nozzle wipe

-

@Danal, thanks, will give it a try. My goal is to wipe PETG every few layers. Need to figure out where to install it since my nozzle doesn't go beyond the bed.

-

I use a silicone cooking brush - something along the lines of these:

The only bit I'm interested is the brush, so the rest is cut off, and the tines are cut down to about 15mm, so they become reasonably stiff. The nice thing about passing the nozzle through the brush seems to be that a) the filament gets caught in the brush, and b) the brush cleans the underside of the hot end and nozzle if mounted at the right height. The hot end isn't in contact with it long enough to impart any significant heat, but even so, the silicone can handle pretty high temps.

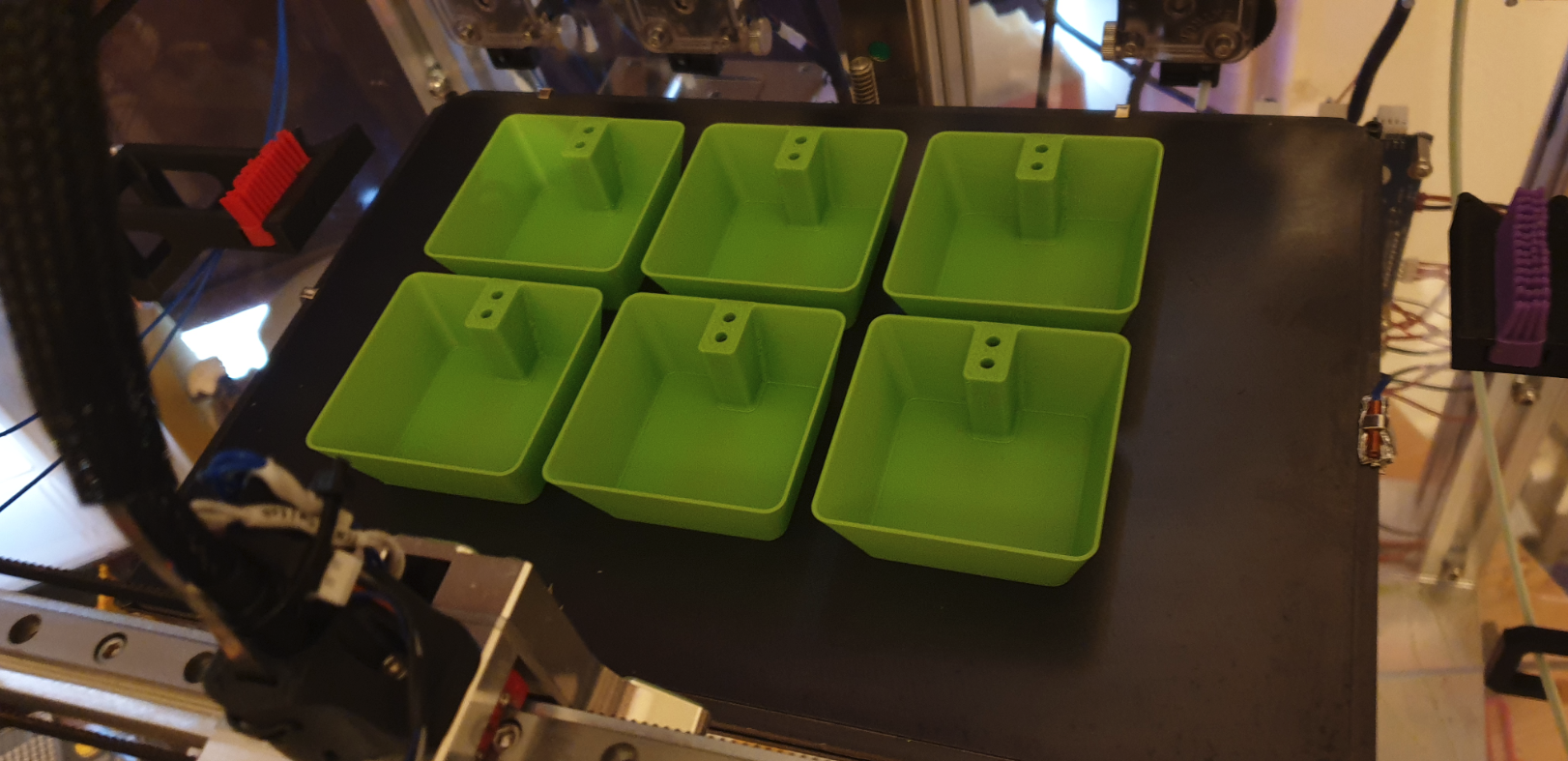

Here's how it ends up looking, with one mounted either side of the bed:

I prime 30mm reasonably fast just infront of the brush to create a thickish string, pass back and forth through the brush along slightly different lines to avoid re-collection of the string, then move immediately to begin printing.

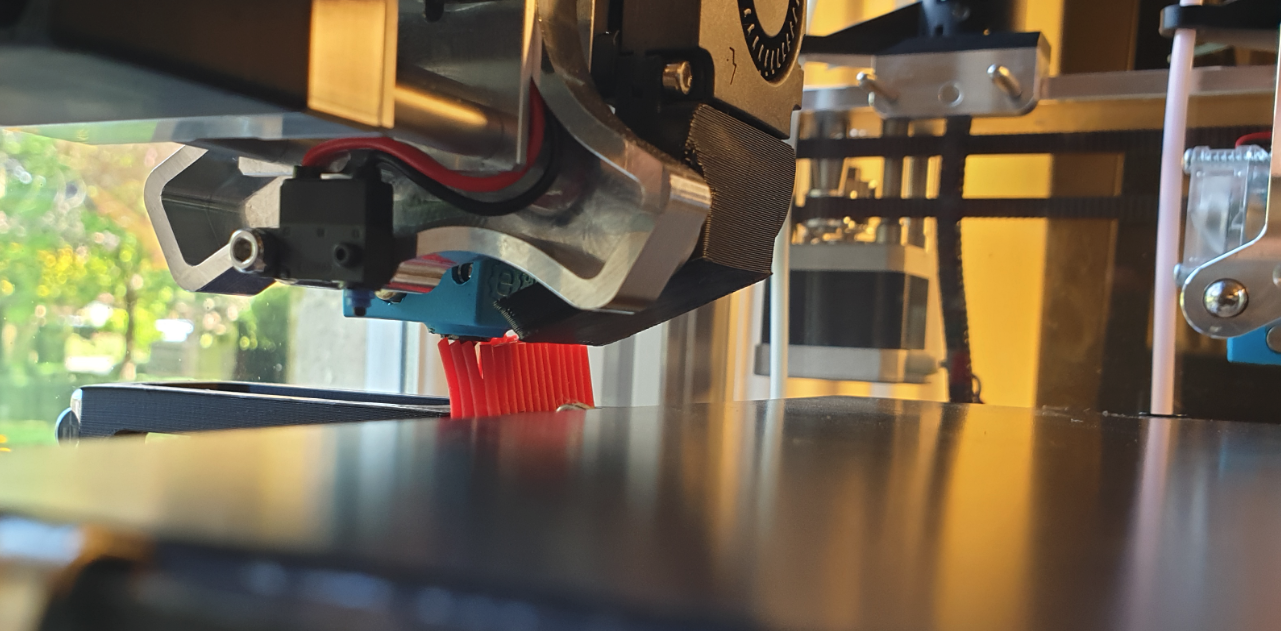

Here's a closer view of the wipe:

-

@SpoonUnit I was looking at that brush too but was afraid bristles are too soft to do anything

-

@zapta said in nozzle wipe:

@Danal, thanks, will give it a try. My goal is to wipe PETG every few layers. Need to figure out where to install it since my nozzle doesn't go beyond the bed.

Why do you feel you need to wipe the nozzle every few layers?

-

@arhi said in nozzle wipe:

if sensors.analog[1].lastReading < 200

echo "Extruder too cold, no point wiping, aborting the wipe"

M99On a multi-tool printer I suggest the following instead:

if state.currentTool < 0 echo "No tool loaded, cancelling wipe" M99 if heat.heaters[tools[state.currentTool].heaters[0]].current < 200 echo "Extruder too cold, no point wiping, aborting the wipe" M99 -

I have been wanting to wipe the nozzle for ages on my Railcore after seeing @deckingman wipe system

I am in the UK and found a company who sells Silicone sheet which can withstand 300 degrees.

Just ordered a 3 and a 4mm sheet from TYM Seals and Gaskets

They have an ebay page also.Regards

Paul -

I can also add that you can stick silicone sheet/strip to aluminium with silicone sanitary adhesive/sealant. So if you can't mill a slot to hold the aluminium, then this method might work.

Caveat 1 - It worked for me but it might depend on the grade/type of silicone you buy.

Caveat 2 - I made sure the aluminium was clean and free of any oil by wiping it with Acetone. Also, the aluminium was newish so hadn't oxidised.

Caveat 3 - Not all silicone adhesives are equal - I used Dow Corning 785 (clear).

Caveat 4 - While it seems to have stuck like the proverbial excrement to bedding fabric, I have no idea how long it will stay stuck (nor any reason to think that it might become detached over time). -

@dc42 said in nozzle wipe:

On a multi-tool printer I suggest the following instead:

Awesome. I gave up on multi tool on the ender5 since e3d ms-tc arrived but still, this is better as I assume a lot of scripts I will use on more printers (as I plan to replace most of my printer boards and unify them to RRF)

-

@deckingman now that you mention "silicone in tube", ages ago I created a heat shield around my old rapman nozzles with silicone for some car gaskets from car parts store that is supposed to be good up to 300C. 250-260C many years later it's still standing so I guess it's usable. I think I seen people use it to mold the heat block socks out of it. Might be interesting to design a mold to create silicone "brush" specifically designed to clean nozzle

-

@arhi I don't see why not. For info, I once made a "sock" for one of my Diamond hot ends using this stuff which is supposedly good for 370 degC https://www.dwrplastics.com/high-temperature-resistant.html. I'd guess something like that would also work if one wanted to make a "brush" from scratch.

-

@deckingman lot of nice molding materials available, unfortunately, not accessible for all of us

.. but this car stuff is available in local shops so ... I'll think about it. I know they have green, red and black. One is I think 300C, other 370C and one is IIRC 700C but I might be wrong will check the shops it's clearly marked on the tube

.. but this car stuff is available in local shops so ... I'll think about it. I know they have green, red and black. One is I think 300C, other 370C and one is IIRC 700C but I might be wrong will check the shops it's clearly marked on the tube

I think bigger issue is "what" to design, what a "perfect" brush for this would look like maybe a "cup", dunno, need to think about it, interesting anyhow

maybe a "cup", dunno, need to think about it, interesting anyhow

-

@CaLviNx said in nozzle wipe:

Why do you feel you need to wipe the nozzle every few layers?

Mostly for PETG. Over time the nozzle collect small pieces that later land on the part.

I also have a Micro Swiss nozzle on order. It supposed to be smooth and 'PETGphobic'. Will see how that one goes.

-

@zapta Slice engineering now use a "plastic repellent coating" on their Vanadium nozzles. I still don't have a working printer so cannot validate just how "plastic repellent" it is though.

-

@deckingman said in nozzle wipe:

@zapta Slice engineering now use a "plastic repellent coating"

I assume it is same "plastic repellent coating" X nozzles from E3D use

I'm not impressed

Maybe I expected too much.

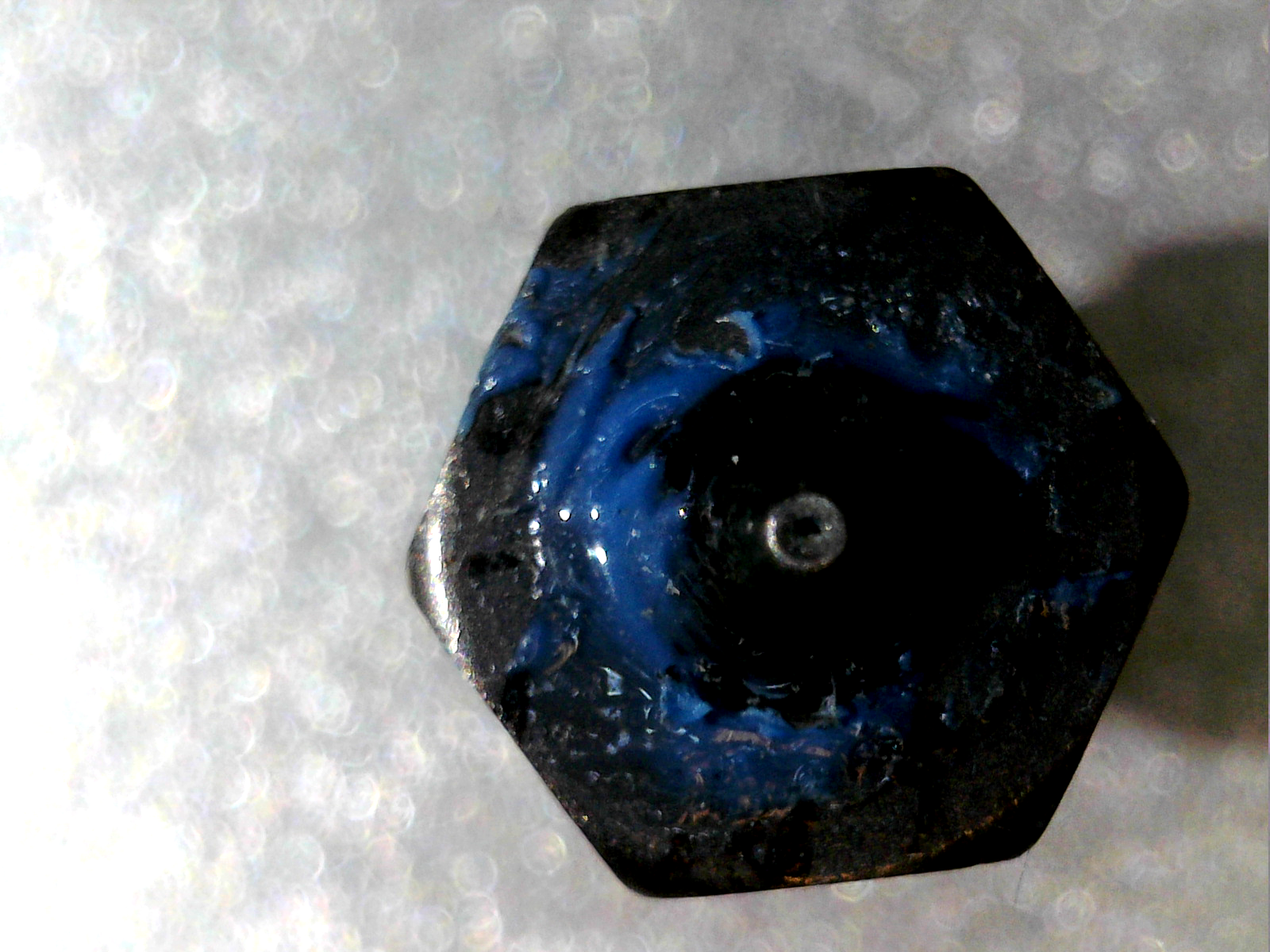

.3mm X nozzle

The "scratches" are from the brass brush

Total printing time - 1 hour PLA + 30min PETG (both blue/greenish so this blue on the nozzle is mix of the two)

impossible to clean cold ... basically I did not notice any difference between this X nozzle and regular brass nozzle

.. no "wow" effect on the top layer, no "wow" layer on the bottom layer... works great just like their normal brass and hardened nozzles but I don't see it's any "better". Replaced it with brass .6mm as .3 is too slow for the stuff I'm printing these days

.. no "wow" effect on the top layer, no "wow" layer on the bottom layer... works great just like their normal brass and hardened nozzles but I don't see it's any "better". Replaced it with brass .6mm as .3 is too slow for the stuff I'm printing these days

-

@zapta I print almost exclusively with petg (das-filament) and after I carry out the initial wipe I don't suffer from build up on the nozzle at all, you might want to optimise your slicer settings if you are finding a buildup on the nozzle, I had to optimise my settings to prevent this too but that was many years ago when I was not that experienced in printing with petg.

-

@arhi said in nozzle wipe:

I assume it is same "plastic repellent coating" X nozzles from E3D use

I wouldn't make that assumption if I were you.

I have a rough idea what Slice Engineering use but I don't know for sure and even if I did, I couldn't divulge that information. I think a fusing process which involves heating the part to around 581 deg C might be involved, but I could be wrong. I have no idea what E3D use except what I've read from their marketing literature.

But I think it would be a mistake to assume that just because one coating from one nozzle manufacturer didn't work for you, that all coatings by all nozzle manufacturers would behave the same. Having said that, as I said before, I can't vouch for the Slice Engineering coating because I haven't been able to test it.

-

@deckingman said in nozzle wipe:

@arhi said in nozzle wipe:

I assume it is same "plastic repellent coating" X nozzles from E3D use

I wouldn't make that assumption if I were you.

It looks exactly the same and I'm pretty sure I heard on some of the videos about mosquito something like "our vanadium nozzle uses same olifobic material as e3d is now using" or something along those lines, but could not find the video... I have no clue what's e3d using neither

Anyhow friend just got his original recently with 5+ nozzles (I think all vanadium coated with this thing) and he just started using them. If not for this police lockout I'd be there with thermal camera already but unfortunately... We'll see in few weeks how will that vanadium looks like

... so far we confirmed that original mosquito has zero issues with PLA (contrary to that damn clone I purchased).

... so far we confirmed that original mosquito has zero issues with PLA (contrary to that damn clone I purchased).But I think it would be a mistake to assume

I always say assumption is mother of all fsckups and when I do assume I'm sure to be clear that I don't "know" but just assume

(actually maybe assume is wrong term here, "suspect" or "almost believe to be" might be more correct)

(actually maybe assume is wrong term here, "suspect" or "almost believe to be" might be more correct) -

@arhi said in nozzle wipe:

X nozzle

The "scratches" are from the brass brushThe brass brush will destroy the X-nozzle coating pretty quickly IIRC.

-

@CaLviNx said in nozzle wipe:

I print almost exclusively with petg (das-filament) and after I carry out the initial wipe I don't suffer from build up on the nozzle at all,

Any suggestion what kind of settings to loo for to avoid buildup? I am using 2mm retraction, 0.95 flow, and 245C. BMG direct extruder + E3D hotend with 0.4mm brass nozzle.

-

First thing is "squish" petg doesn't like being squished into the bed like PLA does. You could be quite alarmed at how much further away from the bed petg likes to be. On my chiron I run a BMG with an e3d nozzle and the retraction on it is all the way upto 5.60mm retraction speed of 40.0mm/s.

I also force retraction between layers (in simplify3d)