How to calculate feed rate?

-

@monster said in How to calculate feed rate?:

Extrusion Width is more like fixed parameter defined by nozzle and btw Volumetric Limit also depends on it, isn't it?

Yes, that's right. It's typical to use a extrusion width equal to the nozzle with or slightly larger. It is set in the slicer.

Layer height is set in the slicer as well.

M203 X3000.00 Y3000.00 Z1000.00 E80.00:80.00:80.00 ; set maximum speeds (mm/min)You must set your extruder max speed to much high than 80mm/min this would explain the snail speed. You should set this value to 8000 perhaps. If you had this set this low during your testing you should change it and then redo your extruder calibration.

-

@Phaedrux said in How to calculate feed rate?:

M203 X3000.00 Y3000.00 Z1000.00 E80.00:80.00:80.00 ; set maximum speeds (mm/min)You must set your extruder max speed to much high than 80mm/min this would explain the snail speed. You should set this value to 8000 perhaps. If you had this set this low during your testing you should change it and then redo your extruder calibration.

Ahaa! That is a bit counter intuitive I'd say - as with loaded filament motor won't go much higher! Thank you for that! I'll redo whole thing again now!

-

@monster The main reason to have it set higher is to allow for retractions which will probably be in the range of 25 to 80mm/s which is substantially faster than the 1.33mm/s you have set. The speed used during printing will depend on the slicer which will choose how fast it needs to go based on how fast you are printing and the extrusion width and layer height.

-

@Phaedrux said in How to calculate feed rate?:

You must set your extruder max speed to much high than 80mm/min this would explain the snail speed. You should set this value to 8000 perhaps. If you had this set this low during your testing you should change it and then redo your extruder calibration.

You were so right about it!

I did it again and now I got stability with G1 E100 F160 twice as fast!

That made Volumetric Limit --> 18.8

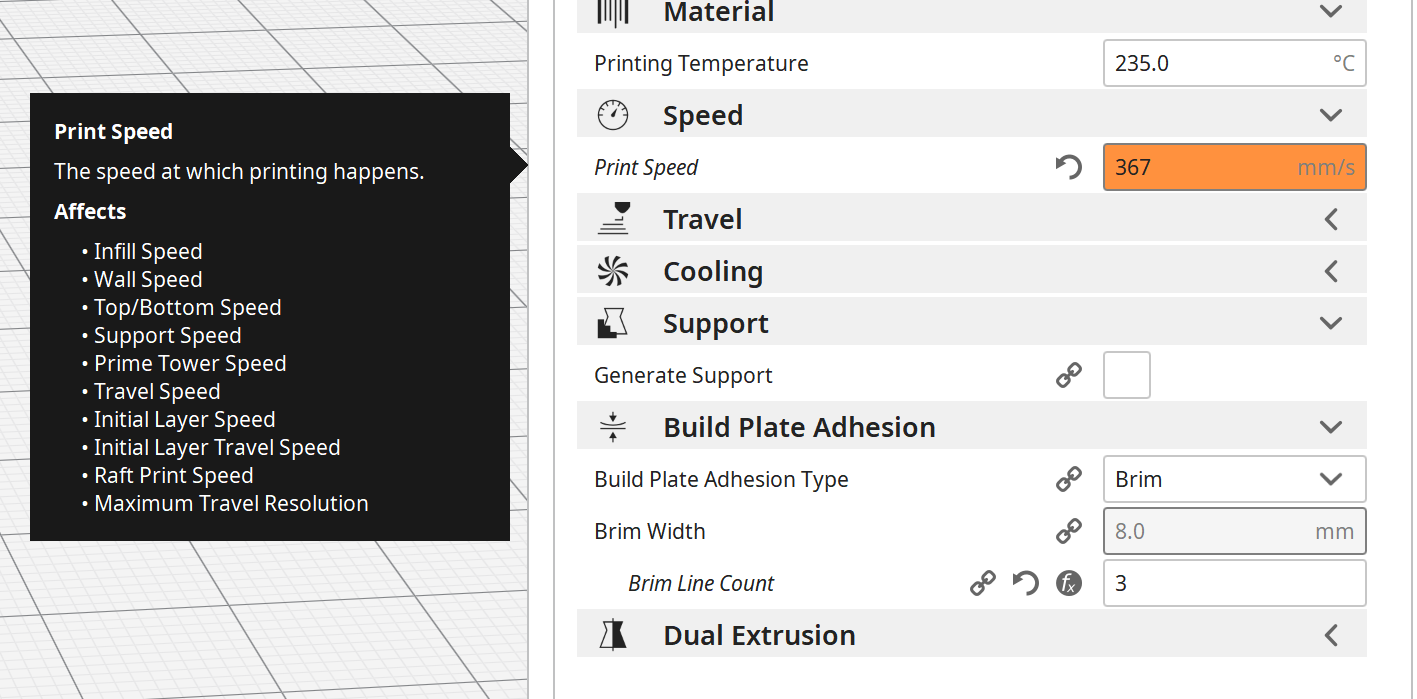

Max Print Speed --> 367Though when it prints nothing changes! Extruder's stepper still a snail

Also slicer doesn't seem very happy about speed:

But retruction speed sounds like ultrasonic

-

I constantly have this feeling that I'm missing some setting either in firmware on in slicer.

Would it be possible to slice that kinda print which would require printer do only one move, lets say one 10cm line of extrusion? And then look in g code and see what slicer set there for extrusion? Would that be helpful? -

@monster said in How to calculate feed rate?:

Max Print Speed --> 367

This is an over ambitious choice for print speed. The extruder may be able to provide enough plastic at that rate, but the rest of the machine likely will not.

It's far more common to use a print speed around 60mm/s for most things due to reasons of model size and geometry, overhangs, bridging, fine detail, etc.

Your

M203 X3000 Y3000also means the max speed is being limited by the firmware to only 50mm/sTo get to 367mm/s you would need to raise the M203 value to 22000mm/min

Note the difference between mm/min and mm/s. Multiply or divide by 60 to convert between them.

You may find this post helpful at this point in your commissioning.

https://forum.duet3d.com/topic/14250/tuning-jerk-accel-speed-settings/3?_=1586556079200

-

@Phaedrux Good points, thank you!!!

I just printed this:

G0 F3600 X10 Y100 Z0.3 ;TYPE:SKIRT G1 F1500 E6.5 G1 X110 E100 F100 ; push 10mm of filament into the nozzle while moving to the X=30 position at the same time G10 G0 F3600 X10 Y105 G11 G1 X110 E100 F200 ; push 10mm of filament into the nozzle while moving to the X=30 position at the same time G10 G0 F3600 X10 Y110 G11 G1 X110 E100 F400 ; push 10mm of filament into the nozzle while moving to the X=30 position at the same time G10 G0 F3600 X10 Y115 G11 G1 X110 E100 F800 ; push 10mm of filament into the nozzle while moving to the X=30 position at the same time G10 G0 F3600 X10 Y120 G11 G1 X110 E100 F1600 ; push 10mm of filament into the nozzle while moving to the X=30 position at the same time G10 G0 F3600 X10 Y125 G11 G1 X110 E100 F3200 ; push 10mm of filament into the nozzle while moving to the X=30 position at the same time G10got that

would you say that this confirms that on firmware side (incl config) all looks correct?

Picture oriented that way that bottom stripe is first print line and top&broken one is last printed line. -

@monster said in How to calculate feed rate?:

would you say that this confirms that on firmware side (incl config) all looks correct?

Printing an actual sliced object would be a better way. I can't tell much from that other than the last one might be good as a prime line....

-

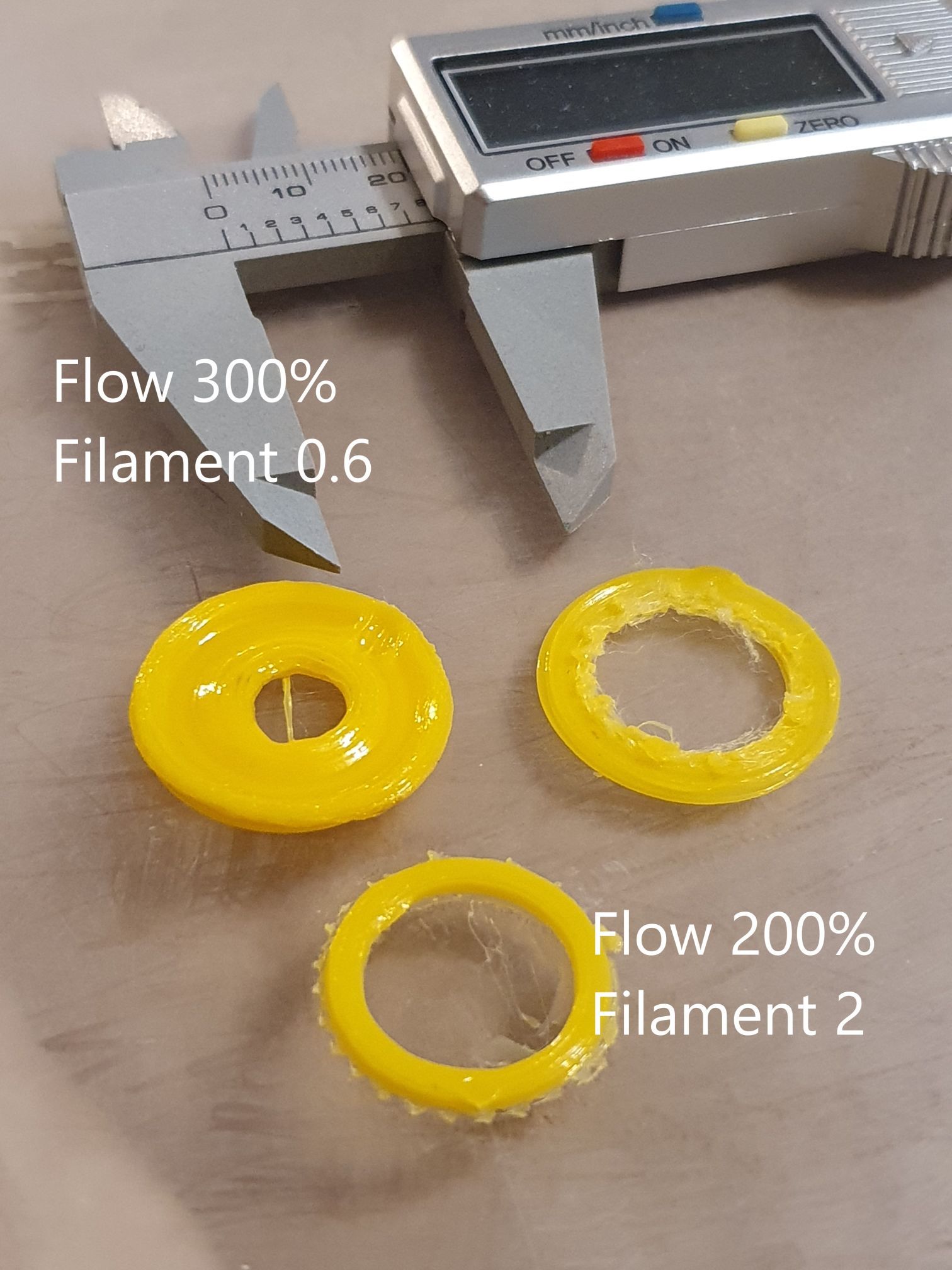

Small step forward achieved

I wasn't progressing no matter I do until I noticed that in firmware I did have a filament set to an extruder used to print sliced object. So I unloaded that filament in WebUI.

Then prints began to reflect changes in Cura.Task was to print a small ring. I know ring isn't very decisive test object but I chosen it as printing ring makes less vibrations then square. Heads are heavy - vibrations significant.

best result (ring at bottom) I could achieve by setting filament flow 200% and setting in printer settings that my extruded loaded with filament 2mm diameter. When actual diameter is 3mm.

Btw retraction isn't happening at all - as it wants to spin motors way too fast. I hear only whistle instead of retraction.

Does loading filament in WebUI needed for some purposes? Perhaps that is factor here and I should somehow define it right in filament config.g?

And lastly. If in WebUI I do extrude with 1mm/s it extrudes kinda slowish but it does eat about of 5mm of filament. If I chose 5mm/s it goes very fast - on the edge of its max speed. Those 15, 30, 60 aren't usable for me. Is there a way to define what speeds I can select in WebUI?

-

@monster said in How to calculate feed rate?:

Does loading filament in WebUI needed for some purposes?

No, that's mainly for setting up specific settings for different kinds of filament. It will work without doing so.

https://duet3d.dozuki.com/Wiki/Filaments

https://duet3d.dozuki.com/Wiki/Duet_Web_Control_Manual#Section_FilamentsWhat settings are you using in your config.g now?

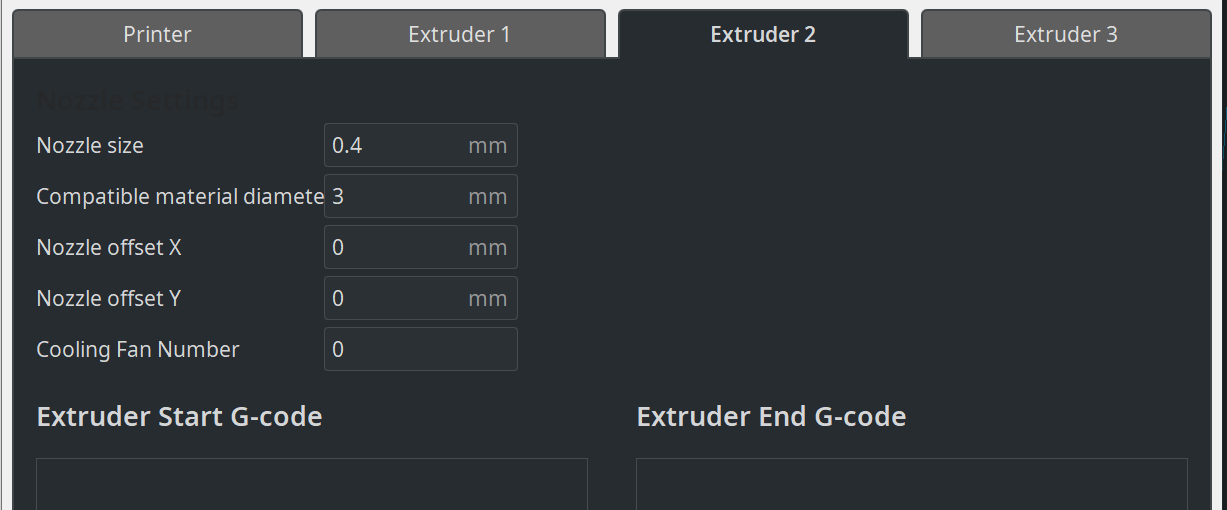

What slicer are you using and what settings do you have set? -

@Phaedrux said in How to calculate feed rate?:

What settings are you using in your config.g now?

What slicer are you using and what settings do you have set?

Now sure if this screenshot covers most relevant settings.

And I just noticed that actual nozzle (as I believe) is 0.25 - I'll change it and try again! -

@monster said in How to calculate feed rate?:

And I just noticed that actual nozzle (as I believe) is 0.25 - I'll change it and try again!

Been trying to print last 10 mins. Some kind of bug was always happening when I Pause&Cancel print. I almost always had to reboot the controller. Now even reboot doesn't work. I'll report this bug just that now still tying to get it to work, it is in state not accepting any commands

-

@monster said in How to calculate feed rate?:

And I just noticed that actual nozzle (as I believe) is 0.25 - I'll change it and try again!

fixed nozzle to 0.25 everything else set to normal (filament 3mm, flow 100%) - catastrophic under extrusion.

-

Is it really 3mm filament?

Is it really a 0.25mm nozzle? -

@Phaedrux

Filament is 3mm diameter, that one is easy to be sure.

For the nozzle story is different I wish to have any idea how to measure it reasonable way... Perhaps somehow comparing length of used filament to length of extruded thread could be the reasonable way still taking into account all possible errors that it has. I have calipers but measuring extruded filament isn't useful. When extruded to open air it a) shrinks b) my calipers will not show it with descent accuracy.

I wish to have any idea how to measure it reasonable way... Perhaps somehow comparing length of used filament to length of extruded thread could be the reasonable way still taking into account all possible errors that it has. I have calipers but measuring extruded filament isn't useful. When extruded to open air it a) shrinks b) my calipers will not show it with descent accuracy.0.25mm came from settings in software that I found still available for this printer (printer is BFB Touch 3D). Two more factors reasonably adding up to it a) nozzles in this heads are very hard to change - so most likely it wasn't even designed to have different once b) line of filament that comes out of nozzle is visually very thing - so it is very believable that it is 0.25

P.S. I wonder is there a test print that would extrude fixed amount filament lets say 1mm above bed and move making some big (easy to measure) rectangular pattern. Then if the extruded line solid (eye accuracy) meaning it didn't brake (under exctrusion) not to tight (over extrusion) then by measuring extruded length and knowing consumed length (and diameter) of filament one could calculate nozzle size (+- accurate)

Sadly it is not very common not to know nozzle size among printer owners - such task probably never was set by anyone.What I've found out last night is that Cura slicer somehow do not set nozzle diameter! Yes, statement

If I go to Cura printer settings and set there for extrude 0.25 then after I close settings and come back - it is back to 0.4

If I go to Cura printer settings and set there for extrude 0.25 then after I close settings and come back - it is back to 0.4

And yet if Cura "thinks" I got 0.4 then it should push more raw filament in extruder, isn't it? But reality is so different that if I print with that then under extrusion is that dramatic that after print I catch myself thinking "do I clean the bed or is it ok to leave it like that and print over..."

Reasonable prints are require flow=N*100% and defining that my filament is lot less in diameter 1-2mm (value of N is factor here ofc)Last night I've tried Prusa slicer. That one accepted my 0.25 noizzle, no problem. If I print same ring as on pictures earlier with right filament size and no other tweaks then it prints the ring bu still under extruded one. Not as bad as in Cura but still bad!

However what is "no no no" thing for Prisa was that printing this ring it made my printer (and whole table) to bounce around!!! Instead of slicing it in nice circle moves (ring 20mm outer diameter 16mm inner diameter 2mm high) it somehow forced it to do lot of small Z shapes and in combination with quick speed it was terrible! I'd rather continue with Cura... -

Eventually I found the way how to tell Cura that nozzle is 0.25

For that C:\Users<usr>\AppData\Roaming\cura\4.5\

and in ALL .cfg files I've added:[values] machine_nozzle_size = 0.25it seems that files located in C:\Users\khano\AppData\Roaming\cura\4.5\definition_changes\ did the trick.

Below photo of 3 prints. Where first two (left to right) are done before fixing nozzle in Cura, but in stead I had setting "line width"=0.2

Interestingly that all 3 of them experience underextrusion on top, first two however get some over extrusion on bottom.

On last one and actually in all of them bottom outer layers (first 2mm) are looking quite neat other 4mm are ugly...

That perhaps fixable in Cura somewhere...But why I have to set such high flow percentage - no idea

-

@monster said in How to calculate feed rate?:

But why I have to set such high flow percentage - no idea

That would indicate the steps per mm is still incorrect.

-

@monster said in How to calculate feed rate?:

However what is "no no no" thing for Prisa was that printing this ring it made my printer (and whole table) to bounce around!!!

Every slicer has many settings and you'll need to dive into them all to really get things under control.

M566 X900.00 Y900.00 M204 P2000 T4000I suggest you change those values a little bit as I think they are too much for this printer. Try:

M566 X600.00 Y600.00 M204 P500 T2000The E steps per mm is likely too high which explains the 800% flow rate.

M92 E6500.00:6500.00:6500.00Try a value of 800 and redo the extruder calibration again.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

-

@Phaedrux said in How to calculate feed rate?:

@monster said in How to calculate feed rate?:

However what is "no no no" thing for Prisa was that printing this ring it made my printer (and whole table) to bounce around!!!

Every slicer has many settings and you'll need to dive into them all to really get things under control.

M566 X900.00 Y900.00 M204 P2000 T4000I suggest you change those values a little bit as I think they are too much for this printer. Try:

M566 X600.00 Y600.00 M204 P500 T2000Extremely good point! I did set it to exactly values you suggested.

The E steps per mm is likely too high which explains the 800% flow rate.

M92 E6500.00:6500.00:6500.00Try a value of 800 and redo the extruder calibration again.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

What is undeniable here is that at this point I could repeat the calibration! I did it couple of days ago and back then I aimed it to be plus/minus accurate, just to see where am I going. Now that I've improved accuracy in prints I should re-calibrate for getting as exact value as possible.

Though I'd have doubts that this could be the reason of my problem, unless I did understand calibration wrong way.

If my memory not mistaking idea of that calibration was:- mark 10cm of raw filament

- command printer to "eat" this 10cm by e.g. "G1 E100 F60"

- ...

- eventually get that "G1 E100 Fxx" will "eat" 10cm

- that xx is my value, except that in config.g it must be in mins not it sec's.

And here I think I found my problem!

(It was worth of repeating what I did)!

(It was worth of repeating what I did)!

I really did find right "G1 E100 Fxx" and then converted xx into mm/min totally not paying attention to the fact that E100 is 10mm not 1 !!!

Tadam! Problem found (I hope)!

-

@monster said in How to calculate feed rate?:

the fact that E100 is 10mm not 1 !!!

E100 is 100mm, or did you mean 10cm?