Solved Help in coding a unique multi-printer

-

I've a unique design of a direct drive dual filament extrusion gadget which uses a single nozzle and a single stepper. The filament change is accomplished by a servo driven swapping mechanism which un-loads one filament and loads the second into the toothed drive hobbs. Think of it as a direct drive single stepper Prometheus. It is light enough to live on a Delta effector and mechanically it functions exceptionally well.

Problem is I'm having trouble coding it - being, after all, just an obsolete mechanical engineer. I'm slicing with S3D running on a Duet 2.nn WiFi.

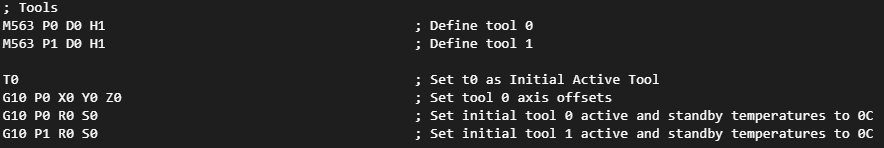

Here are my Tools assignments in config.g

The bed layer prints correctly using "T0 P0" to bypass layer 1 tool-change macros. The problem arises at the first tool change wherein PanelDue displays >>

................... "Error Attempting to extrude with no tool selected".

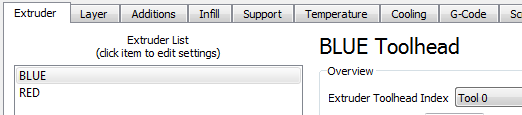

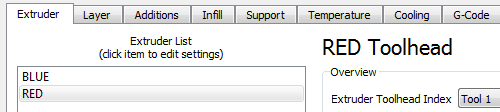

In S3D process-0 extr BLUE is tool 0 and extr RED is tool 1 is process-1

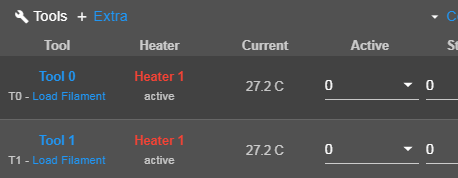

Tools and heater as displayed on the DWC screen are >>

I'm quite confused after several days of mucking about - any suggestions or insight anyone ? -

Please share your tool change files.

-

Thanks for chiming in. The attached text file has everything including Filament-Change.g starting >line 15. I omitted Tpost0.g since it is an exact duplicate of Tpost1 (>line 105 purge bucket routine).

GARP.txt -

@garp said in Help in coding a unique multi-printer:

I've a unique design of a direct drive dual filament extrusion gadget which uses a single nozzle and a single stepper. The filament change is accomplished by a servo driven swapping mechanism which un-loads one filament and loads the second into the toothed drive hobbs.

Like the Dondolo? https://www.thingiverse.com/thing:673816

-

@fma Not even close. Dondolo uses two heater/nozzles and is large, heavy and complicated. My solution has a single heater/nozzle, single two-hobb setup, is very light and simple with a very short, straight hobb to nozzle distance ( ~ 57mm ). My problem lies in g-coding. Probably a very simple solution for someone smart in such matters.

-

@dc42 Simple solution at last - had I but known of the pesky T0 tool set in config.sys. As you must know ( but I didn't ) the "T-1 P0" is inoperative if a tool selection has already been made. Re-reading the g-code Tools section doesn't seem to me to make that point.

One semi-related opinion from me is that it would be helpful in these situations if there were a line-by-line g-code step-through ( or at least an ability to set break points ). I think I might have quickly determined the problem.