrew has a lead (linear movement per turn) of 400/1280 = 0.3125mm. What should it be?

Steps/rev set to 3200 or 6400 would be more normal.

-