configuring for servomotors

-

When using external drivers, the microstepping set by M350 is ignored. So you can leave it as the default x16. What matters is that you set the correct steps/mm in M92.

-

you should check current setting of the servo also, because M906 is also ignored for them.

-

@JoergS5 Yeah, I didn't change that setting because it doesn't do anything with the external drivers. The servomotors take whatever current they need to get the job done. Each has its own power supply connection, and its own power supply.

-

@dc42 Thanks! I'll try again....

-

OK, I got it working, but I don't know why it's working. I jumpered the motors for 1000 steps per rev to match the 1000 line encoders. There are 20 tooth drive pulleys so 1 rev moves 40 mm, so steps/mm should be 1000/40=25, but it isn't. It moves the proper distance at 100 steps/mm.

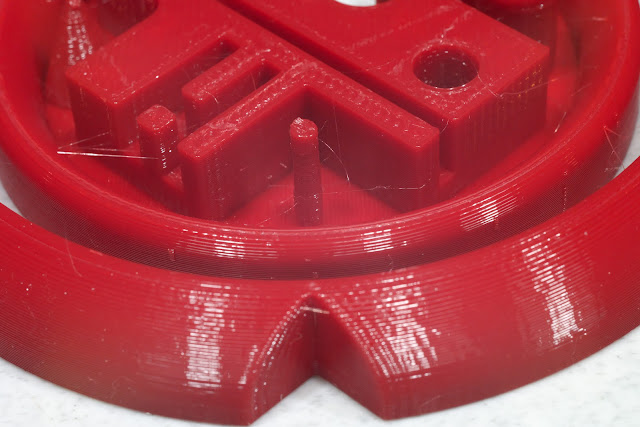

It's printing slowly- 30 mm/sec on a test print first layer, and the first layer starts out like this:

I previously had it set to 20000 steps per rev with 500 steps per mm and it did essentially the same thing. I completed the test print (50 mm/sec after the first layer) at that setting and this is what it looks like:

It's got a pronounced "tree-ring" or "salmon-skin" effect at all the 45 and 135 degree corners of the print (yes, I know it also looks overextruded).

Here's the same print done with steppers, before I installed the servomotors:

Any ideas?

-

@mrehorstdmd said in configuring for servomotors:

OK, I got it working, but I don't know why it's working. I jumpered the motors for 1000 steps per rev to match the 1000 line encoders. There are 20 tooth drive pulleys so 1 rev moves 40 mm, so steps/mm should be 1000/40=25, but it isn't. It moves the proper distance at 100 steps/mm.

I'm a little rusty on encoders, but I'm going to guess this because its a quadrature encoder (4 sensors), so functionally you get 4x the resolution of the disk.

Sorta.It's printing slowly- 30 mm/sec on a test print first layer, and the first layer starts out like this:

It's got a pronounced "tree-ring" or "salmon-skin" effect at all the 45 and 135 degree corners of the print (yes, I know it also looks overextruded).

Here's the same print done with steppers, before I installed the servomotors:

Any ideas?

Yeah, servo's are at their worst at low speeds, as they are not inherently stable/synchronous in the way steppers are. You are probably seeing the limits of the control loop (its jittering back and forth).

You can try re-tuning the PID of the servo.

Or doing something mechanically so they are turning much faster. Or just don't print slow! -

Here's some video - the file was sliced for 50 mm/sec (except 30 on the first layer). I cranked up the speed to see if the mechanism would remain quiet. At 4x (200 mm/sec) it is still quiet. The print is trash- you can't print PETG anywhere close to 200 mm/sec.

Acceleration is only 3k and jerk is only 20, both of which can be increased a lot based on my experience with the sand table, though that may create more print quality issues. If I can get the accuracy problem sorted out, it's going to make a very fast, very quiet printer.

-

@theruttmeister I don't understand why it worked "properly" (never mind the accuracy problem) when I had the steps/rev set to 20k and 500 steps/mm, but when I changed to 1000 steps/rev, it worked "properly" at 100 steps/mm. "Properly" meaning it moved the commanded distance. I'm thinking there may be an issue with pulse duration.

I can tweak the servo parameters, but have no real info on a tuning procedure, so I am using them at factory settings. The manual is little help, and the software that talks to them isn't much more help. It looks like a couple guys in Germany have figured out how to tune them, so I'll try sending some emails.

-

@mrehorstdmd in https://www.facebook.com/groups/137073107015171/ the comment by Rene Bookwoods from July 15 is a similar problem like yours. He expects a too short pulse signal (in a german forum they recommend 3.5 us), another was to lower frequency from 200 kHz to 100 kHz.

A different user recommends setting switch 5 to falling flank/edge (he said it was a recommendation from Sorotec) (was for iHSV57, may be different switch for your servo).

Other problems were bad cable quality and a PSU too weak. -

My guess is that what you are seeing is a limitation of the accuracy of the servo motors, at least as they are tuned now. Typically, 3D printers can resolve to 1/16 microstepping, which is 3200 steps/rev using 1.8deg motors, or 6400 steps/rev using 0.9deg motors. Increasing to x32 microstepping doesn't usually help because the friction is too great. Do the 1000 line encoders on your motors resolve to 1000 points per rev, or are they sensed by quadrature encoders so that they give you 4000 lines per rev? If it's 1000 points per rev then that's quite a lot worse than for a stepper motor.

It will also depend on whether your servos try to achieve the last commanded position, or whether they attempt to guess when the next pulse is to give smoother movement.

I don't see any evidence of missed steps or layer shift in your print, so I think your timings are long enough. However, I suggest you check the hiccup count in case the timings are too long for the print speed.

-

@JoergS5 Thanks for the link. I'll have to spend some time with google translate... Each motor has a 200W power supply, and speed, jerk, and acceleration are all low in the printer, so I don't think it's a power supply issue. I have the pulse width set to 4 us.

@dc42 the specs on the motors are very limited as they come from China. All I know about the encoders is that they are 1000 lines. No idea if they're read in quadrature. Maybe I better open one of them up and have a look. There's no way to know about the control logic. The English manual is poor and so is the software for tuning the parameters. I'll keep playing with it and see what I can get them to do. They may just end up back in the sand table. They worked great for that application.

-

@mrehorstdmd said in configuring for servomotors:

@theruttmeister I don't understand why it worked "properly" (never mind the accuracy problem) when I had the steps/rev set to 20k and 500 steps/mm, but when I changed to 1000 steps/rev, it worked "properly" at 100 steps/mm. "Properly" meaning it moved the commanded distance. I'm thinking there may be an issue with pulse duration.

I can tweak the servo parameters, but have no real info on a tuning procedure, so I am using them at factory settings. The manual is little help, and the software that talks to them isn't much more help. It looks like a couple guys in Germany have figured out how to tune them, so I'll try sending some emails.

I'm more than a little rusty on encoders it turns out. Quadrature means you get 1/4 of the resolution, so your encoder counts are only 250/rev. That means that you can be getting +-0.16mm of drift in X/Y without the servo knowing. In fact there's a very good chance that the motor is jittering by that 0.32mm constantly. It would certainly explain the defects you are seeing.

No idea on the ratios, who knows with cheap Chinese electronics?

-

@theruttmeister said in configuring for servomotors:

I'm more than a little rusty on encoders it turns out. Quadrature means you get 1/4 of the resolution, so your encoder counts are only 250/rev.

I don't think that't right. Say you have an optical linear encoder with 1 black stripe per mm, each pair of stripes separated by a white band of the same width as the stripes (so alternately 0.5mm black and 0.5mm white). Then a quadrature reader will provide 4 transitions per mm, corresponding to the positions at which either of the readers (which are separated by 0.25mm) passes over one of the black-to-white transitions. In theory this means that with 1 stripe per mm you can get 0.25mm resolution.

In practice, the sensors may not detect the two edges of the stripe exactly. For example, the sensitivity of the sensor may be biased so that it changes its output when it is 0.1mm inside the black stripe instead of exactly over the edge. Then the transitions won't occur evenly, and it may be better to count alternate transitions instead of all transitions. This would worsen the resolution to 0.5mm.

On top of this, if the two optical sensors have different biases or they are not exactly 0.25mm apart, then there will be a further irregularity and it may be best to count 1 transition in 4; which would worsen the resolution to 1mm.

So if "1000 lines" really does mean 1000 stripes read by a pair of optical sensors producing quadrature outputs, then I conclude that the resolution will be 1000, 2000 or 4000 counts per rotation, depending on how the controller uses the quadrature output.

-

according to https://webseite.sorotec.de/download/Technische-Daten/servomotoren/jmc/iHSV_600.pdf page 9 P00-10

the iHSV encoder lines can be set by a parameter and can be between 0 and 65535, but I cannot find detail information about the precision. 1000 is only the default setting. In a document was mentioned 1000, 1250 and 2500 as values. The document is for iHSV 42/57/60/86 series.From the images of the iHSV57 servo, the encoder looks like a hall based one, so there are not optical hard limits, just signal resolution (ADC) and measurement errors as the limit (and magnetic distortions).

The used line encoder is the AM26LS32 https://www.ti.com/lit/ds/symlink/am26ls32ac.pdf -

@JoergS5 I interpreted the factory default of 1000 lines in the firmware to be a factory setting based on the specific encoder setup used in the specific motor. There may be other models of motor in which they change the encoder, or supply issues might force changing the encoder, so they would then set it for whatever matched the hardware being used. I could be completely wrong...

-

@mrehorstdmd I was astonished how many parameters can be set. There is eg an electronic gear mentioned in the document, but no explanation for it. When I tune the iHSV, I will try the tool https://github.com/robert-budde/iHSV-Servo-Tool but the setup seems to be a bit complicated in a windows environment.

I searched a while whether there is information about the tolerances for the encoder, something similar to "5% error of the position of the stepper", but I found nothing.

-

@JoergS5 Yeah, lots of stuff to tune, but no information or even a diagram of the control loop and where the parameters fit. I am using default settings for everything for now because of a lack of information on tuning. I opened and saved every image of every settings page from the JMC software and zipped it all into a file here. It provides more information than the manual, but only a little more.

-

@JoergS5 The JMC software for tuning the motors is here. It runs fine on windows, but the UI is awkward, so you'll have to mess around a little to figure it out. You'll need an RS-232 connection, so pick up a USB to RS-232 adapter cable. Look for cables that have the PL2303 chipset. They cost about $10.

-

@mrehorstdmd thank you for gathering all the information.

In a CNC forum they told the servo is so strong that if you set wrong parameters, the whole CNC machine can jump!

I am starting to use the iHSV servos for different tasks (a hacksaw eg), and I like them. I have not tuned them yet however.

-

In the sand table the mechanism has a lot of friction, but not a lot of moving mass. I was concerned that the servomotors wouldn't have enough grunt to make it move based on their torque specs, but servo torque specs aren't the same as stepper torque specs. The steppers were right at their limits running with 2k acceleration at 500 mm/sec. The servos let me run at 20k acceleration and 2000 mm/sec. I think they could go higher but the power supplies kept shutting down! One way to think about it is the servos are rated for 78 W while the steppers are 3V at 1.5A each phase, so maybe 10W or so. In my sand table tests the servos never got more than 2-3C above ambient after more than an hour of operation.

I'll have some time to mess around with it in the next couple days and post any new behavior here.

I wrote a blog post on the motors here. Any new information I get will get added to that post.