BOx Large Format DIY Printer

-

Aw crap I almost bought this one yesterday but decided it was a bit too long.

Meh, I'll try the one I bought and if it's not convincing then I'll give this one a tryThanks!

-

Or look at the orbiter extruder!

-

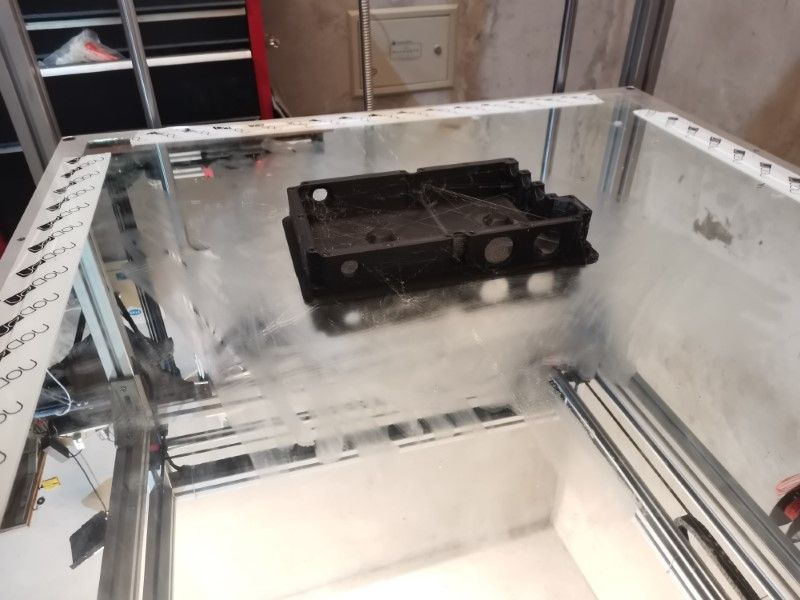

OK so new extruder installed and after fixing a few small issues I installed the heat bed:

it's made of 9 heating pads of 300W each, so that's 2700W in total.

It works really well, the bed is able to hit 60 degree in less than 5 minutes. And since then, no warping anymore.

I've already printed lots of stuff with the printer and so far it works really well. It's getting to the point where it starts being really reliable.

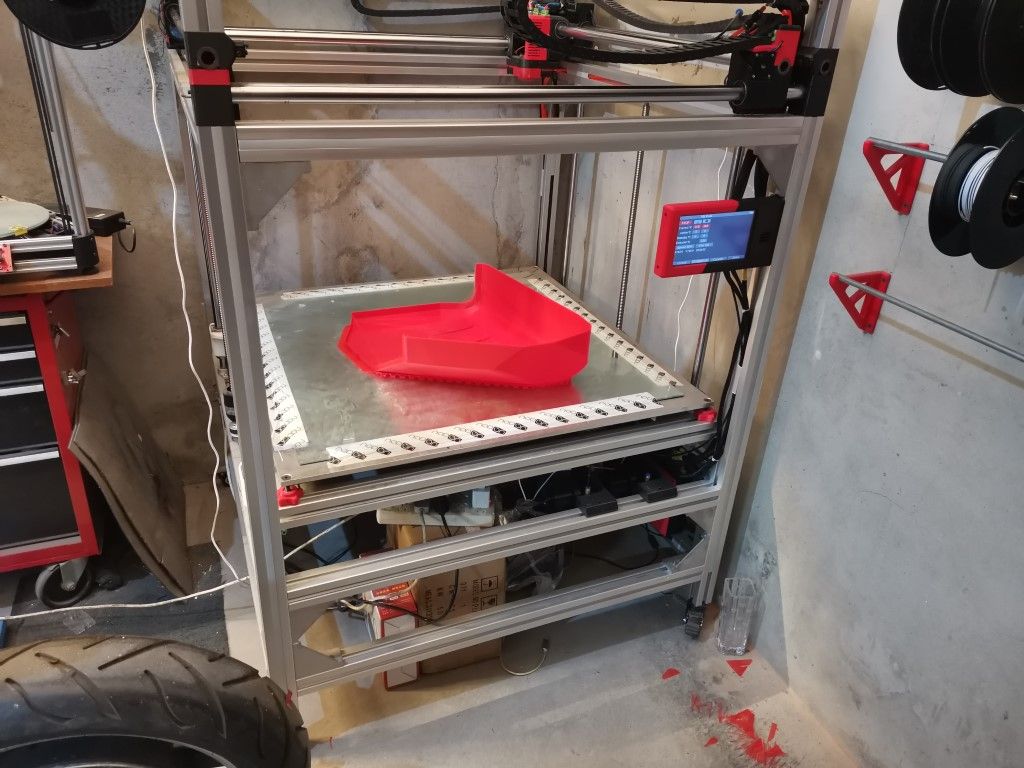

Some parts for my screen articulated arm:

An enclosure for my motorbike's battery monitoring system:

A spool holder system for the printer:

Most of the work on this printer is done, now I'll try making it as reliable as possible.

Also, I received a DueX5 board, so I'll add lots of new functions in the next months, I plan to start ith a 3rd Z axis and then add multi color/multi material capabilities.

-

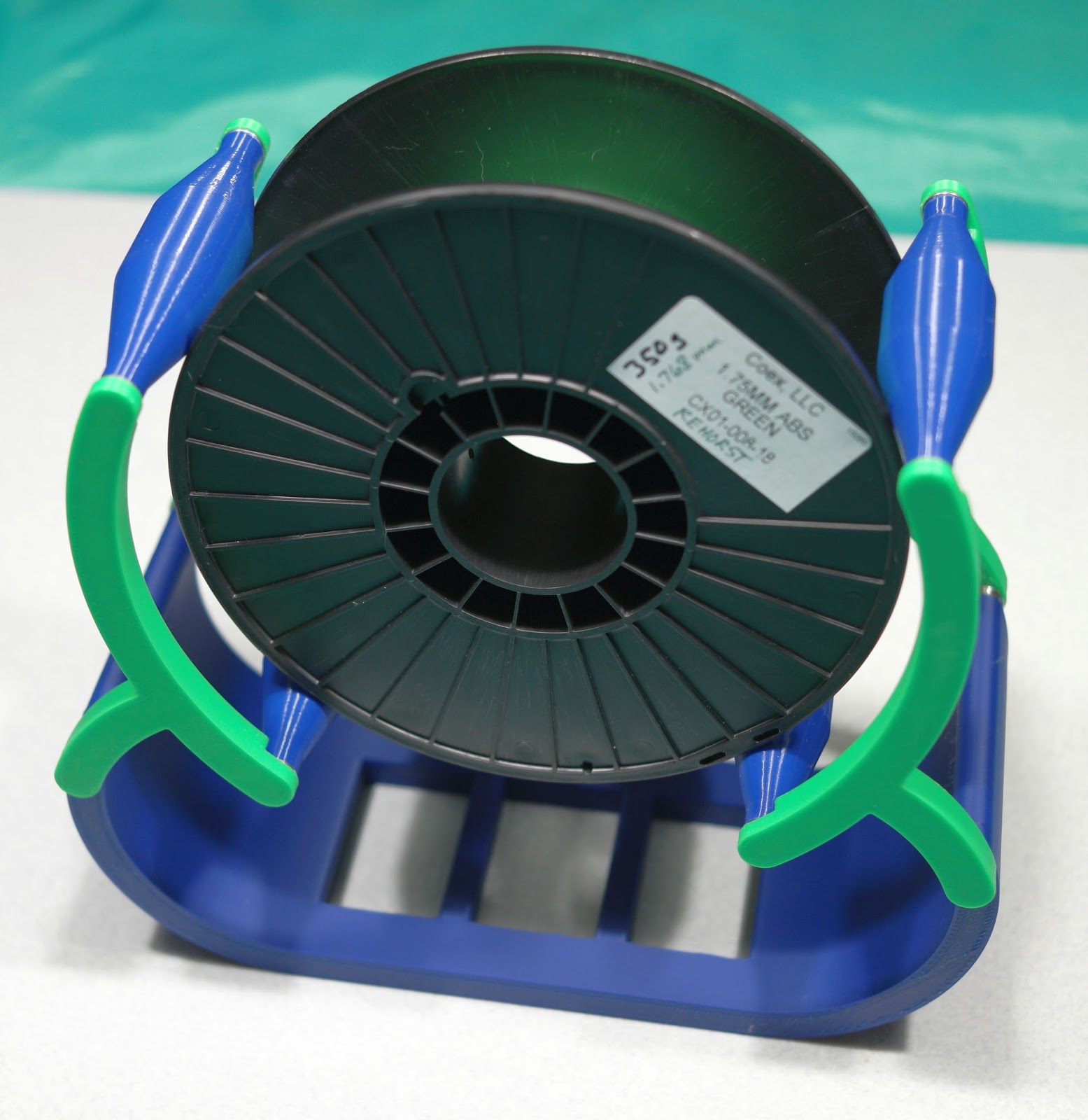

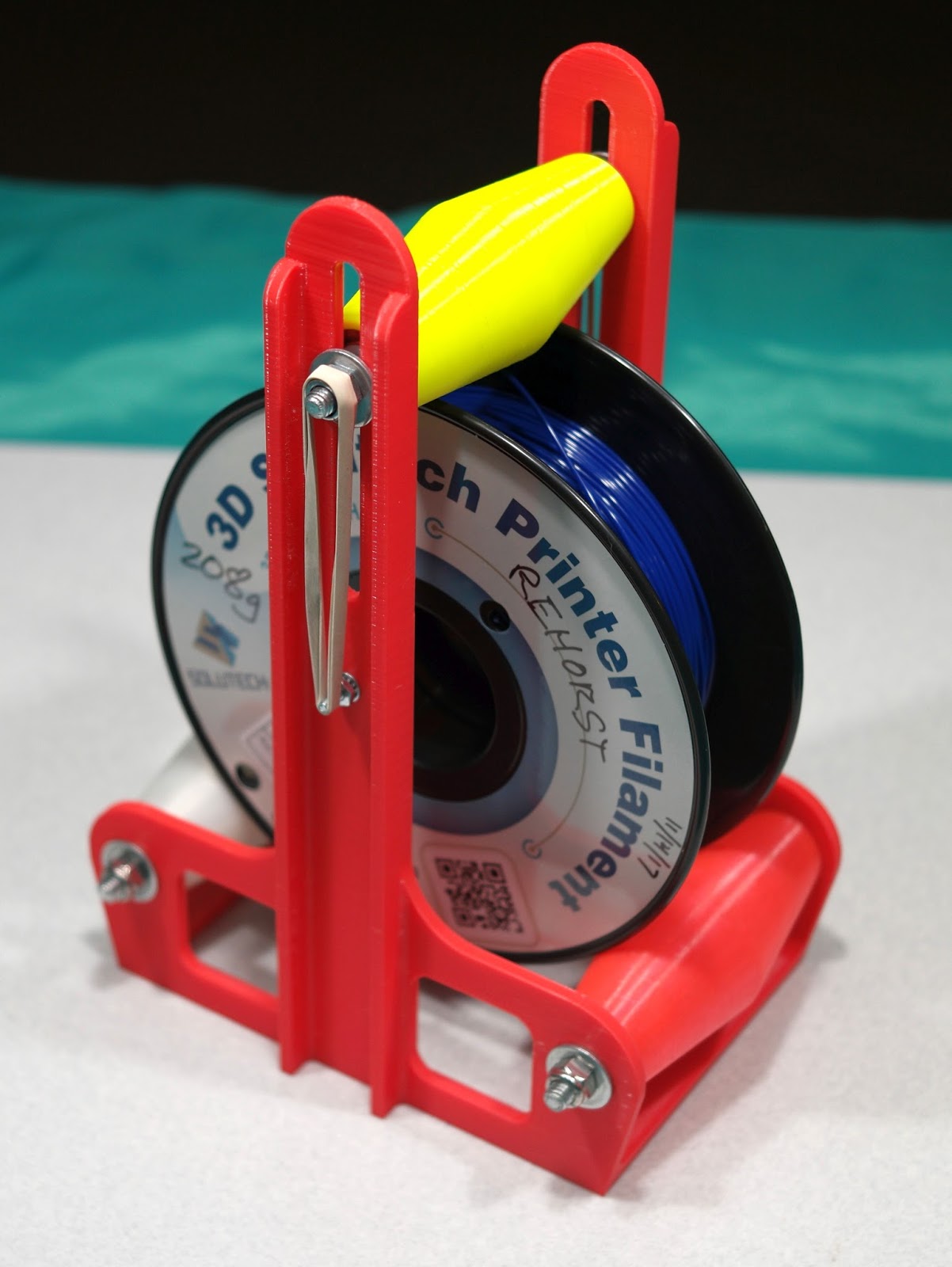

Looks like a great build! Since the printer has an open frame I'm guessing you'll be printing a lot of PLA. PLA likes to spring off the spool, especially when it's a new spool that's wound almost to the edges of the flanges. When the filament springs off the spool it tends to get tangled and that can end a print prematurely. I use two different design spool holders, both of which prevent such problems.

This one uses bearings from hard disc drives (12 of them!). The rollers were printed as single wall vases. The weight of the spool keeps the rollers pressed against the flanges of the spool. The filament can't jump off.

This is the other one. The rollers have F608 bearings and 5/16" bolts with nylock nuts as shafts. The base was printed as a single piece without support material. Another copy of this one has a steel roller on top so the rubber bands aren't needed:

I have found the second one can be used for 5 lb spools if I remove the upper roller- It needs a taller base to be used with all 3 rollers.

-

Thanks for the suggestion!

So Far my system works really fine, but I'll add those rollers if I experience a problem like that in the future

Well, the printer worked perffectly during all the weekend, until I decided to add a filament sensor.

Apparently, the sensorwires were not right, I guess they shorted somehow and this blew up the 5V voltage regulator. Bummer.

The board still works when powered by the USB so I guess it's a good sign that it isn't too damaged aside from the power stage.

Does anyone knows what is the exact reference of this component? From my research so far, it seems to be the A4403GEUTR-T reference, but I'd like to be certain before attempting to repair it so could anyone confirm?

Also, is there any other component usually associated with this part's death? Should I change any component together with this one or just replacing this voltage converter do the trick?As you can see, there is some visible damage on it, but I haven't seen any damage elsewhere:

I happen to have some very skilled people in my company who should be able to rework the board for me, but I'd like to be sure this is the righ component before I ask them to help.

Thanks a lot in advance for your help guys!

-

The red line is over the silk screen, but that appears to be U3?

Perhaps @bearer would be able to answer your specific component question.

-

A4403GEUTR-T / A4403GEU-T is the right part and if the board works from USB odds are good replacing U3 will help yeah.

-

@bearer said in BOx Large Format DIY Printer:

A4403GEUTR-T / A4403GEU-T is the right part and if the board works from USB odds are good replacing U3 will help yeah.

Awesome, thanks a lot !!

-

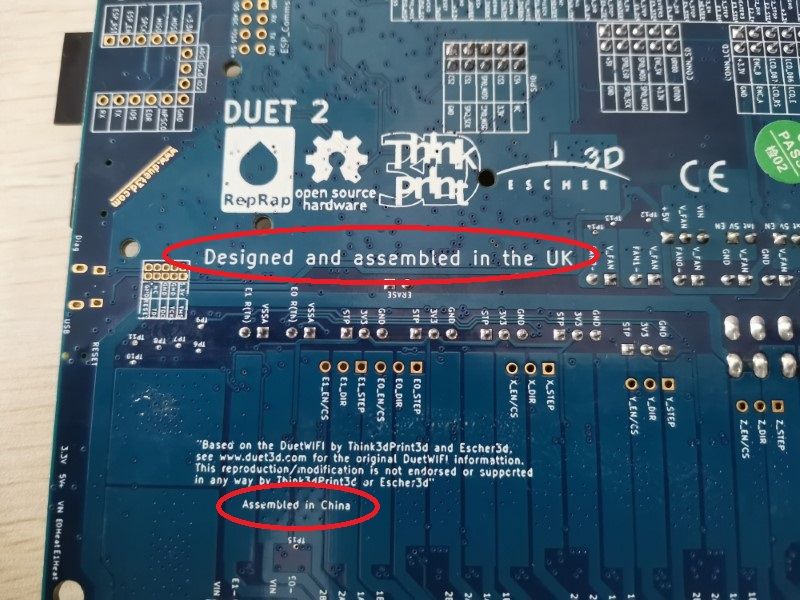

Btw is it a cloned board? (lacking serial sticker on cpu)

Just wondering as a batch of genuine boards were fitted with A4403 chips that seemed to be faulty a while back; wondering the the cloned board could share the same issue or if you had a "incident" leading up to the failure?

-

@bearer it's very possible that this is a clone, I was hoping it to be a real one, but I live in China and getting real stuff here is always a challenge. Is there any way I can know it for sure?

It was mostly my fault, I wired the filament sensor in a wrong way, probably shorting the positive and negative. I've let it like that for 5 minutes before realizing the issue but it was already too late, the chips released the magic smoke already.

-

On the back of the board there may be a silk screen of text that says it's based on the Duet, yadda yadda yadda. Having blue heatsinks and no sticker is usually a good indicator. Plus I don't think there are any authorized resellers in China, so safe to say it's a clone. Don't worry, we don't hold it against you.

-

As you've already discovered you'll get help with pretty much anything but warranty repairs even if its not genuine so don't sweat it; I was just curious as it seemed unlikely for it to be the same issue as with that suspect batch of chips.

-

@Phaedrux Well it seems to be a cloned one then, I probably could have guessed it earlier if I had paid attention to the silkscreen you mentionned:

I don't think that the original ones are both assembled in the UK and assembled in China!

Sometimes we can find real/non cloned hardware even though there is no authorized resellers here, some people import them and then resell without the creator's consent or knowledge. That's how I got my BL touch for instance, some guy imported it from Korea into China. But it's always a bit of a gamble, even the price isn't always a good indicator...

Anyway, thanks a ton for the help, and sorry for not having bought the real one. Maybe you should consider having a reseller here, most people here are ok to pay a premium for quality hardware nowadays in China

-

@MrDui said in BOx Large Format DIY Printer:

thanks a ton for the help, and sorry for not having bought the real one.

No problem, thanks for sharing your giant cool printer with us.

-

your build is really something. I'm particularly impressed by the tidiness and wires routing

-

Good news : we can now add a label "repaired in China" to the "Assembled in China" and "assembled in the UK" on the clone board!

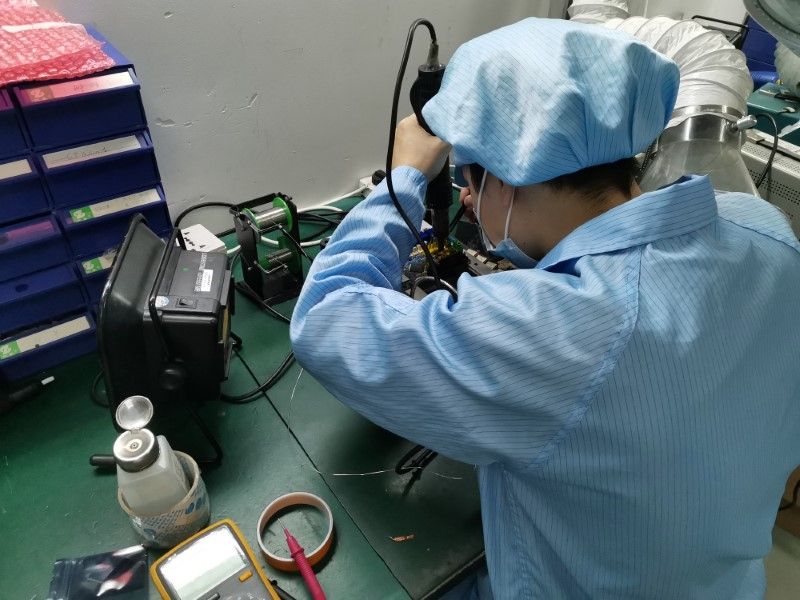

I am lucky to have some very skilled colleagues, this one in particular who repaired the board in less than 5 minutes without breaking a sweat. Amazing guy, really impressive to see!

The board now seem to work just fine, the 5V and 3.3V leds indicate that the voltages are back!

I'll test it later with a SD card, but I'm fairly confident there won't be any problem, it does behave exactly the same as if it were powered up from the USB port. Great success! -

Hello everyone, it's been a while!

The printer is still going strong, I printed kilos and kilos of filament already and it works really well 99.99% of the time.But there is this little 0.01% I'd like to fix. I sometimes, on very rare occasions during fast infills and high accelerations, get some layer shifts.

This is due to my print head being super heavy of course, but instead of going for the reasonable option which would be to lower accelerations and speeds, I'd like to push it even further and go for closed loop to recover from thes kind of situations and go even faster.So I got myself this weird little board:

https://www.aliexpress.com/i/4001273329739.htmlIt features regular step sticks slots, so my plan would like to use these together with some bigtreetech closed loop drivers (these kind of things: https://it.aliexpress.com/item/4000580109464.html )

I'd install those at least on X and Y, and maybe Z later.

Hopefully it shouldn't be too much of an issue for the most part, but I'm wondering about the BL touch I've installed: it is wired on that big extension connector plug on the duet board: problem is, if I plug this extension board then where am I supposed to plug the BL touch?

Did anyone had to face this problem? -

@MrDui said in BOx Large Format DIY Printer:

if I plug this extension board then where am I supposed to plug the BL touch?

On the official expansion board the heater6 and heater7 ports are exposed which can be used for servo control of the bltouch. It looks like the clone lacks that. You might be able to extend the pins anyway though.

https://duet3d.dozuki.com/Wiki/Duet_Expansion_Breakout_Board

-

Lol, it seems like once again I got fooled by a clone.

So I did a continuity test and found out that the pwm pin number 7 isn't connected to anything. So it'll be easy, I'll just have to solder a wire from it.Also, while I'm at it, here are some prints I did with the printer during the past months:

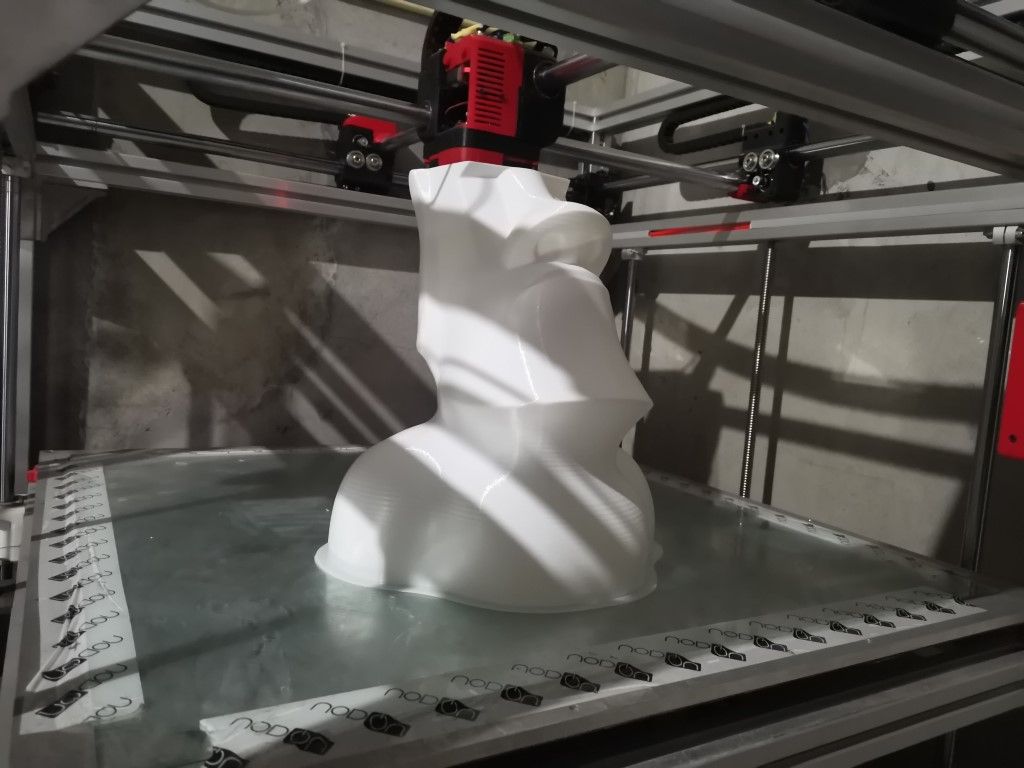

Some large molds to pour silicone:

Fairings for my electric motorbike:

And also for fun a giant moai head:

Each of those prints took less than 20 hours. As you can see, the printer works very well, I havent' got any issue with it since I repaired the fried motherboard.

My next print should be much bigger and take around 36 hours, it'll be a really huge mold to make the bike's fairings out of carbon fiber. The mold should make around 3kg of PLA. Got myself a few 5Kg spools fot that job.

But before doing that, I'd like to test and possibly install the closed loop system, in order to make the printer as realiable as possible.